Академический Документы

Профессиональный Документы

Культура Документы

10 1 1 127 9492

Загружено:

Rina DamanikОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

10 1 1 127 9492

Загружено:

Rina DamanikАвторское право:

Доступные форматы

Maintenance Policies With Two-Dimensional

Warranty

Tom Chen

a

Elmira Popova

b,

a

i2 Technologies, Irving, TX 75039, USA

b

Graduate Program in Operations Research and Industrial Engineering,

Department of Mechanical Engineering, The University of Texas at Austin,

Austin, TX 78712, USA

Abstract

A new maintenance policy which minimizes the total expected servicing cost for an

item with twodimensional warranty is proposed. An iterative procedure to estimate

the items failure rate function from historical observations and an optimization al-

gorithm based on Monte Carlo simulation are applied to obtain the best maintenance

policy. Numerical examples and sensitivity analysis are presented.

Key words: TwoDimensional Warranty, Maintenance, Simulation-Optimization

Corresponding Author. Address: Graduate Program in Operations Research and

Industrial Engineering, Department of Mechanical Engineering , The University

of Texas at Austin, Austin, TX 78712, USA, e-mail:elmira@mail.utexas.edu, fax:

(512)-232-1489

Preprint submitted to Elsevier Science 3 March 2002

1 Introduction

Warranties have become a critical segment of the industrial environment. Of-

ten, manufacturers use the warranty as a marketing tool to advertise the

quality of the products. Oering warranty usually results in additional costs

to the manufacturers. In general, the warranty servicing cost varies from 1%

to 10% of the total sales (see McGuire [11]). This cost depends on the war-

ranty length, item reliability and other costs. If warranty is used properly as

a marketing tool, it could result in increase in sales and market share. If the

revenue exceeds the warranty costs, it is worthwhile to sell the products with

warranty (see, for instance, Blischke and Murthy [1], [14], [15]).

There are two types of warranty policies: one and twodimensional. The one

dimensional warranty is characterized by an interval, called the warranty pe-

riod. The twodimensional warranty is characterized by a region in a two-

dimensional plane with one axis representing age and the other one usage.

For instance, when you buy a new car it usually comes with 3 years or 36,000

miles warranty, whichever comes rst. Under this warranty, the buyer is pro-

vided with a warranty coverage for a maximum time period of 3 years or a

maximum usage of 36,000 miles. If the usage is heavy, the warranty can expire

well before 3 years and if the usage is very light, then the warranty can expire

well before the limit of 36,000 miles is reached.

The case of onedimensional warranty is well studied in the literature(see

Nguyen and Murthy [19],[20], and Jack and Dagpunar [9], among all). We will

concentrate on the articles most relevant to our analysis.

The case of twodimensional warranty is discussed in several papers. Murthy

et al.,[16], use twodimensional renewal processes to model the item failure

behavior under the free replacement and no repair assumption. They represent

the expected warranty cost in terms of renewal functions for four dierent two

dimensional warranty policies. The main assumptions are that the failure of

an item is dependent on item usage and that the item can be in one of the two

statesin use or idle. The failure rate is a function of the age of the unit, the

number of times the current unit has been used, and the duration for which

the buyer has used it until time t. Yang and Nachlas [27] dene a structure for

classifying bivariate warranty problems, and methods for their building and

analysis.

Moskowitz and Chun [13] assume that the failure rate is a function of age and

usage and use a Poisson regression to model the number of failures. There

are several papers using Poisson regression to model failure occurences(see

Jorgeson [10], Gart [8] and Weber [23]). The main assumption is that the item

usage U and age T have a linear relationship: i.e., U = rT, where r is the ratio

2

between U and T. We will make the same assumption in our development.

Chun and Tang [2] assume that when a consumer buys the product, a warranty

does not come with the product but instead the customer has an option to

buy the warranty. The warranty price is analyzed with respect to such factors

as the producers risk preference, the consumers risk preference, consumers

perceptions about the product failure rate and the consumers loyalty to the

original producer in repairing failed products.

Two-attribute warranty policies for non-repairable items are described by Kim

and Rao [26]. They derive analytical expressions for the two-dimensional re-

newal function and cost of warranty under the assumption of bivariate ex-

ponential failure distribution. Chun and Tang [24] consider a two-attribute

warranty policy problem as well from a dierent point of view. They use the

warranty criteria to determine the eligibility of a warranty claim. They ana-

lyze several decision models that estimate the total expected cost under these

policies.

Maintenance policies during warranty are analyzed by several authors. Nguyen

and Murthy [19] consider the following policy: For a xed warranty length W,

the item is replaced by a new one if it fails during (0, W ) and replaced by

a repaired item (which doesnt have to be of the same age) if it fails during

(W, W). A failed item is repaired and added to the collection of the repaired

items if the age of the item is less than and has never been repaired before.

Jack and Dagpunar [9] consider an imperfect maintenance policy over a war-

ranty period. They further assume that each preventive maintenance can re-

duce the age of the machine by x units. Under a constant maintenance cost,

they derive an optimal policy. This assumption is later relaxed in Dagpunar

and Jack [5].

Several authors consider the repair/replacement policy following the expira-

tion of warranty from the consumers point of view. Dagpunar and Jack [4]

consider a consumer who purchases a product with a warranty of length W. If

the product fails before W, the manufacturer is assumed to perform minimal

repair. After the expiration of the warranty, the consumer has to bear all the

expenses of failures. They nd a cost limit a

, such that if the cost of repair

C

r

is smaller than a

, the customer should repair the product, otherwise, buy

a new product. A dierent method for estimation of the lifetime distribution

when additional eld data can be gather after the expiration of the warranty

is presented by Oh and Bai [25].

Chung [3] discusses a model with a maximum repair cost and a model with-

out a maximum repair cost. Sahin and Polatoglu [21] study two types of re-

placement policies following the expiration of warranty: the consumer applies

minimal repair for a xed period of time and replace the unit with a new one

3

at the end of this period, or the unit is replaced at the time of the rst fail-

ure following the minimal-repair period. An excellent summary of warranty

economic decision models is given by Thomas and Rao [28].

This paper proposes a new maintenance policy for twodimensional warranty

period. The policy denition is given in 2, simulationoptimization approach

to obtaining the optimal maintenance strategy and sensitivity analysis are

presented in 3.

Notation

W

u

: Warranty usage limit

W

t

: Warranty time limit

V

t

: Optimal time control limit

V

u

: Optimal usage control limit

C

r

: Cost of minimal repair

C

m

: Cost of replacement

(t, u) : Failure rate at age t and usage u

r : Ratio between the usage and time after the purchase, (r = u/t)

s : Ratio between W

u

and W

t

, (s = W

u

/W

t

)

h : Ratio between V

u

and V

t

, (h = V

u

/V

t

)

2 Maintenance policy with optimal control limits V

t

and V

u

Assume that the twodimensional warranty region is dened by the set

{(0, W

U

) (0, W

T

)}

The maintenance policy covers the maximum warranty period W

T

or the max-

imum warranty usage limit W

U

, whichever comes rst.

Policy denition:

If the item fails in the region dened by the set A = {(0, V

t

) (0, V

u

)}, then

the item is replaced by a new item for a cost of C

m

. If the item fails during the

rest of the warranty region, dened by the set B = {(0, W

u

) (0, W

t

)} \ {A},

then the item is minimally repaired for a cost of C

r

(see Figure 1), where V

u

and V

t

are selected to minimize the total expected warranty (or equivalently

maintenance) cost for the warranty region.

Insert Figure 1 here

This policy is a combination of replacement and minimal repair. As a special

case, one might consider a policy which consists of replacements or minimal

4

repairs only. The rst one is obtained by setting V

t

= W

T

, V

u

= W

U

and

V

t

= 0, V

u

= 0 for the second one.

Nguyen and Murthy [19] consider a similar strategy for onedimensional war-

ranty: the failed item is replaced by a repaired one if it fails during the second

part of the warranty period. However, the age of the repaired item could be

greater than the failed item and only an item which has never failed before

can be repaired. This is one of the main reasons we consider the strategy men-

tioned above: the failed item is minimally repaired to bring the item back to

as good as old state and the item can be repaired more than once. It is also

in our interests to search for a single policy that minimizes the total cost over

all customers. However, this policy might not be the best one for a particular

individual.

Suppose that

The usage of the item U

j

and the time T

j

after the purchase have linear

relation with ratio r

i

for customer i (i.e., U

j

= r

i

T

j

). For each customer,

the ratio r

i

could be dierent. For example, grandmothers car has smaller

r

i

than salespersons r

i

.

The probability distribution of r is known or it can be estimated from

historical information and maintenance records.

The item has an increasing failure rate (IFR) in both time and usage, (t, u),

i.e. its probability of failure increases with time or usage. We will adopt the

iterative maximum likelihood estimation procedure described in 2.1.

2.1 Failure rate estimation

Let N be a random variable for the number of failures. Assume that its

distribution is Poisson with parameter (t, u), where t = time, u = usage.

The corresponding probability mass function is:

P(N = k

j

) =

e

(t,u)

(t, u)

k

j

k

j

!

, where k

j

= 0, 1, 2, 3, . . .

The following functional forms for the failure rate are commonly used in the

twodimensional warranty literature:

(t, u) =

1

t

w

+

2

u

w

and

(t, u) = e

(

1

t

w

+

2

u

w

)

(see Moskowitz and Chun [13]).

5

Many other alternative functional forms are also available for the analysis. To

obtain an estimate of (t, u) we will follow the procedure described in Jorgeson

[10] and Weber [23].

As an illustration, let us assume that (t, u) =

1

t

3/2

+

2

u

3/2

. If the sample

size is s, then the likelihood function can be written as:

L(

1

,

2

) =

s

j=1

e

1

t

3/2

j

+

2

u

3/2

j

_

_

1

t

3/2

j

+

2

u

3/2

j

_

k

j

(k

j

)!

The maximum likelihood estimators of

1

and

2

,

1

and

2

, can be obtained

by solving the following equations:

k

s

j=1

t

3/2

j

_

1

t

3/2

j

+

2

u

3/2

j

_

k

j

1

=

s

j=1

t

3/2

j

k

s

j=1

u

3/2

j

_

1

t

3/2

j

+

2

u

3/2

j

_

k

j

1

=

s

j=1

u

3/2

j

This system of equations does not have a close form solution. Bellow is the

recursive procedure recommended by Jorgeson [10].

Let V be a diagonal matrix with elements

v

j

=

1

t

3/2

j

+

2

u

3/2

j

,

X be a matrix of dimension s 2 with elements

[t

3/2

i

u

3/2

i

], i = 1, . . . , s,

and K be an s 1 vector with elements k

i

, i = 1, . . . , s.

Jorgeson [10] shows that the minimum variance linear unbiased estimator for

= (

1

,

2

) is

=

_

1

,

2

_

= (X

T

V

1

X)

1

X

T

V

1

K

Since V is unknown, the problem is to obtain an estimate of V which in turn

gives an estimate of . Let

V

m

denotes the estimate of V obtained on the m

th

iteration and let the corresponding estimate of be

b

m

= (X

T

V

1

m

X)

1

X

T

V

1

m

K

Let

V

0

be the s s identity matrix and dene

V

m+1

= diag[x

1

b

m

, x

2

b

m

, , x

s

b

m

]

6

We repeat the iterations until a convergence is achieved. At that time

b = (X

T

V

1

X)

1

X

T

V

1

K,

where

V is the matrix such that

V

m+1

=

V

m

within a certain tolerance level .

2.2 Policy analysis

The objective function of the policy dened in 2 will consist of the sum of

the replacement and maintenance cost. We would like to obtain the optimal

control limits, V

t

and V

u

, such that its minimum is obtained. Assume that

r is a random variable with probability distribution function G(.). Then the

objective function will equal to

Z (V

t

, V

u

) = min

{VtR

+

,VuR

+

}

E

r

[R

c

+R

m

] (1)

where E

r

[] is the expectation with respect to the random variable r, R

c

=

E [Replacement Cost], and R

m

= E [Minimal Repair Cost].

To reduce the dimensionality of the problem we consider the following cases:

r > max(h, s), min(h, s) < r < max(h, s), r < min(h, s). The probability of

being in each of the above cases can be easily found:

P [r > max(h, s)] = 1 G[max(h, s)] (2)

P [min(h, s) < r < max(h, s)] = G[max(h, s)] G[min(h, s)]

P [r < min(h, s)] = G[min(h, s)]

Conditional on the value of r, the objective function can be rewritten as:

Z (V

t

, V

u

) = min

{VtR

+

,VuR

+

}

{E

r

[R

c

+R

m

|r > max(h, s)] {1 G[max(h, s)]}

+E

r

[R

c

+R

m

|min(h, s) < r < max(h, s)] {G[max(h, s)] G[min(h, s)]}

+E

r

[R

c

+R

m

|r < min(h, s)] G[min(h, s)]}

For each of these cases the policy will reduce to an onedimensional problem.

Let r

i

be the ratio for customer i.

r

i

h and r

i

s: The item reaches V

u

before it reaches V

t

and reaches

W

u

before W

t

. The policy simplies to: If the item fails during [0, V

u

), then

the item is replaced. If the item fails during [V

u

, W

u

), then it is minimally

repaired.

Insert Figure 2(a) here

7

r

i

h and r

i

< s: The item reaches V

u

before it reaches V

t

and reaches W

t

before W

u

.In this case the onedimensional policy is : If the item fails during

(0, V

u

/r

i

), then the item is replaced. If the item fails during (V

u

/r

i

, W

t

), then

it is minimally repaired.

Insert Figure 2(b) here

r

i

< h and r

i

s: The item reaches V

t

before it reaches V

u

and reaches W

u

before W

t

. The policy simplies to: If the item fails during (0, r

i

V

t

), then

the item is replaced. If the item fails during (r

i

V

t

, W

u

), then it is minimally

repaired.

Insert Figure 2(c) here

r

i

< h and r

i

< s: The item reaches V

t

before it reaches V

u

and reaches

W

t

before W

u

.The policy simplies to: If the item fails during (0, V

t

), then

the item is replaced. If the item fails during (V

t

, W

t

), then it is minimally

repaired.

Insert Figure 2(d) here

To obtain the formulae for R

c

and R

m

let us dene N

1

(t, u) to be the process

for the number of replacements in the box (0, t) (0, u) and N

2

(t, u) to be the

process for the number of minimal repairs. The objective function becomes:

min

{VtR

+

,VuR

+

}

E

r

{C

m

E [N

1

(t, u)|(t, u) A] (3)

+C

r

E

_

N

2

(t, u)|(t, u) B, S

N

1

(t,u)

B

_

P

_

S

N

1

(t,u)

B

_

+C

r

E

_

N

2

(t, u)|(t, u) B, S

N

1

(t,u)

A

_

P

_

S

N

1

(t,u)

A

__

where S

N

1

(t,u)

is the time of the last replacement prior to (t, u).

The times of replacement will follow a renewal process since we are replacing

the failed item with a brand new one, i.e. each time we reset the lifetime

clock of the process to 0. The expected number of replacements will equal

to the expected number of renewals. Let m(t, u) be the expected number of

replacements(renewals) from time 0 to t and usage from 0 to u.

If F denotes the distribution function of the time between replacements and

F

n

its n-fold convolution, then m(t) =

n=0

F

n

(t), see Ross ([22], page 56).

Very few distributions have closed form of the renewal function m(t). There are

some authors who use Phase-type distributions to approximate it(see Neuts

[18] and Dekker [6]).

The item is minimally repaired if it fails during the remaining warranty region

B. Then, keep using the repaired item if no other failures occurred till the end

of the warranty region. The expected number of minimal repairs from 0 to

t equals to

_

t

0

h(x)dx, where h(x) is the failure rate function (see Florez and

Feldman [7], page 216.)

8

To obtain a formula for the associated minimal repair cost we need to condition

of the time of the last renewal/replacement, S

N

1

(t,u)

:

R

m

=C

r

_

E

_

N

2

(t, u)|V

t

< t < W

t

, V

u

< u < W

u

, S

N

1

(t,u)

B

_

(4)

P

_

S

N

1

(t,u)

B

_

+E

_

N

2

(t, u)|V

t

< t < W

t

, V

u

< u < W

u

, S

N

1

(t,u)

A

_

P

_

S

N

1

(t,u)

A

__

where the rst term can be simplied as follows:

E

_

N

2

(t, u)|V

t

< t < W

t

, V

u

< u < W

u

, S

N

1

(t,u)

B

_

= (5)

E [N

2

(t, u)|V

t

< t < W

t

, V

u

< u < W

u

, N

1

(V

t

, V

u

) = 0] =

_

A

(t, u)d(t, u)

and

P

_

S

N

1

(t,u)

B

_

= P [N

1

(V

t

, V

u

) = 0] = 1 F(V

t

, V

u

) (6)

The second term in the expected minimal repair cost involves the time of the

last replacement, S

N

1

(t,u)

being inside the rectangle A. Dene (t

0

, u

0

) to be the

coordinates of S

N

1

(t,u)

. Then,

E

_

N

2

(t, u)|V

t

< t < W

t

, V

u

< u < W

u

, S

N

1

(t,u)

A

_

= (7)

_

C

(t, u)d(t, u)

The set C is dened as {(0, W

t

) (0, W

u

)} \ {(0, t

0

) (0, u

0

)}. Following the

key renewal theorem we get the distribution of S

N

1

(t,u)

:

P

_

S

N

1

(t,u)

A

_

= [1 F(V

t

, V

u

)] +

_

A

[1 F(t x, u y)] dm(x, y) (8)

To obtain the complete formula for the expected minimal repair cost we need to

substitute (5), (6), (7), and (8) into (4). The above analysis provides complete

formula for the objective function. Obviously the minimum solution cannot

be obtained with conventional means. For that reason we will nd the optimal

control limits using simulationoptimization algorithm.

We should add that due to the four cases described above and the linear

relationship between time and usage we have to solve only one dimensional

9

problem. For instance, if the original failure rate function equals to (t, u) =

t +u, then for the rst case it reduces to (t, u) = (u/r

i

, u) = (/r

i

) u +

u =

1

(u). If r

i

h, then the item would reach V

u

before it reached V

t

and the

expected number of replacements will equal to: m(V

t

, V

u

) = m[(1/r

i

)V

u

, V

u

] =

m(V

u

). If r

i

< h, then the item would reach V

t

before it reaches V

u

and

the expected number of replacements will equal to m(V

t

, V

u

) = m[V

t

, r

i

V

t

] =

m(V

u

).

3 Simulation-optimization procedure for obtaining the optimal con-

trol limits

In this section we propose a simulation solution to the optimization prob-

lem dened in (3) given the initial twodimensional warranty region [0, W

t

]

[0, W

u

].

First we x the values of the decision variables (V

t

, V

u

) to (V

t1

, V

u1

). Then, we

simulate values of r

i

by sampling from its distribution. (Note that r

i

equals

to the ratio of the usage and time.) Given a value of r

i

we fall into one of

the four cases described above. Given a case we simulate N failure times and

obtain the average cost. Next we take a dierent set of values for (V

t

, V

u

) and

follow the same procedure to get the average warranty cost. The (V

t

, V

u

) which

gives the minimum average cost is the optimal control limit. We use a grid

algorithm with step sizes

t

and

u

to obtain the optimal solution.

The computational examples attempt to show the sensitivity of the objective

function with respect to one of the cost parameters, C

m

, and the failure rate

function, (t, u). The last set of computations show the robustness of the

optimal control limits when the random number seeds change.

3.1 Maintenance cost sensitivity analysis

Assume that the warranty region is dened by W

t

= 3 and W

u

= 4 and

the failure rate function is (t, u)=1.5t

3

2

+ 0.75u

3

2

. In the next examples, we

increase the replacement cost C

m

and keep everything else unchanged.

Example 3.1 C

m

= 2.5, C

r

=1, and r (3, 2), where (3, 2) is the Gamma

distribution with parameters 3 and 2.

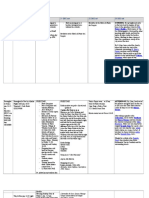

From Table 1, the optimal control limits are in the neighborhood of (V

t

=

2.5, V

u

= 3.5). The zoom in results are listed in Tables 2 and 3. The sim-

ulation results show that when V

t

= 2.4 and V

u

= 3.3, the average cost is

10

minimized at 6.7. The average number of replacements is 2.3. As seen in Ta-

ble 3, the values of the neighboring points of (V

t

= 2.4, V

u

= 3.3) are consistent

with the optimal value.

Example 3.2 C

m

= 3, C

r

=1, and r (3, 2).

Similar to Example 3.1 we obtain that the optimal control limits equal to (see

Table 4)

(V

t

, V

u

) = (2.2, 3.1)

The zoom in results are given in Table 5 and the neighboring points analysis

in Table 6.

Example 3.3 C

m

= 3.5, C

r

=1, and r (3, 2).

From Table 7 the control limits are (V

t

, V

u

) = (2.1, 2.9), the zoom in results

are in Table 8 and Table 9.

A summary of the above three examples is given in Table 11. We can make the

following observation: Let V

t

and V

u

be the original optimal control limits.

If the new optimal control limits are V

new

t

and V

new

u

, respectively when C

m

decreases, then they lie outside of the region dened by (0, V

t

) (0, V

u

).

3.2 Comparison of dierent failure rates

Assume that the warranty is dened by W

t

= 3 and W

u

= 4. The replacement

costs are C

m

= 4,C

r

=1 and r (3, 2). The optimal control limits for the

following three dierent failure rates are compared.

1

(t, u) =t

3

2

+ 0.5u

3

2

2

(t, u) =1.5t

3

2

+ 0.75u

3

2

3

(t, u) =2t

3

2

+u

3

2

The failure rates are such that

2

(t, u) = 1.5

1

(t, u) and

3

(t, u) = 2

1

(t, u).

The optimal control limits for the above failure rates are summarized in Table

10. It appears that the parallel shifts of the failure rate function result into

bigger total warranty cost and number of replacements.

3.3 Stability of the control limits

Next we investigate the stability of the control limits for dierent random

seeds. Dierent random number seeds may lead to dierent control limits. If

11

the dierence between control limits is relatively small, we will condence in

the optimal control limits obtained by the simulation. To test their stability

dierent random number seeds are used for the following example:

Example 3.4 C

m

= 3, C

r

= 1, r (3, 2), and (t, u) = 1.5t

3

2

+ 0.75u

3

2

From the simulation results in Table 6, the optimal control limits in that run

are V

t

= 2.2 and V

u

= 3.1 with average cost 7.8. Fifteen more simulation runs

are performed to obtain the new control limits. They are listed in Table 12.

Table 12 shows that the points are close to each other. Figure 3 gives the

scatter plot of the optimal control limits for dierent random number seeds.

4 Conclusion

In this paper we present a maintenance/replacement policy under two dimen-

sional warranty. If the item fails during the region dened by [0, V

t

) [0, V

u

),

the item is replaced. If the item fails during the rest of the warranty region,

the item is minimally repaired.

This policy is very easy to implement. Once the optimal control limits are

obtained, the manufacturers only need to check the actual item usage and time

after purchase and compare that with (V

t

, V

u

) to determine which actions to

take. For those manufacturers that have many branches around the world (like

car dealers), it is particularly attractive. Getting the customers cooperation

is also very important for maintenance/replacement policies under warranty.

This policy can get the customers support very easily. The policy requires

repairs or replacements only if when item fails. Customers regular operations

would not be interrupted.

We study several cases with dierent cost structures and failure rates. Other

than just comparing the simulation results, we empirically show that if the

maintenance cost C

m

increase (minimal repair cost C

r

unchanged), the new

optimal control limits must lie outside of the region dened by the origin

and the original optimal control limits. Similarly, if the maintenance cost C

m

decreases with minimal repair cost C

r

unchanged, the new optimal control

limits must lie outside of the region dened by original optimal control limits

and the warranty limit. We also investigate the stability of the control limits.

Overall, this policy is easy to implement. The control limits are easy to nd. It

provides a good way to serve maintenance interventions under two-dimensional

warranty.

12

References

[1] W. R. Blischke and D. N. P. Murthy. Product warranty management - i: A

taxonomy for warranty policies. European Journal of Operational Research,

62:127148, 1992.

[2] Y. H. Chun and K. Tang. Determining the optimal warranty price based on the

producers and customers risk preferences. European Journal of Operational

Research, 85:97110, 1995.

[3] K-J. Chung. Optimal repair-cost limit for a customer following expiry of a

warranty. Microelectronics and Reliability, 34, 1994.

[4] J. S. Dagpunar and N. Jack. Optimal repair-cost limit for a consumer following

expiry of a warranty. IMA Journal of Mathematics Applied in Business and

Industry, 4:155161, 1992.

[5] J. S. Dagpunar and N. Jack. Preventive maintenance strategy for equipment

under warranty. Microelectronics and Reliability, 34(6):10891093, 1994.

[6] R. Dekker A simple approximation to the renewal function. IEEE Transactions

on Reliability, pages 7175, 1990.

[7] C. Valdez Florez and R. Feldman. A survey of preventive maintenance models

for stochastically deteriorating single - unit systems. Naval Research Logistics,

36:419 446, 1989.

[8] Gart. Regression analysis of Poisson-distributed data. Journal of the American

Statistical Association, 68:935940, 1973.

[9] N. Jack and J. S. Dagpunar. An optimal imperfect maintenance policy over a

warranty period. Microelectronics Reliability, 3(34):529534, 1994.

[10] D. W. Jorgenson. Multiple regression analysis of a Poisson process. Journal of

the American Statistical Association, 56:235245, 1961.

[11] E. P. McGuire. Industrial product warranties: Policies and practices. In The

Conference Board, New York. 1980.

[12] M. A. J. Menezes and I. S. Currim. An approach for determination of warranty

length. International Journal of Research in Marketing, 9:177195, 1992.

[13] H. Moskowitz and Young Hak Chun. A Poisson regression model for two-

attribute warranty policies. Naval Research Logistics, 41:355376, 1994.

[14] D. N. P. Murthy and W. R. Blischke. Product warranty management - ii: An

integrated frame work for study. European Journal of Operational Research,

62:261281, 1992.

[15] D. N. P. Murthy and W. R. Blischke. Product warranty management - iii:

A review of mathematical models. European Journal of Operational Research,

62:134, 1992.

13

[16] D. N. P. Murthy, B. P. Iskandar, and R. J. Wilson. Two dimensional failure

free warranties: Two-dimensional point process models. Operations Research,

43:356366, 1990.

[17] D. N. P. Murthy and D. G. Nguyen. An optimal repair cost limit policy for

servicing warranty. Mathematical Comput. Modeling, 11:595599, 1988.

[18] M. Neuts. Matrix-Geometric Solutions in Stochastic Models: An Algorithm

Approach. Johns Hopkins University Press, Baltimore, 1981.

[19] D. G. Nguyen and D. N. P. Murthy. An optimal policy for servicing warranty.

Journal of the Operational Research Society, 37:10811098, 1986.

[20] D. G. Nguyen and D. N. P. Murthy. Optimal replace-repair strategy for servicing

products sold with warranty. European Journal of Operational Research,

39:206212, 1989.

[21] I. Sahin and H. Polatoglu. Maintenance strategies following the expiration of

warranty. IEEE Transactions on Reliability, 45(2):220228, 1996.

[22] S. Ross. Stochastic Processes. John Wiley and Sons, New York, 1983.

[23] D. C. Weber. Accident rate potential: An application of multiple regression

analysis of a Poisson process. Journal of American Statistical Association,

66:285288, 1971.

[24] Y. H. Chun and K. Tang. Cost analysis of two-attribute warranty policies based

on the product usage rate. IEEE Transactions of Engineering Management,

46:201209, 1999.

[25] Y. S. Oh and D. S. Bai. Field data analysis with additional after-warranty

failure data. Reliability Engineering & System Safety, 72:18, 2001.

[26] H. G. Kim and B. M. Rao. Expected warranty cost of two-attribute

free-replacement warranties based on a bivariate exponential distribution.

Computers & Industrial Engineering, 38:425434, 2000.

[27] S. -C. Yang and J. Nachlas. Bivariate reliability and availability modeling.

IEEE Transactions on Reliability, 50:2635, 2001.

[28] M. U. Thomas and S. S. Rao. Warranty economic decision models: A summary

and some suggested directions for future research. Operations Research, 47:807

820, 1999.

14

V

u

|V

t

0.0 0.5 1.0 1.5 2.0 2.5 3.0

0.0 14.931 14.958 14.973 15.038 14.914 15.030 14.964

0.5 14.870 14.735 14.540 14.412 14.370 14.461 14.470

1.0 14.855 14.160 12.899 12.399 12.286 12.309 12.399

1.5 14.946 13.924 11.303 10.156 9.920 9.918 9.814

2.0 15.004 13.807 10.532 8.694 8.204 8.066 8.190

2.5 14.969 13.829 10.338 8.165 7.320 7.216 7.362

3.0 14.907 13.772 10.384 7.969 6.979 6.879 7.006

3.5 14.934 13.758 10.356 7.998 6.975 6.810 6.983

4.0 14.878 13.848 10.301 8.017 7.133 7.004 7.301

Table 1

The costs for servicing the warranty for C

m

= 2.5, C

r

=1, and r (3, 2)

V

u

|V

t

2.2 2.3 2.4 2.5 2.6 2.7

3.1 6.853 6.852 6.821 6.837 6.841 6.858

3.2 6.851 6.780 6.776 6.799 6.794 6.826

3.3 6.849 6.780 6.776 6.817 6.817 6.824

3.4 6.820 6.829 6.774 6.776 6.799 6.826

3.5 6.820 6.830 6.807 6.800 6.816 6.829

3.6 6.851 6.827 6.784 6.805 6.816 6.889

3.7 6.925 6.836 6.853 6.837 6.905 6.921

Table 2

Zoom in results for C

m

= 2.5, C

r

=1, and r (3, 2)

V

u

|V

t

2.4000 2.4125 2.4250 2.4375 2.4500 2.4625

3.2250 6.844 6.799 6.752 6.810 6.786 6.781

3.2375 6.765 6.798 6.818 6.778 6.779 6.781

3.2500 6.794 6.798 6.768 6.792 6.783 6.835

3.2625 6.834 6.788 6.713 6.758 6.778 6.768

3.2750 6.775 6.789 6.762 6.803 6.791 6.772

3.2875 6.761 6.816 6.811 6.767 6.807 6.800

3.3000 6.760 6.792 6.795 6.741 6.773 6.770

Table 3

Neighboring points for the optimal control limit for C

m

= 2.5, C

r

=1, and r (3, 2)

15

V

u

|V

t

0.0 0.5 1.0 1.5 2.0 2.5 3.0

0.0 14.931 14.958 14.973 15.038 14.914 15.030 14.964

0.5 14.870 14.788 14.629 14.513 14.472 14.570 14.577

1.0 14.855 14.281 13.147 12.707 12.625 12.661 12.749

1.5 14.946 14.070 11.674 10.647 10.477 10.509 10.431

2.0 15.004 13.958 10.982 9.319 8.935 8.862 9.028

2.5 14.969 13.985 10.817 8.879 8.185 8.175 8.389

3.0 14.907 13.932 10.874 8.744 7.943 7.976 8.202

3.5 14.934 13.913 10.861 8.820 8.018 8.023 8.308

4.0 14.878 14.004 10.810 8.866 8.241 8.309 8.762

Table 4

The Costs for servicing the warranty for C

m

= 3, C

r

=1 and dierent values of V

t

and V

u

V

u

|V

t

2.0 2.1 2.2 2.3 2.4 2.5

2.7 8.098 8.004 7.997 8.044 8.011 8.047

2.8 8.072 8.002 7.966 7.935 8.003 8.033

2.9 8.004 7.979 7.891 7.899 7.892 7.993

3.0 7.952 7.931 7.933 7.921 7.931 7.942

3.1 7.989 7.910 7.943 7.880 7.918 7.965

3.2 7.959 7.892 7.866 7.929 7.933 7.967

3.3 7.979 7.977 7.916 7.938 7.902 7.988

3.4 8.011 7.939 7.915 7.957 7.935 7.961

Table 5

Zoom in table for C

m

= 3 and C

r

=1

16

V

u

|V

t

2.1750 2.1875 2.2000 2.2125 2.2250 2.2375

3.0750 7.908 7.912 7.894 7.859 7.950 7.871

3.0875 7.883 7.906 7.925 7.916 7.875 7.881

3.1000 7.880 7.915 7.943 7.882 7.887 7.917

3.1125 7.865 7.905 7.839 7.889 7.901 7.894

3.1250 7.918 7.891 7.860 7.922 7.875 7.892

3.1375 7.918 7.912 7.914 7.892 7.893 7.890

3.1500 7.886 7.896 7.877 7.929 7.879 7.893

Table 6

Costs for the neighboring points around the optimal value for C

m

= 3 and C

r

=1

V

u

|V

t

0.0 0.5 1.0 1.5 2.0 2.5 3.0

0.0 14.931 14.958 14.973 15.038 14.914 15.303 14.964

0.5 14.870 14.842 14.717 14.614 14.573 14.679 14.684

1.0 14.855 14.402 13.394 13.015 12.963 13.012 13.099

1.5 14.946 14.216 12.045 11.139 11.034 11.101 11.049

2.0 15.004 14.110 11.432 9.944 9.667 9.658 9.865

2.5 14.969 14.140 11.296 9.588 9.049 9.134 9.415

3.0 13.932 14.091 11.365 9.520 8.907 9.074 9.397

3.5 14.934 14.072 11.367 9.642 9.061 9.236 9.633

4.0 14.878 14.160 11.318 9.714 9.349 9.614 10.222

Table 7

The maintenance costs for C

m

= 3.5, C

r

=1 and dierent values of V

t

and V

u

V

u

|V

t

1.8 1.9 2.0 2.1 2.2 2.3

2.7 9.060 9.034 8.964 9.004 8.948 9.040

2.8 9.044 9.012 8.945 8.908 8.956 8.953

2.9 9.064 9.009 8.904 8.948 8.926 8.934

3.0 9.058 8.941 8.981 9.002 8.909 8.937

3.1 9.107 8.999 9.006 8.977 8.966 8.975

3.2 9.107 8.999 9.006 8.977 8.966 8.975

3.3 9.078 9.071 9.000 8.973 8.973 9.007

Table 8

Zoom in table for C

m

= 3.5 and C

r

=1

17

V

u

|V

t

2.0500 2.0625 2.0750 2.0875 2.1000 2.1125

2.8250 8.906 8.951 8.951 8.940 8.922 8.962

2.8375 8.964 8.941 8.925 8.910 8.934 8.980

2.8500 8.936 8.955 8.954 8.942 8.908 8.908

2.8625 8.968 8.892 8.872 8.940 8.899 8.965

2.8750 8.929 8.964 8.912 8.900 8.966 8.939

2.8875 8.960 8.951 8.923 8.942 8.904 8.926

2.9000 9.007 8.903 8.966 8.959 8.948 8.915

Table 9

Maintenance costs for the neighboring points around the optimal control limits for

C

m

= 3.5 and C

r

=1

= t

3

2

+ 0.5u

3

2

= 1.5t

3

2

+ u

3

2

= 2t

3

2

+ u

3

2

Control Limit V

t

1.8875 1.9875 2.1500

Control Limit V

u

2.4875 2.8750 2.9250

Average Cost 7.823 9.811 11.418

Avg. of Replacements 1.342 1.860 2.272

Table 10

Summary of the control limits for dierent failure rates

C

m

= 2.5 C

m

= 3.0 C

m

= 3.5

Control Limit V

t

2.4 2.2 2.1

Control Limit V

u

3.3 3.1 2.9

Average Cost 6.7 7.8 8.9

Average of Replacements 2.2 2.1 2.0

Table 11

Summary of the simulation output for dierent cost structures

18

V

t

V

u

Cost of replacements of repairs

1 2.2378 3.0875 7.8306 2.0937 0.7647

2 2.1500 3.0500 7.8330 2.0207 0.9409

3 2.2750 3.1500 7.8346 2.1303 0.7478

4 2.2625 3.1000 7.8354 2.0994 0.7532

5 2.2750 3.0750 7.8326 2.1107 0.7505

6 2.2125 3.1750 7.8282 2.1011 0.8244

7 2.1125 3.0625 7.8370 1.9915 1.0364

8 2.2750 3.1625 7.8472 2.1435 0.7466

9 2.2750 3.0750 7.8326 2.1107 0.7163

10 2.2500 3.0875 7.8310 2.0922 0.7730

11 2.2500 3.1750 7.8280 2.1327 0.7521

12 2.2375 3.1500 7.8296 2.1174 0.7763

13 2.2500 3.1750 7.8220 2.1327 0.7521

14 2.2750 3.1375 7.8301 2.1228 0.7509

15 2.2500 3.1125 7.8399 2.1028 0.7796

Table 12

Control limits for dierent seeds

19

Usage Salespersons car

Wu

Repair

Vu

Replacement Grandmothers car

Vt Wt

Figure 1 : Maintenance policy and the effect of different users

Usage U=r

i

T

Wu

(Wu/r

i

, Wu)

(Vu/r

i

, Vu)

Vu

Vt Wt Time

Figure 2(a) r

i

? h and r

i

? s

Usage

Wu

U=r

i

T

(Wt, r

i

Wt)

(Vu/r

i

, Vu)

Vu

Vt Wt Time

Figure 2(b) r

i

? h and r

i

< s

Usage U=r

i

T

Wu

(Wu/r

i

,Wu)

Vu

(Vt, r

i

Vt)

Vt Wt Time

Figure 2(c) r

i

< h and r

i

? s

Usage

Wu

Vu

U=r

i

T

(Wt, r

i

Wt)

(Vt, r

i

Vt)

Vt Wt Time

Figure 2(d) r

i

<s and r

i

<h

0

0.5

1

1.5

2

2.5

3

3.5

4

0 0.5 1 1.5 2 2.5 3

Vt

Figure 3. Scatter plot of the control limits

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Which Delivery Method Is Best Suitable For Your Construction Project?Документ13 страницWhich Delivery Method Is Best Suitable For Your Construction Project?H-Tex EnterprisesОценок пока нет

- Memo in Motion For ContemptДокумент118 страницMemo in Motion For ContemptMark SternОценок пока нет

- (DO-CYT-T1-16) - KASSAHUN ComparisionДокумент126 страниц(DO-CYT-T1-16) - KASSAHUN ComparisionMohammed AdaneОценок пока нет

- Zaranda Finlay 684 Manual Parts CatalogДокумент405 страницZaranda Finlay 684 Manual Parts CatalogRicky Vil100% (2)

- Maximum Yield USA 2013 December PDFДокумент190 страницMaximum Yield USA 2013 December PDFmushroomman88Оценок пока нет

- Engineered Cementitious Composites: Practical ApplicationsДокумент26 страницEngineered Cementitious Composites: Practical Applicationsmubashir ahmedОценок пока нет

- Fayol's Principles in McDonald's ManagementДокумент21 страницаFayol's Principles in McDonald's Managementpoo lolОценок пока нет

- Capital Asset Pricing ModelДокумент11 страницCapital Asset Pricing ModelrichaОценок пока нет

- SolidEdge MachineryLibrary V15.00Документ139 страницSolidEdge MachineryLibrary V15.00ttОценок пока нет

- Appendix 9A: Standard Specifications For Electrical DesignДокумент5 страницAppendix 9A: Standard Specifications For Electrical Designzaheer ahamedОценок пока нет

- Ts 391 IltДокумент5 страницTs 391 IltFunnypoumОценок пока нет

- Computer Application in Business NOTES PDFДокумент78 страницComputer Application in Business NOTES PDFGhulam Sarwar SoomroОценок пока нет

- Csit 101 Assignment1Документ3 страницыCsit 101 Assignment1api-266677293Оценок пока нет

- Microprocessor Based Systems: by Nasir Mahmood Nasir - Mahmood@seecs - Edu.pkДокумент15 страницMicroprocessor Based Systems: by Nasir Mahmood Nasir - Mahmood@seecs - Edu.pkMuhammad ZubairОценок пока нет

- BR18 Mechanical Engineering Robotics Semester VIДокумент2 страницыBR18 Mechanical Engineering Robotics Semester VIPRAVEeОценок пока нет

- Machine Problem 6 Securing Cloud Services in The IoTДокумент4 страницыMachine Problem 6 Securing Cloud Services in The IoTJohn Karlo KinkitoОценок пока нет

- Lab Equipment Catalog Research Concept LabДокумент40 страницLab Equipment Catalog Research Concept LabSeetanshu AwasthiОценок пока нет

- Railway Reservation System Er DiagramДокумент4 страницыRailway Reservation System Er DiagramPenki Sarath67% (3)

- Flex VPNДокумент3 страницыFlex VPNAnonymous nFOywQZОценок пока нет

- WebquestДокумент3 страницыWebquestapi-501133650Оценок пока нет

- Webpage citation guideДокумент4 страницыWebpage citation guiderogelyn samilinОценок пока нет

- Britannia FinalДокумент39 страницBritannia FinalNitinAgnihotri100% (1)

- تقرير سبيس فريم PDFДокумент11 страницتقرير سبيس فريم PDFAli AkeelОценок пока нет

- Whitmore EZ-Switch LubricantДокумент1 страницаWhitmore EZ-Switch LubricantDon HowardОценок пока нет

- Salesforce Platform Developer 1Документ15 страницSalesforce Platform Developer 1Kosmic PowerОценок пока нет

- Example Italy ItenararyДокумент35 страницExample Italy ItenararyHafshary D. ThanialОценок пока нет

- NPTEL Web Course On Complex Analysis: A. SwaminathanДокумент19 страницNPTEL Web Course On Complex Analysis: A. SwaminathanMohit SharmaОценок пока нет

- Manual Mue Home RGBДокумент8 страницManual Mue Home RGBJason OrtizОценок пока нет

- Corvette Stingray - Papercraft Sports Car: Food Living Outside Play Technology WorkshopДокумент22 страницыCorvette Stingray - Papercraft Sports Car: Food Living Outside Play Technology WorkshopStylus ClearingОценок пока нет

- FINAL Session 3 Specific GuidelinesДокумент54 страницыFINAL Session 3 Specific GuidelinesBovelyn Autida-masingОценок пока нет