Академический Документы

Профессиональный Документы

Культура Документы

Fluxcoredwire ENG

Загружено:

Suphi YükselИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fluxcoredwire ENG

Загружено:

Suphi YükselАвторское право:

Доступные форматы

www.boehler-welding.

com

FLUX-CORED WELDING WIRES FOR STAINLESS STEELS

www.boehler-welding.com

www.boehler-welding.com

BHLER WELDING

From the very beginning of welding technology, BHLER WELDING has been one of the leading developers, manufacturers and suppliers of welding consumables worldwide. The brand BHLER WELDING offers the entire range of consumables for joint welding. Ever since 1926 customers and partners in more than 100 countries all over the world have put their trust in our products and solutions. The technical knowledge globally gained on site during these eight decades makes BHLER WELDING the preferred partner of leading enterprises in the most demanding industrial sectors. Our experienced application consultants will be pleased to develop together with you the technically and economically optimum solution for your individual requirements.

It goes without saying that our extensive product range is constantly aligned to the current industrial specifications. As one of the pioneers, we are already today working in close cooperation with our customers and partners on the innovative products and solutions of the future. If this brochure does not answer all your questions, we are at your disposal and will be pleased to advise you. For more detailed information about the listed welding consumables and/or our entire range, please refer to our BHLER WELDING manual or visit us on the internet at www.boehler-welding.com

www.boehler-welding.com

Overview

Flux-cored wires for stainless steels General benefits Cost saving potentials Special features Additional process benefits Flux-cored wires for flat and horizontal welding Flux-cored wires for positional welding Metal-cored wires High temperature flux-cored wires Operating parameters Packaging and fields of application 5 6 7 8 9 10 11 12 12 13 14

www.boehler-welding.com

Flux-cored welding wires for stainless steels

BHLER WELDING flux-cored wires combine the outstanding welding characteristics of BHLERs rutile stick electrodes with the productivity advantages of GMAW wires. BHLER WELDING flux-cored wires provide a powerful penetrating arc that deposits a smooth weld with minimum spatter formation. Additionally, precise alloy adjustments ensure high quality welds with excellent corrosion resistance and mechanical properties. To guarantee optimum weld metal chemistry and homogeneity all wires are manufactured utilizing austenitic stainless steel sheaths and agglomerated flux infills. During manufacturing, an automatic system constantly monitors production ensuring that the flux fill is uniformly distributed throughout the entire length of the wire. All wires are manufactured to DIN EN ISO 9001 quality system.

Features and benefits

BHLER flux-cored wires on basket spools, vacuum packaged in moisture resistant bags.

User friendly Reliable and consistent weld quality Smooth welding characteristics Minimum post weld cleaning Increased productivity Decreased welding costs

Take profit

from the cost effective flat & horizontal FCAW wires with their characteristics to provide fast travel speeds, reliable & consistent weld quality & smooth weld profiles from the unbeatable cost saving of FCAW wires for positional welding from decreasing downtimes to a minimum

Dewatering drum for pulp industry, Andritz AG welded with BHLER CN 22/9 N-IG (GTAW) and BHLER CN 22/9 N-FD (FCAW).

BSGA / Werner Krug

BHLER WELDING Flux-Cored Welding Wires

BSGA

www.boehler-welding.com

General benefits

BHLER stainless steel flux-cored welding wires offer a large tolerance window for welding parameters. The wire enters the spray transfer mode typically from appr. 125 Amps. 22 Volts (for 1.2 mm (0.045) wire, Ar/CO2 gas mixture and at 100 Amps, 23 Volt for 0.9 mm (0.035) wire) and produces a powerful penetrating arc that deposits a smooth spatter free weld metal. Welding parameters are consequently easy to set up. Unintentional operator changes to the welding settings can normally be tolerated without loss of quality. This results in excellent overall wire performance with reliable and consistent weld quality. This also reduces the risk of weld defects and associated repair work costs.

Spatter formation

36 34 32

Solid wire 1.2 mm (0.045) Flux-cored wire 0.9 mm (0.035)

Voltage (V)

30 28 26 24 22 20

Solid wire 1.0 mm (0.040) FCAW 1.2 mm (0.045)

Poor bead appearance

18 80 100 150 200 Amperage (A) 250 300

Solid wire 1.2 mm (0.045) The narrow arc causes deep finger penetration which can give rise to lack of side wall fusion defects. As shown above, the bottom plate is hardly fused.

Flux-cored wire 1.2 mm (0.045) Good root penetration and wetting characteristics with particularly high productivity on ceramic backing.

Flux-cored wire 1.2 mm (0.045) The wide arc provides uniform deep penetration with good side wall fusion and smooth weld profile.

BHLER stainless flux-cored wires produce weld metal with excellent bead appearance. The weld deposit is radiographically sound and spatter free with good wetting characteristics. The slag protects the weld pool from oxidation and is easily removed to reveal a smooth weld profile that requires minimum post weld cleaning.

Weld cladding welded with BHLER CN 23/12 Mo-FD (1st layer) and BHLER EAS 4M-FD (2nd layer). This is an ideal application for stainless steel flux-cored wires due to their uniform ferrite levels and optimum corrosion resistance.

Cored wires have a wider arc column than solid wires. Therefore they operate with very safe penetration. The risk of lack of side wall fusion is minimized compared to solid wire welding even when the torch is slightly misdirected due to lack of welder concentration. 6

www.boehler-welding.com

Cost saving potentials

In practical terms, the areas in which considerable economies can be realized in welding will usually be restricted to

Your time saving

Most significant savings in time can be realized in positional welding when compared to pulse GMAW using solid wires. BHLER PW-wires provide, for instance, welding of vertical up welds in half the welding time in comparison to using pulse GMAW. Productivity gains of 20 to 50% can be obtained compared with GMAW using solid wires in the flat and horizontal welding position.

the selection of a more efficient welding process (deposition rate, lbs or kg/hr) mechanisation (increasing the effective arc-time) reduction of welding downtimes (grinding, slag and spatter removal, pickling, repair rates etc.)

Cost comparison

While solid wires usually cost less than flux-cored wires it is the overall total welding costs of the finished component that needs to be taken into consideration. Flux-cored wires offer benefits that greatly reduce the overall welding costs, particularly in such areas as postweld cleaning, pickling, etc. which are often overlooked.

18

flux-cored wire 0.9 mm (0.035)

FCAW GMAW SMAW

850 mm (33.5) 700 mm (27.6) 280 mm (11.0)

8.16

16 14 12

flux-cored wire 1.2 mm (0.045) flux-cored wire 1.6 mm (1/16) solid wire 1.0 mm (0.040)

7.26 6.35 5.44

Deposition rate assuming 100% duty cycle (Ibs/h)

Comparable length of fillet welds made in one minute (throat: 3 mm, welding position 2F)

Deposition rate assuming 100% duty cycle (kg/h)

solid wire 1.2 mm (0.045) coated electrode

Welding position 1G (PA)

10 8 4.54 3.63

FCAW offers 100% faster travel speed = half welding time

5 mm (3/16)

6 2.72

4 mm (5/32)

4 2 100 200 1.81 0.91

10 mm (25/64)

Ampere

300

400

200 150 100 50 0 FCAW wire 1.2 mm (0.045) 90 mm/minute 3.5/minute GMAW wire 1.0 mm (0.040) 180 mm/minute 7/minute

Flux-cored wire 0.9 mm (0.035) 1.2 / 1.6 mm (0.035 / 1/16) Solid wire

Shielding Gas Ar + 18% CO2 Ar + 18% CO2 Ar + 2% CO2

Wire Stick-Out 15 mm (5/8) 20 mm (3/4) 12 mm (1/2)

Butt weld, 2nd layer, 3G-up, base metal UNS S 31803, 10 mm (3/8) plate

Apart from submerged arc welding, GMAW with flux-cored wire is the most productive welding process. The reason for this is the high current density (A/mm2). The current is mainly being conducted through the metal strip, which represents a smaller cross sectional area than solid wires. This in turn results in a resistance heating effect, which causes the wire to melt faster and thus yields higher deposition rates and increased productivity. The overall result being a reduction in welding time and consequently a saving on the main cost which is labor. BHLER WELDING Flux-CoredWelding Wires

Additional cost savings due to

Travel speed (mm/min)

smooth welding characteristics & weld finish less cleaning and pickling reduced costs for shielding gas increased travel speeds less repair work due to radiographically sound weld deposit and safe penetration 7

www.boehler-welding.com

Special features

Sheet metal fabrication using BHLER 0.9 mm (0.035) FCAW wires

Ideal for welding beads with small cross sectional area! For wall thickness 1.5 mm (1/16) (1F, 2F, 3F down). Spray arc transfer with minimized spatter formation with as low as 100 A / 23 V / 9 m/min (354 inch/min). Flat and smooth bead with good wetting characteristics and excellent appearance. Faster travel speeds, reduced heat input and less distortion! An excellent solution to save time and money!

Lap joint Corner joint Welding joints on 2 mm sheet metal Butt weld Fillet weld

Minimum wall thickness

Type of weld Welding position 0.9 mm fillet weld fillet weld fillet weld butt weld butt weld butt weld 2F (horizontal) 3F (vertical down) 3F (vertical up) 1G (flat) 3G (vertical down) 3G (vertical up) 1.5 1.5 5.0 1.5 2.0 5.0 Minimum wall thickness (mm) 0.035 1/16 1/16 3/16 1/16 5/64 3/16 1.2 mm 3.0 3.0 5.0 * 3.0 3.0 5.0 * 0.045 1/8 1/8 3/16 * 1/8 1/8 3/16 *

* for positional welding wires

Lower shielding gas consumption

Stainless steel flux-cored wires are welded using the commercially available shielding gases Ar and 15-25% CO2 or 100% CO2. The gas flow rate is the same as when welding solid wires using Ar and 2% CO2. This has a very positive influence on arc stability, producing a fine, spatter-free droplet transfer with safe penetration. There is no carburization or burn-off of elements with an oxygen affinity, such as chromium, which would be unacceptable for corrosion reasons. This is assured due to the fact that each single metal droplet transfered in the arc is completely covered with slag thus preventing any reaction with the shielding gas. The cost benefits to the user result from lower gas costs as well as lower gas consumption due to shorter welding time.

Complete covering of the droplet with rutile slag

Metal droplet on a flux-cored electrode

Partially peeled slag after cooling off

www.boehler-welding.com

Additional process benefits

Excellent suitability for mechanized welding. Conventional MIG/MAG welding machines are adequate for welding flux-cored welding wires. Ease of handling and troublefree processing make training and re-testing of the welders easier while at the same time maintaining and improving quality assurance aspects. Better accessibility e.g. in single-bevel T-butt welds as a result of welding with longer stick out compared to solid wire. Multi-pass weldability. Very low temper coloration on the weld surface easily removed by brushing plus good wetting and self-releasing slag render multipass welding

easier compared with solid wire especially in CrNi(Mo) steels with a higher chromium content. In addition, the amount of pickling required always remains low regardless of the number of passes. Ideal for partial welds and tack welds. Reduced storage requirement The most common wire diameter of 1.2 mm (0.045) may be used universally for wall thicknesses above 3 mm (1/8) thick with current intensities between 130 A to 280 A and spray-arc welding. In addition to this, there is 0.9 mm (0.035) for sheet metal, as well as the highly efficient PW-type for positional welding also in diameter 1.2 mm (0.045). Use of the 1.6 mm (1/16) dimensions is primarily useful to special applications in the current intensity range 280 350 A.

Mechanized welding with BHLER EAS 4 PW-FD

Application in the pulp and paper industry

BSGA

Flux-cored wires for positional welding

are easy to operate in all welding positions with one single parameter setting. offer powerful penetrating arc, spray transfer, minimum spatter formation, self releasing slag, excellent wetting behaviour, flat and smooth bead profile. enable fast travel speeds and a wide range of operating parameters offer highest productivity.

Macro section from a 49 mm (1.93) wall S 31803 duplex stainless steel pipe weld for the off-shore industry.

BHLER EAS 4 PW-FD with self-releasing slag and X-ray quality weld deposit.

BHLER WELDING Flux-Cored Welding Wires

BSGA

www.boehler-welding.com

Flux-cored wires for flat and horizontal welding

Typical all weld metal properties (shielding gas Ar + 15-25% CO2), as welded condition. Abbreviations: YS = Yield Strength, TS = Tensile Strength, EL = Elongation, CVN = Impact Strength BHLER Standard EN Standard AWS Typical analysis % C Si Mn Cr Ni 0.03 0.70 1.50 19.80 10.50 Mechanical properties N/mm2 YS TS EL CVN 380 560 40% 60 J 32 J -196C -320F mm (inch) Approvals Base metals and other characteristics AISI 304 L, AISI 304, AISI 321, AISI 347, AISI 304 LN, AISI 302. Suitable for service temperatures from -196C to +350C (-320F to 660F).

EAS 2-FD

T 19 9 L R M (C) 3 E308LT0-4(1) 0.9 mm (0.035) T 19 9 L P M (C) 1 E308LT1-4(1)

0.9 (0.035) TV-D, 1.2 (0.045) TV-A, 1.6 (1/16) CWB, GL, DB, BB, SEPROZ, CE, NAKS

SAS 2-FD

T 19 9 Nb R M (C) 3 E347T0-4(1)

C Si Mn Cr Ni Nb C Si Mn Cr Mo Ni

0.03 0.60 1.40 19.00 10.40 + 0.03 0.70 1.50 19.00 2.70 12.00

YS TS EL CVN

420 600 35% 75 J 32 J -196C -320F 400 560 38% 55 J 32 J -120C -184F

1.2 (0.045) 1.6 (1/16)

TV-D, SEPROZ, CE

AISI 347, AISI 304, AISI 321, AISI 304 L, AISI 304 LN, AISI 302. Suitable for service temperatures from -196C to +400C (-320F to 750F).

EAS 4 M-FD

T 19 12 3 L R M (C) 3 E316LT0-4(1) 0.9 mm (0.035) T 19 12 3 L P M (C) 1 E316LT1-4(1)

YS TS EL CVN

0.9 (0.035) TV-D, 1.2 (0.045) TV-A, 1.6 (1/16) CWB, GL, DB, SEPROZ, BB, CE, DNV, LR 1.2 (0.045) 1.6 (1/16)

AISI 316 L, AISI 316, AISI 316 Ti, AISI 316 Cb, AISI 316 LN. Suitable for service temperatures from -120C to +400C (184F to 750F).

SAS 4-FD

T 19 12 3 Nb R M (C) 3

C Si Mn Cr Mo Ni Nb C Si Mn Cr Mo Ni

0.03 0.60 1.30 18.80 2.70 12.20 + 0.035 0.70 1.30 18.80 3.40 13.10

YS TS EL CVN

430 570 35% 65 J 32 J -120C -184F 420 570 32% 50 J 32 J -60C -76F 600 800 27% 60 J 32 J -40C -40F

AISI 316 Cb, AISI 316 Ti, AISI 316, AISI 316 L. Suitable for service temperatures from -120C to +400C (-184F to 750F).

E 317 L-FD

T Z19 13 4 L R M (C) 3 E317LT0-4(1)

YS TS EL CVN

1.2 (0.045) 1.6 (1/16)

For CrNiMo-steels (3-4% Mo) AISI 317 L, AISI 316 LN, AISI 316 L, AISI 317 LN. With high corrosion resistance at service temperatures from -60C to +300C (-76F to 570F).

CN 22/9 N-FD

T 22 9 3 NL R M (C) 3 E2209T0-4(1)

C 0.03 Si 0.80 Mn 0.90 Cr 22.70 Mo 3.20 Ni 9.00 N 0.13 PREN 35 C 0.03 Si 0.60 Mn 1.30 Cr 24.00 Mo 0.40 Ni 9.00 N 0.13 Ferrite acc. to WRC-92 30 C Si Mn Cr Ni 0.10 0.70 6.50 18.50 8.80

YS TS EL CVN

1.2 (0.045)

TV-D, ABS, DNV, GL, RINA, SEPROZ, CWB, CE, LR, DB

UNS S31803, UNS S32205, 1.4462 similar and dissimilar joints. PREN 35. CPT ASTM G48/A or ASTM A923 Method C 22C (72F), Ferrite 30 - 50 FN. Suitable for service temperatures from -40C to +250C (-40F to 480F).

CN 24/9 LDX-FD

T Z24 9 N L R M (C) 3 E2209T0-G

YS TS EL CVN

550 755 28% 60 J 44 J -50C -58F

1.2 (0.045)

TV-D (submitted)

UNS S32101, 1.4162 Ferritic-austenitic Lean-Duplex weld metal with excellent strength and medium corrosion resistance.

A 7-FD

T 18 8 Mn R M (C) 3 E307T0-G

YS TS EL CVN

420 630 39% 60 J 32 J -100C -148F 400 540 35% 60 J 32 J -60C -76F

1.2 (0.045) 1.6 (1/16)

TV-D, CE

Universal application! Very tough & crack resistant alloy. Service temperatures -100C (-148F) up to scaling resistance of +850C (1.560F).

CN 23/12-FD

T 23 12 L R M (C) 3 E309LT0-4(1) 0.9 mm (0.035) T 23 12 L P M (C) 1 E309LT1-4(1)

C Si Mn Cr Ni

0.03 0.70 1.40 23.00 12.50

YS TS EL CVN

0.9 (0.035) TV-D, 1.2 (0.045) TV-A, CWB, 1.6 (1/16) GL, DB, BB, LR, SEPROZ, CE, DNV, RINA 0.9 (0.035) TV-D, 1.2 (0.045) TV-A, 1.6 (1/16) ABS, GL, DNV, DB, BB, RINA, SEPROZ, CE, LR, CWB 1.2 (0.045) 1.6 (1/16) TV-D, CE

Dissimilar joints between high-alloyed Cr- and CrNi-steels to un- and low-alloyed steels. Also for weld cladding. For service temperatures from -60C to +300C (-76F to 570F).

CN 23/12 Mo-FD

T 23 12 2 L R M (C) 3 E309LMoT0-4(1) 0.9 mm (0.035) T 23 12 2 L P M (C) 1 E309LMoT1-4(1)

C Si Mn Cr Mo Ni

0.03 0.60 1.40 23.00 2.70 12.50

YS TS EL CVN

500 700 30% 55 J 32 J -60C -76F

Dissimilar joints between high-alloyed Cr- and CrNi(Mo)-steels to un- and low-alloyed steels. Also for Mo containing weld cladding. For service temperatures from -60C to +300C (-76F to 570F).

NIBAS 70/20-FD

Typ Ni 6082 (NiCr20Mn3 Nb) ENiCr3T0-4

C Si Mn Cr Nb Fe Ni C Si Mn Cr Nb Fe Ni

0.03 0.40 3.20 19.50 2.50 2.50 bal. 0.03 0.30 5.50 19.70 2.40 2.00 bal.

YS TS EL CVN

400 650 39% 135 J 110 J -196C -320F 380 N/mm2 640 N/mm2 41% 130 J 115 J -196C -320F

Alloy 600, 2.4640 Ni Cr 15 Fe, 2.4817 LC-NiCr 15 Fe, 2.4867 NiCr 6015. Nickel-base FCAW wire. For welding of nickel-base alloys, high temperature steels, heat resisting and croyogenic materials, dissimilar joints. Suitable service temp. -196C (-320F) up to scaling resistance of +1.200C (2.190F) S-free atmosphere.

NIBAS 70/20 Mn-FD

Typ Ni 6082 (NiCr20Mn3Nb) ENiCr3T0-4 (mod.)

Re Rm A5 Av

1.2

Alloy 600, 2.4640 Ni Cr 15 Fe, 2.4817 LC-NiCr 15 Fe, 2.4867 NiCr 6015. Nickel-base FCAW wire. For welding of nickel-base alloys, high temperature steels, heat resisting and croyogenic materials, dissimilar joints. Suitable service temp. -196C (-320F) up to scaling resistance of +1.200C (2.190F) S-free atmosphere.

10

www.boehler-welding.com

Flux-cored wires for positional welding

Typical all weld metal properties (shielding gas Ar + 15-25% CO2), as welded condition. Abbreviations: YS = Yield Strength, TS = Tensile Strength, EL = Elongation, CVN = Impact Strength BHLER Standard EN Standard AWS Typical analysis % C Si Mn Cr Ni 0.03 0.70 1.50 19.80 10.50 Mechanical properties N/mm2 mm (inch) 1.2 (0.045) 1.6 (1/16) Approvals Base metals and other characteristics

EAS 2 PW-FD

T 19 9 L P M (C) 1 E308 LT1-4(1)

YS TS EL CVN

380 560 40% 70 J 32 J -196C -320F 390 550 40% 78 J 32 J -196C -320F 420 600 35% 75 J 32 J -120C -184F 400 560 38% 65 J 32 J -120C -184F 390 550 40% 75 J 32 J -196C -320F 430 570 35% 65 J 40 J -120C -184F

TV-D, CWB, DB, SEPROZ, BB, CE, GL

AISI 304 L, AISI 304, AISI 321, AISI 347, AISI 304 LN, AISI 302 Suitable for service temperatures from -196C to +350C (-320F to 660F).

EAS 2 PW-FD (LF)

T 19 9 L P M (C) 1 E308LT1-4(1)

C Si Mn Cr Ni

0.03 0.60 1.40 19.30 10.90

YS TS EL CVN

1.2 (0.045) 1.6 (1/16)

TV-D, CE

1.4301, 1.4306, 1.4541; AISI 304, 304 L, 304 LN, 321, 347 Controlled ferrite content 3-6 FN, cryogenic toughness and lateral expansion till -196C (-320F) e.g. for pipes in LNG-plants, excellent positional welding characteristic.

SAS 2 PW-FD

T 19 9 Nb P M (C) 1 E347T1-4(1)

C Si Mn Cr Ni Nb C Si Mn Cr Mo Ni C Si Mn Cr Mo Ni C Si Mn Cr Mo Ni Nb C Si Mn Cr Mo Ni

0.03 0.70 1.40 19.00 10.40 + 0.03 0.70 1.50 19.00 2.70 12.00 0.03 0.70 1.40 18.10 2.10 12.50 0.03 0.60 1.30 18.80 2.70 12.20 + 0.035 0.70 1.30 18.80 3.40 13.10

YS TS EL CVN

1.2 (0.045)

TV-D, SEPROZ, CE

AISI 347, AISI 304, AISI 321, AISI 304 L, AISI 304 LN, AISI 302 Suitable for service temperatures from -120C to +400C (184F to 750F).

EAS 4 PW-FD

T 19 12 3 L P M (C) 1 E316LT1-4(1)

YS TS EL CVN

1.2 (0.045) 1.6 (1/16)

TV-D, CWB, DB, SEPROZ, BB, CE, LR, DNV, GL

AISI 316 L, AISI 316, AISI 316 Ti, AISI 316 Cb, AISI 316 LN Suitable for service temperatures from -120C to +400C (184F to 750F).

EAS 4 PW-FD (LF)

T Z19 12 3 L P M (C) 1 E316LT1-4(1)

YS TS EL CVN

1.2 (0.045)

1.4401, 1.4404, 1.4571; AISI 316L, 316 Ti, 316 Cb Controlled ferrite content 3-6 FN, cryogenic toughness and lateral expansion till -196C (-320F) e.g. for pipes in LNG- plants, excellent positional welding characteristic.

SAS 4 PW-FD

T 19 12 3 Nb P M (C) 1

YS TS EL CVN

1.2 (0.045)

AISI 316 Cb, AISI 316 Ti, AISI 316 L, AISI 316

Suitable for service temperatures from -120C to +400C. (184F to 750F).

E 317 L PW-FD

T Z19 13 4 L P M (C) 1 E317LT1-4(1)

YS TS EL CVN

380 560 39% 58 J 32 J -60C -76F 600 800 27% 80 J 45 J -46C -51F

1.2 (0.045)

BV, LR, CE

For CrNiMo-steels with increased Mo-content, resp. for corrosion resistant claddings and mild steels, AISI 317L, 317LN, 316 L, 316 LN. Excellent positional welding charac-teristics and fast travel speeds.

CN 22/9 PW-FD

T 22 9 3 NL P M (C) 1 E2209T1-4(1)

C 0.03 Si 0.80 Mn 0.90 Cr 22.70 Mo 3.20 9.00 Ni N 0.13 PREN 35 C Si Mn Cr Ni 0.10 0.80 6.80 18.80 9.00

YS TS EL CVN

1.2 (0.045)

TV-D, ABS, CWB, DNV, GL, RINA, SEPROZ, CE, LR

UNS S31803, UNS S32205, 1.4462 similar and dissimilar joints. PREN 35. CPT ASTM G48/A or ASTM A923 Method C 22C (72F), Ferrite 30-50 FN. Suitable for service temperatures from -50C to +250C (-58F to 480F).

A 7 PW-FD

T 18 8 Mn P M (C) 2 E307T1-G

YS TS EL CVN

420 630 39% 65 J 32 J -100C -148F 400 540 35% 65 J 50 J -60C -76F

1.2 (0.045)

TV-D, NAKS, CE

Universal application. Very tough and crack resistant alloy. Service temperatures -100C (-148F) up to scaling resistance of +850C (1.560F).

CN 23/12 PW-FD

T 23 12 L P M (C) 1 E309LT1-4(1)

C Si Mn Cr Ni

0.03 0.70 1.40 23.00 12.50

YS TS EL CVN

1.2 (0.045) 1.6 (1/16)

TV-D, ABS, SEPROZ, CWB, DB, BB, CE, LR, GL, DNV, RINA TV-D, SEPROZ, BV, CE, LR, DNV

Dissimilar joints between high-alloyed Cr- and CrNi-steels to un- and low-alloyed steels. Also for weld cladding. For service temperatures from -60C to +300C (-76F to 570F).

CN 23/12 Mo PW-FD

T 23 12 2 L P M (C) 1 E309LMoT1-4(1)

C Si Mn Cr Mo Ni C Si Mn Cr Mo Nb Fe Ni

0.03 0.70 1.40 23.00 2.70 12.50 0.05 0.40 0.40 21.00 8.50 3.30 < 1.00 bal.

YS TS EL CVN

530 720 32% 65 J 50 J -60C -76F 500 740 40% 90 J 80 J -196C -320F

1.2 (0.045)

Dissimilar joints between high-alloyed Cr- and CrNi(Mo)-steels to un- and low-alloyed steels. Also for Mo containing weld cladding. For service temperatures from -60C to +300C (-76F to 570F).

NIBAS 625 PW-FD

Typ Ni 6625 (NiCr22Mo9Nb) ENiCrMo3T1-4

YS TS EL CVN

1.2 (0.045)

TV-D, CE

Alloy 625, Alloy 800, 2.4856 NiCr 22 Mo 9 Nb, 2.4858 NiCr 21 Mo, 2.4816 NiCr 15 Fe For high Mo-containing nickel-base alloys and dissimilar joints, creep resistant, heat resistant, cryogenic steels. Suitable service temp. -196C (-320F) up to scaling resistance of +1.200C (2.190F) s-free atmosphere. Extremely resistant to stress corrosion cracking and pitting (PREN 52).

BHLER WELDING Flux-Cored Welding Wires

11

www.boehler-welding.com

Metal-cored wires

Typical all weld metal properties (shielding gas Ar + 15-25% CO2), as welded condition. Abbreviations: YS = Yield Strength, TS = Tensile Strength, EL = Elongation, CVN = Impact Strength BHLER Standard EN Standard AWS Typical analysis % C Si Mn Cr Ni 0.03 0.60 1.40 19.80 10.50 Mechanical properties N/mm2 mm (inch) 1.2 (0.045) 1.6 (1/16) Approvals Base metals and other characteristics

EAS 2-MC

T 19 9 L MM 1 TS308L-MG1 EC308L

YS TS EL CVN

380 540 37% 105 J 32 J -196C -320F 410 560 34% 80 J 32 J -196C -320F 800 990 12% 40 J 580C/8h (1076F) 760 900 16% 65 J 47 J -20C -68F 400 600 42% 70 J 30 J -110C -230F 400 540 32% 90 J 32 J -120C -248F

TV-D, CE

1.4301, AISI 304, 1.4306, AISI 304L, 1.4541, AISI 321, AISI 347, AISI 304LN Suitable for service temperatures from -196C to +350C (-320F to 660F).

EAS 4 M-MC

T 19 12 3 L MM 1 TS316L-MG1 EC316L

C Si Mn Cr Ni Mo C Si Mn Cr Ni Mo

0.03 0.60 1.40 18.80 12.20 2.70 0.025 0.70 0.90 12.00 4.60 0.60

YS TS EL CVN

1.2 (0.045) 1.6 (1/16)

TV-D, CE

1.4401, 1.4404, 1.4571; AISI 316L, 316Ti, 316Cb Suitable for service temperatures from -196C to +400C (-320F to 750F).

CN 13/4-MC

T 13 4 MM 2 TS 410NiMo-MG1 (mod.) EC410NiMo mod.

YS TS EL CVN WBH YS TS EL CVN

1.2 (0.045) 1.6 (1/16)

SEPROZ

1.4317, 1.4313, 1.4351, ACI Grade CA 6 NM, 1.4414 For the fabrication and repair welding of hydro turbine components made of soft martensitic 13% Cr, 4% Ni alloyed steels and cast steels.

A 7-MC

T 18 8 Mn MM1 TS307-MG1 (mod.) EC307 (mod.)

C Si Mn Cr Ni C Si Mn Cr Ni

0.10 0.60 6.30 18.80 9.20 0.03 0.60 1.40 23.00 12.50

YS TS EL CVN

1.2 (0.045) 1.6 (1/16)

TV-D, DB, CE

Universal application! Crack resistant & resistant against cavitation; Very tough down to -110C (-230F), scaling resistant up to 850C (1.560F).

CN 23/12-MC

T 23 12 L MM1 TS309L-MG1 EC309L

YS TS EL CVN

1.2 (0.045) 1.6 (1/16)

Dissimilar joints of high-alloyed Cr- & CrNi(Mo)- steels with un-/low-alloyed steels, for the 1. layer of chemical-resistant claddings. Suitable for service temperatures from -120C to +300C (-184F to 570F).

Creep resistant flux-cored wires

Typical all weld metal properties (shielding gas Ar + 15-25% CO2), as welded condition. Abbreviations: YS = Yield Strength, TS = Tensile Strength, EL = Elongation, CVN = Impact Strength BHLER Standard EN Standard AWS Typical analysis % C Si Mn Cr Ni C Si Mn Cr Ni 0.05 0.60 1.20 19.40 10.10 0.05 0.60 1.20 19.40 10.10 Mechanical properties N/mm2 mm (inch) 1.2 (0.045) Approvals Base metals and other characteristics

E 308 H-FD

T Z19 9 H R M (C) 3 E308HT0-4(1)

YS TS EL CVN

390 585 42% 80 J

TV-D, CE

AISI 304 H, 321 H, 347 H, 304 Controlled ferrite content of 3 - 8 FN. Bimax < 0,001%. Suitable for service temperatures up to +700C (1.300C).

E 308 H PW-FD

T Z19 9 H P M (C) 1 E308HT1-4(1)

YS TS EL CVN

390 585 42% 90 J

1.2 (0.045)

TV-D, CE

For creep resistant austenitic CrNi-steels like AISI 304 H, 321 H, 347 H, 304 Controlled ferrite content of 3 - 8 FN. Bimax 0,001%. Suitable for service temperatures up to +700C (1.300C).

Electron probe microanalysis (EPMA) of the main alloying elements in the ferritic-austenitic microstructure of BHLER CN 22/9 PW-FD duplex weld metal

12

www.boehler-welding.com

Operating parameters

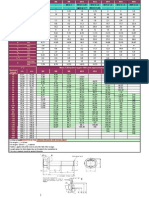

Flat and horizontal welding positions

Welding position Type of joint Wall thickness mm inch 1.5 3 5 5 10 1.5 3 7 8 - 4 - 5 - 15 - 15 - 20 - 5 - 7 - 15 - 20 1/16 1/8 3/16 3/16 3/8 1/16 1/8 9/32 5/16 5/32 3/16 19/32 19/32 25/32 3/16 9/32 19/32 25/32 Wire mm inch 0.9 1.2 1.2 1.2 1.6 0.9 1.2 1.2 1.6 0.035 0.045 0.045 0.045 1/16 0.035 0.045 0.045 1/16 Amperage A 100 130 130 200 200 100 130 200 200 160 150 150 280 350 160 220 280 350 Voltage V 22 23 22 26 25 23 22 26 25 28 24 24 30 33 28 28 30 33 Wire feed speed m /minute inch/minute 8.0 4.5 4.5 8.5 4.5 8.0 4.5 8,5 4.5 15.0 6.0 6.0 14.5 9.5 15.0 10.0 14.5 9.5 315 177 177 335 177 315 177 335 177 591 236 236 571 374 591 394 571 374

downhand and horizontal

lap joint + l-joint I-joint V-groove, root V-groove, fill+cap V-groove, fill+cap fillet weld fillet weld fillet weld fillet weld

Limit the length of arc to 3 mm (1/8) with 0.9 mm (0.035) wire 5 mm (3/16) with 1.2 mm (0.045) wire

The trailing torch angle permits good weld pool control while at the same time promoting defect free sidewall fusion, despite high deposition rates.

Torch positioning, flat and horizontal welding positions

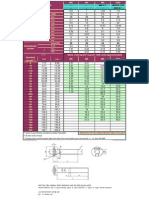

Positional welding

Optimum parameter settings for 1.2 mm (0.045) wire Welding position Type of joint Amperage A 130 150 150 140 180 180 140 170 140 180 180 170 200 200 150 190 Voltage V 23 24 24 24 26 26 23 26 26 28 28 28 29 29 25 28 Wire feed speed m/min. inch/min. 6 7 7 6.5 9 9 6.5 8 6.5 9 9 9 11 11 7 10 236 275 275 256 354 354 256 315 256 354 354 354 433 433 275 394 Range of welding parameters Amperage A Voltage V Wire feed speed inch/min. m/min.

vertical up 3G, 3F overhead 4G, 4F horizontal 2G flat postion 1G

V-groove, root pass V-groove, filler and cap Fillet weld V-groove, root pass V-groove, filler and cap Fillet weld V-groove, root pass V-groove, filler and cap

130 - 200

22 - 30

6 - 11

236 - 433

130 - 200

22 - 30

6 - 11

236 - 433

130 - 250

22 - 32

6 - 13

236 - 512

Limit the length of arc to 3 mm (1/8) with 1.2 mm (0.045) postional welding wire

Torch positioning, positional welding. Slight weaving is recommended for all welding positions

General

Dependent on the characteristics of the welding machine optimum parameter setting can vary accordingly. Recommended shielding gases are Ar and 15 - 25% CO2 or 100% CO2. (When using 100% CO2 it is necessary to increase the welding voltage by 2 V!). The gas flow rate should be 15 - 18 l/min (32 - 38 cubic feet/hr). The wire stick-out should be 15 - 25 mm (19/32 - 1) when welding 1.2 - 1.6 mm (0.045 - 1/16) wires and 12 - 20 mm (1/2 - 25/32) when welding 0.9 mm (0.035) wires. Adequate fume extraction is recommended as always when welding stainless steels. Rebaking: 150C (300F), if necessary! BHLER WELDING Flux-Cored Welding Wires 13

www.boehler-welding.com

Packaging and fields of application

Packaging

Available packaging, basket spool B 300 Flux-cored wires 0.9 mm 0.035 12.5 kg 0.9 mm 0.035 11.3 kg 1.2 mm 0.045 15 kg 1.6 mm 1/16 15 kg Metal-cored wires 1.2 mm 0.045 1.6 mm 1/16 For other forms of supply or dimensions please contact your BHLER representative. 27.6 lb 25 lb 33 lb 33 lb

(USA)

All wires are vacuum packaged in moisture resistant aluminized bags for maximum protection. BHLER WELDING flux-cored wires are precision layer wound and have excellent feeding characteristics.

16 kg 16 kg

33 lb 33 lb

Some applications

Dewatering-filter for the pulp and paper industry, base metal 1.4306 / AISI 304 L, welded with BHLER EAS 2-FD Chemical carrier, cargo vessels, UNS S 31803

Apparatus construction: Duplex steel UNS S31803 / 1.4462, wall thickness 30-40 mm, welded with BHLER CN 22/9 N-FD

Austrian Energy & Environment, Austria

Dissimilar joint weld 3F, welded with BHLER CN 23/12 Mo PW-FD

14

GTI-FIB Ind. Bedrijven bv. te Leeuwarden, NL

www.boehler-welding.com

Additional information

ZE SZUST ERKE SCHWEIS KRAFTW MISCHE FR THER

SCHWEIS SZUST WELDING CONSUMABLES ZE FR DEN STAHLB FOR THE OFFSHORE INDUSTRY AU

DIN WEL LER BH ER SELL BEST

WEL DING CON FOR SUM THE ABL CHE ES MICA L AN D PE

TRO

CHE

MICA

L IN

DUS

TRY

Other brochures about BHLER WELDING welding consumables are available in several languages for selected industries and applications. You will receive more information from the BHLER WELDING sales partners or on the internet at www.boehler-welding.com/english/brochures.htm

The specifications in regard to the type and application of our products are only for the users information. The data specified for the mechanical properties always refer to the weld metal alone under observance of the applicable standards. In the weld joint, the weld metal properties are influenced, among other factors, by the parent metal, the welding position and

the welding parameters. A guarantee of suitability for a certain type of application requires an explicit written agreement in each individual case. Subject to modifications.

Published by BHLER WELDING

Bhler Schweitechnik Austria GmbH Bhler-Welding-St. 1 8605 Kapfenberg / AUSTRIA +43 (0) 3862-301-0 +43 (0) 3862-301-95193 postmaster.bsga@bsga.at www.boehler-welding.com

Your partner:

www.boehler-welding.com

BSGA 03/2012 ENG1300 Cover picture: BHLER WELDING

Вам также может понравиться

- Fransız Elektrot Firması Seçim TablosuДокумент60 страницFransız Elektrot Firması Seçim TablosuSuphi Yüksel100% (2)

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Документ108 страницGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Suphi YükselОценок пока нет

- EN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadДокумент1 страницаEN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadSuphi YükselОценок пока нет

- Fiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Документ1 страницаFiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Suphi YükselОценок пока нет

- Outokumpu Stainless Steel HandbookДокумент92 страницыOutokumpu Stainless Steel HandbookcutefrenzyОценок пока нет

- DIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Документ1 страницаDIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Suphi YükselОценок пока нет

- DIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertДокумент1 страницаDIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertSuphi YükselОценок пока нет

- Einschlaganker Drop in Anchor: Çakma DübelДокумент16 страницEinschlaganker Drop in Anchor: Çakma DübelSuphi YükselОценок пока нет

- 10512Документ1 страница10512Suphi YükselОценок пока нет

- DIN 982 Fiberli AltiKöşe Yüksek Somunlar SpecificationsДокумент1 страницаDIN 982 Fiberli AltiKöşe Yüksek Somunlar SpecificationsSuphi YükselОценок пока нет

- M8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Документ1 страницаM8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Suphi YükselОценок пока нет

- 34801Документ1 страница34801Suphi YükselОценок пока нет

- Thread Size Chart for Metric Hex Nuts (M6 to M20Документ1 страницаThread Size Chart for Metric Hex Nuts (M6 to M20Suphi YükselОценок пока нет

- DIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarДокумент1 страницаDIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarSuphi YükselОценок пока нет

- DIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Документ1 страницаDIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Suphi YükselОценок пока нет

- P B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinДокумент1 страницаP B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinSuphi YükselОценок пока нет

- 1665Документ1 страница1665Suphi YükselОценок пока нет

- P (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeДокумент1 страницаP (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeSuphi YükselОценок пока нет

- Thread Size Chart for Metric Bolts M5 to M16Документ1 страницаThread Size Chart for Metric Bolts M5 to M16Suphi YükselОценок пока нет

- Ref. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinДокумент1 страницаRef. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinSuphi YükselОценок пока нет

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinДокумент1 страницаMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselОценок пока нет

- 6921Документ1 страница6921Suphi YükselОценок пока нет

- Mass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadДокумент1 страницаMass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadSuphi YükselОценок пока нет

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinДокумент1 страницаMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselОценок пока нет

- Storage Tanks Made of SteelДокумент6 страницStorage Tanks Made of SteelHakan Şahinoğlu100% (1)

- Thread Size Dimensions Chart for M12, M16, M20 BoltsДокумент1 страницаThread Size Dimensions Chart for M12, M16, M20 BoltsSuphi YükselОценок пока нет

- A Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Документ1 страницаA Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Suphi YükselОценок пока нет

- Solutions Guide: The Choice of Master CraftsmenДокумент20 страницSolutions Guide: The Choice of Master CraftsmenSuphi YükselОценок пока нет

- SMAW PowerpointДокумент28 страницSMAW PowerpointShankar Gurusamy100% (3)

- SKF Bearing Installation and MaintenanceДокумент146 страницSKF Bearing Installation and MaintenanceDefinal ChaniagoОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Bitumen BasicsДокумент15 страницBitumen BasicslearnafrenОценок пока нет

- ASTM A 751 - 07aДокумент6 страницASTM A 751 - 07analakasaОценок пока нет

- A-Dec Self-Contained Water System: Instructions For UseДокумент8 страницA-Dec Self-Contained Water System: Instructions For UseIliasОценок пока нет

- Lesson 3 - INORGANIC CompoundsДокумент15 страницLesson 3 - INORGANIC CompoundsKym DacudaoОценок пока нет

- 10.chemical Thermodynamics Objective by RajputДокумент3 страницы10.chemical Thermodynamics Objective by RajputMuruganantham MajesticОценок пока нет

- Banana Essence via Fisher EsterificationДокумент9 страницBanana Essence via Fisher EsterificationMaggie KabalanОценок пока нет

- Biodiesel from Waste Canola Oil Reduces EmissionsДокумент36 страницBiodiesel from Waste Canola Oil Reduces EmissionsSherwin CruzОценок пока нет

- Biomaterials Science and Engineering 2011 Intech PDFДокумент469 страницBiomaterials Science and Engineering 2011 Intech PDFraaror100% (1)

- Reversed-Phase Chromatography Principles & Mobile PhasesДокумент13 страницReversed-Phase Chromatography Principles & Mobile PhasesLeonardo GiraldoОценок пока нет

- CHE1503-001 2016 4 B PDFДокумент89 страницCHE1503-001 2016 4 B PDFsal27adamОценок пока нет

- Full Blasting Licence SyllabusДокумент1 страницаFull Blasting Licence Syllabustmadzi0% (1)

- A - Level - Periodic - Table - CambridgeДокумент1 страницаA - Level - Periodic - Table - CambridgecrpОценок пока нет

- Chemistry Project: On "" Investigate Various Constituents of Coffee "Документ12 страницChemistry Project: On "" Investigate Various Constituents of Coffee "arnav100% (1)

- VOLUMETRIC AnalysisДокумент49 страницVOLUMETRIC AnalysisLisa Dea SaryОценок пока нет

- Sr. No: CategoryДокумент42 страницыSr. No: CategoryMonti SainiОценок пока нет

- Gao, 2012 Application of Drug Nanocrystal Technologies On Oral DrugДокумент18 страницGao, 2012 Application of Drug Nanocrystal Technologies On Oral DrugGaluh Primadani100% (1)

- Mechanical Engineering: Aqua SilencerДокумент12 страницMechanical Engineering: Aqua SilencerHarish KumarОценок пока нет

- Wetting Agents and Surface ModifiersДокумент13 страницWetting Agents and Surface ModifiersSeafar YachtingОценок пока нет

- Karl FischerДокумент9 страницKarl FischerArunima GhoseОценок пока нет

- HazMat IAP PlanДокумент12 страницHazMat IAP PlanVanitta RangsitananОценок пока нет

- Chapter 3 SolidДокумент59 страницChapter 3 Solidatikah roshanОценок пока нет

- Electropolishing: Process Considerations: Better Chemistry. Better BusinessДокумент3 страницыElectropolishing: Process Considerations: Better Chemistry. Better Businessjuan carlos pulidoОценок пока нет

- Plastic Road 35pageДокумент35 страницPlastic Road 35pageME A 04 AvisekОценок пока нет

- Simulation of The Pyrolysis Process From Plastic WasteДокумент5 страницSimulation of The Pyrolysis Process From Plastic WasteManicks VelanОценок пока нет

- Most Common Welding Defects ExplainedДокумент6 страницMost Common Welding Defects ExplainedManila CastilloОценок пока нет

- Manufacturing of Sulfuric Acid by Lead Chamber Process and Contact ProcessДокумент14 страницManufacturing of Sulfuric Acid by Lead Chamber Process and Contact ProcessDian Eka FajriyantoОценок пока нет

- Water For RayonДокумент51 страницаWater For RayonAditya ShrivastavaОценок пока нет

- GR 12 Term 2 2018 Ps Practical Booklet A PDFДокумент11 страницGR 12 Term 2 2018 Ps Practical Booklet A PDFSiphelele Fifi AstroBoyОценок пока нет

- Technical Data SheetДокумент2 страницыTechnical Data SheetSham SajaОценок пока нет

- Mucoadhesive Polymers: Means of Improving Drug Delivery: MucoadhesionДокумент4 страницыMucoadhesive Polymers: Means of Improving Drug Delivery: MucoadhesionBrijesh RayОценок пока нет