Академический Документы

Профессиональный Документы

Культура Документы

F50LX Cap 18 (Scarico)

Загружено:

pivarszkinorbertИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

F50LX Cap 18 (Scarico)

Загружено:

pivarszkinorbertАвторское право:

Доступные форматы

18.

EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

F ILLY LX 50

EXHAUST EMISSION CONTROL SYSTEM DIAGRAM .................................................18-0 18 EMISSION CONTROL SYSTEM ......................................................................18-1 EXHAUST SERVICE INFORMATION....................................................................................................18-1 TROUBLESHOOTING...........................................................................................................18-1 MAINTENANCE SCHEDULE ..............................................................................................18-2 SECONDARY AIR CLEANER...............................................................................................18-3 AIR INJECTION CUT-OFF VALVE (A.I.C.V.)....................................................................18-4 REED VALVE..........................................................................................................................18-5 EXHAUST MUFFLER ...........................................................................................................18-6 EXHAUST EMISSION RELATED SYSTEM INSPECTION...............................................18-7

18

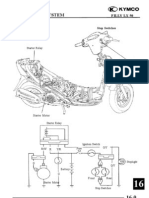

EXHAUST EMISSION CONTROL SYSTEM DIAGRAM

Fresh Air

Carburetor Intake Manifold

Vacuum Tube Secondary Air Inlet Tube

Air Injection Cut-off Valve

Crankshaft

Reed Valve

Valve Piston Engine Oil Exhaust

Secondary Air

Secondary Air Cleaner

Fresh Air

18-0

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

EXHAUST EMISSION CONTROL SYSTEM

F ILLY LX 50

The exhaust emission control system adopted in this model utilizes the reed valve to draw secondary air into the exhaust system for re-combustion by means of exhaust pulsation so as to minimize the exhaust emission. FUNCTION Item Secondary Air Cleaner Purpose Filter secondary air. Function It filters the fresh air drawn for re-burning to prevent dirt or dust from affecting the operation of the air injection cut-off valve. The air injection cut-off valve usually opens to lead air into the exhaust muffler in which air is reburned to reduce CO. When the throttle valve closes suddenly, the air injection cut-off valve is actuated by vacuum to close and cut off secondary air in order to prevent exhaust muffler backfiring due to air in the exhaust system.

Prevent exhaust Air Injection Cut- muffler noise and off Valve backfiring at sudden deceleration.

Reed Valve

the motorcycle speed Control the secondary Whenthe reed valve operatesis less than 50km per hour, to draw secondary air air inlet to reduce CO. into the exhaust system for re-combustion.

SERVICE INFORMATION

GENERAL INSTRUCTIONS During operation, be careful to avoid scalding caused by the exhaust muffler. Note the locations of tubes for proper installation. Replace any damaged tube with a new one. Make sure to tighten the connector of each tube securely TOOLS Vacuum pump SPECIFICATIONS Air injection cut-off valve actuating pressure 250mm/Hg 30 liter/min. Reed valve stopper clearance 6.6mm

TROUBLESHOOTING

High CO at idle speed Damaged or clogged reed valve Damaged or clogged air injection cut-off valve Clogged air cleaner Backfiring at sudden deceleration Damaged reed valve (malfunction) Faulty air injection cut-off valve (unable to close) Carburetor incorrectly adjusted Faulty air cut-off valve Leaking vacuum tube Exhaust muffler noise Faulty air injection cut-off valve Broken vacuum tube Faulty reed valve

18-1

18. EVAPORATIVE/EXHAUST EMISSION

MAINTENANCE SCHEDULE:

(1) PERIODIC MAINTENANCE Item Lubrication Fuel System Air Supply System System Drive System Ignition System

Other

CONTROL SYSTEM

Service Mileage

F ILLY LX 50

300 1000 2000 3000 4000 5000 6000 7000 8000 9000 1000 1100 1200 1300 1400 15000

0 0 0 0 0

Engine oil Oil filter screen Gear oil Motor oil filter Fuel filter Fuel filter screen Carburetor Fuel line Air cleaner Charcoal canister Secondary air cleaner

R R R C C R R I I I I I C C C A A A I I C R R I I I I R R Secondary air inlet line I Intake manifold screw I Purge control valve I I I I Air lines I I I Catalytic converter I I I I Cam chain I I I I Drive chain I I I I Drive belt I I I I Valve clearance I I I I Spark 4-stroke I R Plug 2-stroke I R R R C.D.I. I I I Ignition system wires I I I Bolts and nuts T T T T T T T T T T T T T T T Brake system A A A A A A A A A A A A A A A I: Inspect, A: Adjust, C: Clean, R: Replace, T: Tighten During riding or inspection, if any part is found to be cleaned, adjusted Remarks or replaced, do it directly and take a record if the exhaust emission control system is not seriously affected. It must be reported and approved if the exhaust emission control system is seriously affected. C R I I C A I R I R

R C R

R C

(2) IRREGULAR MAINTENANCE: Item Ignition system Carbon deposit removal Transmission system Piston Contents Inspect and repair when obvious symptoms of ignition failure, engine overheating and stalling are found frequently. Remove carbon deposits from the exhaust system, cylinder head and piston head when the engine horsepower decreases greatly during the service mileage of 10000_ 15000 km. Perform CVT system maintenance and inspection when the engine performance decreases obviously. Severe use in the first 1000 km may cause worn or seized cylinder, piston and piston rings. Clean or replace with new ones if necessary.

18-2

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

F ILLY LX 50

SECONDARY AIR CLEANER

REMOVAL Remove the frame body covers. Remove the two nuts attaching the rear light shell. Remove the rear turn signal light bulb and replace with a new one.

Rear Light Shell Disconnect the secondary air cleaner connecting tube. Remove the air cleaner attaching bolts and the air cleaner.

Nuts

Air Injection Cut-off Valve

Bolt

Vacuum Tube Tube to Reed Valve Secondary Air Cleaner

DISASSEMBLY Remove the two screws attaching the air cleaner cover to remove the cover. Remove the air cleaner element. Inspect the air cleaner. INSTALLATION The installation sequence is the reverse of removal.

Air Outlet Tube

Air Cleaner Element

The secondary air cleaner must be

assembled and installed properly to avoid dust entering the air cleaner.

Air Injection Cut-off Valve

Screws

Air Inlet Tube

18-3

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

F ILLY LX 50

AIR INJECTION CUT-OFF VALVE INSPECTION Inspect the air injection cut-off valve flow using a vacuum pump. If the flow is not within the specified values, replace with a new one. The flow should be at least 30 liter/min when a vacuum of 250mm/Hg is applied. The flow should be at least 1.6 liter/min when a vacuum of 320mm/Hg is applied. Check each connecting tube for cracks or damage and replace if necessary.

Air Injection Cut-off Valve Vacuum Pump

INSTALLATION The installation sequence is the reverse of removal.

When installing, be careful not to bend

or twist the tubes and check for proper installation. The tube length is very important to its performance, use the tube of same specification for replacement.

18-4

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

Cylinder Head Cover Bolts

F ILLY LX 50

REED VALVE

REMOVAL Remove the met-in box and frame center cover. Disconnect the secondary air inlet tube connector. Remove the four cylinder head cover bolts and two secondary air outlet tube bolts.

Secondary Air Inlet Tube Bolt

Reed Valve Cover Bolts

Screws

INSPECTION Remove the three screws attaching the reed valve cover and the reed valve. Check the reed valve for damaged or weak reeds. Check the reed valve seat for cracks, damage or clearance between the seat and reed. Check the gasket and O-ring for damage or deterioration and replace if necessary. Reed valve stopper clearance: 6.6mm

Reed Stopper

INSTALLATION Install the reed valve in the reverse order of removal.

When installing, be careful not to bend

or twist the tubes and check for proper installation.

18-5

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

EXHAUST MUFFLER

REMOVAL Remove the two exhaust muffler joint lock nuts and two exhaust muffler lock bolts. Remove the exhaust muffler.

F ILLY LX 50

Exhaust Muffler Joint Lock Nut

The temperature of exhaust muffler is

very high. Be careful to avoid burns during working.

Exhaust Muffler

Lock Bolts

INS PECTION 1. Inspect the exhaust muffler and joint for damage or crack. Replace if necessary. 2. Inspect the exhaust muffler joint packing collar for deformation or damage. Replace if necessary.

A large amount of unburned mixture

INSTALLATION 1. Install the exhaust muffler in the reverse order of removal.

flowing into the high-heat catalytic converter will burn again and cause damage to the converter due to overheat. Pay attention to the following. Use 92# or 95# nonleaded gasoline only. (Leaded gasoline will cause catalytic converter failure.) During riding, do not turn the ignition switch OFF to avoid a large amount of unburned mixture flowing into the exhaust muffler. Faulty ignition system or fuel system will cause overheat and damage to the catalytic

converter.

18-6

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

EXHAUST EMISSION RELATED SYSTEM INSPECTION

Clean or replace the air cleaner. ( 3-4) Clean and adjust the carburetor. ( 3-5) Inspect the auto bystarter system. ( 5-4) Clean and inspect the spark plug. ( 3-4) Inspect the ignition system. ( 3-6)

F ILLY LX 50

EXHAUST EMISSION TEST AND ADJUSTMENT 1. Start the engine and warm up for several minutes. (Engine surface temperature 50_ 60 ) 2. Adjust the idle speed to 1900rpm. 3. Connect the emission tester sampling pipe to the exhaust muffler. Standard: CO: 2.50.5% HC: 700PPM max. 4. If CO or HC exceeds the specified values, adjust the carburetor pilot screw (P.S.) until CO and HC are within the specified standard values. P.S. Opening: 2_ turns 5. If the adjustment of carburetor makes no difference, inspect exhaust emission related system. ( 18-9)

18-7

Вам также может понравиться

- F50LX Cap 17 (Imp Elettrico)Документ6 страницF50LX Cap 17 (Imp Elettrico)pivarszkinorbertОценок пока нет

- F50LX Cap 14 (Imp Ricarica)Документ11 страницF50LX Cap 14 (Imp Ricarica)carbikegeОценок пока нет

- F50LX Cap 16 (Imp Avviamento)Документ6 страницF50LX Cap 16 (Imp Avviamento)pivarszkinorbertОценок пока нет

- F50LX Cap 15 (Imp Accensione)Документ6 страницF50LX Cap 15 (Imp Accensione)pivarszkinorbertОценок пока нет

- F50LX Cap 11 (Albero Motore)Документ7 страницF50LX Cap 11 (Albero Motore)pivarszkinorbertОценок пока нет

- F50LX Cap 13 (Ruota Sospensione Post)Документ7 страницF50LX Cap 13 (Ruota Sospensione Post)pivarszkinorbertОценок пока нет

- F50LX Cap 10 (Riduzione Finale)Документ6 страницF50LX Cap 10 (Riduzione Finale)pivarszkinorbertОценок пока нет

- F50LX Cap 09 (Trasmissione)Документ14 страницF50LX Cap 09 (Trasmissione)pivarszkinorbertОценок пока нет

- F50LX Cap 06 (Rimozione Motore)Документ6 страницF50LX Cap 06 (Rimozione Motore)pivarszkinorbertОценок пока нет

- F50LX Cap 08 (Cilindro Pistone)Документ8 страницF50LX Cap 08 (Cilindro Pistone)pivarszkinorbertОценок пока нет

- F50LX Cap 04 (Lubrificazione)Документ7 страницF50LX Cap 04 (Lubrificazione)pivarszkinorbertОценок пока нет

- F50LX Cap 05 (Alimentazione)Документ20 страницF50LX Cap 05 (Alimentazione)pivarszkinorbertОценок пока нет

- F50LX Cap 03 (Manutenzione)Документ12 страницF50LX Cap 03 (Manutenzione)pivarszkinorbertОценок пока нет

- F50LX Cap 02 (Plastiche Marmitta)Документ6 страницF50LX Cap 02 (Plastiche Marmitta)pivarszkinorbertОценок пока нет

- F50LX Cap 01 (Info Generali)Документ26 страницF50LX Cap 01 (Info Generali)pivarszkinorbert100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Hornos Keen OvensДокумент8 страницHornos Keen Ovensjinyuan74Оценок пока нет

- Finite Element Simulation of Conventional and High Speed Machining of Ti6Al4V AlloyДокумент9 страницFinite Element Simulation of Conventional and High Speed Machining of Ti6Al4V AlloyArul KirubakaranОценок пока нет

- BHFQ22P1517 ImДокумент14 страницBHFQ22P1517 ImAlberto Bravo SánchezОценок пока нет

- Fuente Segura Hose 10 Edicion InglesДокумент470 страницFuente Segura Hose 10 Edicion InglesAnonymous voPTZ0r00100% (2)

- 2000 KVA Caterpillar 3516 Gen Set Data SheetДокумент8 страниц2000 KVA Caterpillar 3516 Gen Set Data SheetMohamed Hamdallah100% (1)

- NPCP Chapter 6Документ6 страницNPCP Chapter 6Cristian OmacОценок пока нет

- (Ricardo, Ponce) 16-Essential Hydraulic Components - Maintenance R2Документ27 страниц(Ricardo, Ponce) 16-Essential Hydraulic Components - Maintenance R2Raúl Marcelo Veloz100% (1)

- Volume 01 Principles of FlightДокумент303 страницыVolume 01 Principles of FlightYousif AL AyoubiОценок пока нет

- Everything You Need To Know About CarburetorsДокумент7 страницEverything You Need To Know About CarburetorsDoran100% (1)

- Mechanical Engineering BookДокумент2 страницыMechanical Engineering BookvikasmaeОценок пока нет

- Corrente em MancalДокумент146 страницCorrente em MancalEdsonTomaselliОценок пока нет

- AD0068959Документ47 страницAD0068959ali_raza117Оценок пока нет

- QAQC Weekly Report (14072017)Документ15 страницQAQC Weekly Report (14072017)Namta GeorgeОценок пока нет

- Steam InjectorДокумент5 страницSteam InjectorJannel TobongbanuaОценок пока нет

- Waukesha Gas Engine Maintenance ManualДокумент7 страницWaukesha Gas Engine Maintenance Manualagusnnn56% (9)

- Opoc Engine ReportДокумент34 страницыOpoc Engine Reportapi-32792277367% (3)

- Brownian Motion & Diffusion: - DefinitionДокумент9 страницBrownian Motion & Diffusion: - DefinitionAndreaОценок пока нет

- 30-2si (Low Ambient Temp - Pressure Control Accessory)Документ16 страниц30-2si (Low Ambient Temp - Pressure Control Accessory)yogbru2010Оценок пока нет

- Shell Helix Ultra Professional AF 5W-20: Performance, Features & Benefits Main ApplicationsДокумент2 страницыShell Helix Ultra Professional AF 5W-20: Performance, Features & Benefits Main ApplicationsCristiBvОценок пока нет

- Valve Body Identification Guide Valve Body Identifi Cation GuideДокумент11 страницValve Body Identification Guide Valve Body Identifi Cation GuideUlloaEliasОценок пока нет

- Manual de Entrenamiento cfm56Документ216 страницManual de Entrenamiento cfm56Reinaldo Orejuela100% (2)

- Norwegian Maritime-Equipment 2016Документ568 страницNorwegian Maritime-Equipment 2016budiazis100% (1)

- Pew 209 .02Документ59 страницPew 209 .02Raj BindasОценок пока нет

- Experiment 3 - Flow Over Supersonic AirfoilДокумент14 страницExperiment 3 - Flow Over Supersonic AirfoilSanthosh KumarОценок пока нет

- RHQ-IOCL-CPMSL-2020 Rev.0 Master Supplier ListДокумент224 страницыRHQ-IOCL-CPMSL-2020 Rev.0 Master Supplier ListKunal100% (1)

- Simba E7-SeriesДокумент8 страницSimba E7-SeriesVictor BalboaОценок пока нет

- Tsubaki Emerson Gearmotor HypoidДокумент228 страницTsubaki Emerson Gearmotor HypoidDillan Stwart Quintero ParraОценок пока нет

- Manual John Deere 244JДокумент18 страницManual John Deere 244JYoriel GuzmanОценок пока нет

- CH 3 Review Load and Stress AnalysisДокумент33 страницыCH 3 Review Load and Stress AnalysisAnas TubailОценок пока нет

- Doser Line Fuel Valve Dd1513Документ7 страницDoser Line Fuel Valve Dd1513cheolllОценок пока нет