Академический Документы

Профессиональный Документы

Культура Документы

CNC Lubricacion

Загружено:

Anonymous D5QForitcОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CNC Lubricacion

Загружено:

Anonymous D5QForitcАвторское право:

Доступные форматы

1-1203-US

Compact Units for Oil

Group MKU 0.1, 0.2 or 0.5 l/min

These MKU compact units were developed

to supply intermittently operated single-line

central lubrication systems with lubricant.

The basic model contains a gear pump with

drive motor as well as the set of valves

required for pressure relief and limitation

(safety valve). The lubricant reservoir material

is metal or plastic.

The units are controlled depending on their

design

by hand

(unit with a pushbutton DK)

by an external control system

by a built-in electronic control and moni-

toring unit,

timer or counter with adjustable interval

and monitoring time

by a built-in electronic control unit

with adjustable interval time and fixed

pump running time.

The control and monitoring unit is either

a timer for time-dependent control or a

counter for load-dependent control.

Special features:

Preliminary lubrication

(lubrication after the supply voltage is

turned on)

Pump delay time

Pressure dependent cut-off

Monitoring of pressure build-up

Monitoring of pump running time

Possible monitoring elements:

Pressure switch (DS) monitors the auto-

matic pressure build-up

Level indicator (WS)

Pressure gauge (MA) displays the pres-

sure response in the main line

Monitoring contact (d2) turns off machine

if pressure fails to build up

Indicator light, green (SL1)

shows that pump is running

Indicator light, red (SL2) indicates a fault

if pressure fails to build up or if there is a

low level of lubricant in the reservoir

(only with built-in level indicator)

Compact Units for Oil, Group MKU

2 1-1203-US

1) The 20 % duty cycle is the ratio of the pump running time to the subsequent idle time.

Example: 1 minute of pump running time requires at least 5 minutes of idle time.

The maximum permissible pump running time amounts to 3 minutes.

That results in a necessary idle time of 15 minutes.

2) Take appropriate measures to protect contacts when switching inductive loads.

Notice!

Not all lubricants are suitable for central lubrication systemts. The lubri-

cant selected by the user should be approved by the Willy Vogel AG.

All equipment may only be installed and/or assembled by qualified

personnel. Observe existing safety regulations.

See operating instruction 951-130-172.

Gear pump unit

Flow rate at 50 Hz: . . . . . . . . 0.1, 0.2 or 0.5 l/min

Flow rate at 60 Hz: . . . . . . . . 0.12, 0.24 or 0.6 l/min

in relation to a service viscosity of 140 mm

2

/s, at a back pressure of p = 5 bar

Operating pressure . . . . . . . . 30 bars

corresponds to actual value of built-in safety valve

Operating temperature . . . . . . +10 to +40 C

Medium . . . . . . . . . . . . . oil on a petroleum basis

or synthetic basis

compatible with . . . . . . . . . plastics, NBR elastomers,

copper, copper alloys

Service viscosity

MKU1 units: . . . . . . . . 20 - 750 mm

2

/s

MKU2, MKU5 units: . . . . . 20 - 1500 mm

2

/s

Reservoir capacity . . . . . . . . nominal 1.8 , 3 or 6 l

Reservoir material . . . . . . . . plastic or metal

Type of enclosure . . . . . . . . . IP 54

Frequency / voltage . . . . . . . . 50 / 60 Hz, 115 V AC or

50 / 60 Hz, 230 V AC

please indicate when ordering

Motor with built-in thermostatic switch

Mode of operation . . . . . . . . S3, 20 % (1.25 to 25 min)

duty cycle

1

)

Power consumption approx. . . . 50 Hz: 115 W; 60 Hz: 140 W

Speed . . . . . . . . . . . . . . 50 Hz: 2700 rpm;

60 Hz: 3300 rpm

Level indicator

Function . . . . . . . . . . . . . opens in event of low lubricant

Max. switching voltage . . . . . . 42 V AC

Max. switching current . . . . . . 0.7 A

(ohmic load)

Max. contact rating . . . . . . . . 50 VA

2

)

Pressure switch

Type of contacts . . . . . . . . . closes when pressure builds up

Max. switching voltage . . . . . . 42 V AC

Max. switching current . . . . . . 2.5 A

(ohmic load)

Max. contact rating . . . . . . . . 30 VA

2

)

Switching pressure . . . . . . . . 20 bars

?

A

M/

S0 ber

0.5 ber

20 ber

?

M

Anwendungsbeispiel: Universalfrsmaschine

Technical data

+1

-2

Compact Units for Oil, Group MKU

3 1-1203-US

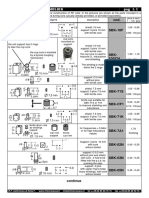

Delivery Reservoir Reservoir Control Components

rate capacity material

manual/ Hydraulic Wiring Draw-

Order No. [l/min] [l] *) external IG12 IG38-30 IZ38-30 DK DS WS MA layout diagram ing

MKU1-K2-20000 0.1 1.8 K Extern 1 1 1

MKU1-K2-20003 0.1 1.8 K Extern 1 1 1

MKU1-KW2-20000 0.1 1.8 K Extern 1 1 1

MKU1-KW2-20001 0.1 1.8 K Extern 1 1 1

MKU1-KW2-20003 0.1 1.8 K Extern 1 1 1

MKU1-KW2-20004 0.1 1.8 K Extern 1 1 1

MKU2-K3-20000 0.2 3 K 2 2 2

MKU2-K3-22005 0.2 3 K 2 3 2

MKU5-K3-22005 0.5 3 K 2 3 2

MKU2-KW3-20001 0.2 3 K 2 2 2

MKU2-KW3-20003 0.2 3 K 2 2 2

MKU2-KW3-20004 0.2 3 K 2 2 2

MKU2-KW3-20005 0.2 3 K 2 2 2

MKU2-KW3-21003 0.2 3 K 2 4 2

MKU2-KW3-21005 0.2 3 K 2 4 2

MKU2-KW3-22001 0.2 3 K 2 3 2

MKU2-KW3-22003 0.2 3 K 2 3 2

MKU2-KW3-22011 0.2 3 K 2 3 2

MKU2-KW3-22013 0.2 3 K 2 3 2

MKU5-KW3-20001 0.5 3 K 2 2 2

MKU5-KW3-20003 0.5 3 K 2 2 2

MKU5-KW3-22003 0.5 3 K 2 3 2

MKU2-KW6-20001 0.2 6 K 2 2 3

MKU2-KW6-20003 0.2 6 K 2 2 3

MKU2-KW6-22003 0.2 6 K 2 3 3

MKU5-K6-22005 0.5 6 K 2 3 3

MKU5-KW6-20001 0.5 6 K 2 2 3

MKU5-KW6-22001 0.5 6 K 2 3 3

MKU5-KW6-22003 0.5 6 K 2 3 3

MKU2-BW3-20001 0.2 3 B 2 2 4

MKU2-BW3-20003 0.2 3 B 2 2 4

MKU2-BW3-20005 0.2 3 B 2 2 4

MKU2-BW3-21003 0.2 3 B 2 4 4

MKU2-BW3-22001 0.2 3 B 2 3 4

MKU2-BW3-22003 0.2 3 B 2 3 4

MKU2-BW3-22011 0.2 3 B 2 3 4

MKU2-BW3-22013 0.2 3 B 2 3 4

MKU5-BW3-21003 0.5 3 B 2 4 4

*) Reservoir material: K = plastic. B = metal

= components contained in the unit. DK = pushbutton / DS = pressure switch / WS = level indicator / MA = pressure gauge

Units overview

Compact Units for Oil, Group MKU

4 1-1203-US

l55

2

8

5

l0

l

5

l

0

4

l

2

2

]

M

l

4

x

l

.

5

S

4

l

]

l

4

l

8

.

5

22

6

.

6

2

x

]

l0

0

20

m|n

mex

P

ber

P

.5

S0

40

Drawing 1

MKU1-K(W)2-...

P P]

R]

R]

0l/4]

m|n

mex

ber

20

P

40

S0

0

l0

0l/4]

lS

-286

256

2l5

-5

l80

-5

2SS

-5

l0

o

28

0

l8

l5

l6S

5

26.5

l

]

0l/4

5.5

2

]

4

8

.

5

Drawing 2

MKU2-K(W)3-...

MKU1-K(W)2-...

MKU2-K(W)3-...

1

) Ports tapped for solderrless tube

connection for 8 mm diam. tube

2

) Diameter for power lead 6...8 mm

1

) Diameter for power lead 8...10 mm

2

) Diameter for power lead 6...12 mm

(only MKU2-K(W)3-20...)

Compact Units for Oil, Group MKU

5 1-1203-US

R]

P] P

R]

0l/4]

0l/4]

ber

l0

0

S0

40

20

P

-286

4

8

.

5

o

l0

2SS

-5

l80

-5

256

2l5

-5

5

lS

0

l

20S.5

l

]

26.5

Sl4

5.5

0l/4

2

]

Drawing 4

MKU2-BW3-...

P

P]

R]

m|n

mex

l0 S0

0 ber 40

20

P

0l/4]

0l/4]

l

]

2

]

0l/4

5.5

0

5

0

l

20

SSS

l

8

0

l

2

2 20

ll0 S5 ll0

5

0

o8.5Sx]

R]

Drawing 3

MKU2-KW6-...

MKU2-KW6-...

MKU2-BW3-...

1

) Diameter for power lead 8...10 mm

2

) Diameter for power lead6...12 mm

(only MKU2-KW6-20...)

1

) Diameter for power lead 8...10 mm

2

) Diameter for power lead 6...12 mm

(only MKU2-BW3-20...)

Compact Units for Oil, Group MKU

6 1-1203-US

10 1 2 3 4 5 6 8 7 9 12 11

DS

1~

M

P Q

WS

N L1

PE

Wiring diagram 1

X1

X2

optional

1

)

PE

plug-type connector

DIN 43650-A

1

DS WS

Q P

SL

1

)

M

1~

1a 1b 1

PE 1 2 3 3 4 5 5 6 7 7 8 9

C

1

)

DK

B

K

(

s

w

)

R

D

(

r

t

)

B

U

(

b

l

)

B

K

(

s

w

)

B

N

(

b

r

)

B

N

(

b

r

)

3 2

N L1/S L1

Wiring diagram 2

X1

X2

IG/IZ38-30-I

optional

1

)

L1 N PE

plug-type connector

DIN 43650-A

1 2

DS

WS

Q

P

MK with counter mode only

normal operation

fault

fault

d2:24

d2:12

d2:22

230V

AC

SL1 SL2

24VDC

DK

I1

12

C

115VAC

I5 - I4 I3 + I2 + L1 B1 B2 N N N d1 C

d1

1

)

1

)

1

)

MK

M

1~

B

K

(

s

w

)

B

N

(

b

r

)

B

U

(

b

l

)

N N

d2

21

22

24

d2

22

24

21

12

L1 L1 d1

B1 B2 L1 L1

Wiring diagram 3

X1

X2

T

h

e

s

e

c

o

n

n

e

c

t

i

o

n

s

a

r

e

m

a

d

e

b

y

t

h

e

c

u

s

t

o

m

e

r

optional

1

)

L1 N PE

plug-type connector

DIN 43650-A

DS

1 2

WS WS

L1 N N

DK DS DK

N 18 18 C

1b

DK

1

1a

DS

1

)

WS Q

1

)

BK (sw)

BN (br)

BU (bl)

M

1~

C

IG12

SL

P

Wiring diagram 4

P

M

20 bars

0.5 bar 30 bars

Hydraulic layout 1

MKU 1

R P

1

P

2

M

20 bars

0.5 bar 30 bars

Hydraulic layout 2

MKU 5

Legend (wiring diagrams 1-4)

L1 / N . . . . . . . . terminal for operating voltage

DK . . . . . . . . . . pushbutton for intermediate lubrication

DS . . . . . . . . . . pressure switch

WS . . . . . . . . . . level indicator,

contact illustration: full reservoir

M. . . . . . . . . . . pump motor

C . . . . . . . . . . . capacitor

SL1. . . . . . . . . . indicator light (green) for PUMP ON

SL2. . . . . . . . . . indicator light (red) for FAULT

Compact Units for Oil, Group MKU

7 1-1203-US

The compact units with 3- or 6-liter

reservoirs may be equipped with an elec-

tronic control unit for intermittently operated

single-line central lubrication systems.

Optionally with

IG38-30-I for time-dependent control

IZ38-30-I for load-dependent control

IG12for time-dependent control

(without monitoring functions)

Functions

IG38-30-I: timer mode (time-dependent)

IZ38-30-I: counter mode

(load-dependent)

Preliminary lubrication (lubrication after

the supply voltage is switched on)

Pump delay time

Monitoring of pressure build-up

Monitoring of pump runtime limitation

Monitoring of lubricant level with wire-

break detection (level indicator opens if

lubricant level is critical)

The units conform to the following directives:

Electromagnetic compatibility

89/336/EWG; 91/31/EWG

Low voltage directive

73/23/EWG; 93/68/EWG

Control and monitoring unit with pre-lubrication

IG38-30-I, time-dependent or IZ38-30-I, load-dependent

Technical data

Rated voltage . . . . . . . . . . . . . . . . . . 115 or 230 V AC

Rated frequency . . . . . . . . . . . . . . . . . 50/60 Hz

Interval duration preselectable in 12 stages:

IG38-30-I (min) . . . . . . . . . . . . . . . . . 1; 2; 4; 8; 16; 32; 64; 128

IZ38-30-I (pulses) . . . . . . . . . . . . . . . . 256; 512; 1024; 2048

Pump delay time, nonadjustable . . . . . . . . . 15 s

Pump runtime limitation, nonadjustable . . . . . 60 s

Design . . . . . . . . . . . . . . . . . . . . . . board-mounted

Control unit without pre-lubrication

IG12, time-dependent

Functions

Timer with adjustable interval time and

constant lubrication time

Operation always begins with an interval

when the supply voltage is switched on

Intermediate lubrication via pushbutton DK

is possible at any time during an interval

Technical data

Rated voltage . . . . . . . . . . . . . . . . . . 115 or 230 V AC

Rated frequency . . . . . . . . . . . . . . . . . 50/60 Hz

Interval time (min)

preselectable in 10 stages: . . . . . . . . . . . . 1,5; 3; 6; 12; 24; 48; 96; 192; 384; 768

As-delivered setting . . . . . . . . . . . . . . . interval time set for 1.5 min

Contact time, fixed . . . . . . . . . . . . . . . . 20 s

Design . . . . . . . . . . . . . . . . . . . . . . plastic housing

Terminal bloc for . . . . . . . . . . . . . . . . . level indicator (WS) and

pressure switch (DS)

This brochure was presented by:

Order No. 1-1203-US

Subject to change without notice! (06/2007)

The contents of this publication are the copyright of the publisher and may

not be reproduced (even extracts) unless permission is granted. Every care

has been taken to ensure the accuracy of the information contained in this

publication but no liability can be accepted for any loss or damage whether

direct, indirect or consequential arising out of use of the information con-

tained herein.

All products from VOGEL may be used only for their intended purpose. If

operating instructions are supplied together with the products, the provi sions

and information therein of specific relevance to the equipment must be

observed as well.

In particular, we call your attention to the fact that hazardous materials of any

kind, especially the materials classified as hazardous by EC Directive 67/548/

EEC, Article 2, Par. 2, may only be filled into VOGEL centralized lubricatio n

systems and components and delivered and/or distributed with

the same after consultation with and written approval from VOGEL.

All products manufactured by VOGEL are not approved for use in conjunction

with gases, liquefied gases, pressurized gases in solution and fluids with a

vapor pressure exceeding normal atmospheric pressure (1013 mbars) by

more than 0.5 bar at their maximum permissible temperature.

Competence center for industrial applications

Willy Vogel Aktiengesellschaft

SKF Lubrication Solutions

Motzener Strasse 35/37 12277 Berlin Germany

PF 970444 12704 Berlin Germany

Tel. +49 (0)30 72002-0 Fax +49 (0)30 72002-111

info@vogel.skf.com www.vogelag.com

SKF Group 2007

SKF and VOGEL are registered trademarks of the SKF Group.

Вам также может понравиться

- V Ring PDFДокумент26 страницV Ring PDFAnonymous D5QForitcОценок пока нет

- Gagemaker 2004 CatalogДокумент32 страницыGagemaker 2004 CatalogAnonymous D5QForitcОценок пока нет

- V Ring PDFДокумент26 страницV Ring PDFAnonymous D5QForitcОценок пока нет

- Rotary Seals Vrings - PD PDFДокумент25 страницRotary Seals Vrings - PD PDFAnonymous D5QForitcОценок пока нет

- CFR 2011 Title29 Vol5 Sec1910 215 PDFДокумент13 страницCFR 2011 Title29 Vol5 Sec1910 215 PDFAnonymous D5QForitcОценок пока нет

- Herramientas de Mecanizado VARGUSДокумент336 страницHerramientas de Mecanizado VARGUSAnonymous D5QForitcОценок пока нет

- ECДокумент44 страницыECAnonymous D5QForitcОценок пока нет

- Handel Violin Sonata 4 ScoreДокумент12 страницHandel Violin Sonata 4 ScoreAnonymous D5QForitcОценок пока нет

- Lo Nuevo de Herramientas VARGUSДокумент336 страницLo Nuevo de Herramientas VARGUSAnonymous D5QForitcОценок пока нет

- Herramientas de Mecanizado VARGUSДокумент336 страницHerramientas de Mecanizado VARGUSAnonymous D5QForitcОценок пока нет

- Company Information & Technical BrochureДокумент30 страницCompany Information & Technical Brochure@@@AAA@@@Оценок пока нет

- Accessories: Scan These QR CodesДокумент12 страницAccessories: Scan These QR CodesAnonymous D5QForitcОценок пока нет

- Manual - de - Bolso - Fanuc 16i 18i 21i MODEL BДокумент988 страницManual - de - Bolso - Fanuc 16i 18i 21i MODEL BJeffsouza2016100% (4)

- IMSLP39920-PMLP87487-Handel - HWV372 Violin and Cello PartДокумент7 страницIMSLP39920-PMLP87487-Handel - HWV372 Violin and Cello PartAnonymous D5QForitcОценок пока нет

- Association of Well Head Equipment Manufacturers Post Office Box 1166 Bellaire, Texas 77401Документ9 страницAssociation of Well Head Equipment Manufacturers Post Office Box 1166 Bellaire, Texas 77401Anonymous D5QForitcОценок пока нет

- Conical ThreadДокумент9 страницConical ThreadAnonymous D5QForitcОценок пока нет

- Tap CatalogueДокумент42 страницыTap CatalogueAnonymous D5QForitcОценок пока нет

- SRFH20S25XДокумент1 страницаSRFH20S25XAnonymous D5QForitcОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ut 70 CДокумент48 страницUt 70 CKi SeyОценок пока нет

- Technical Manual AIRVO 2Документ33 страницыTechnical Manual AIRVO 2Jef RobboОценок пока нет

- Ne856 2sc5011 2sc5006 2sc4226 2sc3355 2sc3603 2sc3356 2sc3357 2sc3603 2sc4093Документ25 страницNe856 2sc5011 2sc5006 2sc4226 2sc3355 2sc3603 2sc3356 2sc3357 2sc3603 2sc4093JourneyОценок пока нет

- Design and Development of Variable Frequency Ultrasonic Pest RepellerДокумент14 страницDesign and Development of Variable Frequency Ultrasonic Pest RepellerS shek DhavudОценок пока нет

- Skillful Reading Writing Level 3 Unit 9 SoundДокумент10 страницSkillful Reading Writing Level 3 Unit 9 SoundJonatan CamposОценок пока нет

- SOLO V1 201 User Manual B PDFДокумент98 страницSOLO V1 201 User Manual B PDFAlejo ArenillaОценок пока нет

- Hazards: 1. The Concept of HazardДокумент25 страницHazards: 1. The Concept of HazardManas ChetryОценок пока нет

- Electromagnetic WavesДокумент54 страницыElectromagnetic WavesjosephrandalldeiparineОценок пока нет

- ASM Pmis3 enДокумент7 страницASM Pmis3 enpepeОценок пока нет

- MMS-Week6-Exercise5 Creating An OscilloscopeДокумент9 страницMMS-Week6-Exercise5 Creating An Oscilloscopesaujan126Оценок пока нет

- MCR-f-UI-DC: Universal Frequency TransducerДокумент17 страницMCR-f-UI-DC: Universal Frequency TransducerforoОценок пока нет

- User Manual - InT001Документ23 страницыUser Manual - InT001omerОценок пока нет

- 04 - Elements of EchocardiographyДокумент56 страниц04 - Elements of EchocardiographyMariana CabralОценок пока нет

- Cópia de HM786 Uv&VHF Service Manual V00 - EngДокумент268 страницCópia de HM786 Uv&VHF Service Manual V00 - EngALEX FERNANDESОценок пока нет

- Unit of Measure Python Module PDFДокумент25 страницUnit of Measure Python Module PDFBijoy ChetiaОценок пока нет

- Ieee 299 1997Документ44 страницыIeee 299 1997Israel OrdoñezОценок пока нет

- Electromagnetic MeasurmentsДокумент232 страницыElectromagnetic Measurmentsshahram atashiОценок пока нет

- GRC TutorialДокумент29 страницGRC Tutorialorg25grОценок пока нет

- Wave Speed, Frequency, PeriodДокумент4 страницыWave Speed, Frequency, PeriodI Putu Yoga Widi LaksanaОценок пока нет

- Aiwa+Cx Nsz50lh SMДокумент40 страницAiwa+Cx Nsz50lh SMSandro Aniello LunascoОценок пока нет

- Diagnostics InformationДокумент10 страницDiagnostics InformationabyzОценок пока нет

- Feeder Protection and Control REF601 and REJ601 ANSI: Product GuideДокумент20 страницFeeder Protection and Control REF601 and REJ601 ANSI: Product GuideAdarsh SharmaОценок пока нет

- Speed Command HZ: - Inv032 - Movevelocityhz: This FBДокумент3 страницыSpeed Command HZ: - Inv032 - Movevelocityhz: This FBJosephОценок пока нет

- Type 3560C HardwareДокумент32 страницыType 3560C Hardwarecorentoulf0% (1)

- Preparatory Year Program Computer Science (PYP 002)Документ34 страницыPreparatory Year Program Computer Science (PYP 002)Hassan AlfarisОценок пока нет

- 1SP02 EMC32 DataReduction V1Документ46 страниц1SP02 EMC32 DataReduction V1AndreeaОценок пока нет

- ELEC1010 Homework 1Документ4 страницыELEC1010 Homework 1Yuen Hei Max LeeОценок пока нет

- BC-6000 Installation Guide V9.0 enДокумент114 страницBC-6000 Installation Guide V9.0 enHuy Trung GiápОценок пока нет

- KITS AND COIL ASSEMBLIES Pag L 1Документ24 страницыKITS AND COIL ASSEMBLIES Pag L 1Pisu Miau Pisu MiauОценок пока нет

- Sing150 LP enДокумент792 страницыSing150 LP enJorge SilvaОценок пока нет