Академический Документы

Профессиональный Документы

Культура Документы

Pump

Загружено:

arvidkumar87060Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pump

Загружено:

arvidkumar87060Авторское право:

Доступные форматы

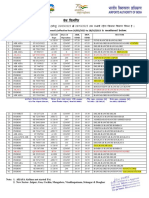

NAME PLATE DETAILS EQPT. SR NO. RATING NDE BEARING S.

NO ACTIVITY ESSENTIAL PRE-REQUISTES 1 The labels are available for the equipments and their modules and they match with the data sheets. The name plate legend agrees with the approved Plant Nomenclature is clearly visible, properly fixed, durable and correct with labels. Approach to the plant item is adequate for testing or commissioning purpose. Lighting in the area of the plant item is adequate for safety. Any other requisite safety provision is adequate for immediate commissioning activity. Entire installation should be completed . All necessary locks and keys for pad-locks, interlocks etc., are available. Check for the following(BEFORE RUNNING): 8 Confirm that pump spindle is free to rotate. MAKE FRAME TYPE FLOW RATE DE BEARING STATUS (Y/N) REMARKS

CAPACITY

HEAD

SPEED

4 5

6 7

Clearance certificate/communication is given for running the pump by the erection department. Check the integrity of foundations, grouting, anchor bolts, dowels etc. Ensure tightness of pump casing base bolts without strain.

10

11

12

Check that suction & discharge pipe is properly supported as per the approved drawing. Confirm that lifting lugs / eyes are rendered inoperable and (if applicable) holes plugged and threads identified. The alignment with prime mover (motor) is proper and alignment readings are handy. All moving parts should be adequately guarded. Pump spindle should be free to rotate when uncoupled from motor. Check the tightness of the flange joints and no fitting element is missing. All alarms and parameters connected with pump and its auxiliaries are commissioned. The suction and discharge pipes should be cleaned by removing foreign material if any. Suction & Discharge valve should be commissioned and its operation is satisfactory with Protection & interlocks. Suction & discharge valves opening and closing from local is checked for emergency operation. Remote operation of the suction & discharge valves should be checked, if provided. Check that the pump gland packings and casing joints are satisfactory. Check that gland leakage arrangement made is satisfactory for the fluid being pumped. Check that priming & drainage arrangements are satisfactory for fluid being pumped. Correct grade and sufficient quantity of grease is filled in the DE/NDE bearing cups. Confirm that all the pressure gauges, pressure switches etc. properly mounted after necessary calibration as per drawing. The pending list of items on the system is available.

13

14

15

16

17

18

19

20

= 21

22

23

24

25

26

27

Confirm pipe work for drains are routed to suitable destination. Check the DOR of the pump by bump start Safety

28

29 30

First aid kit should be available near the site. Ambulance should be deployed near the site. Check for the following (AFTER RUNNING):

1 2

Start the pump and note the starting time. Keep the discharge valve in full close position. Ensure that the discharge valve opens fully after the pump has accelerated to full speed. Measure the vibrations at all bearings of pump and motor and record them. Measure static pressure at pump suction & discharge. Check for any abnormal noise in the pump and motor.

5 Note down the time taken by the discharge valve for full opening. 6 Check for medium leakage from pump casing and joints. 7 If the pump is running normal, keep the pump running for 4 hrs to check the vibration level. Confirm that pump prime can be established and maintained. Confirm integrity of pump glands and seals. By carefully listening to the pump noise, establish any obivious signs of cavitation. During the continuous operation of the pump the "Operational parameters" should be logged. Record the following for every 15 min for first one hour of run and

10 11

every hour till trial run is completed. 12 a)Vibration level b)Motor current c) Bearing temperatures of pump. d)Suction & discharge pressure. e)pump inboard bearing temperature f)pump outboard bearing temperature

Вам также может понравиться

- Summer ScheduleДокумент2 страницыSummer Schedulearvidkumar87060Оценок пока нет

- Govt. Intiatives and SchemesДокумент6 страницGovt. Intiatives and Schemesarvidkumar87060Оценок пока нет

- SC Order EPS Letter 24.01.2023Документ3 страницыSC Order EPS Letter 24.01.2023arvidkumar87060Оценок пока нет

- (WWW - Entrance-Exam - Net) - PHARMA.D 001Документ1 страница(WWW - Entrance-Exam - Net) - PHARMA.D 001arvidkumar87060Оценок пока нет

- Electricity Distribution Losses Reduced by Raising VoltageДокумент164 страницыElectricity Distribution Losses Reduced by Raising Voltagearvidkumar87060100% (1)

- Books and Authors SummaryДокумент2 страницыBooks and Authors Summaryarvidkumar87060Оценок пока нет

- Syllabus-Technical PositionsДокумент5 страницSyllabus-Technical PositionsAashima PurohitОценок пока нет

- FDI in Various SectorsДокумент1 страницаFDI in Various Sectorsarvidkumar87060Оценок пока нет

- MECHANICAL ENGINEERING MCQДокумент38 страницMECHANICAL ENGINEERING MCQManish KumarОценок пока нет

- Statics and Strength FormulasДокумент1 страницаStatics and Strength FormulasRichard TsengОценок пока нет

- BAJA Final Scores Virtuals 2020Документ19 страницBAJA Final Scores Virtuals 2020Team ZEPHYRAОценок пока нет

- India's Ranking in World IndecesДокумент2 страницыIndia's Ranking in World Indecesarvidkumar87060Оценок пока нет

- Eng PuzzleДокумент1 страницаEng PuzzlePrem AnandОценок пока нет

- Integration Formulas: 1. Common IntegralsДокумент5 страницIntegration Formulas: 1. Common IntegralssiegherrОценок пока нет

- Quants FormulaeДокумент6 страницQuants Formulaevpundlik_882747Оценок пока нет

- Current Affairs PDFДокумент198 страницCurrent Affairs PDFarvidkumar87060Оценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Maths ShortcutsДокумент7 страницMaths ShortcutsNirmalОценок пока нет

- Quants-Points 2 Remember For CAT and XATДокумент10 страницQuants-Points 2 Remember For CAT and XATbilalak1990Оценок пока нет

- Maths Shortcuts2Документ11 страницMaths Shortcuts2arvidkumar87060Оценок пока нет

- Eng PuzzleДокумент6 страницEng Puzzlearvidkumar87060Оценок пока нет

- Vedic Maths Tutorial (Interactive)Документ6 страницVedic Maths Tutorial (Interactive)arvidkumar87060Оценок пока нет

- Insights Mind Maps: Future of BitcoinsДокумент2 страницыInsights Mind Maps: Future of Bitcoinsarvidkumar87060Оценок пока нет

- Vedic Maths TutorialДокумент12 страницVedic Maths TutorialNitin Jain100% (15)

- Quants FormulaeДокумент6 страницQuants Formulaevpundlik_882747Оценок пока нет

- Green Marine Plywood - GreenplyДокумент3 страницыGreen Marine Plywood - Greenplyarvidkumar87060Оценок пока нет

- ResumeДокумент3 страницыResumearvidkumar87060Оценок пока нет

- Economic Development and Social ProgressДокумент2 страницыEconomic Development and Social Progressarvidkumar87060Оценок пока нет

- Examinationnotice 2006Документ20 страницExaminationnotice 2006anon-842459100% (9)

- Govt. Intiatives and SchemesДокумент6 страницGovt. Intiatives and Schemesarvidkumar87060Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Future Trends - Challenges of IPM - Climatic ChangeДокумент15 страницFuture Trends - Challenges of IPM - Climatic ChangeMandre DynaОценок пока нет

- CMP2015 - Challenges in Niobium FlotationДокумент11 страницCMP2015 - Challenges in Niobium FlotationrodrigoОценок пока нет

- Planiseal 288: Flexible, Cementitious Mortar For WaterproofingДокумент4 страницыPlaniseal 288: Flexible, Cementitious Mortar For WaterproofingDumbledore The 3rdОценок пока нет

- General Organic and Biological Chemistry 2Nd Edition Frost Test Bank Full Chapter PDFДокумент31 страницаGeneral Organic and Biological Chemistry 2Nd Edition Frost Test Bank Full Chapter PDFBradMartiniczn100% (8)

- DiureticsДокумент4 страницыDiureticsNazmul Islam AbirОценок пока нет

- 9271silicone Dynamics Keypad Design GuideДокумент32 страницы9271silicone Dynamics Keypad Design GuideSherifОценок пока нет

- An Up-To-Date Review of Digoxin Toxicity and Its ManagementДокумент6 страницAn Up-To-Date Review of Digoxin Toxicity and Its ManagementNusieba IbrahimОценок пока нет

- IKA RV10 Rotary Evaporators PDFДокумент18 страницIKA RV10 Rotary Evaporators PDFBrian Bob SiregarОценок пока нет

- H2S RefersherДокумент35 страницH2S RefersherAhmed AbdallahОценок пока нет

- ECOLOGY OF OCHRE JELLIESДокумент3 страницыECOLOGY OF OCHRE JELLIESGeorge KrashosОценок пока нет

- How Cells Release Stored EnergyДокумент57 страницHow Cells Release Stored EnergykylevОценок пока нет

- Aa Brochure Eng PDFДокумент4 страницыAa Brochure Eng PDFJeff YauОценок пока нет

- Beginner Soapmaking Instructions and Recipes Revised PDFДокумент37 страницBeginner Soapmaking Instructions and Recipes Revised PDFstefanovicsanjaОценок пока нет

- PESSI Tenders Medicines Interferon SyringesДокумент77 страницPESSI Tenders Medicines Interferon SyringesAsim IdreesОценок пока нет

- PIT AND FISSURE SEALANT GUIDEДокумент2 страницыPIT AND FISSURE SEALANT GUIDEAhmed FoudaОценок пока нет

- DT-9 - Lesson 4Документ8 страницDT-9 - Lesson 4Amit Kr GodaraОценок пока нет

- The Water Cycle: Word Bank: Runoff, Transpiration, Evaporation, InfiltrationДокумент11 страницThe Water Cycle: Word Bank: Runoff, Transpiration, Evaporation, InfiltrationJessica OliverОценок пока нет

- Acid and Bases QuestДокумент4 страницыAcid and Bases QuestSanthiya MadhavanОценок пока нет

- Film Extrusion Technical GuideДокумент64 страницыFilm Extrusion Technical GuideLubomirBenicek0% (1)

- Changes in MaterialsДокумент7 страницChanges in MaterialsMyat Myat OoОценок пока нет

- Engineering Design Process DevelopmentДокумент4 страницыEngineering Design Process DevelopmentpixulinoОценок пока нет

- Norox Mekp-925hДокумент2 страницыNorox Mekp-925hEngTamerОценок пока нет

- C Ch-6 ThermodynamicsДокумент11 страницC Ch-6 Thermodynamicssher dillОценок пока нет

- 26529Документ61 страница26529MASTER_SANDMANОценок пока нет

- Waste Management: Fabio Dal Magro, Haoxin Xu, Gioacchino Nardin, Alessandro RomagnoliДокумент10 страницWaste Management: Fabio Dal Magro, Haoxin Xu, Gioacchino Nardin, Alessandro RomagnoliKARAN KHANNAОценок пока нет

- Low Temperature Cure Strategies For Powder Coatings - IndiaДокумент12 страницLow Temperature Cure Strategies For Powder Coatings - IndiawolfkynОценок пока нет

- Material Safety Data Sheet: Böhler AWS E 316 L-17Документ6 страницMaterial Safety Data Sheet: Böhler AWS E 316 L-17Sivaneswaran SabaratnamОценок пока нет

- Scope Location 1 TC-6212Документ33 страницыScope Location 1 TC-6212NISAR AHMEDОценок пока нет

- Astm d2488Документ12 страницAstm d2488Daniel Anijar100% (1)

- Blasting Painting Procedure For Structural Steel Rev 00Документ17 страницBlasting Painting Procedure For Structural Steel Rev 00Praful N KОценок пока нет