Академический Документы

Профессиональный Документы

Культура Документы

Garments A Z

Загружено:

Zaman ParvezИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Garments A Z

Загружено:

Zaman ParvezАвторское право:

Доступные форматы

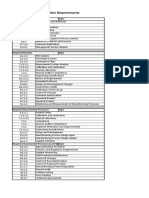

Chapter 1 Merchandising 1 1.1 Introduction 2 1.2 Literature survey 3 1.2.1 Primary survey 3 1.2.2 Secondary survey 8 1.2.

2(a) Costing 11 1.2.2(b) Preparation of BOM 13 1.2.2(c) Approvals 13 1.2.2(d) Preparation of the order file and maintenance of the same 14 1.2.2(e) Procurement of materials 14 1.2.2(f) Issue of materials to the fabric department 15 1.2.2(g) Pre production meeting 16 1.2.2(h) Production monitoring 17 1.2.2(i) Order completion report 19 1.3 Records maintained/merchandisers package file 20 1.4 Process flow 22 1.5 Questionnaire 24 Chapter 2 fabric store 26 2.1 Introduction 27 2.2 Literature survey 28 2.2.1 Primary survey 28 2.2.1.1 Inspection procedures 30 2.2.1.2 Four point system for fabric checking 30 2.2.1.3 Different types of defects 31 2.2.1.4 Shade banding 32 2.2.2 Secondary survey 33 2.2.2.1 Department statistics 33 2.2.2.2 Vendors 34 2.2.2.3 Some general procedures 35 2.2.2.3.1 Fabric store process control procedure 35 2.2.2.3.2 Shrinkage test 36 2.2.2.3.3 The dyeing process 36 2.2.2.3.4 Color fastness test 37 2.2.2.3.5 Points to be ensured before the fabric is discharged to the production 37 2.2.2.3.6 Other observations 38 2.2.2.4 Capacity calculation 39 2.4 Records maintained 40 2.5 Process flow 41 2.6 Problems observed 42 Chapter 3 accessories store 43 3.1 Introduction 44 3.2 Literature survey 45 3.2.1 Primary survey 45 3.2.1.1 Functions of the trims store 46 3.2.1.2 Units for Measurement of Accessories 47 3.2.1.3 Trim store process control procedure 48 3.2.1.4 Types of trims stored in the department are: 50 3.2.1.4.1 Standard strengths for threads 51 3.2.1.4.2 Button performance 52 3.2.1.4.3 Wash care Label details 53 3.2.2 Secondary survey 54

3.2.2.1 Goods procurement procedure 55 3.2.2.2 Vendors 56 3.2.2.3 Trims inspection 57 3.2.2.4 Other accessories in the store 59 3.2.2.5 Some general procedures 62 3.2.2.6 Infrastructure 64 3.3 Reports maintained 65 3.4 Process flow 68 3.5 Questionnaire 69 Chapter 4 spreading and cutting 71 4.1 Introduction 72 4.2 Literature survey 73 4.2.1 Primary survey 73 4.2.1.1 Spreading quality 74 4.2.1.2 Marker placing 75 4.2.2 Secondary survey 76 4.2.2.1 Cut Order Planning 76 4.2.2.2 Order Assignments 77 4.2.2.3 Fabric Requisition and Stores Procedures 79 4.2.2.4 Sub Storing Procedure 79 4.2.2.5 Lay Planning 79 4.2.2.6 Spreading Activity 80 4.2.2.7 How to handle bowing? 82 4.2.2.8 Quality controller 83 4.2.2.9 Roles of a Spreader 84 4.2.2.10 Cutting Activity 86 4.2.2.11 Block cutting/re-cutting 87 4.3 Department statistics 88 4.3.1 Cutting machine 88 4.3.2 Sharpening abrasive belt 88 4.3.3 Tables for spreading and cutting 89 4.3.3.4 Department hierarchy 89 4.3.3.5 Some general observations 90 4.4 Records maintained 92 4.5 Process flow 93 4.6 Questionnaire 95 Chapter 5 sorting and bundling 98 5.1 Introduction 99 5.2 Literature survey 100 5.2.1 Primary survey 100 5.2.2 Secondary survey 102 5.2.2.1 General observations 102 5.3 Records maintained 105 5.4 Process flow 106 5.5 Questionnaire 107 Chapter 6 sampling 108 6.1 Introduction 109 6.2 Literature survey 110 6.2.1 Primary survey 110 6.2.2 Secondary survey 112 6.2.2.1 Pattern making for sampling 112 6.2.2.1(a) Basic requirements for pattern development 112 6.2.2.2 Standard operating procedures 113 6.2.2.3 Grading in CAD 114

6.2.2.4 Proto sample making 114 6.2.2.5 Ensuring the fit 114 6.2.2.6 Pre production sample 115 6.2.2.7 Size set 115 6.2.2.8 Sewing the samples 115 6.2.2.9 Inputs 115 6.2.2.10 Quality parameters in sampling 116 6.2.2.11 Machines 116 6.2.2.12 some general procedures 117 6.3 Records maintained 118 6.4 Process flow 120 6.5 Questionnaire 122 Chapter 7 Pre production planning and R & D 123 7.1 Introduction 124 7.2 Literature survey 125 7.2.1 Primary survey 125 7.2.2 Secondary survey 127 7.2.2.1 Production and control activities 127 7.2.2.1.1 Production report 127 7.2.2.1.2 Billing report 127 7.2.2.1.3 Shift wise production report 127 7.2.2.1.4 Line wise WIP Report 127 7.2.2.1.5 Management review report 128 7.2.2.1.6 Finishing WIP Report 128 7.2.2.1.7 Dispatch report 128 7.2.2.1.8 Embroidery report 128 7.2.2.1.9 Factory report of the month 128 7.2.2.1.10 Reports comprise of 129 7.2.2.2 Planning 130 7.2.2.3 R & D of a style 131 7.2.2.4 Devising new methods 133 7.2.2.3.1 Jugaad 133 7.3 Records maintained 134 7.4 Process flow 135 7.4.1 Pre production 135 7.4.2 R & D 136 Chapter 8 finishing and packing 138 8.1 Introduction 139 8.2 Literature survey 140 8.2.1 Primary survey 140 8.2.1.1 Finishing and packaging 140 8.2.1.2 Standards in finishing department 141 9.2.2 Secondary survey 142 8.2.2.1 Button marking & Attachment 142 8.2.2.2 Thread trimming 142 8.2.2.3 General checking and mending 142 8.2.2.4 Spotting 143 8.2.2.5 Loose threads 143 8.2.2.6 Measurement 144 8.2.2.7 Pressing 144 8.2.2.8 Measurement after pressing 144 8.2.2.9 Checking of marks 144 8.2.2.10 Final Inspection 144 8.2.2.11 Folding 144 8.2.2.12 Needle Detecting 145

8.2.2.13 Tagging 145 8.2.2.14 Polybag packaging 145 8.2.2.15 Size sorting and carton packing 146 8.2.2.16 Problems due to finishing 146 8.2.2.17 Trims used in finishing 147 8.2.2.18 hierarchy 147 8.2.2.19 packing parameters 148 8.2.2.20 Hanger packing 149 8.3 Records maintained 150 8.4 Process flow 151 8.4.1 Finishing 151 8.4.2 Packaging 153 8.5 Questionnaire 155 Chapter 9 quality 157 9.1 Introduction 158 9.2 Literature survey 159 9.2.1 Primary survey 159 9.2.1.1 General checkpoints 159 9.2.2 Secondary survey 161 9.2.2.1 Work instruction 161 9.2.2.1.1 Fabric audit 161 9.2.2.1.2 Cut parts inspection 162 9.2.2.1.3 End line checking 162 9.2.2.1.4 Basic quality flaws due to stitching 163 9.2.2.1.5 Audit 164 9.2.2.1.6 Filter points 164 9.2.2.1.7 Re checking 164 9.2.2.1.8 Post pressing inspection 165 9.2.2.1.9 Online audit 165 9.2.2.1.10 Inspection points 166 9.3 Records maintained 167 9.4 Process flow 168 9.5 Questionnaire 169 Chapter10 Pattern making and CAD 170 10.1 Introduction 171 10.2 Literature survey 172 10.2.1 Primary survey 172 10.2.1.1 Pattern making 172 10.2.1.2 CAD 172 10.2.2 Secondary survey 173 10.2.2.1 Requirements of the pattern making and the CAD department 174 10.2.2.2 Documents maintained 174 10.2.2.3 Software used 175 10.2.2.4 Digitizer 175 10.2.2.4.1 Process of digitizing 176 10.2.2.5 Grading 177 10.2.2.6 Cut order planning 177 10.2.2.7 Marker making 178 10.2.2.8 Plotter 179 10.3 Records maintained 180 10.4 Process flow 181 Chapter 11 maintenance 183 11.1 Introduction 184

11.2 Literature survey 185 11.2.1 Primary survey 185 11.2.1.1 Maintenance 185 11.2.1.1.1 Functions on the department 187 11.2.1.2 Service 187 11.2.1.3 Machine maintenance 187 11.2.1.3.a Breakdown maintenance 187 11.2.1.3.b Corrective maintenance 188 11.2.1.3.c Preventive maintenance 188 11.2.1.3.d Scheduled maintenance 188 11.2.1.4 Need of maintenance 188 11.2.2 Secondary survey 189 11.2.2.1 Maintenance schedule 189 11.2.2.2 Housekeeping 190 11.2.2.2.1 Housekeeping schedule 190 11.2.2.3 Needle handling 191 11.2.2.3.1 The needle replacement procedure 191 11.2.2.3.2 Needle control policy 192 11.2.2.3.3 Broken needle replacement procedure 193 11.2.2.4 Daily activities of this department include following checking's 193 11.2.2.5 Following to be checked every 15 days 194 11.2.2.6 Other activities 194 11.2.2.7 Machines in the industry 195 11.3 Records maintained 197 11.4 Questionnaire 198 Chapter 12 Industrial engineering 199 12.1 Introduction 200 12.2 Literature survey 201 12.2.1 Primary survey 201 12.2.2 Secondary survey 208 12.2.2.1 Responsibilities of the IE department 208 12.2.2.2 Line balancing 209 12.2.2.2.1 The purpose of production line balancing 209 12.2.2.2.2 Effective line balancing or planning depends on 211 12.2.2.3 Line setting 211 12.2.2.4 I.E. and necessities 212 Chapter 13 sewing 213 13.1 Introduction 214 13.2 Literature survey 215 13.2.1 Primary survey 215 13.2.1.1 Standard operating procedure in production department 215 13.2.1.2 Quality process in sewing line. 216 13.2.1.3 Requirements of sewing section 216 13.2.2 Secondary survey 218 13.2.2.1 Style analysis and line plan 218 13.2.2.2 Pre production meeting 218 13.2.2.3 Order planning 218 13.2.2.4 Order planning in the factory 219 13.2.2.5 Production system 220 13.2.2.5.1The progressive bundle system 220 13.2.2.6 Batch setting procedure 222 13.2.2.7 Bulk production 223 13.2.2.8 Material handling equipment 223 13.2.2.9 The layout 224

13.2.2.10 General observations at the floor 224 13.2.2.11 Problems encountered 226 13.3 Records maintained 226 13.4 Process flow 228 13.5 Questionnaire 229 Chapter 14 style study 232 14.1 About the style 233 14.1.1 Sample worksheet 234 14.1.2 Specifications for sewing of the garment 235 14.2 Bill of materials 236 14.3 Measurement chart 237 14.4 Operation breakdown 238 14.5 Time study 241 14.5.1 Spreading 242 14.5.2 Cutting 242 14.5.3 Sewing 243 14.6 Method study 262 14.7 The line plan 273 14.8 Cut order planning 275 14.9 Order tracking 276 14.10 Costing 277 Chapter 15 Appendix 279 15.1 Alteration report 280 15.2 Visual inspection report 281 15.3 Size set/ Pilot/Initial 10 Pcs visual report 282 15.4 Broken needle investigation report 283 15.5 Fabric challan 284 15.6 Fabric inspection report 285 15.7 Issue slip 286 15.8 Preventive maintenance (Monthly) 287 15.9 Preventive maintenance (Weekly) 287 15.10 Weekly maintenance schedule for fusing machine 288 15.11 Weekly maintenance of steam press 288 15.12 AQL auditing report 289 15.16 Broken needle record 291 15.17 Costing sheet 292 15.18 Daily cutting report 293 15.19 Daily finishing report 294 15.20 End line checking 295 15.21 Metal detector product log 296 15.22 Needle detector calibrations 297 15.23 OCR Production 298 15.24 Stitching inspection report 299 15.25 Style analysis report 300 15.26 Used needle record 301 15.27 Visual inspection report 302 15.28 Layouts 303 15.28.1 Production floor layout 303 15.28.2 Process flow 304 15.28.3 Finishing 305 15.28.4 Cutting 306 15.29 Mini markers 307

Вам также может понравиться

- Handbook For Process Plant Project Engineers by Peter WatermeyerДокумент344 страницыHandbook For Process Plant Project Engineers by Peter Watermeyeramoy23Оценок пока нет

- Ray Prasad, Surface Mount Technology (SMT) 2-Nd Edition (Технология поверхностного монтажа)Документ791 страницаRay Prasad, Surface Mount Technology (SMT) 2-Nd Edition (Технология поверхностного монтажа)Михаил100% (1)

- Plaxis 2D ManualДокумент320 страницPlaxis 2D ManualAndreas Fendisa Putra100% (3)

- General Information 15: Shop Manual Hyundai I20Документ967 страницGeneral Information 15: Shop Manual Hyundai I20SOMCAR O CENTROОценок пока нет

- Biscuit, Cookie and Cracker Manufacturing Manuals: Manual 4: Baking and Cooling of BiscuitsОт EverandBiscuit, Cookie and Cracker Manufacturing Manuals: Manual 4: Baking and Cooling of BiscuitsОценок пока нет

- Kumar & Suresh - Production & Operation ManagementДокумент5 страницKumar & Suresh - Production & Operation ManagementanuanuaОценок пока нет

- Drilling Fluids Processing HandbookОт EverandDrilling Fluids Processing HandbookРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Current Area Item Assembly Process Production Qa CheckingДокумент32 страницыCurrent Area Item Assembly Process Production Qa Checkingteresa100% (1)

- Water Cad Users GuideДокумент456 страницWater Cad Users GuideGjorgji1234Оценок пока нет

- Pasos de PpapДокумент3 страницыPasos de PpapJoseLuisMartinezGarciaОценок пока нет

- Pro V10 IrricadHelp ManualДокумент964 страницыPro V10 IrricadHelp ManualNzar HamaОценок пока нет

- Ppgua Aug 2008 As Rolled Out Feb 2009Документ589 страницPpgua Aug 2008 As Rolled Out Feb 2009faiz111180100% (5)

- Concrete RemovalДокумент129 страницConcrete RemovalShuo ShiОценок пока нет

- Water Cad Users GuideДокумент440 страницWater Cad Users GuideCak UlinОценок пока нет

- Aptiv Customer Specific RequirementsДокумент41 страницаAptiv Customer Specific RequirementsHemant GuptaОценок пока нет

- IATF 16949 DocumenДокумент1 страницаIATF 16949 Documenpunitg_2Оценок пока нет

- Project Management TopicsДокумент10 страницProject Management Topicsmuhamadrafie1975Оценок пока нет

- Handbook of Quality Integrated Circuit ManufacturingОт EverandHandbook of Quality Integrated Circuit ManufacturingРейтинг: 5 из 5 звезд5/5 (1)

- PR 1051Документ28 страницPR 1051Arsalan AhmadОценок пока нет

- Plaxis 2D Reference ManualДокумент290 страницPlaxis 2D Reference Manualjames_frank0% (1)

- Title Page I Approval Sheet II Acknowledgement III V List of Tables VI List of Figures VIII X Chapter One: Introduction 1Документ6 страницTitle Page I Approval Sheet II Acknowledgement III V List of Tables VI List of Figures VIII X Chapter One: Introduction 1yelОценок пока нет

- Blue - VDA - Standardized Process For Handling Customers ComplaintsДокумент137 страницBlue - VDA - Standardized Process For Handling Customers ComplaintsOmar TellezОценок пока нет

- Rotary Clinker ThesisdesignДокумент199 страницRotary Clinker ThesisdesignGia Hưng Quách HòaОценок пока нет

- BOD2 - User Instructions - V3 - 2020 - 06Документ60 страницBOD2 - User Instructions - V3 - 2020 - 06Julia Montelin Powers100% (1)

- Efbw Guide 2012-1Документ112 страницEfbw Guide 2012-1Satya Pradeep PulakurthiОценок пока нет

- 1 Introduction To The Best Workover and Completion Practices 1Документ10 страниц1 Introduction To The Best Workover and Completion Practices 1Jerson F. PeñaОценок пока нет

- 2013 Guideline For Validation of Manual Cleaning and Manual Chemical Disinfection of Medical Devices PDFДокумент52 страницы2013 Guideline For Validation of Manual Cleaning and Manual Chemical Disinfection of Medical Devices PDFvan roadmanОценок пока нет

- Hitachi 917 Analyzer - User ManualДокумент406 страницHitachi 917 Analyzer - User Manualmylove2804100% (1)

- LMFC250 Fine Crusher ManualДокумент47 страницLMFC250 Fine Crusher ManualazelmeisОценок пока нет

- Refrigerated CentrifugeДокумент77 страницRefrigerated CentrifugeAlex SarmientoОценок пока нет

- QRS01Документ62 страницыQRS01Stephen WanjihiaОценок пока нет

- Ista Rules 2022 02 Sampling 1Документ52 страницыIsta Rules 2022 02 Sampling 1maritzaОценок пока нет

- UFGS Watertube BoilersДокумент94 страницыUFGS Watertube BoilersDeclanОценок пока нет

- G4 F CDC Final Project ReportДокумент226 страницG4 F CDC Final Project ReportDiệu Anh NguyễnОценок пока нет

- A Study On Apparel Export Order From The Time of Receipt Till The Time of ShipmentДокумент44 страницыA Study On Apparel Export Order From The Time of Receipt Till The Time of ShipmentSHRUTI CHUGH100% (1)

- Moe SaplДокумент214 страницMoe Saplsarveshkdahiya100% (2)

- Apparel Internship Report (Silver Spark Apparel LTD Unit-2, Gauribidanur)Документ108 страницApparel Internship Report (Silver Spark Apparel LTD Unit-2, Gauribidanur)nitinkr10100% (5)

- Clausul IATFДокумент8 страницClausul IATFAhmad ZainuddinОценок пока нет

- IntroДокумент6 страницIntroYash RayuduОценок пока нет

- Part - I Instruction To Tenderers and 1.1Документ19 страницPart - I Instruction To Tenderers and 1.1Hemanth KumarОценок пока нет

- IATF IA CHecklistДокумент2 страницыIATF IA CHecklistDamodaran RajanayagamОценок пока нет

- Relativity - Admin Guide - 8.2 PDFДокумент450 страницRelativity - Admin Guide - 8.2 PDFGu ZhipengОценок пока нет

- Iso 9001:2008 To Iso 9001:2015 Cross Reference Chart 436850307Документ21 страницаIso 9001:2008 To Iso 9001:2015 Cross Reference Chart 436850307avinash_k007Оценок пока нет

- Piping and Instrumentation Diagram A Stepwise Approach (Avinashkumar Vinodkumar Karre) (Z-Library)Документ210 страницPiping and Instrumentation Diagram A Stepwise Approach (Avinashkumar Vinodkumar Karre) (Z-Library)bonc omorogbeОценок пока нет

- Berdasarkan Penyataan Di AtasДокумент31 страницаBerdasarkan Penyataan Di AtasrajeswaryОценок пока нет

- Ray P. Prasad (Auth.) - Surface Mount Technology - Principles and Practice-Springer Netherlands (1989)Документ616 страницRay P. Prasad (Auth.) - Surface Mount Technology - Principles and Practice-Springer Netherlands (1989)Muhammad Fatiyan RizkilahОценок пока нет

- ZF QD83-2018 - English-French - WebДокумент70 страницZF QD83-2018 - English-French - WebBESОценок пока нет

- TCVN 6474-2007 EngДокумент366 страницTCVN 6474-2007 EngPham Ngoc Khan100% (1)

- Studio Rip XF ManualДокумент193 страницыStudio Rip XF ManualWillian CastilloОценок пока нет

- Biscuit, Cookie and Cracker Manufacturing Manuals: Manual 2: Biscuit DoughsОт EverandBiscuit, Cookie and Cracker Manufacturing Manuals: Manual 2: Biscuit DoughsОценок пока нет

- Industrial Process Control: Advances and ApplicationsОт EverandIndustrial Process Control: Advances and ApplicationsРейтинг: 2 из 5 звезд2/5 (1)

- Lean Maintenance: Reduce Costs, Improve Quality, and Increase Market ShareОт EverandLean Maintenance: Reduce Costs, Improve Quality, and Increase Market ShareРейтинг: 5 из 5 звезд5/5 (2)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersОт EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersОценок пока нет

- Biscuit, Cookie and Cracker Manufacturing Manuals: Manual 5: Secondary Processing in Biscuit ManufacturingОт EverandBiscuit, Cookie and Cracker Manufacturing Manuals: Manual 5: Secondary Processing in Biscuit ManufacturingОценок пока нет

- Creatively Focused Teamwork Stress Multi Task Fast: Pro-Active Critical Path TrackingДокумент2 страницыCreatively Focused Teamwork Stress Multi Task Fast: Pro-Active Critical Path TrackingZaman ParvezОценок пока нет

- Creatively Focused Teamwork Stress Multi Task Fast: Pro-Active Critical Path TrackingДокумент2 страницыCreatively Focused Teamwork Stress Multi Task Fast: Pro-Active Critical Path TrackingZaman ParvezОценок пока нет

- New Microsoft Office Word DocumentДокумент6 страницNew Microsoft Office Word DocumentZaman Parvez100% (1)

- 450 WongДокумент12 страниц450 WongZaman ParvezОценок пока нет

- Need To KnowДокумент30 страницNeed To KnowZaman ParvezОценок пока нет

- SPCДокумент7 страницSPCZaman ParvezОценок пока нет

- SPCДокумент7 страницSPCZaman ParvezОценок пока нет

- Random InspectionДокумент12 страницRandom InspectionZaman ParvezОценок пока нет

- Sampling Plan For Product InspectionДокумент16 страницSampling Plan For Product InspectionZaman ParvezОценок пока нет

- New Microsoft Office Word 97 - 2003 DocumentДокумент2 страницыNew Microsoft Office Word 97 - 2003 DocumentZaman ParvezОценок пока нет

- Product Quality ChecklistДокумент5 страницProduct Quality ChecklistZaman ParvezОценок пока нет

- PO TemplateДокумент2 страницыPO TemplateZaman ParvezОценок пока нет

- Sampling Plan For Product InspectionДокумент16 страницSampling Plan For Product InspectionZaman ParvezОценок пока нет

- PO TemplateДокумент2 страницыPO TemplateZaman ParvezОценок пока нет

- Random InspectionДокумент12 страницRandom InspectionZaman ParvezОценок пока нет

- Sampling Plan For Product InspectionДокумент16 страницSampling Plan For Product InspectionZaman ParvezОценок пока нет

- Product InspectionДокумент16 страницProduct InspectionZaman ParvezОценок пока нет

- Sampling Plan For Product InspectionДокумент16 страницSampling Plan For Product InspectionZaman ParvezОценок пока нет

- Product InspectionДокумент16 страницProduct InspectionZaman ParvezОценок пока нет

- Product InspectionДокумент16 страницProduct InspectionZaman ParvezОценок пока нет

- Product Quality ChecklistДокумент5 страницProduct Quality ChecklistZaman ParvezОценок пока нет

- 15 Ways To Avoid Problems With Your Suppliers Ebook v1.0Документ11 страниц15 Ways To Avoid Problems With Your Suppliers Ebook v1.0Zaman ParvezОценок пока нет

- Product InspectionДокумент16 страницProduct InspectionZaman ParvezОценок пока нет

- Sampling Plan For Product InspectionДокумент16 страницSampling Plan For Product InspectionZaman ParvezОценок пока нет

- AQLДокумент6 страницAQLarivaazhiОценок пока нет

- 15 Ways To Avoid Problems With Your Suppliers Ebook v1.0Документ11 страниц15 Ways To Avoid Problems With Your Suppliers Ebook v1.0Zaman ParvezОценок пока нет

- Cost of Quality in GarmentsДокумент4 страницыCost of Quality in GarmentsZaman ParvezОценок пока нет

- SkillDevt TextileToday Jan2010Документ1 страницаSkillDevt TextileToday Jan2010Zaman ParvezОценок пока нет

- Cost of QualityДокумент2 страницыCost of QualityZaman Parvez100% (1)

- A Factory Case Study - WORK STUDYДокумент4 страницыA Factory Case Study - WORK STUDYreplyjoe4Оценок пока нет

- SAP Ariba Solutions and SAP S4HANA The Path To Procurement TransformationДокумент2 страницыSAP Ariba Solutions and SAP S4HANA The Path To Procurement TransformationJose SantosОценок пока нет

- Melling Supplier Quality Manual Rev 12Документ21 страницаMelling Supplier Quality Manual Rev 12ALEX MURPHYОценок пока нет

- Chapter 1 - Introduction To Engineering DesignДокумент0 страницChapter 1 - Introduction To Engineering DesignwanpudinОценок пока нет

- System Engineering Gudie BookДокумент323 страницыSystem Engineering Gudie BookArifОценок пока нет

- Crescent International Bakelite ProjectДокумент7 страницCrescent International Bakelite ProjectMuhammad Mubasher Rafique100% (1)

- Kaizen (Continuous Improvement) & Quality CirclesДокумент2 страницыKaizen (Continuous Improvement) & Quality Circlespinku_smile100% (1)

- Slitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)Документ3 страницыSlitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)smartcad60Оценок пока нет

- 7 Tools of Total Quality ManagementДокумент19 страниц7 Tools of Total Quality ManagementJeet Pawar100% (1)

- Job Order CostingДокумент8 страницJob Order CostingAndrea Nicole MASANGKAYОценок пока нет

- A Study of Warehouse Management System in SingaporeДокумент8 страницA Study of Warehouse Management System in SingaporeRaj PalОценок пока нет

- Marketing Tools Presentasi QM CertificationДокумент10 страницMarketing Tools Presentasi QM CertificationSanti Hadi WidiyastomoОценок пока нет

- Chapter Four: Theory of Production and Cost 4.1 Introduction: Definition and Basic ConceptsДокумент34 страницыChapter Four: Theory of Production and Cost 4.1 Introduction: Definition and Basic Conceptsbrook zelekeОценок пока нет

- Chopra3 PPT ch02Документ21 страницаChopra3 PPT ch02SatishОценок пока нет

- The New Food Safety Standard ISO 22000. Assessment, Comparison and Correlation With HACCP and ISO 9000:2000. The Practical Implementation in Victual BusinessДокумент16 страницThe New Food Safety Standard ISO 22000. Assessment, Comparison and Correlation With HACCP and ISO 9000:2000. The Practical Implementation in Victual BusinessuknowgaryОценок пока нет

- Module For ACC 206 Understanding ExpensesДокумент12 страницModule For ACC 206 Understanding ExpensesMerecci Angela De ChavezОценок пока нет

- Boeing Australia LimitedДокумент11 страницBoeing Australia Limitedprameet4uОценок пока нет

- Yamazumi Chart 1 0Документ1 страницаYamazumi Chart 1 0Ayman AliОценок пока нет

- Cost Concept, Terminologies and BehaviorДокумент8 страницCost Concept, Terminologies and BehaviorANDREA NICOLE DE LEONОценок пока нет

- ODUNOLA Michael Olayinka's CVДокумент5 страницODUNOLA Michael Olayinka's CVmaverick231Оценок пока нет

- Internal AnalysisДокумент26 страницInternal AnalysisLenggi Puspita MarzukiОценок пока нет

- Design of ProcessДокумент35 страницDesign of Processsujeetleopard100% (1)

- S&OP Part II Enabling Technology Larry Lapide PDFДокумент3 страницыS&OP Part II Enabling Technology Larry Lapide PDFOmar Enrique Gonzalez RozoОценок пока нет

- Data SalesДокумент45 страницData SalesChacaОценок пока нет

- PresentationДокумент16 страницPresentationvishaldadhichОценок пока нет

- 1b.understanding Quality Procedures in SAMPLING & Sample DevelopmentДокумент15 страниц1b.understanding Quality Procedures in SAMPLING & Sample DevelopmentNeetek SahayОценок пока нет

- Optimization of Machining Parameters For Surface Roughness in Milling OperationДокумент5 страницOptimization of Machining Parameters For Surface Roughness in Milling OperationArmando Rosas GonzalitosОценок пока нет

- Supply Chain Management: Inventory Models - (Wisner Ch7 Pp. 222-234)Документ26 страницSupply Chain Management: Inventory Models - (Wisner Ch7 Pp. 222-234)Guiliano Grimaldo FERNANDEZ JIMENEZОценок пока нет

- An Application of SMED Methodology PDFДокумент4 страницыAn Application of SMED Methodology PDFIng Raul OrozcoОценок пока нет

- Ge8077 TQM Unit IV NotesДокумент30 страницGe8077 TQM Unit IV NotesTT GAMER VBKОценок пока нет