Академический Документы

Профессиональный Документы

Культура Документы

Bond Strength of The Brick Masonry

Загружено:

IAEME PublicationИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bond Strength of The Brick Masonry

Загружено:

IAEME PublicationАвторское право:

Доступные форматы

International Journal of Civil Engineering and Technology (IJCIET), INTERNATIONAL JOURNALJuly- December (2012), ISSN 0976 6308 AND

D OF CIVIL ENGINEERING (Print), ISSN 0976 6316(Online) Volume 3, Issue 2, IAEME TECHNOLOGY (IJCIET)

ISSN 0976 6308 (Print) ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), pp. 380-386 IAEME: www.iaeme.com/ijciet.asp Journal Impact Factor (2012): 3.1861 (Calculated by GISI) www.jifactor.com

IJCIET

IAEME

BOND STRENGTH OF THE BRICK MASONRY

C.Freeda Christy1, R.Mercy Shanthi2 and D. Tensing3 School of Civil Engineering, Karunya University, Coimbatore-641114, Tamil Nadu, India

ABSTRACT This paper presents the experimental investigations of small burnt clay brick masonry samples. The shear bond strength has been obtained from 3 brick triplets. An experimental programme examining the bond strength of mortar-unit joints was therefore carried out, using mortars with and without pozzolans. It has been found that the strength and deformation characteristics of masonry constituents obtained from these tests are more representative of the actual composite behaviour of masonry. But, there is a need for energy efficient and environment friendly alternative materials for masonry. Fly ash blocks or bricks represent one such alternative for masonry applications. The deformation characteristics of individual brick and mortar have been determined and found to be different due to the composite action between the brick and mortar joint. The research quantified the differences in bond strengths achieved with various mortar/masonry unit combinations. Keywords: Bricks, bond, pozzalona, triplet INTRODUCTION Masonry is a material built with brick units and mortar. Behaviour of masonry greatly depends on the characteristics of masonry units, mortar and the bond between them. Bond strength is dependent on many interrelated factors that can directly affect bond development (e.g. unit surface absorption, pore structure, mortar composition, mortar water retentivity and curing conditions) or indirectly affect bond strength (e.g. unit surface texture and workmanship). It was also suggested that both mortar quality and surface absorption criteria of the masonry unit are the most significant parameters in developing good bond and bond strength, Goodwin and West (1982)1 and McGinley (1990)2. While the surface absorption characteristics define the rate and volume of water to move from the mortar to the unit and the quality of the mortar defines the amount of water available at the interface and the strength of hydration products deposited in the unit surface pores.

380

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308 (Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

BRICKS Brick is a ceramic material mainly used in construction industry and it is one of the most important building materials. Its production process involves forming of clay into rectangular blocks of standard size, followed by firing to temperature ranging from 900 1200C. It is made of clay or shale and when given desired shape is dried and fired into a durable ceramic product. Energy consumption and pollution are the two important environmental and cost concerns related to the brick industry. Compressive strength of brick is important as an indicator of masonry strength and as a result brick strength has become an important requirement in brickwork design. Surface characteristics and suction are the most important properties in determining bond capability. Other durability indices have also been developed based on relationship of porosity and water absorption. (i) Major usage in the world for construction is clay bricks; many researchers are presently looking for newer options because they need low cost materials, which are also environmentally friendly. The process of manufacturing clay bricks also requires high energy to burn due to the emission of CO2 gas from this process. Fly ash, a waste industrial product is being used in cement and building material industries. The effect of brick absorption property due to variable raw materials used in its manufacturing was shown by Surej et al. (1998)3. The property of total absorption capacity of the brick is also very important for the performance of the brick. A high absorption results in vulnerability to volume changes that would result in cracking of the bricks and structural damage in buildings. It also would lead to cracking in the event of freezing and thawing of the water inside the pores. Too little absorption also not desired, because rain water rather than getting partially absorbed by the brick would tend to run off very quickly towards the joints and may find its way into the building as well as reduce the durability of the mortar joints. The absorption is the amount of water which is taken up from the mortar to fill pores in the clay brick. Water absorption tests were performed on fly ash bricks and clay bricks as per IS 3495 (1992)4. Water absorption of bricks is usually measured by 24 h cold immersion test allows water to be absorbed into pores, which are easily filled under cold condition where all pores are filled up with water. The average comparison of water absorption in the clay bricks and the fly ash bricks is shown in Fig.1.

Water absorption of bricks

15.0 10.0 5.0 0.0 Fly ash bricks Clay bricks

Fig.1 Comparison of water absorption in fly ash bricks and the clay bricks The water absorption of both clay brick and the fly ash brick were within the limit of 20% of its weight. The water absorption of the clay brick was observed as 13.7% higher than the fly ash brick. From the results, it was understood that fly ash brick has moderate level of water absorption behaviour and hence fly ash based construction may yield good structure performance.

381

Water absorption of bricks in %

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308 (Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

INITIAL RATE OF ABSORPTION (IRA) The initial rate of absorption is of great importance for laying the bricks and bonding with the mortar. Mariarosa Raimondo (2009)5 reported that a high IRA results in too quick drying of the mortar and strung out for the bed joint and stiffens so rapidly that the bricks in the next course cannot be properly bedded and thus weakens the mortar and reduces its adherence to the brick. On the other hand, if the IRA is too low, the surface of the brick adjacent to the mortar would absorb the excess water and the bricks tend to float on the mortar bed, which makes it difficult to lay plumb walls at a reasonable rate and result in very weak layer of the mortar that would not have penetrated enough into the surface crevices and pores of the brick. In either case there will be poor bond. The bond between the brick and the mortar is largely influenced by the capacity of the brick to absorb water and the ability of the mortar to retain the water. This water is needed for the proper hydration of cement where the mortar contacts the brick. The power of a brick to absorb water is measured by the initial rate of absorption as per ASTM C 67 (2009)6. Masonry walls built using brick units with a low initial rate of absorption (IRA) often have lower bond strength than walls built with moderate IRA units because very little water is available to be absorbed into the unit during installation into the wall. Therefore, high absorption brick should be wetted prior (3 hrs to 24 hrs) to lying in order to reduce the absorption and allow the brick's surface to dry. Drysdale et al (1992)7 observed that if IRA is less than 0.25g/cm2/min, which is a case for low absorption bricks, then such bricks may tend to flow on mortar particularly if the bricks are damp. On the other hand if IRA is more than 1.5g/cm2/min a poor brick mortar bond may result because of rapid suction of water in mortar by bricks. The details of the initial rate of absorption experiment are indicated in Fig.2.

Fig. 2 Test on brick for initial rate of absorption The brick specimen is weighed as w1. Then the brick is placed into 1cm depth of water for 60 seconds. Finally, the brick is removed from water and weighed as w2. The initial rate of absorption (IRA) or suction is the rate of absorption of water in the first minute after contact of the bed surface with water. The IRA is calculated as, Initial Rate of Absorption (IRA) in (gram/cm2/ minute) = (w2 w1) / contact area ---- Eq 1 Excessive water suction in the brick can lead to considerable reduction in brick masonry strength, because bricks absorb excess amount of water from the mortar and thus interfere with complete hydration of the cement. In this experiment initial rate of absorption obtained for clay brick was 0.16g/cm2/min and for the fly ash brick was 0.63 g/cm2/min respectively. From the results, it was understood that the bond between the clay brick and the cement mortar is less when compared to the fly ash brick and the cement mortar. MORTAR MIX Mortar is used as a means of sticking or bonding bricks together and to take up all irregularities in the bricks. Although mortars form only a small proportion of a masonry wall as a whole, its characteristics have a large influence on the quality of the brick masonry. The

382

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308 (Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

primary mechanism for the development of bond strength is cement hydration (the chemical action initiated when water is added to cement). High cement-content mortars are thus beneficial, as discussed by Samia Guirguis (2003)8 in which a considerably higher bond strength was achieved using a 1:1/4:3 (cement:lime:sand) mortar than when using a 1:1:6 mortar. Also discussed that the movement of fine particles (cementitious components and fine sand) towards the brick/mortar interface while the mortar is still fluid is extremely important in developing bond between the mortar and the masonry units. The utilization of fly ash as cement replacement material in mortar or as additive in cement introduces many benefits from economical, technical and environmental points of view as per Erdog Du (1998)9. The use of fly ash is accepted in recent years primarily due to saving of cement, consuming industrial waste and making durable materials, especially due to the improvement in the quality stabilization of fly ash, as stated by Li Yijin (2007)10. Fly ash is another type of pozzolanic material widely being used as a cement/fine aggregate replacement as reported by Rajamane (2007)11. Many researchers, viz. Rafat (2003)12 and Chaid et al (2004)13 indicated that low-calcium fly ash (class F) improves the interfacial zone microstructures. Portland cement hydrates to produce calcium hydroxide as much as 20% to 25% by weight. Joshi and Lohitia (1997)14 reported that, when the pozzolanic materials in the form of fly ash are added to the cements, the C-H of hydrated cement is consumed by the reactive SiO2 portion of these pozzolanas. This pozzolanic reaction improves the microstructure of cement composites as additional C-S-H gel is formed and also the pore size refinement of the hydrated cement occurs. BOND STRENGTH The function of mortar in masonry wall is to bind the individual bricks or blocks together to form a single element to resist the movement and stress; and (in external walls) provide as a weather proof barrier. The bond between the mortar and the masonry units is one of the most important properties of masonry construction, particularly when it is load bearing such as in low-rise buildings. The bond between the mortar and the masonry units is one of the most important properties of masonry construction. Poor bond and low bond strength is a major weakness of brickwork. This bond is affected by many interrelated factors associated with both masonry units and mortar. The mortar with partial replacement of fine aggregate with fly ash is varied (0%, 10% and 20%) and studied for the bond strength. The intent was to enhance the bond strength of the masonry by altering the microstructure of the mortar-unit interface. The shear characteristics of the brick masonry and the interfacial interaction parameters of brick/mortar joint were determined on masonry prism; by triplet prism test as reported by Sarangapani (2002)15. There are two types of bonds between the mortar and the brick units: chemical and friction. Tensile strength at the interface is primarily due to the chemical bond. Hence, the chemical bond depends upon the absorption rate of the brick units as reported by Reda Taha and Shrive (2002)16. Therefore, high absorption rate of the brick units decreases the strength of the bond. Thus, brick units are usually wetted with water before they are laid. The shear strength at the interface between the surface of mortar layer and the surface of the brick unit is by the friction and the chemical bond between the mortar and the brick units. The purpose for testing an assemblage of triplet brick prism is to determine the maximum bond-shear strength retained by the joint between the mortar and the brick. The bond shear strength is determined by testing a triplet specimen such that only shear stresses develop in between the mortar and the masonry unit contact planes as shown in Fig. 3.

383

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308 (Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME July

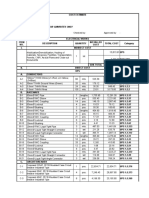

Fig. 3 Triplet bond test on brick masonry Bond strength of brick masonry triplet prisms was investigated in this test. The unreinforced triplet brick prisms of size 230mm x 220mm x 110mm were used in this study. The reinforced brick prisms were made with woven mesh at the bed joints of the brick masonry. The mortar used for the construction has the ratio of 1: 6 cement mortar mix with 0%, 10% and 20% replacement of fine aggregate with fly ash. The clay brick masonry (CBM) and the fly ash brick masonry (FBM) with partial replacement of fine aggregate with fly ash of (CBM10, CBM20, FBM10 and FBM20) were tested for both unreinforced and reinforced with woven wire mesh (CBMR, CBM10R, CBM20R, FBM, FBM10R and FBM20R). The shear strength was obtained from the triplet test as shown in Fig.3, where the brick in the re middle is sheared and the upper and lower bricks are supported. The vertical shear load (P (Pv) was applied at the uniform rate with a hydraulic jack until shear failure occurred. The masonry specimen is considered as a short beam subjected to an average bond stress and subjected evaluated as; Bond stress, b = Pv / 2A --------------- Eq 2 Where, Pv = Vertical compressive load in N; A = Cross sectional area of the triplet prism in mm2; mm The triplet shear prism detail with the breaking load and the bond stress (b) for various brick ) prisms are reported in Table 1. Table 1 Triplet shear prism detail Specimen Hexagonal wire Specimen dimension mesh (mm) CBM Unreinforced 250x220x110 CBM10 Unreinforced 250x220x110 CBM20 Unreinforced 250x220x110 CBMR Reinforced 250x220x110 CBM10R Reinforced 250x220x110 CBM20R Reinforced 250x220x110 FBM Unreinforced 250x220x110 FBM10 Unreinforced 250x220x110 FBM20 Unreinforced 250x220x110 FBMR Reinforced 250x220x110 FBM10R Reinforced 250x220x110 FBM20R Reinforced 250x220x110

384

Breaking load (N) 3234 3498 4752 5742 5544 7260 11946 24948 20988 44946 72996 62964

Bond stre strength, (b) MPa 0.064 0.069 0.094 0.113 0.110 0.143 0.236 0.493 0.415 0.888 1.443 1.244

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308 (Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

The shearing load at failure is recorded as the maximum capacity of shear force retained by brick mortar bond. Lourenco (2004)17 reported that the shear strength of brick masonry along the bed joint is the function of the bond strength between the mortar and the brick units under zero compressive load. The comparison of bond stress of the brick masonry is depicted in Fig.4.

Bond strength on brick masonry

1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 Bond strength, MPa

0% FA 10%FA 20% FA

CBM

CBMR

FBM

FBMR

Unreinforced and reinforced clay brick and fly ash brick masonry

Fig. 4 Bond strength of brick masonry From the results, it was found that the bond strength of reinforced clay brick masonry in the ratio of 1:6 cement mortar was increased to 43.68% than unreinforced clay brick masonry. Also, the bond strength of reinforced fly ash brick masonry in 1:6 cement mortar was increased to 73.42% than the unreinforced fly ash brick masonry. The clay brick masonry with 20% replacement of fine aggregate with fly ash in 1:6 cement mortar gave the higher bond strength. Further, the fly ash brick masonry with 10% replacement of fine aggregate with fly ash in the ratio of 1:6 cement mortar gave the higher bond strength as it react with the pozzalona to produce strong calcium silicate hydrates. Reda Taha and Shrive (2002)16 reported that the reactivity of the pozzolanas affects the interface bond development as the high reactive pozzolanas allow for early formation of the CSH gel and these strong hydrates will provide the mechanical interlock between the unit and the mortar enhancing the bond strength. CONCLUSIONS

Based on the triplet shear test, the presence of fly ash had a strong influence on the brick-mortar joint. The bond strength of unreinforced clay brick masonry in the ratio of 1:6 cement mortar with 20% replacement of fine aggregate with fly ash was 1.45 times more than the unreinforced clay brick masonry in the ratio of 1:6 cement mortar. The bond strength of reinforced clay brick masonry in the ratio of 1:6 cement mortar with 20% replacement of fine aggregate with fly ash was 1.5 times more than the unreinforced clay brick masonry. The bond strength of reinforced fly ash brick masonry in the ratio of 1:6 cement mortar with 10% replacement of fine aggregate with fly ash was twice than the unreinforced fly ash brick masonry. Incorporation of fly ash in the brick masonry resulted in the reaction of pozzolanas with the calcium hydrate which produced strong calcium silicate hydrates, thus enhancing the bond strength of the brick masonry with the modification of the microstructure of the mortar-brick unit interface.

385

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308 (Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

REFERENCES 1. Goodwin, J.F. and West, W.H. (1982). A Review of the Literature on Brick/Mortar Bond, Proceedings of the British Ceramic Society, Vol. 30, No. 23, pp. 23-37 2. McGinley, W.M. (1990). IRA and The Flexural Bond Strength of Clay Brick Masonry, Masonry : Components to assemblages, Matthys, J.H., Ed., American Society for Testing and Materials, ASTM STP 1063, pp. 217-234 3. Surej Rk, Fazio P, Feldman D (1998). Development of new Durability Index For Clay Bricks, J. Architectural Eng., p. 87-93 4. IS 3495 : Part 1 to 4 : 1992 Methods of tests of burnt clay building bricks - Part 1 : Determination of compressive strength - Part 2 : Determination of water absorptionPart3 : Determination of efflorescence - Part 4 : Determination of warpage, Bureau of Indian Standards, New Delhi, India, 1992 5. Mariarosa Raimondo, Michele Dondi, Davide Gardini, Guia Guarini and Francesca Mazzanti, Predicting the initial rate of water absorption in clay bricks, Construction and Building Materials, Vol 23, 2009, p 2623 6. ASTM C- 67-09, Standard test method of sampling and testing brick and structural clay tile, ASTM standard, USA 2009 7. Drysdale R G, Hamid A A and Baker L R, Masonry structures behavior and design, Prentice Hall Inc. A Simon and Schuster Company, Englewood Cliffs, New Jersey, 1992, p 763 8. Samia Guirguis, July 2003, Masonry bond strength, Cement and concrete association of Australia, pp 1- 4 9. Erdog Du and Turker P, Effects of fly ash particle size on strength of portland cement fly ash mortars, Cement Concrete Research, Vol 28, 1998, p 1217 10. Li Yijin, Zhou Shiqiong, Yin Jian and Gao Yingli, International workshop on Development and Concrete Technology, The effect of fly ash on the fluidity of Cement paste, mortar, and concrete 2007, p 339 11. Rajamane N P, Annie Peter J and Ambily P S, Prediction of compressive strength of concrete with fly ash as sand replacement material Cement and Concrete Composites, Vol 29, 2007, p 218 12. Rafat Siddique, Effect of fine aggregate replacement with class F fly ash on the mechanical properties of concrete, Cement and Concrete Research, Vol 33, 2003, p 539 13. Chaid R, Jauberthie R and Rendell F, Influence of a natural pozzolana on the properties of high performance mortar, Indian Concrete Journal, 2004, p 22 14. Joshi R C and Lohitia R P, Advances in concrete Technology, edited by Malhotra, Gordon and Breach Science Publishers, Netherlands, 1997, p 24 15. Sarangapani G, Venkatarama Reddy B V and Jagadish K S, Structural characteristics of bricks, mortars and masonry, Journal of Structural Engineering, Vol 29, No 2, July 2002, p 101 16. Reda Taha M M and Shrive N G, The use of pozzalons to improve bond and bond strength 9th Canadian Masonry Symposium, 2002 17. Lourenco P B, Barros J O and Oliveira J T, Shear testing of stack bonded masonry, Construction and Building Materials, Vol 18, 2004, p 125

386

Вам также может понравиться

- Experimental Study On Compressive Strength of Sediment Brick MasonryДокумент7 страницExperimental Study On Compressive Strength of Sediment Brick MasonryPradip SarkerОценок пока нет

- Watershed ManagementДокумент10 страницWatershed ManagementSai RamОценок пока нет

- A Review The Effect and Behaviour of Concrete Using Lime Stone PowderДокумент6 страницA Review The Effect and Behaviour of Concrete Using Lime Stone PowderIJRASETPublicationsОценок пока нет

- Effect of Water-Cement Ratio On The Compressive Strength of Gravel - Crushed Over Burnt Bricks Concrete.Документ9 страницEffect of Water-Cement Ratio On The Compressive Strength of Gravel - Crushed Over Burnt Bricks Concrete.Alexander DeckerОценок пока нет

- Predicting The Drying Shrinkage Behavior of High SДокумент10 страницPredicting The Drying Shrinkage Behavior of High SjasonОценок пока нет

- Filler Slab Report PDFДокумент65 страницFiller Slab Report PDFabhishek p100% (1)

- Construction and Building Materials: Kaijian Huang, Xijun Shi, Dan Zollinger, Mirmilad Mirsayar, Aiguo Wang, Liwu MoДокумент9 страницConstruction and Building Materials: Kaijian Huang, Xijun Shi, Dan Zollinger, Mirmilad Mirsayar, Aiguo Wang, Liwu MoRamón RamalhoОценок пока нет

- ConcreteДокумент42 страницыConcreteAmos kiprutoОценок пока нет

- Reinforced MasonaryДокумент37 страницReinforced MasonaryRAHULОценок пока нет

- Engineered Cementitious Composites For Structural ApplicationsДокумент8 страницEngineered Cementitious Composites For Structural ApplicationsInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Research ArticleДокумент10 страницResearch ArticlePankaj MunjalОценок пока нет

- Experimental Study Light Weight Concrete Using LECA, Silica Fumes, and Limestone As AggregatesДокумент10 страницExperimental Study Light Weight Concrete Using LECA, Silica Fumes, and Limestone As AggregatesIJRASETPublicationsОценок пока нет

- Durability of Concrete With Differential Concrete Mix DesignДокумент10 страницDurability of Concrete With Differential Concrete Mix Designshoyeeb ahmedОценок пока нет

- Building Mat II HANDOUTДокумент100 страницBuilding Mat II HANDOUTBiruktawitОценок пока нет

- Civil - IJCE - Internal Curing Paper111Документ8 страницCivil - IJCE - Internal Curing Paper111iaset123Оценок пока нет

- What Is Concrete?Документ5 страницWhat Is Concrete?tracyvanaОценок пока нет

- Chapter 1 Fundamentals Concrete TechnologyДокумент50 страницChapter 1 Fundamentals Concrete Technologyaman sudiОценок пока нет

- Unit 2 Aggregates: Concrete TechnologyДокумент23 страницыUnit 2 Aggregates: Concrete TechnologyAnonymous WalvB8Оценок пока нет

- Effects of Salt Water On ConcreteДокумент6 страницEffects of Salt Water On ConcretePaschal Maziku100% (1)

- Material HandoutДокумент77 страницMaterial Handoutgebretsadikaraya211626Оценок пока нет

- Horpibulsuk 2010Документ11 страницHorpibulsuk 2010Gloria MolinaОценок пока нет

- No Fine Mix DesignДокумент8 страницNo Fine Mix DesignSANJAY TОценок пока нет

- 3 ReportДокумент41 страница3 ReportGatha S.GiridharОценок пока нет

- In Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteДокумент9 страницIn Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteA M Yasin ArmanОценок пока нет

- Use of Quarry Dust in The Binding Mortar and Its Effect On Mechanical Characteristics of Brick MasonryДокумент14 страницUse of Quarry Dust in The Binding Mortar and Its Effect On Mechanical Characteristics of Brick MasonryCarlo ElopreОценок пока нет

- Final BodyДокумент63 страницыFinal BodyAbubakar MusaОценок пока нет

- Dr. C. D. Modhera - Day 3 - Session 1Документ93 страницыDr. C. D. Modhera - Day 3 - Session 1mbgfknjhgfОценок пока нет

- Clogging Mechanism of Permeable Concrete A ReviewДокумент10 страницClogging Mechanism of Permeable Concrete A ReviewGuilherme GesserОценок пока нет

- Prediction of Early Age Shrinkage of Reinforced Cement ConcreteДокумент4 страницыPrediction of Early Age Shrinkage of Reinforced Cement ConcreteSurabhiBhatОценок пока нет

- Mathematical Model To Predict The Permeability of Water Transport in Concrete StructureДокумент7 страницMathematical Model To Predict The Permeability of Water Transport in Concrete StructureAntonioRodriguezОценок пока нет

- Experimental Study On Concrete Using Glass Powder and Granite PowderДокумент5 страницExperimental Study On Concrete Using Glass Powder and Granite PowderijaertОценок пока нет

- 01 Cotm 2103 HandoutДокумент102 страницы01 Cotm 2103 HandoutDëø VølëñtëОценок пока нет

- 08 Bhshan A. BawaskarДокумент20 страниц08 Bhshan A. BawaskaranilОценок пока нет

- Influence of Recycled Aggregate On Slump and Bleeding of Fresh ConcreteДокумент8 страницInfluence of Recycled Aggregate On Slump and Bleeding of Fresh ConcreteAlfredo Landaverde GarcíaОценок пока нет

- 5 AmornpunyapatДокумент17 страниц5 Amornpunyapatmahdi najafzadehОценок пока нет

- Sriravindrarajah2012 PDFДокумент8 страницSriravindrarajah2012 PDFLokesh KОценок пока нет

- Mathew Proposal Final FinalДокумент44 страницыMathew Proposal Final FinalDr. MirandaОценок пока нет

- Lab 2 FullreportДокумент12 страницLab 2 FullreportMuhammad Zikry Bin RosliОценок пока нет

- Concrete Technology Assignment 1Документ18 страницConcrete Technology Assignment 1Boiki RabewuОценок пока нет

- Influence of Cement Dose On The Durability of Structures in Stabilized Compressed Earth BlocksДокумент12 страницInfluence of Cement Dose On The Durability of Structures in Stabilized Compressed Earth BlocksIJAR JOURNALОценок пока нет

- Assigment 1 For BSCДокумент16 страницAssigment 1 For BSCSaddam Abdulrahman AlazzaniОценок пока нет

- The Effect of Water Cement Ratio (WCR) On Compressive StrengthДокумент7 страницThe Effect of Water Cement Ratio (WCR) On Compressive StrengthfaresОценок пока нет

- Structural Behavior of Lightweight Interlocking Brick SystemДокумент13 страницStructural Behavior of Lightweight Interlocking Brick SystemnawirОценок пока нет

- An Experimental Investigation On Stabilized Mud MortarДокумент9 страницAn Experimental Investigation On Stabilized Mud MortarasyreenhaikalОценок пока нет

- Influence of Fibers On Drying Shrinkage in Restrained ConcreteДокумент13 страницInfluence of Fibers On Drying Shrinkage in Restrained ConcreteBenharzallah KrobbaОценок пока нет

- Water Absorption Capacity of Low Calcium Fly Ash and Slag Based Geopolymer ConcreteДокумент4 страницыWater Absorption Capacity of Low Calcium Fly Ash and Slag Based Geopolymer Concretealok chaudharyОценок пока нет

- Ces 412 Unit 1 Les 1-2Документ31 страницаCes 412 Unit 1 Les 1-2JessaОценок пока нет

- Influence of Fibers On Drying Shrinkage in Restrained ConcreteДокумент3 страницыInfluence of Fibers On Drying Shrinkage in Restrained ConcreteIcha FarisaОценок пока нет

- Kshuboo 2nd PaperДокумент5 страницKshuboo 2nd PaperPriyanshiОценок пока нет

- CONCRETEДокумент14 страницCONCRETEabubakar mukhtarОценок пока нет

- Chapter Three Concrete Composition of ConcreteДокумент30 страницChapter Three Concrete Composition of ConcreteFekadu AberaОценок пока нет

- Water Absorption Capacity of Concrete Cubes With Sorptivity CoefficientДокумент7 страницWater Absorption Capacity of Concrete Cubes With Sorptivity CoefficientfurqanОценок пока нет

- Microstructure As A Critical Factor of Cement Mortars' Behavior: The Effect of Aggregates' PropertiesДокумент11 страницMicrostructure As A Critical Factor of Cement Mortars' Behavior: The Effect of Aggregates' PropertiesKhang LaiОценок пока нет

- Ijciet: ©iaemeДокумент13 страницIjciet: ©iaemeIAEME PublicationОценок пока нет

- Concret CementДокумент29 страницConcret CementKamal Hameed Al-taiy100% (1)

- Chapter-1: 1.1 GENERALДокумент55 страницChapter-1: 1.1 GENERALvineela saiОценок пока нет

- Chapter-1 Concrete: 1.2 Properties of Concrete: 1.2.1 Increase of Strength With AgeДокумент59 страницChapter-1 Concrete: 1.2 Properties of Concrete: 1.2.1 Increase of Strength With AgeN. Neeraj kumarОценок пока нет

- Porous ConcreteДокумент23 страницыPorous ConcreteSunanda Desai Ramteerth100% (1)

- Unit 8Документ16 страницUnit 8sandeep nandaОценок пока нет

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsОт EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsОценок пока нет

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyДокумент14 страницModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationОценок пока нет

- Voice Based Atm For Visually Impaired Using ArduinoДокумент7 страницVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationОценок пока нет

- Broad Unexposed Skills of Transgender EntrepreneursДокумент8 страницBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationОценок пока нет

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiДокумент16 страницInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationОценок пока нет

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesДокумент10 страницImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationОценок пока нет

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesДокумент15 страницAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationОценок пока нет

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaДокумент9 страницA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationОценок пока нет

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentДокумент13 страницA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationОценок пока нет

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesДокумент18 страницRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationОценок пока нет

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurДокумент7 страницA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationОценок пока нет

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiДокумент16 страницA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationОценок пока нет

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESДокумент9 страницEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationОценок пока нет

- A Review of Particle Swarm Optimization (Pso) AlgorithmДокумент26 страницA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationОценок пока нет

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentДокумент8 страницKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationОценок пока нет

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDДокумент19 страницApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationОценок пока нет

- Various Fuzzy Numbers and Their Various Ranking ApproachesДокумент10 страницVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationОценок пока нет

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsДокумент13 страницOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationОценок пока нет

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsДокумент8 страницDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationОценок пока нет

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksДокумент10 страницA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationОценок пока нет

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsДокумент13 страницAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationОценок пока нет

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelДокумент9 страницFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationОценок пока нет

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorДокумент7 страницModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationОценок пока нет

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceДокумент7 страницQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationОценок пока нет

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionДокумент6 страницSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationОценок пока нет

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsДокумент13 страницPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationОценок пока нет

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceДокумент5 страницA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationОценок пока нет

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsДокумент9 страницAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationОценок пока нет

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesДокумент6 страницEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationОценок пока нет

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationДокумент7 страницFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationОценок пока нет

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsДокумент10 страницIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationОценок пока нет

- Alexander C. Scordelis and Concrete ShellsДокумент39 страницAlexander C. Scordelis and Concrete ShellsErick OsorioОценок пока нет

- Pile Foundation Analysis Cap. 3Документ34 страницыPile Foundation Analysis Cap. 3Angel Cuellar100% (1)

- Angulo CoronamientoДокумент1 страницаAngulo CoronamientoJoel Pacheco DiazОценок пока нет

- E62 Cable DuctsДокумент8 страницE62 Cable DuctsAnorld WalkerОценок пока нет

- Greenhouse StructuresДокумент8 страницGreenhouse StructuresjancudakОценок пока нет

- Report On Folded Plates & Space FrameДокумент12 страницReport On Folded Plates & Space FrameShez ZyОценок пока нет

- Global Review of Spray-On Structural Lining Technologies: Subject Area: InfrastructureДокумент184 страницыGlobal Review of Spray-On Structural Lining Technologies: Subject Area: InfrastructuresaishankarlОценок пока нет

- Architectural Connections GuideДокумент70 страницArchitectural Connections GuideTon LeeОценок пока нет

- BoqДокумент2 страницыBoqJohn Carlo TolentinoОценок пока нет

- 4.5.33 Guidelines For Lime Stabilization PDFДокумент4 страницы4.5.33 Guidelines For Lime Stabilization PDFVictor Thobias100% (1)

- AAN016 V1 U StructFluidsДокумент18 страницAAN016 V1 U StructFluidspaularibОценок пока нет

- Making Structure More Sustainable: Unbonded P-T I-Sects (Voided Slab) Maturity SensingДокумент32 страницыMaking Structure More Sustainable: Unbonded P-T I-Sects (Voided Slab) Maturity SensingGokul KgsОценок пока нет

- Dynaflo DP 60hz CatalogДокумент44 страницыDynaflo DP 60hz Catalognpclap67% (3)

- Circulation in Vertical DirectionДокумент10 страницCirculation in Vertical DirectionMugdha BakdeОценок пока нет

- Inventaa Hollow WallsДокумент6 страницInventaa Hollow WallsSumedh GuptaОценок пока нет

- Mechanical and Electrical System (BFC 32602) Sem I 2020/2021 Assignment: Answer All QuestionsДокумент3 страницыMechanical and Electrical System (BFC 32602) Sem I 2020/2021 Assignment: Answer All Questionscxyung98Оценок пока нет

- Thermiculite 815Документ1 страницаThermiculite 815Benoit LabreОценок пока нет

- Fatigue - A Complex Subject - Some Simple ApproximationsДокумент107 страницFatigue - A Complex Subject - Some Simple Approximationslcm327Оценок пока нет

- Twin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveДокумент7 страницTwin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveMoriyasu NguyenОценок пока нет

- Analyses and Use of Software Ansys and Franc2d For Fracture MechanicsДокумент8 страницAnalyses and Use of Software Ansys and Franc2d For Fracture MechanicsPradeep KunduОценок пока нет

- Tube Fittings BMT SuperlokДокумент66 страницTube Fittings BMT SuperlokmsajanjОценок пока нет

- Ceramic-Disc-Brakes ReportДокумент17 страницCeramic-Disc-Brakes ReportArjun Sagar.100% (2)

- Technical Data Sheet For The HSV Stud Anchor Technical Information ASSET DOC 2331315Документ5 страницTechnical Data Sheet For The HSV Stud Anchor Technical Information ASSET DOC 2331315seroloОценок пока нет

- Presentación Diseño Por Desempeño - Es.enДокумент65 страницPresentación Diseño Por Desempeño - Es.enbasabi12Оценок пока нет

- Creep Void Detection in 1Cr.5Mo (13CrMo44) Steels PDFДокумент2 страницыCreep Void Detection in 1Cr.5Mo (13CrMo44) Steels PDFriz121477Оценок пока нет

- What Is PlumbingДокумент22 страницыWhat Is PlumbingTroychristian MallariОценок пока нет

- Cost Estimation of Socialized HousingДокумент3 страницыCost Estimation of Socialized HousingDesiree IndacОценок пока нет

- Thermosel BrochureДокумент2 страницыThermosel BrochuremegacobОценок пока нет

- Technical SpecificationsДокумент258 страницTechnical SpecificationsSami HilalОценок пока нет

- Simple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Документ5 страницSimple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Bißék ŚílwàlОценок пока нет