Академический Документы

Профессиональный Документы

Культура Документы

Pref

Загружено:

dongarth0 оценок0% нашли этот документ полезным (0 голосов)

49 просмотров2 страницыA single defect can easily cost PS100 in diagnosis and repair if it is detected early. Techniques for optimizing maintenance intervals and spares holdings have become popular. 'RAMS' clauses in contracts, and in invitations to tender, are now commonplace.

Исходное описание:

Оригинальное название

69022_pref

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документA single defect can easily cost PS100 in diagnosis and repair if it is detected early. Techniques for optimizing maintenance intervals and spares holdings have become popular. 'RAMS' clauses in contracts, and in invitations to tender, are now commonplace.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

49 просмотров2 страницыPref

Загружено:

dongarthA single defect can easily cost PS100 in diagnosis and repair if it is detected early. Techniques for optimizing maintenance intervals and spares holdings have become popular. 'RAMS' clauses in contracts, and in invitations to tender, are now commonplace.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

xix

After three editions, in 1993, Reliability, Maintainability in Perspective became Reliability,

Maintainability and Risk. The 6th edition, in 2001, included my PhD studies into common

cause failure and into the correlation between predicted and achieved feld reliability. Once

again it is time to update the material as a result of developments in the functional safety area.

The techniques that are explained apply to both reliability and safety engineering and are also

applied to optimizing maintenance strategies. The collection of techniques concerned with

reliability, availability, maintainability and safety are often referred to as RAMS.

A single defect can easily cost 100 in diagnosis and repair if it is detected early in

production, whereas the same defect in the eld may well cost 1000 to rectify. If it transpires

that the failure is a design fault then the cost of redesign, documentation and retest may well

be in tens or even hundreds of thousands of pounds. This book emphasizes the importance of

using reliability techniques to discover and remove potential failures early in the design cycle.

Compared with such losses, the cost of these activities is easily justied.

It is the combination of reliability and maintainability that dictates the proportion of time that

any item is available for use or, for that matter, is operating in a safe state. The key parameters

are failure rate and down time, both of which determine the failure costs. As a result,

techniques for optimizing maintenance intervals and spares holdings have become popular

since they lead to major cost savings.

RAMS clauses in contracts, and in invitations to tender, are now commonplace. In defense,

telecommunications, oil and gas, and aerospace these requirements have been specied for

many years. More recently the transport, medical and consumer industries have followed suit.

Furthermore, recent legislation in the liability and safety areas provides further motivation for

this type of assessment. Much of the activity in this area is the result of European standards

and these are described where relevant.

Software tools have been in use for RAMS assessments for many years and only the

simplest of calculations are performed manually. This eighth edition mentions a number

of such packages. Not only are computers of use in carrying out reliability analysis but

are themselves the subject of concern. The application of programable devices in control

Preface

xx Preface

equipment, and in particular safety-related equipment, has widened dramatically since the

mid-1980s. The reliability/quality of the software and the ways in which it could cause

failures and hazards is of considerable interest.

Chapters 17 and 22 cover this area.

Quantifying the predicted RAMS, although important in pinpointing areas for redesign, does

not of itself create more reliable, safer or more easily repaired equipment. Too often, the

author has to discourage efforts to rene the accuracy of a reliability prediction when an

order of magnitude assessment would have been adequate. In any engineering discipline the

ability to recognize the degree of accuracy required is of the essence. It happens that RAMS

parameters are of wide tolerance and thus judgements must be made on the basis of one- or,

at best, two-gure accuracy. Benet is only obtained from the judgement and subsequent

follow-up action, not from rening the calculation.

A feature of the last four editions has been the data ranges in Appendices 3 and 4. These

were current for the fourth edition but the full 'up-to-date` database is available in FARADIP.

THREE (see last four pages of the book).

DJS

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Nurse Call SystemДокумент5 страницNurse Call SystemJamal BanziОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- AIS Vs GIS (EN)Документ17 страницAIS Vs GIS (EN)Sándor BarabásОценок пока нет

- Literature Review On Online Recruitment SystemДокумент8 страницLiterature Review On Online Recruitment Systemfvgj0kvd100% (1)

- Porras - Module No. 1Документ6 страницPorras - Module No. 1Hanna PorrasОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Information Systems Architecture and Technology - Proceedings of 39th International Conference On Information Systems Architecture and TechnologyДокумент384 страницыInformation Systems Architecture and Technology - Proceedings of 39th International Conference On Information Systems Architecture and TechnologyDheeraj ChalasaniОценок пока нет

- Welcome To Potential Failure Modes AND Effect Analysis Process FMEA-4 EditionДокумент68 страницWelcome To Potential Failure Modes AND Effect Analysis Process FMEA-4 EditionSundaramoorthy ArumugamОценок пока нет

- Holidays List 2019Документ8 страницHolidays List 2019SR RaoОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Safeway WarehouseДокумент8 страницSafeway WarehouseRichard M PattonОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Objective 9 Characteristics of Information: 1 Availability/accessibilityДокумент4 страницыObjective 9 Characteristics of Information: 1 Availability/accessibilityAggrie OsbourneОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Reddy J.N. - Solution Manual For Introduction To Finite Element Analysis-MGH (2005)Документ13 страницReddy J.N. - Solution Manual For Introduction To Finite Element Analysis-MGH (2005)Debabrata PodderОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Collection and Use of Intelligence in Policing Public Order EventsДокумент32 страницыThe Collection and Use of Intelligence in Policing Public Order EventsSteph ClicheОценок пока нет

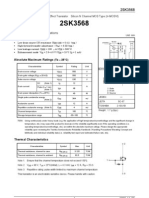

- 2 SK 3568Документ6 страниц2 SK 3568Angel De Dios RosoОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- E101-3248 - Diamond Power Boiler Cleaning ProductsДокумент12 страницE101-3248 - Diamond Power Boiler Cleaning ProductsKartika SuryawanОценок пока нет

- 2008-06 Handbook For Robustness Valdiation EE-Modules EnglishДокумент148 страниц2008-06 Handbook For Robustness Valdiation EE-Modules Englishparigomo2Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Chapter 06Документ39 страницChapter 06kОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Cs 67007Документ4 страницыCs 67007IqbalAsifОценок пока нет

- Lecture-5 SREДокумент39 страницLecture-5 SREEsta AmeОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Causal Factors of Malaysian Landslides: A Narrative StudyДокумент7 страницCausal Factors of Malaysian Landslides: A Narrative StudyMOGANESWARY A/P RENGANATHANОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Honeywell Solutions With MTLДокумент11 страницHoneywell Solutions With MTLJagadesh CS NadarОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Quality Gurus & Their ViewsДокумент53 страницыQuality Gurus & Their Viewsaakash sharmaОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 2021 BSOC - Presentation Rev.1Документ15 страниц2021 BSOC - Presentation Rev.1Dragos NeaguОценок пока нет

- Electricity Billing System: Software Requirement SpecificationДокумент34 страницыElectricity Billing System: Software Requirement SpecificationKushal ShОценок пока нет

- Operations Strategy and CompetitivenessДокумент68 страницOperations Strategy and CompetitivenessJane LobОценок пока нет

- WARMAN Guidelines 2016Документ7 страницWARMAN Guidelines 2016Glass-Half-EmptyОценок пока нет

- Specification: Rev. A English Jun / 2002Документ35 страницSpecification: Rev. A English Jun / 2002Java JavaОценок пока нет

- TS 16949 RequirementsДокумент5 страницTS 16949 RequirementsVasudev DevОценок пока нет

- APC White PapersДокумент27 страницAPC White Papersmonarch_007100% (1)

- If You NeedДокумент5 страницIf You NeedAlexОценок пока нет

- Ta 8252 HДокумент14 страницTa 8252 HNiraj Suroopjeet0% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)