Академический Документы

Профессиональный Документы

Культура Документы

CAM Lecture Plan 2012

Загружено:

Ravee IndИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CAM Lecture Plan 2012

Загружено:

Ravee IndАвторское право:

Доступные форматы

SRI RAMAKRISHNA INSTITUTE OF TECHNOLOGY, COIMBATORE-10 (Approved by AICTE, New Delhi Affiliated to Anna University, Chennai) Department of Mechanical

l Engineering

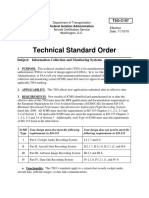

Course Title: TOTAL QUALITY MANAGEMENT Department : Mechanical Engineering Semester : Eight Course Instructor : M.R.RAVEENDRAN, AP / MECH

Number of Credits: 3 Programme : B.E Academic Year : 2013 -2014

Prerequisite Courses : Engineering Economics, Principles of Management, Computer Aided Manufacturing

Text Books: T1.Dale H.Besterfiled, et al., Total Quality Management, Pearson Education Asia, III Ed, Indian Reprint, 2006. Reference Books : R1.James R. Evans and William M. Lindsay, The Management and Control of Quality, (6th Edition), South-Western (Thomson Learning), 2005. R2.Oakland, J.S. TQM Text with Cases, Butterworth Heinemann Ltd., Oxford, Third Edition, 2003. R3.Subburaj R., Total Quality Management, Tata McGraw-Hill Education Private Ltd, 2005 R4.Suganthi, L and Anand Samuel, Total Quality Management, Prentice Hall (India) Pvt. Ltd., 2006. R5.Janakiraman,B and Gopal, R.K, Total Quality Management Text and Cases, Prentice Hall (India) Pvt. Ltd., 2006. e-Learning Resources : https://www.msu.edu/course/fsm/325/l_tqm.pd tqmnotes.blogspot.com/ freevideolectures.com Business Management IIT Kharagpur www.iannauniversity.com/.../ge2022-total-quality-manage... Instructor Mail : Raveen_82mech@yahoo.co.in Course Objectives : At the end of the course the student should be able 1. To understand the basics Quality Management 2. To understand the fundamentals of Six sigma. 3. To understand the constructional features of Management tools 4. To understand the basics of ISO procedures

Course Plan: Sl.No. Unit Unit I- INTRODUCTION Topics to be Discussed Introduction - Need for quality Unit Objectives Referenc e No. of Periods Required

To Understand familiar with quality

T1

T1

Evolution of quality, Definition of quality - Dimensions of manufacturing and service quality, Basic concepts of TQM

To understand the origin of TQM

To understand some basic concepts of TQM

T1

Definition of TQM TQM Framework Contributions of Deming, Juran and Crosby CAD/CAM software packages, Barriers to TQM

To understand the basic frame work

T1

T1 To understand about packages

Total : 9 Leadership Strategic quality 6 planning Quality statements - Customer focus Customer orientation, Customer satisfaction, Customer complaints, Customer retention Employee involvement Motivation, Empowerment Team and Teamwork Recognition and Reward, Performance appraisal Continuous process improvement PDSA cycle, 5s, Kaizen - Supplier To be familiar with Leadership Principles T1 2

Unit II - TQM PRINCIPLES

T1

8 9 10 11

To understand the functions of a Quality and about Customers

T1 T1 T1

1 2 1 1

To understand the significance of Customers

T1

Total : 9 12 13 14 15 16 17 18 Total : 9 20 21 22 23 24 25 UNIT III- TQM TOOLS & TECHNIQUES I

The seven traditional tools of quality New management tools Six-sigma: Concepts, methodology applications to manufacturing service sector including IT Bench marking Reason to bench mark- Bench marking process FMEA Stages, Types

To understand the old tools of Management To understand about the new tools of Management To understand the rejection techniques To be able to familiar with Target setiing To understand the basics Failures in industries

T1 T1 T1 T1 T1 T1 T1

1 1 1 1 1 1 1

UNIT IV- TQM TOOLS & TECHNIQUES II

Quality circles Quality Function Deployment (QFD) TPM Concepts, improvement needs Cost of Quality Performance measures

To understand the Quality circumstances To be able to familiar with cost and quality To be able to familiar with measures of performance

T1 T1 T1 T1 T1 T1

2 1 2 2 1 1

Total : 9 26 27 28 29 UNIT V- QUALITY SYSTEMS

Need for ISO 9000- ISO 90002000 Quality System Elements, Documentation, Quality auditing Concepts, Requirements and Benefits Case studies of TQM Implementation in manufacturing systems, service sectors including IT.

To understand the functions of ISO To be able to familiar Documentation and Maintenance

T1 T1 T1 T1

2 2 2 1

30

T1

Total 45

Additional Contents over and above the curriculum:

Module I

35

Difference between Six & Three Sigma in It sector

To understand the implementation issues

T1

Module II

36

Latest ISO tools

To understand the implementation issues

T1

Total : 9 Total duration required : 45 periods + 6 periods for Tests = 45 Periods Assignments / Tutorials / Case Study / Innovative Work : Assignment : A1. Implemantation of Six Sigma in IT sector Submission Deadline for A1 : March 25th, 2013 A2. Implemantation of TPM IT sector Submission Deadline for A2 : February 25, 2013 Case Study / Innovative Work: C1. C1: Conduct a Innovative Work on TQM software packages

Course Assessment Plan:

1. Internal Assessment (20) 1.1 Internal Assessment Test 1 will be conducted for 50 Marks. (5*2=10 & 2*20=40) 1.2 Internal Assessment Test 2 will be conducted for 50 Marks. (5*2=10 & 2*20=40) 1.3 Internal Assessment Test 3 will be conducted for 50 Marks. (5*2=10 & 2*20=40) Tests as per the schedule given by the university - Best two performance is considered for assessment out of 15. 1.4 Course Attendance assessment out of 5 ( Attendance percentage 96-100 : 5; 91-95 : 4; 86-90 : 3; 81-85 : 2; 76-80 : 1) 2. External Assessment (80) University will conduct end semester examination for 100 marks (10*2=20 & 5*16=80) Performance will be considered for assessment out of 80. Course Outcome: The outcome of this course is that the students understand the basics of Management Principles. The students are able to manage Quality concepts. The students are able to understand the basics of Database Management System. They also gain knowledge about the Industrial management issues. PEOs Mapping : This Course is conducted to achieve the following Programme Educational Objectives (PEOs): I. Be able to apply the principle of Mechanical engineering, Mathematics, Mechatronics, Automobile Engineering and related Engineering field to solve real time problems appropriate to the discipline and succeed in the career. II. III. IV. Be able to contribute and communicate effectively in multidisciplinary projects and perform services related to mechanical engineering to meet the customer requirements satisfactory in both quality and quantity. Function with ethics and responsibility and also professionally involve and contribute to the society. Update the modern trends in engineering and technology through continuous learning and be the leaders in their professional society. The Outcome of this course facilitate to attain the following Program Outcomes (POs): Outcome c: Graduates will demonstrate an ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability, and sustainability. Outcome k : an ability to use the techniques, skills, and modern engineering tools necessary for engineering practice

COURSE INSTRUCTOR

HOD/MECH

PRINCIPAL

Вам также может понравиться

- MT II QP 3 TestДокумент2 страницыMT II QP 3 TestRavee IndОценок пока нет

- SL - No CO Questions Cognitive LevelДокумент1 страницаSL - No CO Questions Cognitive LevelRavee IndОценок пока нет

- Placement Record 2012-2013 MRRДокумент3 страницыPlacement Record 2012-2013 MRRRavee IndОценок пока нет

- Course Plan (Version No: 1 Date: 3.2.2016) Course Coordinator Name: M.R.Raveendran Department: Mechanical EngineeringДокумент2 страницыCourse Plan (Version No: 1 Date: 3.2.2016) Course Coordinator Name: M.R.Raveendran Department: Mechanical EngineeringRavee IndОценок пока нет

- Ex No. 5 (A) EX No 5. (B) EX No 5. (C) EX No 5. (D)Документ1 страницаEx No. 5 (A) EX No 5. (B) EX No 5. (C) EX No 5. (D)Ravee IndОценок пока нет

- Pre Analysis Diagram-MCTRДокумент2 страницыPre Analysis Diagram-MCTRRavee IndОценок пока нет

- Cad Cam Lab - EquipДокумент2 страницыCad Cam Lab - EquipRavee IndОценок пока нет

- Course File Content Check List-BCДокумент1 страницаCourse File Content Check List-BCRavee IndОценок пока нет

- Study of Shaping Machine: BaseДокумент3 страницыStudy of Shaping Machine: BaseRavee IndОценок пока нет

- Computer Aided Drafting and Modelling LAb 05-12-20141Документ3 страницыComputer Aided Drafting and Modelling LAb 05-12-20141Ravee IndОценок пока нет

- Ex No. 5 (A) EX No 5. (B) EX No 5. (C) EX No 5. (D)Документ1 страницаEx No. 5 (A) EX No 5. (B) EX No 5. (C) EX No 5. (D)Ravee IndОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Caldon Lefm 240ci Ultrasonic Flow Meters: Integral Manifold DesignДокумент6 страницCaldon Lefm 240ci Ultrasonic Flow Meters: Integral Manifold DesignJim LimОценок пока нет

- Business Plan - A TeahouseДокумент6 страницBusiness Plan - A TeahouseJoe DОценок пока нет

- Adhesive Film & TapeДокумент6 страницAdhesive Film & TapeJothi Vel MuruganОценок пока нет

- Basler Electric TCCДокумент7 страницBasler Electric TCCGalih Trisna NugrahaОценок пока нет

- 2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyДокумент9 страниц2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyNMarkatosОценок пока нет

- Reservoir Bag Physics J PhilipДокумент44 страницыReservoir Bag Physics J PhilipJashim JumliОценок пока нет

- Sco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Документ4 страницыSco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Udaya PrathimaОценок пока нет

- Computer in Community Pharmacy by Adnan Sarwar ChaudharyДокумент10 страницComputer in Community Pharmacy by Adnan Sarwar ChaudharyDr-Adnan Sarwar Chaudhary100% (1)

- Hailey College of Commerce University of PunjabДокумент12 страницHailey College of Commerce University of PunjabFaryal MunirОценок пока нет

- 12 Constructor and DistructorДокумент15 страниц12 Constructor and DistructorJatin BhasinОценок пока нет

- Tso C197Документ6 страницTso C197rdpereirОценок пока нет

- Modular ResumeДокумент1 страницаModular ResumeedisontОценок пока нет

- 5070 s17 QP 22 PDFДокумент20 страниц5070 s17 QP 22 PDFMustafa WaqarОценок пока нет

- Eu Clinical TrialДокумент4 страницыEu Clinical TrialAquaОценок пока нет

- Catalogo HydronixДокумент68 страницCatalogo HydronixNANCHO77Оценок пока нет

- Mtech Vlsi Lab ManualДокумент38 страницMtech Vlsi Lab ManualRajesh Aaitha100% (2)

- Pepcoding - Coding ContestДокумент2 страницыPepcoding - Coding ContestAjay YadavОценок пока нет

- Gifted Black Females Attending Predominantly White Schools Compressed 1 CompressedДокумент488 страницGifted Black Females Attending Predominantly White Schools Compressed 1 Compressedapi-718408484Оценок пока нет

- Chapter 12Документ15 страницChapter 12kk5522Оценок пока нет

- 2017-04-27 St. Mary's County TimesДокумент32 страницы2017-04-27 St. Mary's County TimesSouthern Maryland OnlineОценок пока нет

- Enemies Beyond Character Creation SupplementДокумент8 страницEnemies Beyond Character Creation SupplementCain BlachartОценок пока нет

- Cs205-E S3dec18 KtuwebДокумент2 страницыCs205-E S3dec18 KtuwebVighnesh MuralyОценок пока нет

- Menara PMB Assessment Criteria Score SummaryДокумент2 страницыMenara PMB Assessment Criteria Score SummarySyerifaizal Hj. MustaphaОценок пока нет

- Cutler Hammer Dry Type TransformerДокумент220 страницCutler Hammer Dry Type TransformernprajanОценок пока нет

- Altura Architect & Interior Design BriefДокумент56 страницAltura Architect & Interior Design BriefDave WongОценок пока нет

- Performance Evaluation Report For Practicum TraineesДокумент2 страницыPerformance Evaluation Report For Practicum TraineesJ.S100% (3)

- ФО Англ.яз 3клДокумент135 страницФО Англ.яз 3клБакытгуль МендалиеваОценок пока нет

- Andromeda: Druid 3 Warborn06Документ5 страницAndromeda: Druid 3 Warborn06AlanОценок пока нет

- 120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnДокумент9 страниц120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnAlex TranОценок пока нет

- Line Integrals in The Plane: 4. 4A. Plane Vector FieldsДокумент7 страницLine Integrals in The Plane: 4. 4A. Plane Vector FieldsShaip DautiОценок пока нет