Академический Документы

Профессиональный Документы

Культура Документы

Reliability

Загружено:

Andy DolmanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Reliability

Загружено:

Andy DolmanАвторское право:

Доступные форматы

HPIN RELIABILITY

HEINZ P. BLOCH, RELIABILITY/EQUIPMENT EDITOR

HB@HydrocarbonProcessing.com

Reasonable pump life assessed from published statistics

In the preface to a recent Pump Users Handbook (ISBN 0-88173517-5) we alluded to pump failure statistics. These failure statistics are often translated into mean-time-between-failure (MTBF). For what its worth, and so as not to get enmeshed in arguments, many of the best-practices plants in the early 2000s simply took all their installed pumps, divided this number by the number of repair incidents, and multiplied it by the time period being observed. For a well-managed and reasonably reliability-focused US refinery with 1,200 installed pumps and 156 repair incidents in one year, the MTBF would be 1,200/156 = 7.7 years. The refinery would count replacing parts as a repair incidentany partsregardless of cost. In this case, a drain plug worth $1.70 or an impeller costing $5,000 would show up the same way on the MTBF statistics. Only replacing lube oil would not be counted as a repair. The best-practices plants total repair cost for pumps would include costs for all direct and indirect labor, materials, indirect labor and overhead, administration, labor to procure parts, and even the prorated cost of pump-related fire incidents. References to the stated average cost of pump repairs are: $10,287 in 1984 and $11,000 in 2005. We believe this indicates, in relative terms, a repair cost reduction, because a 2005-dollar bought considerably less than the 1984dollar. It can be reasoned that predictive maintenance and similar monitoring having led to a trend toward reduced failure severity. Using the same bare-bones measurement strategy and from published data and observations made in the course of performing maintenance effectiveness studies and reliability audits in the late 1990s and early 2000s, the MTBFs of Table 1 have been estimated.

Other studies of pump statistics. In early 2005, Gordon

TABLE 1. Pump mean-times-between-failures (years)

ANSI pumps, average, US ANSI/ISO pumps average, Scandinavian pulp and paper plants API pumps, average, US API pumps, average, Western Europe API pumps, repair-focused refinery, developing country API pumps, Caribbean region API pumps, best-of-class, US refinery, California All pumps, best-of-class petrochemical plant, US, Texas All pumps, major petrochemical company, US, Texas 2.5 3.5 5.5 6.1 1.6 3.9 9.2 10.1 7.5

TABLE 2. Suggested refinery seal target MTBFs (months)

Excellent Very good Average Fair Poor >90 70/90 70 62/70 <62

TABLE 3. Realistic target pump and component lifetimes (months)

(Note that target is less than best actually achieved) Refineries Chemical and other plants Seals, excellent Seals, average Couplings, all plants Bearings, all plants 90 70 Membrane type Gear type Continuous operation Spared operation 55 45 120 > 60 60 120 48

Buck, the John Crane Companys chief engineer for field operations in Baton Rouge, Louisiana, examined the repair records for a number of refinery and chemical plants and obtained meaningful reliability data for centrifugal pumps. A total of 15 operating plants having nearly 15,000 pumps were included in the survey. The smallest of these plants had about 100 pumps; several plants had over 2,000 pumps. All plants were located in the US. Also, all plants had some sort of pump reliability program in progress. Some of these programs could be considered as new; others as renewed and still others as established. Many of these plants, but not all, have an alliance contract with John Crane. In some cases, the alliance contract included having a John Crane technician or engineer onsite to coordinate various aspects of the program. Not all plants are refineries, however, and different results can be expected elsewhere. In chemical plants, pumps have traditionally been throw away items since chemical attack limited their life. Things have improved in recent years, but the limited space available in DIN and ASME stuffing boxes limits the type of seal that can be fitted to more compact and simple versions. Lifetimes in chemical installations are generally believed to be around 50% to 60% of the refinery values.

Pumps (Based on series system calculation)

Target pump and component lifetimes. Based on the

lifetime levels being achieved in 2000 and combined with the known best practice as outlined in available reference texts, the target component lifetimes of Table 3 are recommended and should be considered readily achievable. It should again be emphasized that many plants are achieving these levels. Nevertheless, to reach these pump lives, the pump components must be operating at the highest levels. An unsuitable seal with a lifetime of one month or less will have a catastrophic effect on pump MTBF, as would a badly performing coupling or bearing. HP

The author is HPs Equipment/Reliability Editor. A practicing engineer with over

40 years of applicable experience, he advises process plants worldwide on reliability improvement and maintenance cost-avoidance topics.

HYDROCARBON PROCESSING MARCH 2006

I1

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Investigator Name: Event Assessed: Date of Assessment: Checklist For Formal, Written Reports (See Chapter 11)Документ1 страницаInvestigator Name: Event Assessed: Date of Assessment: Checklist For Formal, Written Reports (See Chapter 11)Andy DolmanОценок пока нет

- Investigator Name: Event Assessed: Date of Assessment: Investigation Follow-Up Checklist Addressed? Follow-Up Issues Yes NoДокумент1 страницаInvestigator Name: Event Assessed: Date of Assessment: Investigation Follow-Up Checklist Addressed? Follow-Up Issues Yes NoAndy DolmanОценок пока нет

- Sample Investigation Improvement Checklist Incident Investigation GuidelineДокумент2 страницыSample Investigation Improvement Checklist Incident Investigation GuidelineAndy DolmanОценок пока нет

- Investigator Name: Event Assessed: Date of AssessmentДокумент1 страницаInvestigator Name: Event Assessed: Date of AssessmentAndy DolmanОценок пока нет

- Checklist For Developing An Incident Investigation PlanДокумент1 страницаChecklist For Developing An Incident Investigation PlanAndy DolmanОценок пока нет

- PSM Investigation Compliance Checklist Incident Investigation GuidelineДокумент1 страницаPSM Investigation Compliance Checklist Incident Investigation GuidelineAndy DolmanОценок пока нет

- Incident InvestДокумент1 страницаIncident InvestAndy DolmanОценок пока нет

- Investigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineДокумент1 страницаInvestigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineAndy DolmanОценок пока нет

- Flashback From Waste Gas Incinerator Into Air Supply Piping: Rohm and Haas Texas Inc Deer Park, TX 77536Документ8 страницFlashback From Waste Gas Incinerator Into Air Supply Piping: Rohm and Haas Texas Inc Deer Park, TX 77536Andy DolmanОценок пока нет

- Quick Checklist For Investigators: Physical ItemsДокумент4 страницыQuick Checklist For Investigators: Physical ItemsAndy DolmanОценок пока нет

- Investigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineДокумент1 страницаInvestigator Name: Event Assessed: Date of Assessment:: Sample Human Factors Checklist Incident Investigation GuidelineAndy DolmanОценок пока нет

- Comprehensive List of CausesДокумент1 страницаComprehensive List of CausesAndy DolmanОценок пока нет

- Sample Formal Report Outline Incident Investigation GuidelineДокумент1 страницаSample Formal Report Outline Incident Investigation GuidelineAndy DolmanОценок пока нет

- Investigator Name: Event Assessed: Date of AssessmentДокумент1 страницаInvestigator Name: Event Assessed: Date of AssessmentAndy DolmanОценок пока нет

- Incident InvestДокумент16 страницIncident InvestAndy DolmanОценок пока нет

- Customize This List For Your Use. See The CCPS Guideline For Investigating Chemical InformationДокумент4 страницыCustomize This List For Your Use. See The CCPS Guideline For Investigating Chemical InformationAndy DolmanОценок пока нет

- Incident InvestДокумент1 страницаIncident InvestAndy DolmanОценок пока нет

- Incident InvestДокумент5 страницIncident InvestAndy DolmanОценок пока нет

- Appendix A: Relevant OrganizationsДокумент3 страницыAppendix A: Relevant OrganizationsAndy DolmanОценок пока нет

- Propane Tank Flare Off in Topeka Cause and Effect Chart: (Simplified Version) 12-2-02Документ2 страницыPropane Tank Flare Off in Topeka Cause and Effect Chart: (Simplified Version) 12-2-02Andy DolmanОценок пока нет

- Appendix G: Quick Checklist For InvestigatorsДокумент5 страницAppendix G: Quick Checklist For InvestigatorsAndy DolmanОценок пока нет

- Appendix C: Photography Guidelines For Maximum ResultsДокумент3 страницыAppendix C: Photography Guidelines For Maximum ResultsAndy DolmanОценок пока нет

- Appendix F: Selected OSHA and EPA Incident Investigation RegulationsДокумент3 страницыAppendix F: Selected OSHA and EPA Incident Investigation RegulationsAndy DolmanОценок пока нет

- Appendix B: Professional Assistance DirectoryДокумент2 страницыAppendix B: Professional Assistance DirectoryAndy DolmanОценок пока нет

- Incident InvestДокумент21 страницаIncident InvestAndy DolmanОценок пока нет

- Incident InvestДокумент17 страницIncident InvestAndy DolmanОценок пока нет

- Checklist To Prepare For An Inspection Incident Investigation GuidelineДокумент1 страницаChecklist To Prepare For An Inspection Incident Investigation GuidelineAndy DolmanОценок пока нет

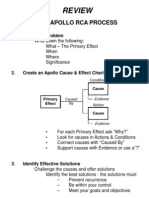

- Review: The Apollo Rca ProcessДокумент1 страницаReview: The Apollo Rca ProcessAndy DolmanОценок пока нет

- Continuous Improvement For The Incident Investigation SystemДокумент10 страницContinuous Improvement For The Incident Investigation SystemAndy DolmanОценок пока нет

- Incident InvestДокумент17 страницIncident InvestAndy DolmanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Selectra Proxl: Delivering Trouble Free Results Laboratories Can TrustДокумент2 страницыSelectra Proxl: Delivering Trouble Free Results Laboratories Can TrustMohamed AldamanhouryОценок пока нет

- WijnHoven 1998 PDFДокумент15 страницWijnHoven 1998 PDFnita selviaОценок пока нет

- Load and Resistance Factor Rating of Concrete Segmental Bridges - AASHTO Manual For Bridge Evaluation Provisions and Special ConsiderationsДокумент3 страницыLoad and Resistance Factor Rating of Concrete Segmental Bridges - AASHTO Manual For Bridge Evaluation Provisions and Special ConsiderationsKY PengОценок пока нет

- A Report On Internal Control & Compliance Management in AB Bank & Brac Bank LimitedДокумент18 страницA Report On Internal Control & Compliance Management in AB Bank & Brac Bank Limitedনূরুল আলম শুভ0% (1)

- Customer Connect - Predictive Asset Maintenance With IoT and Maintenance Cloud May 2019Документ30 страницCustomer Connect - Predictive Asset Maintenance With IoT and Maintenance Cloud May 2019vinoth4iОценок пока нет

- The Domino A100Документ2 страницыThe Domino A100Darren RisleyОценок пока нет

- Office He Peop 'S Couns District of Columbia: FT Le ElДокумент37 страницOffice He Peop 'S Couns District of Columbia: FT Le Elaaron_m_morrisseyОценок пока нет

- Srs IeeeДокумент31 страницаSrs IeeeShashwat Singh Chauhan (Mr. Iconic)Оценок пока нет

- Quality Management and Supply Chain Management in SonyДокумент12 страницQuality Management and Supply Chain Management in SonyPavan NaiduОценок пока нет

- Improving Software QualityДокумент22 страницыImproving Software QualityShahin FatimaОценок пока нет

- MSG Hydraulic Gear Pump (Anjas)Документ9 страницMSG Hydraulic Gear Pump (Anjas)Anjas Maulana IswantoОценок пока нет

- L 32Документ7 страницL 32Gustavo Suarez CoronadoОценок пока нет

- 01 AR DFMEA - TemplateДокумент3 страницы01 AR DFMEA - TemplateAndrew DoОценок пока нет

- Design and Performance of Pneumatic-Hydraulic Unmanned Aircraft System (UAS) Launch SystemДокумент7 страницDesign and Performance of Pneumatic-Hydraulic Unmanned Aircraft System (UAS) Launch SystemAhmad Zubair RasulyОценок пока нет

- Availability Vs ReliabilityДокумент4 страницыAvailability Vs ReliabilityevanОценок пока нет

- Innovation and Improvements in Batch Centrifugal Designs.: 2.1 ReliabilityДокумент7 страницInnovation and Improvements in Batch Centrifugal Designs.: 2.1 ReliabilityRAJKUMARОценок пока нет

- TMU9compact Bro en 3607-3874-12 v0200Документ16 страницTMU9compact Bro en 3607-3874-12 v0200Cyrant EnterprisesОценок пока нет

- Chapter 4 - Building Competitive Advantage Through Functional-Level StrategyДокумент38 страницChapter 4 - Building Competitive Advantage Through Functional-Level StrategyShaik Hasnat Isfar100% (3)

- Ohc AssessmentДокумент8 страницOhc AssessmentLuthfi ArdiansyahОценок пока нет

- H-93498 NOMEX Setting The Standard BrochureДокумент24 страницыH-93498 NOMEX Setting The Standard BrochureJemal MusaОценок пока нет

- Procurement PerformanceДокумент28 страницProcurement PerformanceSandeep PanchalОценок пока нет

- Max 1532Документ8 страницMax 1532Nivas SubburayanОценок пока нет

- HOMA Wastewater Treatment DN80 DN150Документ40 страницHOMA Wastewater Treatment DN80 DN150wolf_nsОценок пока нет

- Baggage Carousels: The Latest Standard in Design and ReliabilityДокумент4 страницыBaggage Carousels: The Latest Standard in Design and ReliabilityarhescobarОценок пока нет

- 2 - Asia Pacific Rail 2019 - Post Event ReportДокумент36 страниц2 - Asia Pacific Rail 2019 - Post Event ReportJigisha VasaОценок пока нет

- Ranger Pro Wireless Condition Monitoring Datasheet - 125M5237Документ11 страницRanger Pro Wireless Condition Monitoring Datasheet - 125M5237Nurdin MubarokОценок пока нет

- ME6012-Maintenance-Engineering 2 MarksДокумент14 страницME6012-Maintenance-Engineering 2 MarksAravind SelvaОценок пока нет

- Isocom: ISP06, ISP25, ISP40, ISP60Документ12 страницIsocom: ISP06, ISP25, ISP40, ISP60LAUTHUSОценок пока нет

- En 12101-3Документ104 страницыEn 12101-3Mohammad100% (1)

- Gas Turbine Controls For Generator Drive ApplicationsДокумент4 страницыGas Turbine Controls For Generator Drive Applicationsewok2030100% (1)