Академический Документы

Профессиональный Документы

Культура Документы

Cooling Water Model

Загружено:

Shruti SharmaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cooling Water Model

Загружено:

Shruti SharmaАвторское право:

Доступные форматы

Piping Pressure Drop Functions by Stephen Hall, PE

PIPESIZE, a comprehensive pipe sizing spreadsheet template is available from http://www.pipesizingsoftware.com PIPESIZE includes pre-formatted datasheets, extensive tables of piping and material properties, and other great features.

This template contains a Visual Basic for Applications (VBA) function to facilitate the building of pressure drop templates. It is written for American units of measure; the PIPESIZE template has functions for SI Units This function is designed for liquid water only; PIPESIZE works with any liquid or gas, and PIPESIZE also solves compressible flow problems that are either isothermal or adiabatic.

Input Data Required Pipe Data Inside Diameter of Pipe Surface Roughness Equivalent Length Fluid Data Mass Flow Rate Upstream Pressure Temperature

units inches feet feet

value 1.380 0.00080 100

lb/hr psia deg F

30,000 55.0 80

Note: the viscosity and density are computed in the Function subroutine using the following formulas: Viscosity, lb/ft-h = -0.23535 + 208.65 / Tin - 2074.8 / Tin ^ 2 Density, lb/ft3 = 62.7538 - 0.00353 * Tin - 0.0000482 * Tin ^ 2 Calculation Downstream Pressure Pressure Drop, friction

psia psi

21.7 33.32

To calculate pressure drop directly, if Upstream Pressure is unknown, use an arbitary value for pressure (in this example, 100): Pressure Drop, friction psi 33.32

Function PDUSa(W, Pin, Pout, d, L, epsilon, Optional Tin) ' Pressure Drop due to friction in a round pipe for water only ' with the following arguments ' Specify two of the following three; function will compute the third ' W = mass flow rate, lb/hr ' Pin = inlet, or upstream, pressure, psia ' Pout = outlet, or downstream pressure, psia ' Pipe properties ' d = pipe inside diameter, inches ' L = pipe length, feet ' epsilon = Surface roughness is in units feet ' Fluid properties ' Tin -- inlet temperature, deg F (default to 60)

' Fluid properties ' Tin -- inlet temperature, deg F (default to 60) ' Density -- calculated for water, lb/ft3

nd other great features.

essure (in this example, 100):

Simple Cooling Water Distribution System Model by Stephen Hall www.pipesizingsoftware.com Assumptions: Each user controls its own flow rate with a control valve Pressure in the supply pipe is controlled with a bypass Pressure Control Valve The RED cells are user inputs The YELLOW HIGHLIGHTED cells are the pressures calculated at each node Black cells are calculated values See Sheet 1 for an explanation of the VBA macro that calculates the pressures Notes:

Sep-12

It would be easy to model water losses, such as consumption by a user with no return to the loop Uncontrolled flow through a user can also be modeled, but requires an iterative calculation - in this case, the flow would be determined by the equivalent length of the user and the pressure differential from It is also easy to add a pump (using the pump curve) and have it determine the the flow into the supply pipe With a model like this, expanded to hundreds of user points and with many branch lines, "what if" games can be p The "what if" analysis could be used to see the effect of changing the setpoint of the pressure control valve, use o

Supply Pipe 6 inch 80 deg F

Return Pipe 6 inch 20 psig 500 ft

500 gpm 56.14 psig

User 1

100 F 50 gpm

89.6 F 500 gpm 24.97 psig

300 ft 450 gpm 53.71 psig User 2 95 F 100 gpm

300 ft 88.4 F 450 gpm 27.39 psig

500 ft User 3 350 gpm 51.24 psig 105 F 75 gpm

500 ft 86.5 F 350 gpm 29.86 psig

250 ft User 4 275 gpm 85 F 80 gpm

250 ft 81.5 F 275 gpm

50.47 psig

30.63 psig 200 ft 300 ft 50 psig 195 gpm 80 F Pressure Control Valve 30.94 psig

Pipe Roughness:

0.0008 ft

e pressure differential from supply to return nto the supply pipe "what if" games can be played ressure control valve, use of different pumps, etc.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Method Statement of T-Beams PDFДокумент14 страницMethod Statement of T-Beams PDFKAmi KaMranОценок пока нет

- Today! 2 Activity Book AKДокумент10 страницToday! 2 Activity Book AKMark Arenz Corixmir80% (5)

- TAS360VoIP ExДокумент56 страницTAS360VoIP ExOscar Damián Gómez HernándezОценок пока нет

- Full Site PDFДокумент23 страницыFull Site PDFpursuwОценок пока нет

- TMJДокумент38 страницTMJAnonymous 6kAmeZzIОценок пока нет

- Chapter 1thermodynamicsДокумент10 страницChapter 1thermodynamicsMatthew SmithОценок пока нет

- Lecture Seven Gears: Common Gear TypesДокумент8 страницLecture Seven Gears: Common Gear TypesShruti SharmaОценок пока нет

- Chapter 6 AvailabilityДокумент6 страницChapter 6 Availabilitygovind4ever5Оценок пока нет

- Focused Group DiscussionДокумент8 страницFocused Group DiscussionShruti SharmaОценок пока нет

- Basic ThermoДокумент46 страницBasic ThermoShruti SharmaОценок пока нет

- Dense Ball PackingДокумент334 страницыDense Ball PackingLucas RibeiroОценок пока нет

- Barge 180Ft Deck Load Capacity & Strength-Rev1Документ52 страницыBarge 180Ft Deck Load Capacity & Strength-Rev1Wahyu Codyr86% (7)

- MOE XT2-XT4 110... 125V Ac/dcДокумент3 страницыMOE XT2-XT4 110... 125V Ac/dcLê Xuân ĐịnhОценок пока нет

- Crimin Q and A Set 1Документ6 страницCrimin Q and A Set 1Marc angelo RegnerОценок пока нет

- Transient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanДокумент4 страницыTransient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanVerruumm AmineОценок пока нет

- Remote Control Based Home Appliances Final ReportДокумент22 страницыRemote Control Based Home Appliances Final ReportVishal Vn50% (2)

- Higher Unit 11 Topic Test: NameДокумент17 страницHigher Unit 11 Topic Test: NamesadiyaОценок пока нет

- Igcse ReadingДокумент4 страницыIgcse ReadingIvonne PuspakencanaОценок пока нет

- Government Schemes: Ministry of Agriculture and Farmers' WelfareДокумент29 страницGovernment Schemes: Ministry of Agriculture and Farmers' WelfareDushyant MudgalОценок пока нет

- A Very Old MachineДокумент20 страницA Very Old MachineSwathi G. SalemОценок пока нет

- Unit-3: Grid FrameworkДокумент44 страницыUnit-3: Grid FrameworkMUKESH KUMAR P 2019-2023 CSEОценок пока нет

- Video Wall, Digital Signage & C'Type Serial NumberДокумент8 страницVideo Wall, Digital Signage & C'Type Serial NumberAbhijit BarmanОценок пока нет

- Sperm Cell: Specialised CellsДокумент2 страницыSperm Cell: Specialised CellsRhynnieОценок пока нет

- WhittleMIME 413-513 Workshop 1 2014Документ26 страницWhittleMIME 413-513 Workshop 1 2014Diana Catalina Munera0% (1)

- MECH0018.1 Assignment 2 QP Fall 2021Документ17 страницMECH0018.1 Assignment 2 QP Fall 2021saleem razaОценок пока нет

- Hinomoto Tractor Parts Catalogue 2018 C144, C174, E150, E180, E230, E250, E280, E384Документ63 страницыHinomoto Tractor Parts Catalogue 2018 C144, C174, E150, E180, E230, E250, E280, E384Monica Mascarenhas0% (1)

- Low - Pass FilterДокумент8 страницLow - Pass FilterSaurabh BhiseОценок пока нет

- HISTOPATHДокумент38 страницHISTOPATHDennis Louis Montepio BrazaОценок пока нет

- Chapter-01 Introduction: Sonadanga Residential Area (1st Phase)Документ17 страницChapter-01 Introduction: Sonadanga Residential Area (1st Phase)MAFRID HAYDARОценок пока нет

- Report On RoboticsДокумент40 страницReport On Roboticsangelcrystl4774Оценок пока нет

- 2CCC413001C0203 S800Документ60 страниц2CCC413001C0203 S800Sang SekОценок пока нет

- Global Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelДокумент33 страницыGlobal Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelThiyagarajan JayaramenОценок пока нет

- Catalogo Smartline Transmitter Family Ferrum Energy 变送器Документ12 страницCatalogo Smartline Transmitter Family Ferrum Energy 变送器peng chaowenОценок пока нет

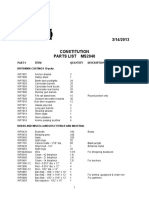

- MS2040 Constitution Parts ListДокумент6 страницMS2040 Constitution Parts ListTemptationОценок пока нет

- LEM 91-161 Fla E 0612Документ13 страницLEM 91-161 Fla E 0612Julen IturriozОценок пока нет