Академический Документы

Профессиональный Документы

Культура Документы

Penelitian

Загружено:

Adrin Ma'rufИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Penelitian

Загружено:

Adrin Ma'rufАвторское право:

Доступные форматы

Open Veterinary Journal, (2012), Vol.

2: 40-45 ISSN: 2226-4485 (Print) ISSN: 2218-6050 (Online) Submitted: 15/03/2012 Accepted: 29/04/2012

Original Article Published: 12/05/2012

_____________________________________________________________________________________

Estimating fermentation characteristics and nutritive value of ensiled and dried pomegranate seeds for ruminants using in vitro gas production technique

M. Taher-Maddah, N. Maheri-Sis*, R. Salamatdoustnobar and A. Ahmadzadeh Department of Animal Science, Shabestar Branch, Islamic Azad University, Shabestar, Iran _____________________________________________________________________________________________ Abstract The purpose of this study was to determine the chemical composition and estimation of fermentation characteristics and nutritive value of ensiled and dried pomegranate seeds using in vitro gas production technique. Samples were collected, mixed, processed (ensiled and dried) and incubated in vitro with rumen liquor taken from three fistulated Iranian native (Taleshi) steers at 2, 4, 6, 8, 12, 16, 24, 36, 48, 72 and 96 h. The results showed that ensiling lead to significant increase in gas production of pomegranate seeds at all incubation times. The gas volume at 24 h incubation, were 25.76 and 17.91 ml/200mg DM for ensiled and dried pomegranate seeds, respectively. The gas production rate (c) also was significantly higher for ensiled groups than dried (0.0930 vs. 0.0643 ml/h). The organic matter digestibility (OMD), metabolizable energy (ME), net energy for lactation (NEL) and short chain fatty acids (SCFA) of ensiled pomegranate seeds were significantly higher than that of dried samples (43.15%, 6.37 MJ/kg DM, 4.43 MJ/kg DM, 0.5553 mmol for ensiled samples vs. 34.62%, 5.10 MJ/kg DM, 3.56 MJ/kg DM, 0.3680 mmol for dried samples, respectively). It can be concluded that ensiling increases the nutritive value of pomegranate seeds. Keywords: Drying, Ensiling, Gas production, Nutritive value, Pomegranate seeds. _____________________________________________________________________________________________ Introduction Using agro-industrial by-products is an alternative method for overcoming shortages and higher prices of conventional feed in ruminant nutrition. Many byproducts have a substantial nutritive value as animal feed. Thus cereals can be largely replaced by these byproducts and therefore competition between human and animal for nutrition is less. Furthermore, using these by-products in animal nutrition can solve related environmental problems (Mirzaei-Aghsaghali and Maheri-Sis et al., 2008). Pomegranate (Punica granatum L.) is an important fruit crop in tropical and subtropical regions of the world as well as in Mediterranean countries with moderate temperatures. The pomegranate is native to Iran with 7105 tons produced annually (Khoshnam et al., 2007; Mansouri et al., 2011). Iran is also a major exporter of pomegranates, with an increase from 14,075 metric tons (2003) to 27,439 metric tons (2007) (FAO/WHO, 2009). This fruit is either consumed fresh or used in the juice industry. Increasing agro-industrial units for producing pomegranate juice led to increased processing of by-products including peels and seeds (Shabtay et al., 2008). Pomegranate seeds constitute about 3% of the weight of the fresh fruit. The major chemical components of pomegranate seeds are: 1) Hydroxybenzoic acids: Ellagic acid, 3,3-Di-Omethylellagic acid, 3,3.4-Tri-O-methylellagic acid; 2) Conjugated fatty acids: Punicic acid (cis-9, trans11, cis-13 octadecatrienoic acid); 3) Non-Conjugated fatty acids: Linoleic acid, Oleic acid, Palmitic acid, Stearic acid; 4) Sterols: Stigmasterol, -Sitosterol, Daucosterol, Camesterol, Cholesterol, 17--Estradiol, Estrone, Testosterone, Estriol; 5) Tocopherols: tocopherol; 6) Triterpenes: Ursolic acid, Oleanolic acid; 7) Isoflavones: Genistein, Daidzein; 8) Phenyl aliphatic glycosides/Lignins: Coniferyl-9-O-[Dapiofuranosyl (16)-O--D-glucopyranoside, Sinapyl-9-O-[D-apiofuranosyl (16)-O--Dglucopyranoside, Phenylethyl rutinoside, Icariside D1 (Prakash and Prakash, 2011). Pomegranate seed oil comprises 1220% of total seed weight. The oil consists of about 80% conjugated octadecatrienoic fatty acids, with a high content of cis 9, trans 11, cis 13 acid (i.e. punicic acid), synthesized from nonconjugated octadecadienoic fatty acid. Linoleic acid which is the most important essential fatty acid, constitute about 7% of pomegranate seed oil. The presence of these components in pomegranate seed, make it a functional food and is believed to be beneficial to health by acting as an antioxidant as well as having anti-cancer and anti-inflammatory properties (Lansky and Newman, 2007). In spite of sufficient knowledge of the biological effects of pomegranate seeds in human and animal health, there is scant information on its nutritive value for ruminants (Feizi et al., 2005; Shabtay et al., 2008; Modarresi et al., 2010; Mirzaei-Aghsaghali et al.,

________________________________________________________________________________________________________ *Corresponding Author: Dr. Naser Maheri-Sis, Department of Animal Science, Shabestar Branch, Islamic Azad University, Shabestar, Iran. Tel.: +98 471 2225311-4. Email: nama1349@gmail.com 40

http://www.openveterinaryjournal.com M. Taher-Maddah et al. Open Veterinary Journal, (2012), Vol. 2: 40-45 ________________________________________________________________________________________________________

2011). Feizi et al., (2005) demonstrated that pomegranate seeds can be used in animal nutrition and that inclusion of pomegranate seeds up to 25% of the diet had no negative effect on the intake and digestibility of nutrients. Shabtay et al., (2008) reported that using pomegranate by-products in levels up to 20% of dietary DM in feedlot calves diet increased feed intake and consequently average daily weight gain. Modarresi et al., (2010) concluded that pomegranate seed pulp is an inexpensive source of feed and can be replaced with part of energy rich feed for goats, such as cereal grains. Mirzaei-Aghsaghali et al. (2011) suggested that pomegranate seed can be used as a relatively good agro-industrial by-product for ruminant nutrition. Pomegranate seed pulp can be used in fresh, dried and ensiled forms in animal nutrition. Due to its potential for rapid spoiling it is usually preserved. Drying and ensiling are two common preservation methods of wet feeds for further use. Each of these methods has distinct advantages and disadvantages. Due to the environmental conditions in which pomegranates are harvested, sun-drying is difficult, therefore ensiling is the preferred method. Among routine feed evaluation methods (in vivo, in situ and in vitro), in vitro gas production technique is a cost and time effective tool for illustration of fermentation kinetics and estimating nutritive value of feedstuffs, particularly for polyphenolic content in feed in developing countries (Makkar, 2005; MaheriSis et al., 2007). The objectives of this study were to determine chemical composition and estimating fermentation parameters [a: the gas production from soluble fraction (ml/200mg DM), b: the gas production from insoluble but fermentable fraction (ml/200mg DM), c: rate constant of gas production during incubation (ml/h)] and nutritive value [organic matter digestibility (OMD), metabolizable energy (ME), net energy for lactation (NEL) and short chain fatty acids (SCFA)] of dried and ensiled pomegranate seeds using in vitro gas production technique. Methods and Material Samples collection and treatments Fresh pomegranate seeds samples (after juice extracting; with no any other parts of pomegranate byproducts such as peels) were collected from traditional (local) pomegranate juice production units, in Tehran, Iran. After mixing, half of the samples were air-dried (7 days (d) at room temperature i.e. about 25 degrees Celcius) and ground (1mm and 5mm screen). The remaining samples were ensiled in P.V.C tubes for 45 d. Chemical analysis and in vitro gas production were conducted at the laboratory of Animal Science Research Institute in Karaj, Iran.

Chemical Analysis Dry matter (DM) was determined by drying the samples at 105oC overnight and reduced to ash by igniting (burning) the samples in a muffle furnace at 525oC for 8h. Nitrogen (N) content was measured by the Kjeldahl method (AOAC, 1990). Crude protein (CP) was calculated as N 6.25. Neutral detergent fiber (NDF) and acid detergent fiber (ADF) were determined by procedures outlined by Van Soest et al. (1991). Non-fibrous carbohydrate (NFC) is calculated using the equation of NRC (2001); NFC = 100 (NDF + CP + EE + Ash). In vitro gas production procedure Fermentation of dried and ensiled pomegranate seed samples were carried out with rumen fluid obtained from three fistulated Iranian native steers (Taleshi) fed twice daily a diet containing alfalfa hay (60%) and concentrate mixture (40%) following the method described by Menke and Steingass (1988). Both solid and liquid rumen fractions were collected before the morning feeding, placed in an insulated plastic container, sealed immediately and transported to the laboratory. Approximately 200 mg (DM) of each sample was weighed into 100 ml glass syringes. The fluid-buffer mixture (30 ml) was transferred into 100 ml glass syringes. The glass syringes containing samples and rumen fluid-buffer mixture were subsequently incubated at 39oC. The syringes were gently shaken 30 min after the start of incubation. The gas production was determined at 2, 4, 6, 8, 12, 24, 48, 72 and 96 h of incubation. All samples were incubated in triplicate with three syringes containing only rumen fluid-buffer mixture (blank). The net gas productions of samples were determined by subtracting the volume of gas produced in the blanks. Gas production data were fitted to the model of rskov and McDonald (1979): Y = a + b (1-e-ct) Where Y is the gas production at time t, a the gas production from soluble fraction (ml/200mg DM), b the gas production from insoluble but fermentable fraction (ml/200mg DM), c the gas production rate constant (ml/h), a + b the potential gas production (ml/200mg DM) and t is the incubation time (h). The ME, NEL and OMD of pomegranate seeds were calculated using equations of Menke and Steingass (1988) as: ME (MJ /kg DM) = 2.20 + 0.136 GP + 0.057 CP NEL (MJ/kg DM) = 0.115 GP + 0.0054 CP + 0.014 EE - 0.0054 CA - 0.36 OMD (g/kg DM) = 14.88 + 0.889 GP + 0.45 CP + 0.0651 CA Where, GP is 24 h net gas production volume (ml/200 mg DM), and CP, EE, CA are crude protein, ether extract and crude ash (g/kg DM), respectively.

41

http://www.openveterinaryjournal.com M. Taher-Maddah et al. Open Veterinary Journal, (2012), Vol. 2: 40-45 ________________________________________________________________________________________________________

Short chain fatty acids (SCFA) are calculated by equation of Getachew et al. (1999): SCFA (mmol) = -0.0601 + (0.0239 GP) Where, GP is 24 h net gas production volume (ml/200mg DM). Statistical analysis All of the data obtained from three replicates were analyzed using software of SAS (1991) and the means of two sample groups were separated by independentsamples t-test (McDonald, 2008). Results and Discussion The chemical analysis of ensiled and dried pomegranate seeds (Table 1) showed that NDF, ADF, EE and ash content of pomegranate seeds decreased and NFC and CP content were increased by ensiling. In other words, dried seeds have higher fiber components (cellulose, hemicelluloses and lignin) than ensiled forms.

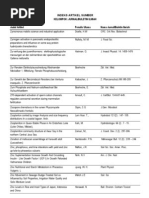

Table 1. Chemical composition of dried and ensiled pomegranate seeds (%) Items Dried Ensiled DM 96.61 42.76 CP 8.07 11.65 EE 12.00 11.00 Ash 2.80 2.05 NDF 77.00 62.00 ADF 55.00 45.00 NFC 0.13 13.30

DM: dry matter, CP: crude protein, EE: ether extract, NDF: neutral detergent ber, ADF: acid detergent ber, NFC: non fibrous carbohydrate.

geographic, climatic and soil characteristics), amount of foreign materials and impurities as well as different processing and measuring methods. It is clear that, different chemical composition can result in different nutritive value (Maheri-Sis et al., 2007; 2008). Gas production volumes (ml/200mg DM) from in vitro incubation of pomegranate seed samples at different incubation times are illustrated in Table 2 and Figure 1.

Table 2. Gas production volume (ml/200mg DM) of dried and ensiled pomegranate seeds at different incubation times Incubation Dried Ensiled P value S.E.M times (h) 2 6.20 7.67 0.0184 0.2702 4 9.45 13.46 0.0001 0.1108 6 11.79 16.90 0.0005 0.3462 8 13.18 17.84 0.0002 0.2458 12 15.12 20.90 0.0004 0.3660 24 17.91 25.76 0.0001 0.3660 48 21.87 28.65 0.0004 0.4400 72 23.34 29.97 0.0001 0.3099 96 23.49 30.12 0.0001 0.3116

Lansky and Newman (2007) stated that pomegranate seed matrix includes lignin, fusion products of cell wall components and hydroxycinnamic acids, and potently antioxidant lignin derivatives. Maheri-Sis (2010) indicated that about 50% of hemicelluloses of ensiled plants may be degraded during ensiling process. Degradation of hemicelluloses content can result in lower NDF and ADF content of ensiled materials. Chemical compositions of dried pomegranate seeds in the current study were inconsistent with findings of Feizi et al., (2005) and Mirzaei-Aghsaghali et al., (2011). According to Feizi et al., (2005) the amount of DM, OM, CP, crude fiber (CF), EE, nitrogen free extract (NFE) of pomegranate seeds were 94.8, 96.8, 11.4, 38.9, 1, and 45.5, respectively; whereas MirzaeiAghsaghali et al., (2011) reported that DM, CP, EE, NDF, ADF and NFC content of pomegranate seeds were 95.10, 15.40, 6.00, 68.00, 49.00 and 13.50%, respectively. These differences in chemical composition of byproducts may be due to a difference in starting materials, varieties, growing conditions (i.e.

Fig. 1 Gas production volume of dried and ensiled pomegranate seeds in different incubation times

Results indicate that ensiling leads to significant increase in gas production of pomegranate seeds at all incubation times. The gas volume at 24 h incubation, were 25.76 and 17.91 ml/200mg DM for ensiled and dried pomegranate seeds, respectively. Sommart et al. (2000) demonstrated that gas volume is a good parameter for predicting digestibility, fermentation end products and microbial protein synthesis of the substrate by rumen microbes in the in vitro system. Mirzaei-Aghsaghali et al., (2011) reported that gas volume after 24 h incubation of dried pomegranate seed was 22.90 ml/200mg DM. Amount of gas produced at 24 h incubation is the most important criteria for estimating ME, NEL, OMD and SCFA; because of its high positive correlation by the nutritive value of feedstuffs (Menke and Steingass, 1988).

42

http://www.openveterinaryjournal.com M. Taher-Maddah et al. Open Veterinary Journal, (2012), Vol. 2: 40-45 ________________________________________________________________________________________________________

However, different gas production in various studies can be due to different chemical constituents in the feed tested, animal types and breeds and quality of inoculum source (Menke and Steingass, 1988; Getachew et al., 2004; Maheri-Sis et al., 2008). Gas production parameters (a, b, c) and estimated values of OMD, ME, NEL and SCFA of dried and ensiled pomegranate seeds are shown in Table 3.

Table 3. In vitro gas production parameters and estimated metabolisable energy (ME), net energy for lactation (NEL), Organic matter digestibility (OMD) and short chain fatty acids (SCFA) of dried and ensiled pomegranate seeds Items Dried Ensiled P value S.E.M a (ml) 5.23 4.84 0.6554 0.5668 b (ml) 17.98 24.62 0.0023 0.6820 a+b (ml) 23.20 29.46 0.0426 0.3283 c (ml/h) 0.0643 0.0930 0.0002 0.0007 ME (MJ/ 5.10 6.37 0.0001 0.0496 Kg DM) NEL (MJ/ 3.56 4.43 0.0001 0.0368 Kg DM) OMD (%) 34.62 43.15 0.0001 0.3246 SCFA 0.3680 0.5553 0.0001 0.0008 (mmol)

a: the gas production from soluble fraction (ml/200mg DM) b: the gas production from insoluble but fermentable fraction (ml/200mg DM) c: rate constant of gas production during incubation (ml/h) a + b: the potential gas production (ml/200mg DM)

Although there are no significant differences between gas production of soluble fraction (a) in ensiled and dried pomegranate seeds, insoluble but fermentable fraction (b), potential gas production (a+b) and rate constant of gas production (c) of treatments were significantly higher for ensiled than that of dried samples. Our data is in agreement with Mirzaei-Aghsaghali et al., (2011); based on their reports, amount of gas production parameters i.e. a, b, a+b and c were 5.69, 49.12, 54.18 ml/200 mg DM and 0.0141 ml/h, respectively. Valizadeh et al. (2009) found that ensiling caused decrease in rumen degradation of pistachio byproducts (which is tannin rich by-product similar to pomegranate by-products). Blummel and Becker (1997) suggest that the soluble fraction (a) of feeds makes it easily attachable by rumen microbes and resulted in more gas production. Also the gas volume at asymptote (b) is an important index for predicting feed intake.Thus, it can be concluded that ruminants need to consume higher amount of ensiled than dried pomegranate seeds. Higher amount of gas production as well as rate of gas production in ensiled compared to dried samples may be affected by carbohydrate fractions (NFC), which

are readily available to microbial fermentation. Maheri-Sis et al. (2008) suggested that different chemical components of feeds (e.g. Starch, NFC, OM, CP, NDF and soluble sugars contents) can result in different levels of in vitro gas production. They have found that decreasing NDF and ADF and increasing NFC content of feedstuffs clearly results in higher in vitro gas production. Therefore, higher NFC and lower NDF and ADF content of ensiled pomegranate seeds may be major reason for the difference in gas production and consequent nutritive value. The organic matter digestibility (OMD), metabolizable energy (ME), net energy for lactation (NEL) and short chain fatty acids (SCFA) of ensiled pomegranate seeds were significantly higher in comparison with that of dried samples (43.15%, 6.37 MJ/kg DM, 4.43 MJ/kg DM, 0.5553 mmol for ensiled samples vs. 34.62%, 5.10 MJ/kg DM, 3.56 MJ/kg DM, 0.3680 mmol for dried samples, respectively). Results of the current research agree with findings of Mirzaei-Aghsaghali et al., (2011), who reported that estimated amounts of OMD, ME and SCFA of dried pomegranate seeds were 42.34%, 6.20 MJ/kg DM and 0.504 mmol, respectively. Feizi et al. (2005) determined that digestibility of DM, OM, CP, CF, EE, energy, NFE, total digestible nutrients (TDN) and digestible OM content in DM of pomegranate seed were 44.8, 44.7, 62.5, 21.5, 38.3, 45, 61.5, 45.9 and 48.4%, respectively. Blummel et al. (1999) stated that gas volumes were produced quantitatively and qualitatively as a result of SCFA production (the amount of fermentative CO2 and CH4 could be accurately calculated from the amount and proportion of acetate, propionate and butyrate present in the incubation medium). Therefore increasing amount of SCFA had led to an increase in gas production which resulted in increased digestion and energy value. In ruminants, acetate, propionate and butyrate (as predominant SCFAs), are readily absorbed and assimilated as a nutrient source. The SCFA account for between 50-70% of digestible energy intake (Mirzaei-Aghsaghali et al., 2011). Between half and two-third of the total metabolizable energy may originate from these volatile fatty acids (VFA) produced from fermentative degradation by microorganisms in the rumen. Type of VFA produced is highly dependent on the type of diet, on the type of substrate fermented, and on the fermentation conditions (Bannink, 2007). Conclusion The results of the current study based on chemical composition, OMD, ME, NEL and SCFA indicates that ensiling increases the nutritive value of pomegranate seeds and it is a better preservation

43

http://www.openveterinaryjournal.com M. Taher-Maddah et al. Open Veterinary Journal, (2012), Vol. 2: 40-45 ________________________________________________________________________________________________________

method than drying for this by-product. Moreover ensiled pomegranate seeds have a higher nutritive value than dried for ruminants under in vitro conditions. However there is a need for in vivo studies to support the in vitro findings. Acknowledgments This article is adopted from M.Sc. thesis in animal science, Islamic Azad University, Shabestar Branch (thesis supervisor: Dr. N. Maheri-Sis). We would like to acknowledge Mr. Ali Noshadi, Mr. Mohammad Salamatazar and Mr. Bakhshali Khodaparast for their valuable assistance. The authors are grateful to the laboratories of Animal Science Research Institute, Karaj, Iran as well as Islamic Azad University, Shabestar Branch. ___________________________________________ References AOAC. 1990. Official Method of Analysis. 15 th Edn. Washington DC. USA, Association of Official Analytical Chemists. pp. 66-88. Bannink, A. 2007. Modelling volatile fatty acid dynamics and rumen function in lactating cows. PhD Thesis, Wageningen University., the Netherlands. pp. 262. Blummel, M., Aiple, K.P., Steingass, H. and Becker, K. 1999. A note on the stoichiometrical relationship of short chain fatty acid production and gas formation in vitro in feedstuffs of widely different quality. J. Anim. Physiol. Anim. Nutr. 81, 157-167. Blummel, M. and Becker, K. 1997. The Degradability characteristics of fifty-four roughages and roughage neutral detergent fibers as described by in vitro gas production and their relationship to voluntary feed intake. Br. J. Nutr. 77, 757-768. FAO/WHO. 2009. Project document for a regional standard for Pomegranate. FAO/WHO Coordinating Committee for the Near East. Fifth Session. Tunis, Tunisia, 26 - 29. January. Feizi, R., Ghodratnama, A., Zahedifar, M., Danesh Mesgaran, M. and Raisianzadeh, M. 2005. Apparent digestibility of pomegranate seed fed to sheep. Proceeding of British Society of Animal Science. p. 222. Getachew, G., Makkar H. P. S. and Becker, K. 1999. Stoichiometric relationship between short chain fatty acid and in vitro gas production in presence and absence of polyethylene glycol for tannin containing browses, EAAP Satellite Symposium, Gas production: fermentation kinetics for feed evaluation and to assess microbial activity. 18-19 August, Wageningen, The Netherlands. Getachew, G., Robinson, P.H., DePeters, E.J. and Taylor, S.J. 2004. Relation-ships between chemical compositions, dry matter degradation and

in vitro gas production of several ruminant feeds. Anim. Feed Sci. Technol. 111, 57-71. Khoshnam, F., Tabatabaeefar, A., Ghasemi Varnamkhasti, M. and Borghei, A. 2007. Mass modeling of pomegranate (Punica granatum L.) fruit with some physical characteristics. Sci. Hortic. 114, 21-26. Lansky, E.P. and Newman, R.A. 2007. Punica granatum (pomegranate) and its potential for prevention and treatment of inflammation and cancer. J. Ethnopharmacol. 109, 177-206. Maheri-Sis, N. 2010. Ruminal protein and cell wall degradation kinetics of food-industrial by-products using nylon bags technique. PhD Thesis, Islamic Azad University, Science and Research Branch, Tehran, Iran. pp.178. Maheri-Sis, N., Chamani, M., Sadeghi, A.A., MirzaAghazadeh and A., Aghajanzadeh-Golshani, A. 2008. Nutritional evaluation of kabuli and desi type chickpeas (cicer arietinum L.) for ruminants using in vitro gas production technique. Afr. J. Biotechnol. 7, 2946-2951. Maheri-Sis, N., Chamani, M., Sadeghi, A.A., MirzaAghazadeh, A. and Safaei, A.A. 2007. Nutritional evaluation of chickpea wastes for ruminants using in vitro gas production technique. J. Anim. Vet. Adv. 6, 1453-1457. Makkar, H.P.S. 2005. In vitro gas methods for evaluation of feeds containing phytochemicals. Anim. Feed Sci. Technol. 123, 291-302. Mansouri, Y.S., Khazaei, J., Hassan-Beygi, S.R. and Mohtasebi, S.S. 2011. Post harvest characteristics of pomegranate (Punica granatum L.) fruit. Cercetri Agronomice in Moldova. 146, 5-16. McDonald, J. H. 2008. Handbook of Biological Statistics. Sparky House Publishing, Baltimore. Menke, K.H. and Steingass, H. 1988. Estimation of the energetic feed value obtained from chemical analysis and in vitro gas production using rumen fluid. Anim. Res. Dev. 28, 7-55. Mirzaei-Aghsaghali, A. and Maheri-Sis, N., 2008. Nutritive value of some agro-industrial byproducts for ruminants - A review. World J. Zool. 3, 40-46. Mirzaei-Aghsaghali. A., Maheri-Sis, N., Mansouri, H., Razeghi, M. E., Mirza-Aghazadeh, A., Cheraghi, H. and Aghajanzadeh-Golshani, A. 2011. Evaluating potential nutritive value of pomegranate processing by-products for ruminants using in vitro gas production technique. ARPN J. Agric. Biol. Sci. 6, 45-51. Modarresi, S.J., Fathi Nasri, M.H., Dayani, O. and Rashidi, L. 2010. The effect of pomegranate seed pulp feeding on DMI, performance and blood metabolites of southern Khorasan crossbred goats. Anim. Sci. Res. 20, 123-132 (in Persian).

44

http://www.openveterinaryjournal.com M. Taher-Maddah et al. Open Veterinary Journal, (2012), Vol. 2: 40-45 ________________________________________________________________________________________________________

NRC. 2001. Nutrient requirements of dairy cattle. (7 th Ed.) National Research Council, National Academy Press, Washington, DC. rskov, E.R. and McDonald, I. 1979. The Estimation of protein degradability in the rumen from incubation measurements weighed according to rate of passage. J. Agric. Sci. 92, 499-503. Prakash, C.V.S. and Prakash, I. 2011. Bioactive chemical constituents from pomegranate (Punica granatum) juice, seed and peel- A Review. Int. J. Res. Chem. Environ. 1, 1-18. S.A.S. Institute, 1991. SAS for windows, Version 6.0, Ed. SAS Institute Inc., Cary, NC. Shabtay, A., Eitam, H., Tadmor, Y., Orlov, A., Meir, A., Weinberg, P., Weinberg, Z.G., Chen, Y., Brosh, A., Izhaki, I. and Kerem, Z. 2008. Nutritive and antioxidative potential of fresh and stored pomegranate industrial byproduct as a novel beef

cattle feed. J. Agric. Food Chem. 56, 1006310070. Sommart, K., Parker, D.S., Rowlinson, P. and Wanapat, M. 2000. Fermentation characteristics and microbial protein synthesis in an in vitro system using cassava, rice straw and dried ruzi grass as substrates. Asian-Aust. J. Anim. Sci. 13, 1084-1093. Valizadeh, R., Naserian, A.A. and Vahmani, P. 2009. Influence of drying and ensiling pistachio byproducts with urea and molasses on their chemical composition, tannin content and rumen degradability parameters. J. Anim. Vet. Adv. 8, 2363-2368. Van Soest, P.J., Robertson, J.B. and Lewis, B.A. 1991. Methods for dietary neutral detergent fiber, and non starch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74, 3583-3597.

45

Вам также может понравиться

- Rice Bran and Rice Bran Oil: Chemistry, Processing and UtilizationОт EverandRice Bran and Rice Bran Oil: Chemistry, Processing and UtilizationLing-Zhi CheongОценок пока нет

- Spurgeon's Color Atlas of Large Animal Anatomy The EssentialsДокумент169 страницSpurgeon's Color Atlas of Large Animal Anatomy The EssentialsAdrin Ma'ruf100% (9)

- CVB Feed Table 2021 544Документ700 страницCVB Feed Table 2021 544prishix0% (1)

- Art Fortification of Mango Peel CookiesДокумент4 страницыArt Fortification of Mango Peel CookiesGabrielОценок пока нет

- 225020-Article Text-800728-1-10-20200117Документ17 страниц225020-Article Text-800728-1-10-20200117Aiman HaziqОценок пока нет

- Protein Extraction From Sour Cherry Kernel PDFДокумент10 страницProtein Extraction From Sour Cherry Kernel PDFdr.sameer sainiОценок пока нет

- FahimdaneshДокумент6 страницFahimdaneshAlfred Kouassi KouakouОценок пока нет

- Agriculture Journal Phytochemical Screening and Gc-Ms Analysis of Garudan Samba Traditional Rice VarietyДокумент4 страницыAgriculture Journal Phytochemical Screening and Gc-Ms Analysis of Garudan Samba Traditional Rice VarietyAgriculture JournalОценок пока нет

- Khayasenegalensis Seed Chemical Characterization and Potential UsesДокумент7 страницKhayasenegalensis Seed Chemical Characterization and Potential UsesAisha Mustapha FunmilayoОценок пока нет

- Biochemical and Functional Properties of Moringa Oleifera Leaves and Their Potential As A Functional FoodДокумент12 страницBiochemical and Functional Properties of Moringa Oleifera Leaves and Their Potential As A Functional FoodKike PalaciosОценок пока нет

- 68596-Article Text-142595-1-10-20110804Документ10 страниц68596-Article Text-142595-1-10-20110804Aisha Mustapha FunmilayoОценок пока нет

- Effects of Processing On Physicochemical and Antinutritional Properties of Black Turtle Bean (Phaseolus Vulgaris L.) Seeds FlourДокумент11 страницEffects of Processing On Physicochemical and Antinutritional Properties of Black Turtle Bean (Phaseolus Vulgaris L.) Seeds FlourUgoStanОценок пока нет

- Rhodototula Glutinis BiodieselДокумент5 страницRhodototula Glutinis BiodieseljrmattarОценок пока нет

- Dragon FruitДокумент8 страницDragon FruitLive LikeОценок пока нет

- Avocado Seeds: Extraction Optimization and Possible Use As Antioxidant in FoodДокумент30 страницAvocado Seeds: Extraction Optimization and Possible Use As Antioxidant in FoodĐeŋýzař Đ ZòįđýckОценок пока нет

- Jurnal RSMДокумент12 страницJurnal RSMNurlailiFalasifaОценок пока нет

- Pal Jadeja 2019 Microwave Assisted Extraction For Recovery of Polyphenolic Antioxidants From Ripe Mango MangiferaДокумент15 страницPal Jadeja 2019 Microwave Assisted Extraction For Recovery of Polyphenolic Antioxidants From Ripe Mango Mangiferajoyhar9Оценок пока нет

- Article Peu Impo Isolation, Screening and Comprehensive Characterization of CandidateДокумент9 страницArticle Peu Impo Isolation, Screening and Comprehensive Characterization of CandidateMalak HamrouniОценок пока нет

- Chemical Composition of Mung BeanДокумент8 страницChemical Composition of Mung BeanEuler MiquilenaОценок пока нет

- 225 2017-CJFSДокумент8 страниц225 2017-CJFSYuliet SusantoОценок пока нет

- Utilization of Mango Peels and Seed Kernels Powders As Sources of Phytochemicals in BiscuitДокумент8 страницUtilization of Mango Peels and Seed Kernels Powders As Sources of Phytochemicals in BiscuitbarenakedearthОценок пока нет

- Anticancer Potential and Antioxidant Properties of ArtocarpusДокумент13 страницAnticancer Potential and Antioxidant Properties of ArtocarpusluthfianamiftasyafitriОценок пока нет

- 133680-Article Text-488513-1-10-20190218Документ13 страниц133680-Article Text-488513-1-10-20190218Supawinee KointhaОценок пока нет

- Effect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsДокумент4 страницыEffect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsthesijОценок пока нет

- Ijmai 01 201Документ6 страницIjmai 01 201Nur Aini IktikhafsariОценок пока нет

- 18-06-2021-1624012489-6-IMPACT - IJRANSS-4. IJRANSS-May 2021 - Proximate Composition of Some Selected Fruits Peels in NigeriaДокумент10 страниц18-06-2021-1624012489-6-IMPACT - IJRANSS-4. IJRANSS-May 2021 - Proximate Composition of Some Selected Fruits Peels in NigeriaImpact JournalsОценок пока нет

- Ngampeerapong C 2019Документ12 страницNgampeerapong C 2019Fauzi SatriaОценок пока нет

- Chemical Composition of Some Selected Fruit PeelsДокумент10 страницChemical Composition of Some Selected Fruit PeelsDaniel David ArangurenОценок пока нет

- Organochlorine Pesticide Residues Analysis From Cow Milk: A ReviewДокумент6 страницOrganochlorine Pesticide Residues Analysis From Cow Milk: A ReviewSergio MaquilonОценок пока нет

- 4 IJANS Novel Bitter MelonДокумент10 страниц4 IJANS Novel Bitter Meloniaset123Оценок пока нет

- Carbohydrate Polymers: SciencedirectДокумент7 страницCarbohydrate Polymers: SciencedirectRomeo RojasОценок пока нет

- In Vitro Callus and in Vivo Leaf Extract of Gymnema Sylvestre Stimulate - Cells Regeneration and Anti-Diabetic Activity in Wistar RatsДокумент7 страницIn Vitro Callus and in Vivo Leaf Extract of Gymnema Sylvestre Stimulate - Cells Regeneration and Anti-Diabetic Activity in Wistar Ratsapi-198310771Оценок пока нет

- Investigation of Microalgae For High Lipid Content Using Palm Oil Mill Effluent (Pome) As Carbon SourceДокумент5 страницInvestigation of Microalgae For High Lipid Content Using Palm Oil Mill Effluent (Pome) As Carbon SourceAmalinaArouraОценок пока нет

- Utilisation of Red Palm Olein in Formulating Functional Chocolate SpreadДокумент6 страницUtilisation of Red Palm Olein in Formulating Functional Chocolate SpreadRod LopОценок пока нет

- 1 s2.0 S1876610214016622 Main PDFДокумент7 страниц1 s2.0 S1876610214016622 Main PDFJhoao VelaОценок пока нет

- Determination of Biologically Actie Constituents of The Fruits of Cucumis Sativus Linn Using GC-MS AnalysisДокумент5 страницDetermination of Biologically Actie Constituents of The Fruits of Cucumis Sativus Linn Using GC-MS Analysisavian_roseОценок пока нет

- FEUMBApaper 4Документ11 страницFEUMBApaper 4Andrawus DanjumaОценок пока нет

- Production and Optimization of Extracellular Alkaline Protease FromДокумент12 страницProduction and Optimization of Extracellular Alkaline Protease FromHimanni JileliaОценок пока нет

- Characterization of Antihyperglycemic and Antiretroviral Components of Momordicacharantiabitter MelonДокумент5 страницCharacterization of Antihyperglycemic and Antiretroviral Components of Momordicacharantiabitter MelonWinarso D. WidodoОценок пока нет

- Arturo-Perdomo2021 Article ExtractionAndCharacterizationOДокумент12 страницArturo-Perdomo2021 Article ExtractionAndCharacterizationOAstridОценок пока нет

- Biochemical and Environmental Studies On Neem Leaves and SeedДокумент26 страницBiochemical and Environmental Studies On Neem Leaves and SeedMauricio PiñeresОценок пока нет

- Jas T 4681316637000Документ11 страницJas T 4681316637000Florentina ParaschivОценок пока нет

- Salfarina RamliДокумент9 страницSalfarina RamliMellisa Laura MintoroОценок пока нет

- Production of Fufu From Yellow Cassava Roots Using The Odourlessflour Technique and The Traditional Method Evaluation OfcarotenoidДокумент7 страницProduction of Fufu From Yellow Cassava Roots Using The Odourlessflour Technique and The Traditional Method Evaluation OfcarotenoidNNMSAОценок пока нет

- Arruda 2016Документ11 страницArruda 2016Abdelouahab BenseddikОценок пока нет

- Wound Healing1Документ8 страницWound Healing1basu68Оценок пока нет

- Optimization and Characterization of An Extruded Snack Based On Taro Flour (Colocasia Esculenta L.) Enriched With Mango Pulp (Mangifera Indica L.)Документ12 страницOptimization and Characterization of An Extruded Snack Based On Taro Flour (Colocasia Esculenta L.) Enriched With Mango Pulp (Mangifera Indica L.)José Manuel Juárez-BarrientosОценок пока нет

- Chemical Composition Antibacterial Activity and Mechanism of Action of Essential Oil From Seeds of Fennel Foeniculum Vulgare Mill 2014 Food ControlДокумент8 страницChemical Composition Antibacterial Activity and Mechanism of Action of Essential Oil From Seeds of Fennel Foeniculum Vulgare Mill 2014 Food ControlAni IoanaОценок пока нет

- Pectin From Ripe Peels of Mango CultivarsДокумент10 страницPectin From Ripe Peels of Mango CultivarsIsabel Tacunan CastilloОценок пока нет

- Cashew in Breeding Research SynthesisДокумент8 страницCashew in Breeding Research SynthesisAnowar RazvyОценок пока нет

- tjas,+TJAS 53 (3) 4Документ16 страницtjas,+TJAS 53 (3) 4Pin NapachaОценок пока нет

- Food Research International: Alma Fernanda Sánchez Maldonado, Elizabeth Mudge, Michael G. Gänzle, Andreas SchieberДокумент8 страницFood Research International: Alma Fernanda Sánchez Maldonado, Elizabeth Mudge, Michael G. Gänzle, Andreas SchieberMaria MihaelaОценок пока нет

- Potential of Lemongrass Leaves Extract Cymbopogon Citratus As Prevention For Oil OxidationДокумент6 страницPotential of Lemongrass Leaves Extract Cymbopogon Citratus As Prevention For Oil OxidationAdriana Lucia MerchanОценок пока нет

- Physicochemical and Functional Properties of Starches of Two Quality Protein Maize (QPM) Grown in Côte D'ivoireДокумент10 страницPhysicochemical and Functional Properties of Starches of Two Quality Protein Maize (QPM) Grown in Côte D'ivoireMatache GabrielaОценок пока нет

- 2252-Article Text-8408-2-10-20201018Документ17 страниц2252-Article Text-8408-2-10-20201018Samantha Garcia NovoaОценок пока нет

- Amon409 415Документ7 страницAmon409 415MogleОценок пока нет

- Food Chemistry: Dalbir Singh Sogi, Muhammad Siddiq, Ibrahim Greiby, Kirk D. DolanДокумент7 страницFood Chemistry: Dalbir Singh Sogi, Muhammad Siddiq, Ibrahim Greiby, Kirk D. Dolan891218Оценок пока нет

- Biocatalysis and Agricultural Biotechnology: Susan Hartwig Duarte, Gislaine Ghiselli, Francisco MaugeriДокумент5 страницBiocatalysis and Agricultural Biotechnology: Susan Hartwig Duarte, Gislaine Ghiselli, Francisco MaugeriLathoifulIsyarohОценок пока нет

- Artigo Final Das Farinhas PublicadoДокумент9 страницArtigo Final Das Farinhas PublicadoLala MouraОценок пока нет

- Urbanisation in India Sociological ContrДокумент12 страницUrbanisation in India Sociological Contrpratyushkumarbanua71Оценок пока нет

- Bioethanol Production From Glycerol by Mixed Culture SystemДокумент6 страницBioethanol Production From Glycerol by Mixed Culture SystemPablo PaganiОценок пока нет

- Novel Proteins for Food, Pharmaceuticals, and Agriculture: Sources, Applications, and AdvancesОт EverandNovel Proteins for Food, Pharmaceuticals, and Agriculture: Sources, Applications, and AdvancesОценок пока нет

- Effects of Xylazine-Ketamine-Diazepam Anesthesia On Blood Cell Counts and Plasma Biochemical Values in Sheep and GoatsДокумент5 страницEffects of Xylazine-Ketamine-Diazepam Anesthesia On Blood Cell Counts and Plasma Biochemical Values in Sheep and GoatsAdrin Ma'rufОценок пока нет

- Jadwal Bandara 2015Документ68 страницJadwal Bandara 2015Adrin Ma'rufОценок пока нет

- International Taxation IssuesДокумент35 страницInternational Taxation IssuesAdrin Ma'rufОценок пока нет

- Isolasi Dan Identifikasi Bakteri Di Lingkungan Laboratorium Mikrobiologi Klinik RSUDZA Banda AcehДокумент8 страницIsolasi Dan Identifikasi Bakteri Di Lingkungan Laboratorium Mikrobiologi Klinik RSUDZA Banda AcehAdrin Ma'rufОценок пока нет

- International Budgeting and Performance EvaluationДокумент31 страницаInternational Budgeting and Performance EvaluationAdrin Ma'rufОценок пока нет

- International Accounting & Multinational Enterprises: Lee H. Radebaugh Sidney J. Gray Ervin L. BlackДокумент26 страницInternational Accounting & Multinational Enterprises: Lee H. Radebaugh Sidney J. Gray Ervin L. BlackAdrin Ma'rufОценок пока нет

- Glycosaminoglycan GAG Supplements Glucosamine ChondroitinДокумент1 страницаGlycosaminoglycan GAG Supplements Glucosamine ChondroitinAdrin Ma'rufОценок пока нет

- 01Документ3 страницы01Adrin Ma'rufОценок пока нет

- Snake AnatomyДокумент7 страницSnake AnatomyAdrin Ma'rufОценок пока нет

- Laryngeal Paralysis: Pathophysiology, Diagnosis, and Surgical RepairДокумент13 страницLaryngeal Paralysis: Pathophysiology, Diagnosis, and Surgical RepairAdrin Ma'rufОценок пока нет

- Wound CareДокумент2 страницыWound CareAdrin Ma'rufОценок пока нет

- 33 Ethnoveterinary Practices of India PDFДокумент8 страниц33 Ethnoveterinary Practices of India PDFAdrin Ma'rufОценок пока нет

- Anastesi Clode - OCULARANESTHETICSДокумент4 страницыAnastesi Clode - OCULARANESTHETICSAdrin Ma'rufОценок пока нет

- Epidemiology BooksДокумент5 страницEpidemiology BooksAdrin Ma'rufОценок пока нет

- Pathophysiology and Treatment of Hypertrophic CardiomyopathyДокумент29 страницPathophysiology and Treatment of Hypertrophic CardiomyopathyAdrin Ma'rufОценок пока нет

- Ultrasonograph yДокумент2 страницыUltrasonograph yAdrin Ma'rufОценок пока нет

- Sumber (Jurnal)Документ931 страницаSumber (Jurnal)Bebek Jantan TangguhОценок пока нет

- Final Material by Dhruv 2nd Edition PDFДокумент789 страницFinal Material by Dhruv 2nd Edition PDFmadheshvet50% (6)

- In Vitro Rumen Fermentation Kinetics and Microbial Biomass Synthesis of Unconventional Sugarcane Trash and Concentrates Using Cattle InoculumsДокумент4 страницыIn Vitro Rumen Fermentation Kinetics and Microbial Biomass Synthesis of Unconventional Sugarcane Trash and Concentrates Using Cattle Inoculumsjaishankar chanduОценок пока нет

- Ruminal Acidosis Aetiopathogenesis Prevention and TreatmentДокумент60 страницRuminal Acidosis Aetiopathogenesis Prevention and TreatmentDavid uribeОценок пока нет

- Materi 1Документ49 страницMateri 1Fadilah NurziyaОценок пока нет

- Animal Microbe InteractionsДокумент50 страницAnimal Microbe InteractionsDoods GaldoОценок пока нет

- Course Title: Large Animal Medicine-I: Systemic Diseases of Digestive SystemДокумент35 страницCourse Title: Large Animal Medicine-I: Systemic Diseases of Digestive SystemFarhan NobelОценок пока нет

- PHD Castro PDFДокумент214 страницPHD Castro PDFGIANCARLOОценок пока нет

- R. Ørskov - Energy NutritionДокумент157 страницR. Ørskov - Energy NutritionEdwin FrancoОценок пока нет

- Digestibilité Et Paramètres de Croissance Chez La LapineДокумент73 страницыDigestibilité Et Paramètres de Croissance Chez La LapineFerchichi dhouhaОценок пока нет

- PhilzДокумент9 страницPhilzEduardo ViolaОценок пока нет

- 1614339648PTE Writing Pratice Paper 9Документ4 страницы1614339648PTE Writing Pratice Paper 9simОценок пока нет

- 11-Arid-953, Poisonous Plants To AnimalsДокумент12 страниц11-Arid-953, Poisonous Plants To AnimalsVet Rizwan MajeedОценок пока нет

- Questions To AnswerДокумент3 страницыQuestions To AnswerjaneОценок пока нет

- Feed Additives in Ruminant Nutrition FINALДокумент39 страницFeed Additives in Ruminant Nutrition FINALjss_bustamanteОценок пока нет

- CSIRO Lowering Ruminant Methane Emissions Through Improved Feed Conversion EfficiencyДокумент11 страницCSIRO Lowering Ruminant Methane Emissions Through Improved Feed Conversion EfficiencyHéctor W Moreno QОценок пока нет

- Adaptations of Carnivores and Herbivores To Their DietДокумент4 страницыAdaptations of Carnivores and Herbivores To Their DietNadine MonkamОценок пока нет

- AAN CHAP 6. Voluntary Feed Intake and Its RegulationДокумент23 страницыAAN CHAP 6. Voluntary Feed Intake and Its RegulationDame NegaroОценок пока нет

- Boosty Vo-TechnicalДокумент45 страницBoosty Vo-TechnicalDrGanesh Saini100% (1)

- Carbohydrate Metabolism The RuminantДокумент12 страницCarbohydrate Metabolism The RuminantJuni ClaudiaОценок пока нет

- Dr. T.K. Walli (Animal Nutrition)Документ15 страницDr. T.K. Walli (Animal Nutrition)Mayank Tandon100% (2)

- Nutrient Requirements of Beef Cattle e 974Документ23 страницыNutrient Requirements of Beef Cattle e 974sicario.bingchillingОценок пока нет

- Coleman (1979) - The Role of Rumen Protozoa in The Metabolism of Ruminants Given Tropical FeedsДокумент15 страницColeman (1979) - The Role of Rumen Protozoa in The Metabolism of Ruminants Given Tropical Feedsdaniela castroОценок пока нет

- Utilization of Oil Palm Co-Products As Feeds For Livestock in MalaysiaДокумент60 страницUtilization of Oil Palm Co-Products As Feeds For Livestock in MalaysiaRobert PaulisОценок пока нет

- Reduction of Enteric Methane Through The Use of Feed SupplementДокумент49 страницReduction of Enteric Methane Through The Use of Feed SupplementErlon HonoratoОценок пока нет

- K01299 - 20211018160945 - SBF3043 Chapter 3 - Digestive SystemДокумент52 страницыK01299 - 20211018160945 - SBF3043 Chapter 3 - Digestive SystemChimChim UrkОценок пока нет

- Nutrition in AnimalsДокумент13 страницNutrition in AnimalsaksrswainОценок пока нет

- Nutrition and Feeding of Sheep and GoatsДокумент57 страницNutrition and Feeding of Sheep and GoatsHaolitОценок пока нет

- Carbohydrate Digestion and Metabolism Overview of Carbohydrate DigestionДокумент11 страницCarbohydrate Digestion and Metabolism Overview of Carbohydrate DigestionLonely WolfОценок пока нет