Академический Документы

Профессиональный Документы

Культура Документы

Selective Coating June 27

Загружено:

Oleg ShkolnikИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Selective Coating June 27

Загружено:

Oleg ShkolnikАвторское право:

Доступные форматы

June 2012

Ben-Gurion University of the Negev

Faculty of Engineering Sciences

Faculty Unit of Energy Engineering

By: Oleg Shkolnik

Supervisor: Prof. Daniel Feuermann

Photothermal coatings based on functional

nanomaterials for the efficient conversion of solar

energy

Supported by: Ministry of Energy and Water Resources

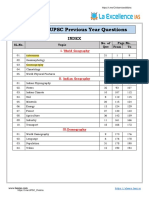

Outline

Theoretical short introduction and motivation

Project description

Review of different types of coatings

Experimental setup and methodology

Current results and future experiments

-

=

= (

)

Thermal conductivity of various

materials at 0 C

Material k ( W/ m C )

Copper 385

Aluminum 202

Carbon steel 1% C 43

Glass wool 0.0038

Air 0.024

= according to Kirchhoffs law

=

1

1

(

1

4

2

4

)

0

Boltzmann law

+ + = 1 according to energy balance

Net heat transfer

from surface

1

What is selective coating

A selective absorber coating or material is a thin layer (of

the order of m) on the surface, or a material which exhibits

optical properties that drastically vary from one spectral

region to another

The solar spectrum and the re-radiated spectrum of the hot

absorber are separated at relatively low temperature of the

absorber. However, the higher the temperature of the

surface the more the absorbed solar radiation and the

emitted spectra overlap

Selective coating was pioneered by Tabor in 1956 in Israel

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0 1000 2000 3000 4000 5000

e

f

f

i

c

i

e

n

c

y

(

%

)

wavelength(nm)

C=100

T=550 C

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0 1000 2000 3000 4000 5000

e

f

f

i

c

i

e

n

c

y

(

%

)

wavelength(nm)

C=25

T=800 C

0 0

( ) (0.95) (0.07) (0.95) (0.07)

cr cr

cr cr

cr sun sun bb bb

q C I d C I d I d I d

o c c c

= +

} } } }

Evaluation of critical wavelength and efficiency estimation

Selective coating the complete project

This work is a part of a collaborative project of

developing thin nanocomposite layers for high

temperature (above 500 C)

The samples are prepared at Hebrew University

at chemical department by two groups of

researchers (Mandler and Magasi et al.,)

The Electro-Dynamic analysis of particles mixture is

performed at TAU Electrical Engineering department by

Steinberg et al.

The optical properties measured at Sede Boqer and TAU

( Feuermann and Kribus et al.,)

`

Goals of the project

The global purpose of this research is to construct a spectrally selective

ceramic matrix with embedded nanoparticles for photo thermal conversion,

stable at high temperature applications.

Each group has its specific requirements to meet.

Hebrew University group :

Solar absorption at 300-2500 nm range (AM 1.5),

above 95% of the total energy.

Low thermal emittance < 0.1

The coating will be designed for continuous

use at a temp >500 C (in air)

Optical properties of selective coatings

BGU :

Detailed measurements of spectral and angular reflectance at ambient

and elevated temperatures

Measurements of solar absorptance at high solar concentration

TAU:

Prof. Kribus Group

Measuring the of emissivity

IR Camera 214 m

Pyroelectric sensor 0.316 m

Prof. Steiberg group

Theoretical calculations based on use

Maxwell equations in order to evaluate

the by knowing the dielectric

constant of the absorbing particles

Basics assumptions:

Homogeneous distribution

particles should be one 0.1-0.2 of

the wavelength

Spherical, ellipsoidal, or needle

like particles

Types of absorbers

1. Intrinsic absorbers- e.g., HfC(Hafnium Carbide ): two

categories of materials fall into this group : transition metals

and semiconductors. Unfortunately most selective metals

exhibit the cutting edge, of good absorber to pore emitter

too earlier at the solar spectrum and therefore not suitable

for solar applications

Carl M. Lampert Solar Enegy materials 1( 1979)

2. Multilayer absorbers (e.g., Al

2

0

3

/Mo/ Al

2

0

3

):

Multilayer thin films are dielectric-metal combinations which act

like a selective filter for energy absorption

Particular wavelengths of solar energy are absorbed by multiple

reflections in the dielectric-metal layers

Such coatings are commonly produced by sputter deposition

technologies with AR layer on the top

N. Selvakumar, Harish C. Barshilia, Materials & Solar Cells (2011)

3. Optical trapping: it is possible to produce a

surface with a such roughness that will absorb

the visible part of the solar spectrum by pure

geometrical means while being opaque

to the infrared spectrum

4. Metal dielectric (cermet): highly

absorbing metal dielectric

composites consisting of nano or

micro scale particles embedded in a

dielectric or ceramic matrix

Structure of cermet:

thin protective layer to prevent diffusion

single layer with uniform particles distribution

single layer with graded particles distribution

double layer - according to fundamental modeling it has higher photo-thermal

conversion efficiency

Cermet types and structures

Offers high degree of flexibility , solar selectivity can be optimized by proper

choice of coating thickness

Particle size- it is possible to shift the absorbing and scattering cutoffs to higher

wavelengths when the particle radius increases

Possible to predict optical properties using effective medium theories for example

the optimum pore diameter d

p

=0.08 m of nickel pigmented alumina coatings

have been determined

Usage at broad range of temperatures

In addition solar absorbance can be boosted with a proper choice of substrates and

AR layer.

After a long research and development in solar materials, the cermet remains one of

the best and promising candidates for high temperature application

Advantages of cermets over other candidates for

high temperature applications

International Energy Agency (IEA) performance criterion (PC) developed for a flat-plate

collector selective absorber testing.

=

+ 0.25 0.05

lifetime of at least 25 years and decrease in the annual solar fraction of 5%

Service lifetime testing for this criterion is performed by exposing the absorber coating for

200 h at 250C

If the material survives , it is then exposed for 75 h at 300 C hand roll followed by 600 h at

40 C and 95 %relative humidity

No similar criterion has been developed for testing the service lifetime of high temperature

absorbers for CSP.

Degradation of the high temperature absorbers usually causes increasing emittance ; in

addition while the emittance of many materials after exposure to high temperature does

not return to the original emittance measured ( e.g., paint), for some materials the

emittance changes at high temperature and returns to the original value

Long term stability

Different matrices were investigated for CERMET layers, more exactly 2 categories

of matrices (silica and alumina). Both alumina and silica matrices are transparent

to IR and are stable at high temperature.

Black coatings were prepared by dispersing black pigment (black 26) in the

different matrices, adding dispersant and additives. The coatings were dried at

750C during 1 hour under air.

SEM of alumina film with Black 26

First set of experiments:

Solar irradiation one sun

Ambient temperature

Measurements of 4 samples

s

i

wet thickness 40 m

wet thickness 6 m

achieve

1000K

experimental setup

4 side faces

of furnace

back face of

furnace

Front face Total loss

heat loss by convection

5.7 W 2 W 23.9 W 31.6 W

heat loss by radiation

6.6 W 2.4 W 13.6 W 22.6 W

Results for HU samples

s

Azimuthal effects inside the specular region

rotating the sample

to observe any difference

in surface structure

s

The structure of the surface has obviously a strong effect

s

rotating the sample

to observe any difference

in surface structure

Azimuthal effects outside the specular region

s

polar angle effect around specular direction

B-CZ-10.1A ferro 8m

0

10

20

30

40

50

60

70

0 10 20 30 40 50 60 70

polar angle s(deg)

r

e

f

l

e

c

t

a

n

c

e

(

%

)

i=30 s=0

i=45 s=0

here

i

=

s

Specular effects in polar direction (

s

) at two

incidence angles

We simply average the directional reflectance over

the wavelengths. This is of course not a correct

measure but should give some qualitative indication

of a relative specularity of the different samples.

all the results on one graph

polar angle effect at i=30 s=0

0

50

100

150

200

250

0 10 20 30 40 50 60 70

polar angle s (deg)

r

e

f

l

e

c

t

a

n

c

e

(

%

)

B-CZ-STS-10.2 4.7m

B-CZ-STS-10.2A 6m

B-CZ-10.2B 5.9m

B-CZ-STS-9.2 2.6m

B-CZ-10.1 4m

B-CZ-10.1A 8m

s

15

45

s

=60

30

MS 1.3 (two layers) at elevated temperature of 600K

we had to cut off at 1100nm because thermal radiation was too

large at the longer wavelengths.

0

200

400

600

800

1000

1200

1400

1600

1800

900 1000 1100 1200 1300 1400 1500 1600 1700

r

e

l

.

i

n

t

e

n

s

i

t

y

(

%

)

wavelength (nm)

relative intensity from MS13 sample in the dark

compared to gray reference under illumination

we get 10 times the intensity from thermal

radiation than from light reflected

MS 1.3 at 600K

attempt to increase signal to noise ratio by

optics

better means of measuring temperature

measurement in the solar furnace (to obtain

directly) and will be closer to realistic

conditions.

at high temperatures measurements

even a very bright lamp is not sufficient

while dealing with very absorbing samples

ultimately will

be used in solar

furnace

Sample inside solar furnace

The next day photos after heating to max temperature 430 C

Experimental setup using a PCX Condenser Lens 125mm Diam x

500mm Focal Length

A) we have considered using a lens and the sun

Lens position

Problem:

Stability of direct beam solar radiation.

Ephemeral nature of solarradiation.

Region that the sensor

sees

Light spot that sensor

sees

Placing the sample at focal plane

Sample position

What did we achieve?

much higher intensity

light spot completely in the measured region

experiments at wide angles

Hopefully solved uniformity problem

sample

holder

sample

holder

Region that the sensor

sees

Light spot that sensor

sees

s

0

5

10

15

20

25

30

35

40

45

400 600 800 1000 1200 1400 1600 1800

r

e

f

l

e

c

t

a

n

c

e

(

%

)

wavelength(nm)

polar angle effect i=30 s=0

MS-CZ- 17C 8.7m

s=-10

s=0

s=10

s=20

s=30

s=40

s=50

s=60

s

0

5

10

15

20

25

30

35

40

-10 0 10 20 30 40 50 60 70

r

e

f

l

e

c

t

a

n

c

e

(

%

)

polar angle s (deg)

polar angle effect i=30 s=0-corrected by solar spectrum

17A17F 2.5 15.7m

17B - 2.5m

17F - 4.8m

17A - 5.16m

17C - 8.7m

17E - 9.1m

17D - 15.7m

sample

reflectance in non-

specular region

reflectance in specular

region

weighted average

reflectance over both regions

absorbtance

(

i

=30)

17A -5.16m 0.050 0.198 0.053 0.9470.004

17B-2.5m 0.067 0.223 0.070 0.9300.005

17C-8.7m 0.050 0.161 0.053 0.9470.004

17D-15.7m 0.043 0.158 0.045 0.9550.003

17E-9.1m 0.043 0.170 0.046 0.9540.003

17F-4.8m 0.044 0.183 0.046 0.9540.003

Acknowledgments

This research is supported by the Ministry of energy

and water within the framework of the program of

scholarships in the field of renewable energy.

I would like to acknowledge my supervisor Prof. Daniel

Feuermann for invaluable support, guidance and

scientific assistance.

Thank you

for your attention

Вам также может понравиться

- Minfm66645 Astm A312 Grade s32615Документ4 страницыMinfm66645 Astm A312 Grade s32615Oleg ShkolnikОценок пока нет

- Gmail - Receipt for Your Payment to 公良 俊杰Документ4 страницыGmail - Receipt for Your Payment to 公良 俊杰Oleg ShkolnikОценок пока нет

- Iarjset 2019 6411Документ6 страницIarjset 2019 6411Oleg ShkolnikОценок пока нет

- Iarjset 2019 6411Документ6 страницIarjset 2019 6411Oleg ShkolnikОценок пока нет

- Sustainability 09 00520Документ23 страницыSustainability 09 00520Jhonni Rentas DulingОценок пока нет

- Rotem Piping Specification Piping Accessories Rotem Catalogue No 2/522/1Xy/3Z0Документ1 страницаRotem Piping Specification Piping Accessories Rotem Catalogue No 2/522/1Xy/3Z0Oleg ShkolnikОценок пока нет

- Illian U: Academic PositionsДокумент11 страницIllian U: Academic PositionsOleg ShkolnikОценок пока нет

- NB-27 - 2012 A Guide For Blowoff VesselsДокумент1 страницаNB-27 - 2012 A Guide For Blowoff VesselsOleg ShkolnikОценок пока нет

- SP-03 New StructuresДокумент36 страницSP-03 New StructuresOleg ShkolnikОценок пока нет

- NR-040 FS: Removable Cover Check Valves For Reclaimed Water, Wastewater and SludgeДокумент4 страницыNR-040 FS: Removable Cover Check Valves For Reclaimed Water, Wastewater and SludgeOleg ShkolnikОценок пока нет

- Removable Cover Check Valves For Potable Water Pump StationsДокумент4 страницыRemovable Cover Check Valves For Potable Water Pump StationsOleg ShkolnikОценок пока нет

- Energies: Heat Transfer in Latent High-Temperature Thermal Energy Storage Systems-Experimental InvestigationДокумент19 страницEnergies: Heat Transfer in Latent High-Temperature Thermal Energy Storage Systems-Experimental InvestigationOleg ShkolnikОценок пока нет

- Water HammerДокумент34 страницыWater HammerM Favio Palacios Solórzano100% (1)

- SP-03 New StructuresДокумент36 страницSP-03 New StructuresOleg ShkolnikОценок пока нет

- BALLДокумент18 страницBALLOleg ShkolnikОценок пока нет

- BUTTERFLYДокумент11 страницBUTTERFLYOleg ShkolnikОценок пока нет

- GLOBEДокумент19 страницGLOBEOleg ShkolnikОценок пока нет

- Entropy Formula For Ricci Flow PerelmanДокумент39 страницEntropy Formula For Ricci Flow PerelmanNdewura Jakpa100% (1)

- Entropy Formula For Ricci Flow PerelmanДокумент39 страницEntropy Formula For Ricci Flow PerelmanNdewura Jakpa100% (1)

- GATEДокумент21 страницаGATEOleg ShkolnikОценок пока нет

- Gears Engineering InformationДокумент138 страницGears Engineering InformationoperationmanagerОценок пока нет

- Deciphering Weld SymbolsДокумент11 страницDeciphering Weld SymbolsAhmad Reza AtefОценок пока нет

- 01 Polymer ComparisonДокумент4 страницы01 Polymer ComparisonOleg ShkolnikОценок пока нет

- Werma Sirens and Horns PDFДокумент288 страницWerma Sirens and Horns PDFOleg ShkolnikОценок пока нет

- 2213 Ca P0Документ1 страница2213 Ca P0Oleg ShkolnikОценок пока нет

- Bearing Design in Machinery - A. Harnoy (Marcel Dekker, 2003) WWДокумент640 страницBearing Design in Machinery - A. Harnoy (Marcel Dekker, 2003) WWoptimist5Оценок пока нет

- 2211 Ca P0Документ1 страница2211 Ca P0Oleg ShkolnikОценок пока нет

- Re - 0331-TEC-UDS-ING-0981 Condensate System Miscellaneous List R0a CommentsДокумент4 страницыRe - 0331-TEC-UDS-ING-0981 Condensate System Miscellaneous List R0a CommentsOleg ShkolnikОценок пока нет

- 2212 Ca P0Документ1 страница2212 Ca P0Oleg ShkolnikОценок пока нет

- ASTM D3035 - Polyethylene PE Pipes - DimensionsДокумент4 страницыASTM D3035 - Polyethylene PE Pipes - DimensionsOleg Shkolnik100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Dokumen Tanpa Judul-3Документ7 страницDokumen Tanpa Judul-3alyagrlyyОценок пока нет

- LIS Note Sheet 8-5Документ6 страницLIS Note Sheet 8-5Pulan KodagodaОценок пока нет

- The Burning Bridge by Poul AndersonДокумент29 страницThe Burning Bridge by Poul AndersonCritteranneОценок пока нет

- Physics Paper 3 TZ1 SLДокумент36 страницPhysics Paper 3 TZ1 SLRᴇᴀʟ RᴜᴋʜsᴀʀОценок пока нет

- Planets in The Solar SystemДокумент7 страницPlanets in The Solar SystemannmarieОценок пока нет

- 5W2H Action Infographics by SlidesgoДокумент16 страниц5W2H Action Infographics by SlidesgoPetro CruzadoОценок пока нет

- Grilled Cheese Sandwich Recipes by SlidesgoДокумент53 страницыGrilled Cheese Sandwich Recipes by Slidesgoarmadanti shafiraОценок пока нет

- Math Subject For High School Probability and StatisticsДокумент86 страницMath Subject For High School Probability and StatisticsMaricelОценок пока нет

- Giants 1 Inherit The StarsДокумент235 страницGiants 1 Inherit The StarsHangTheBankersОценок пока нет

- DLL - Science 3 - Q4 - W8Документ3 страницыDLL - Science 3 - Q4 - W8Rose Dagdag-LaguitaoОценок пока нет

- Prehistoric Frozen World Thesis Defense by SlidesgoДокумент48 страницPrehistoric Frozen World Thesis Defense by Slidesgostrawhat470Оценок пока нет

- PRETESTДокумент55 страницPRETESTMedy Lumagui MarasiganОценок пока нет

- Geography Question BankДокумент198 страницGeography Question BankChandan NayakОценок пока нет

- Answers To End-Of-Chapter Questions For Chapter 9, Conduction, Convection and RadiationДокумент3 страницыAnswers To End-Of-Chapter Questions For Chapter 9, Conduction, Convection and RadiationMencam AsongОценок пока нет

- Alex Gleason-Is The Bible From Heaven-Is The Earth A GlobeДокумент433 страницыAlex Gleason-Is The Bible From Heaven-Is The Earth A Globeexpanse100% (8)

- AstronomyДокумент37 страницAstronomyPrasad Shah100% (1)

- Mars AspectsДокумент2 страницыMars AspectsLeo JonesОценок пока нет

- Hide and SeekДокумент6 страницHide and SeekjavedarifОценок пока нет

- Watercolor Company ProfileДокумент50 страницWatercolor Company ProfileDaniОценок пока нет

- Solar System NotesДокумент5 страницSolar System Notesatiqah zakiОценок пока нет

- QuizДокумент14 страницQuizsoumyajit1986Оценок пока нет

- Jamboard Style Education Slides by SlidesgoДокумент54 страницыJamboard Style Education Slides by SlidesgoGenesis J. AdamesОценок пока нет

- Knowles 2003 Solar Envelope PDFДокумент11 страницKnowles 2003 Solar Envelope PDFEgonVettorazziОценок пока нет

- Earth Science Study Guide Answers FinalДокумент73 страницыEarth Science Study Guide Answers FinalIAN GamingОценок пока нет

- Jean-Jeffreys Tidal TheoryДокумент32 страницыJean-Jeffreys Tidal TheoryLaurianne Lim0% (1)

- Building ConstructionДокумент37 страницBuilding ConstructionPalash Mehta100% (1)

- Midterm Earth SciДокумент2 страницыMidterm Earth SciPablo Ragay Jr100% (1)

- National Novel Writing MonthДокумент63 страницыNational Novel Writing MonthXII MIPA A RACHMAT SUPARMANSYAHОценок пока нет

- Grade 11 STEM SubjectsДокумент4 страницыGrade 11 STEM SubjectsNikka N. Nazario100% (1)

- Astronomer's Computer CompanionДокумент438 страницAstronomer's Computer CompanionCGETC T1Оценок пока нет