Академический Документы

Профессиональный Документы

Культура Документы

WIT - Well Operations Manual

Загружено:

Saer OklaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WIT - Well Operations Manual

Загружено:

Saer OklaАвторское право:

Доступные форматы

Pressure testing of Coil Tubing PCE

Weekly Full BOP Test This test will be carried out every seventh day that the CTU unit is in operation, AND before any stimulation or clean out operation. 1. Rig up temporary pipework (TPW) from the pump unit to KWV. Ensure there is a check valve between the TPW and the KWV. Ensure the TPW is secured by restraining wire. 2. Stab on the BOP and function test all rams. 3. Flush the coil with water to the cellar until clean returns. 4. Before stabbing on the injector head, inspect the BHA and remove and inspect the check valves. Check the overall condition of the BHA. 5. Open up the Lo-torque valve at the T piece at the wellhead and flush the surface lines with water to the cellar until clean returns. 6. Test surface lines. Close the KWV and pressure test the surface lines to 5000 psi, observe for any leaks. 7. Test Xmas tree valves. Close the UMV, SWV and WV, open the KWV. Test Xmass-tree and WV to 3500psi. Monitor pressure drop-off. Grease and cycle valves if required. 8. Stab on injector. 9. Test Blind Rams. Close blind rams, open SWV and pressure test against blind rams to 3500psi via the KWV 10. Run in BHA to below pipe rams. 11. Test check valves. Close the slip rams around the coil and energize the stripper. Apply 1000 psi via the KWV to the riser. Open the coil tubing reel inlet valve or monitor a gauge at the real inlet valve and observe for any leaks through BHA-check valves. If a leak occurs, remove the injector, change out the check valves and re-test. 12. Test stripper & connections. With the stripper still closed, pressure up via coil to 3500 psi to pressure test the connections between the tree cap and the stripper. 13. Test Pipe rams Close the pipe rams. Open the Lo-torque valve on the BOPs kill line. Pressure test via the coil tubing to 5000 psi

Observe for leaks thro the BOP kill line that may indicate the pipe rams are not holding pressure. 14. Bleed off the pressure via the KWV and open the pipe rams. Close the BOP lotorque valve. 15. Purge the reel if necessary. BOP function test, Stripper test & BHA check-valves test. This test will be carried out on every rig up. 1. Rig up temporary pipe-work (TPW) from the pump unit to KWV. Ensure there is a check valve between the TPW and the KWV. Ensure the TPW is secured by restraining wire. 2. Stab on the BOP and function test all rams. 3. Open up the Lo-torque valve at the T piece at the wellhead and flush the surface lines with water to the cellar until clean returns. 4. Test surface lines. Close the KWV and pressure test the surface lines to 5000 psi, observe for any leaks. 5. Test Xmas tree valves. Close the UMV, SWV and WV, open the KWV. Test Xmass-tree and WV to 3500psi. monitor pressure drop-off. Grease and cycle valves if required. 6. Flush the coil with water until clean returns. 7. Before stabbing-on the injector head, inspect the BHA and remove and inspect the check valves. Check the overall condition of the BHA. 8. Stab the injector onto the riser/BOPs 9. Test check valves. Close the slip rams around the coil and energize the stripper. Apply 1000 psi via the KWV to the riser. Open the coil tubing reel inlet valve or monitor a gauge at the real inlet valve and observe for any leaks through BHA-check valves. If a leak occurs, remove the injector, change out the check valves and re-test. 10. Test stripper and connections. With the stripper still closed, pressure up via coil to 3500 psi to pressure test the connections between the tree cap and the stripper. 11. Bleed off pressure, purge the reel if required.

Вам также может понравиться

- Formula SheeДокумент6 страницFormula SheeSaer OklaОценок пока нет

- Formula SheeДокумент6 страницFormula SheeSaer OklaОценок пока нет

- 2.875x6.4 l80 STD JfebearДокумент1 страница2.875x6.4 l80 STD JfebearSaer OklaОценок пока нет

- Ob ObjectivesДокумент1 страницаOb ObjectivesSaer OklaОценок пока нет

- FISHINGДокумент1 страницаFISHINGSaer OklaОценок пока нет

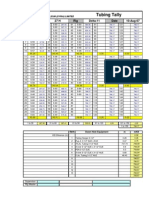

- Tubing Tally: Delta-11 Well 27 H Rig Date 10-Aug-07Документ1 страницаTubing Tally: Delta-11 Well 27 H Rig Date 10-Aug-07Saer OklaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Cobra Callisto TorneirasДокумент6 страницCobra Callisto TorneirasJoão Athayde e MeloОценок пока нет

- Piping Catalogue Component Naming StandardДокумент121 страницаPiping Catalogue Component Naming StandardRené Abanto GarciaОценок пока нет

- Flange Ansi b16.5 Vs Iso 7005-2Документ45 страницFlange Ansi b16.5 Vs Iso 7005-2Allan EscobarОценок пока нет

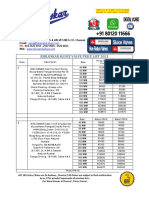

- Piping Class Detail: ENI Database PROJ: JA0051 REV: 2 DOC: CAFC-00-SP-P-00OO30Документ1 страницаPiping Class Detail: ENI Database PROJ: JA0051 REV: 2 DOC: CAFC-00-SP-P-00OO30Asma GouasmiaОценок пока нет

- Price List Parry WareДокумент12 страницPrice List Parry Warehrjeanne100% (1)

- Tuberia de Acero Al Carbono API 5L / ASTM A53 / A106Документ6 страницTuberia de Acero Al Carbono API 5L / ASTM A53 / A106RicОценок пока нет

- Skematik PT Ispat Bukit BajaДокумент1 страницаSkematik PT Ispat Bukit BajadolensiallaganОценок пока нет

- Boiler #1 - Aug 2012 - PMD 6473Документ6 страницBoiler #1 - Aug 2012 - PMD 6473Muhammad Hafiz AimanОценок пока нет

- PVC Project Report PDFДокумент21 страницаPVC Project Report PDFifiokОценок пока нет

- FM SYLLABUS PolyДокумент7 страницFM SYLLABUS PolyprasobhaОценок пока нет

- Kirloskar Sluice Valve Price List 2021: Valid From 10-12-2021 Till 31-04-2022 (Subject To Confirmation Thereafter)Документ3 страницыKirloskar Sluice Valve Price List 2021: Valid From 10-12-2021 Till 31-04-2022 (Subject To Confirmation Thereafter)jhony Mud100% (1)

- NC Plumbing and Drainlaying Modules (Omnibus) Final 2023Документ192 страницыNC Plumbing and Drainlaying Modules (Omnibus) Final 2023kuzivakwashemungate28Оценок пока нет

- Plumbing: Produced by An Autodesk Student VersionДокумент1 страницаPlumbing: Produced by An Autodesk Student VersionCamille ArielОценок пока нет

- Advert For Junior PositionsДокумент10 страницAdvert For Junior Positionsleku amosОценок пока нет

- Market Analysis - Manufacturing Unit of PVC PipesДокумент21 страницаMarket Analysis - Manufacturing Unit of PVC PipesShreya SonthaliaОценок пока нет

- 10-DSRF-N 10K Ductile Cast Iron Gate Valve (Flange Type) TOYO VALVE 37700451 - MonotaRO PhilippinesДокумент2 страницы10-DSRF-N 10K Ductile Cast Iron Gate Valve (Flange Type) TOYO VALVE 37700451 - MonotaRO PhilippinesFredie LabradorОценок пока нет

- Proposed Office Plan For: Water LayoutДокумент1 страницаProposed Office Plan For: Water LayoutDesign HubОценок пока нет

- Do CSG 25 Sep 2023Документ3 страницыDo CSG 25 Sep 2023cahbagus1267Оценок пока нет

- PNC00005Документ23 страницыPNC00005YakubuОценок пока нет

- ACW Booster Pump CalculationДокумент7 страницACW Booster Pump CalculationgreenenergykolkataОценок пока нет

- Pipe Joints: Engineering StandardДокумент7 страницPipe Joints: Engineering Standard234ahmedОценок пока нет

- Hengli Pipe Fittings FactoryДокумент6 страницHengli Pipe Fittings FactoryhlpipefittingsОценок пока нет

- Ke01 00 000 KD P TD 0015 000 - D03Документ501 страницаKe01 00 000 KD P TD 0015 000 - D03Maffone NumerounoОценок пока нет

- 2 iPLEX uPVC Pipes and FittingsДокумент17 страниц2 iPLEX uPVC Pipes and FittingsP YeungОценок пока нет

- Ascaso Steel Uno Professional (Boiler Version) Parts DiagramДокумент23 страницыAscaso Steel Uno Professional (Boiler Version) Parts DiagramRedouane RchoukОценок пока нет

- E36 Mass Air Flow Sensor AssyДокумент2 страницыE36 Mass Air Flow Sensor AssyFijiTel EighteenCents PerMinuteОценок пока нет

- R0404-MT - Rev - 0 DF Da Bateria de CicloneДокумент2 страницыR0404-MT - Rev - 0 DF Da Bateria de CiclonecaapasaОценок пока нет

- DighoriДокумент74 страницыDighoriSRR QAQCОценок пока нет

- Instrument Manifold Systems: Instrument, Direct, and Remote-Mount Manifolds and Modular SystemsДокумент30 страницInstrument Manifold Systems: Instrument, Direct, and Remote-Mount Manifolds and Modular SystemsBasheer MohamedОценок пока нет

- APV Test Procedure API 598Документ3 страницыAPV Test Procedure API 598Zain AlwaliОценок пока нет