Академический Документы

Профессиональный Документы

Культура Документы

Evaluation of Operational Parameters Involved in Electrolytic Defluoridation Process

Загружено:

TJPRC PublicationsОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Evaluation of Operational Parameters Involved in Electrolytic Defluoridation Process

Загружено:

TJPRC PublicationsАвторское право:

Доступные форматы

International Journal of Civil, Structural, Environmental and Infrastructure Engineering Research and Development (IJCSEIERD) ISSN 2249-6866 Vol.

2 Issue 4 Dec - 2012 23-32 TJPRC Pvt. Ltd.,

EVALUATION OF OPERATIONAL PARAMETERS INVOLVED IN ELECTROLYTIC DEFLUORIDATION PROCESS

1

NEHA MUMTAZ, 2GOVIND PANDEY, 3PAWAN KUMAR LABHSETWAR & 4SUBHASH P. ANDEY Student of M.Tech (Civil) Environmental Engineering, M. M. M. Engineering College, Gorakhpur, U. P., India Associate Professor, Department of Civil Engineering, M. M. M. Engineering College, Gorakhpur, U. P., India

2 3

Principal Scientist and Head, Water Technology and Management Division, National Environmental Engineering Research Institute (NEERI), Nagpur, India

Principal Scientist, Water Technology and Management Division, National Environmental Engineering Research Institute (NEERI), Nagpur, India

ABSTRACT

In the present work, the performance of electrolytic defluoridation by continuous process with aluminium electrodes has been investigated to look into the effects of operation parameters on the performance of electrolytic defluoridation process. The process utilizes sacrificed anodes to form active coagulant, which is used to remove the pollutant by precipitation and flotation in situ. It involves the anodic dissolution of aluminium by passing direct current (DC) in fluoride bearing water. The aluminium hydroxide is formed and binds the fluoride. The electrolytic dissolution of aluminium anodes in water produces aqueous Al3+ species and hydrogen bubbles at the aluminium cathodes. The pH value was found to be an important variable that affected fluoride removal significantly. The optimal influent pH range is 6.07.0 at which effective defluoridation can be achieved and optimum value is adopted as 6.5. Different operational conditions such as composition of sodium fluoride (NaF) based stock solutions (5, 6, 8, 10 mg/L), flow rates and current intensity were varied and performance of the process has been examined. Their influence on the defluoridation efficiency, the effect of initial pH of raw water and the amount of aluminium released (coagulant) have being investigated. It is revealed that current intensity has little effect on fluoride removal and the residence time requirement increases with the rise in initial fluoride concentration.

KEYWORDS: Aluminium Electrodes, Coagulant, Continuous Process, Electrolytic Defluoridation, Operational

Parameters, Water Treatment

INTRODUCTION

One of the major challenges faced by mankind today is to provide safe drinking water to a vast population around the world. It is learnt that fluoride concentrations in groundwater in the world ranges from 0.01 to 48 mg/L. According to the guidelines of World Health Organization (WHO) issued in 2011, the guideline value is 1.5 mg/l for drinking water quality. People in more than 35 nations across the globe face issues of excess fluoride in drinking water, the intensity and severity of which varies with the environmental settings in terms of their geographical and economical status. Fluorides are released into the environment naturally through weathering and dissolution of rock minerals, in emissions of volcanoes, and in marine aerosols. The two most populated countries of the world, China and India, stand at the top in the list of worst hit nations in groundwater contamination with fluoride. In both these countries, the major source of fluoride pollution is the natural weathering process. Drinking water containing high fluoride content for longer time can result in mottling of teeth, softening of bones and ossification of tendons and ligaments. (Ayoob et al, 2008).

24

Neha Mumtaz, Govind Pandey, Pawan Kumar Labhsetwar & Subhash P. Andey

Desirable concentration of fluoride to be maintained in drinking water is 1 mg/L and permissible limit in the absence of alternate sources is 1.5 mg/L as per Indian drinking quality standards (IS 10500-1991). The burden of disease associated with fluoride, therefore, arises from the adverse effects of both excess and insufficient fluoride. The International Programme of Chemical Safety (ICPS, 1984) note that, The quantity of fluoride needed for mineralization processes is small, and because of the ubiquitous distribution of fluoride, true deficiency is unlikely to occur in human beings. One of the major challenges faced by mankind today is to provide clean water to a vast majority of the population around the world. Emamjomeh et al. (2009) enunciated that fluoride concentrations in groundwater in the world range from 0.01 up to 48mg/L. Excessive fluoride concentrations have been reported in groundwater of more than 20 developed and developing countries including India where 19 states are facing acute fluorosis problems. (State of Environment Report India, 2009). Technologies for Defluoridation of Water - An Overview There are several defluoridation processes tested or employed globally, such as adsorption (Azbar and Turkman, 2000), chemical precipitation ( Azbar and Turkman, 2000,), and electrochemical method (Shen et al., 2003). Currently, some of the popular processes for drinking water defluoridation are the adsorption using activated alumina (Ghorai and Pant, 2005, Tripathy et al., 2006, Chauhan et al., 2007), bone char (Mjengera and Mkongo, 2003, Hernandez-Montoya, 2007) activated carbon (Daifullah et al., 2007, Kumar et al., 2007), other adsorbents (Biswas et al., 2007) and the coagulation using aluminum salts (Pinon - Miramontes et al., 2003). Other major processes for defluoridation include electro- dialysis (Tahaikt et al., 2006), reverse osmosis (Arora et al., 2004) and nanofiltration (Hu and Dickson, 2006). According to Zuoa et al., (2008), the membrane processes are known to be effective means for defluoridation but this not only removes the beneficial contents present in water during defluoridation, but also increases the operational cost. Electrolytic Defluoridation Currently, there is a growing interest in Electrocoagulation (EC) process or electrolytic defluoridation. The technique is used to treat restaurant wastewater (Chen et al., 2000), textile wastewater (Bayramoglu et al., 2004), and fluoride-containing wastewater effectively. Electrocoagulation process (EC) using sacrificial aluminum electrodes has been demonstrated to be an effective process since it does not require a substantial investment, presents similar advantages as chemical coagulation and reduces disadvantages, (Hu et al., 2005) and less waste slurry production (Essadki et al., 2009). Defluoridation efficiency by electrocoagulation process depends on applied current intensity, initial fluoride concentration, initial pH, raw water quality and flow rate. The main reactions involved in the EC are as following:

Al Al3+ +3H2O Al(OH)3 +xF 2H2O + 2e-

Al3+ +3eAl(OH)3 +3H+ Al(OH)3xFx +xOH H2 +2OH

at the anode

at the cathode

Evaluation of Operational Parameters Involved in Electrolytic Defluoridation Process

25

It is generally accepted that the EC process involves three successive stages: (a) formation of coagulants by electrolytic oxidation of the sacrificial electrode; (b) destabilization of the contaminants, particulate suspension, and breaking of emulsions; (c) aggregation of the destabilized phases to form flocs.

METHODS

In India, most of the work on defluoridation process is done using batch mode. Here, in the present study the main focus is on electrolytic defluoridation by continuous process which is more efficient and less time consuming in comparison to the batch process. The methodology applied in the present study is illustrated here. Experimental Protocol In its simplest form, an electro-coagulating reactor is made up of an electrolytic cell with one anode and one cathode. When connected to an external power source, the anode material electrochemically corrodes due to oxidation, while the cathode is subjected to passivation. A feed tank of 200 L (A nestable tank) capacity was filled with raw water of initial fluoride concentrations of 5, 8, 6 and 10 mg/L. The initial pH of raw water was adjusted around 6.5-6.9 by adding concentrated HCl. A peristaltic pump of maximum efficiency of 1L/min was used to maintain the flow rate accordingly for a continuous process. The flow rate was adjusted by setting the rpm (rotation per minute) on the digital display. Experiments were performed in a reactor consisting of plastic bucket of 19 L capacity. A direct current (DC) by stabilized power supply (TESTRONIX 34C, Volt and Ampere Digital Display) was applied to the terminal electrodes in which electrical current was controlled by a variable transformer. Constant current was maintained during each run by appropriately adjusting the impressed cell voltage from a regulated DC power supply. A bucket of 52 cm height and diameter of 44 cm was used as a settling tank in the lab scale experiment for electrolytic defluoridation by continuous process. Electrode Configurations Aluminum plates were cut from a commercial grade aluminum sheet (99% purity) of 2 mm thickness each with a dimension of 100 mm180 mm and an effective area of 180 cm2 on each side. Distance between the electrodes was 5 mm. Monopolar configurations with three aluminium plate electrodes were used. Central plate was connected to anode and two end plates were connected to cathode. The electrodes were designed with a surface area to volume ratio of 7.2 m2 / m3 which is within cited range of 6.9 - 43 m2 / m3 as reported by P.K. Holt, 2003. Raw water of various fluoride concentrations was prepared by diluting the stock solution in tap water. The experimental procedure was divided into two major steps i.e. start up batch process and Continuous treatment process. Each run was conducted using 19 litre of raw water in the reactor for start-up batch process and rendering it upto the desired limit of 1 mg/L by providing proper detention time. Detention time (t) is calculated by using Eq. 1 based on Faradays law: m =K . i . t Where, m = Weight of aluminium dissolved (g) K = Electro-chemical constant i = Current (Ampere) (1)

26

Neha Mumtaz, Govind Pandey, Pawan Kumar Labhsetwar & Subhash P. Andey

t = Time of electrolysis Value of m can be calculated by; m= (C0 Cf) volume (Al / F) Where, C0 = Initial fluoride concentration = 5 mg/l Cf = Fluoride conc. in treated water = 1 mg/L Volume = Volume of treated water Al/F ratio = 3 (At pH 6) All experiments were conducted at room temperature in the range 26 28 C. Concentrated hydrochloric acid was used for pH adjustment to 6.0-6.5 which is the optimum range for efficient electrocoagulation process. Current was varied from 2.0A to 3.0A, however, it was held constant for each run by appropriately adjusting the impressed cell voltage from a regulated DC power supply. The Ion Selective Electrode method was used to determine concentration of fluoride and in the treated water, residual aluminium estimation was carried out by Eriochrome cyanine R method. (2)

RESULTS

In the study, experiments were conducted to ascertain the feasibility of electrolytic defluoridation process in a continuous mode and the effects of operational parameters on electrolytic defluoridation process are discussed here. Effect of Initial pH on Fluoride Concentration The experiment was conducted to study the effect of initial pH on the efficiency of electrolytic defluoridation process. The influent pH was found to be one of the important factors affecting the performance. In the electrolytic defluoridation system, the fluoride on electrodes and flocs solely determines the fluoride removal efficiency. The adsorption on flocs and defluoridation by electrodes is of primary importance to understand fluoride distribution. The optimal pH range found was 67, at which higher fluoride removal efficiency could be reached, but the fluoride removal efficiency varies with variation in pH. Lower pH is favorable for early fluoride removal in the EC process. The pH could be increased not only because of the hydrogen generation at the EC cathodes, but also the liberation of hydroxide ions from aluminum hydroxide due to the substitution of fluoride ions. Therefore, further increase of the influent pH would decrease the defluoridation capability. Since aluminum hydroxide is an amphoteric hydroxide, high pH will lead to the formation of Al (OH) 4 which is soluble and does not take part in defluoridation. Effect of pH on fluoride reduction for batch and continuous processes are shown in Fig. 1 and 2 respectively.

Fig. 1: Effect of pH on Fluoride Reduction for Start-Up Batch Process at 2 Ampere (C0=10 Mg/L)

Evaluation of Operational Parameters Involved in Electrolytic Defluoridation Process

27

Fig. 2: Effect of pH on Fluoride Reduction for Continuous Process at 2 Ampere (C0=5 Mg/L) The experiments were conducted to determine the effect of pH variation on fluoride removal efficiency, keeping other parameters constant and the optimum fluoride reduction was observed between pH 6 and 7 for influent fluoride concentration 5 mg/l. With this in view, the working pH in the optimum range of 6-7 was adopted as 6.5, which yielded the best results. Effect of Current Intensity on Fluoride Concentration It was found that current intensity has little effect on defluoridation because the principal factor influencing adsorption of fluoride by flocs is the pH of the solution. Consequently, an increase in current intensity leads to an increase in power requirement. Infact, there should be an optimal current applied for the electrolytic defluoridation system. Increasing current intensity would accelerate the liberation rate of Al3+ and OH ions. The rapid liberation of Al3+ and OH ions from the surface of the electrode would make the solution around the anode and cathode extremely acidic or basic respectively, which would decrease the removal efficiency of electrodes as depicted in Fig. 3, 4 and 5.

Fig. 3: Effect of 2 Ampere Current on Fluoride Removal

Fig. 4: Effect of 2.5 Ampere Current on Fluoride Removal

28

Neha Mumtaz, Govind Pandey, Pawan Kumar Labhsetwar & Subhash P. Andey

Fig. 5: Effect of 3 Ampere Current on Fluoride Removal Both rapid liberation and short run time would lead to incomplete reaction around the electrodes due to insufficient time to reach dynamic equilibrium. Therefore, optimal current density should be maintained. Effect of Influent Fluoride Concentration The experiments were conducted by varying initial fluoride concentrations 5, 6, 8, 10 mg/L, keeping all other experimental conditions identical. Figures 6, 7, 8 and 9 illustrate fluoride reduction below 1 mg/l for pH 6.5 and current intensity 2, 2.5 and 3 amperes.

Fig. 6: Effect of Current Intensity on Removal of Fluoride (Concentration: 5 Mg/L)

Fig. 7: Effect of Current Intensity on Removal of Fluoride (Concentration: 6 Mg/L)

Evaluation of Operational Parameters Involved in Electrolytic Defluoridation Process

29

Fig. 8: Effect of Current Intensity on Removal of Fluoride (Concentration: 8 Mg/L)

Fig. 9: Effect of Current Intensity on Removal of Fluoride (Concentration: 10 Mg/L) These figures reflect that the retention time required for an acceptable residual fluoride concentration, which is <1mg/l of fluoride, increases when the initial concentration is increased. Maximum fluoride removal efficiency was observed at current intensity of 3 A. The defluoridation efficiency of electrodes tended to decrease since they required longer time with the initial F concentration rising. Effect of Flow Rate on Defluoridation Efficiency In the study, a continuous stirred tank reactor was utilized and a peristaltic pump was used to maintain the desired flow rate. To study the effect of flow rate on defluoridation efficiency, operating experimental parameters such as fluoride concentration 5 mg/l, 3 ampere current and pH 6.5 were kept constant for various flow rates. The study of the effect of flow rates on the removal efficiency of a continuous type of electrolytic process, which is given in Fig. 10, reveals that the flow rate of 550 ml/min gives the optimum results with residual fluoride concentration within the desirable limit.

Fig. 10: Effect of Various Flow Rates on Defluoridation Efficiency

30

Neha Mumtaz, Govind Pandey, Pawan Kumar Labhsetwar & Subhash P. Andey

Residual Aluminium in Treated Water The residual aluminium found in treated water is one of the important factors, because leaching of the same was demonstrated in the experiments conducted. Aluminium found above 0.2 mg/L in drinking water, is a risk cause of Alzheimer disease (AD) in humans (WHO, 1997). Effect of different current intensities on the concentration of residual aluminium is shown in fig. 11. Higher residual aluminium was found at optimum removal efficiency with current intensity 3 ampere and pH 6.5, but it is not beyond permissible limit in drinking water for the current intensities 2 and 2.5 ampere for lower fluoride concentrations. The optimum current intensity of 2 ampere with optimum pH of 6.5 gives better results in comparison to higher current intensities. Therefore, it can be inferred that the variation in current intensity with optimum pH of 6.5 for electrolytic defluoridation process is not effective.

Fig. 11: Effect of Current Intensity on Residual Aluminium Concentration

CONCLUSIONS

In the present work, the laboratory scale study has focussed on the feasibility of electrolytic defluoridation as a viable methodology of water treatment in a continuous mode and the following facts were revealed: 1. The overall defluoridation efficiency varies with initial fluoride concentration that is altered by operating parameters such as pH, current intensity initial fluoride concentration and flow rate. 2. 3. With the rise in initial fluoride concentration, the time required for the desired removal efficiency increases. Current intensity has little influence on fluoride removal and optimum removal was found at 3 A for fluoride removal. 4. Acidic pH has more fluoride removal efficiency with higher residual aluminium concentration in treated water. Therefore, it is recommended to maintain pH in the range 6-7 for maximum fluoride removal and the optimum pH may be taken as 6.5. 5. The study of the effect of flow rates on the removal efficiency of a continuous type of electrolytic process reveals that the flow rate of 550 ml/min has the optimum results with residual fluoride concentration within the desirable limit. 6. 7. Considering aluminium leaching, optimum conditions are observed to be at current intensity 2 A and pH 6.5. The approach proposed in this study could provide not only a useful insight into optimization of EC process but also more detailed information on residual aluminium in the process.

Evaluation of Operational Parameters Involved in Electrolytic Defluoridation Process

31

REFERENCES

1. Arora M., Maheshwari R.C., Jain S.K. and Gupta A., (2004), Use of membrane technology for potable water production, Desalination, Vol. 170 pp: 105112. 2. Ayoob S., Gupta A. K. and Venugopal (2008), A Conceptual Overview on Sustainable Technologies for the Defluoridation of Drinking Water, Critical Reviews in Environmental Science and Technology , Vol. 38:6, pp 401-470. 3. Azbar, N. and Turkman A. (2000), Defluoridationin drinking waters. Water Science and Technology, Vol. 42 (12), pp: 403407. 4. Bayramoglu M., Kobya M., Can O.T., Sozbir M., (2004), Operating cost analysis of electrocoagulation of textile dye wastewater, Sep. Purification Technology, Vol. 37 pp: 117125. 5. Biswas, K., Saha S.K. and Ghosh U.C. (2007), Adsorption of fluoride from aqueous solution by a synthetic Iron+3- Aluminum+3 mixed oxide, Ind. Eng. Chem. Res. Vol. 46, pp:53465356. 6. Chauhan V.S., Dwivedi P.K. and Iyengar L. (2007), Investigations on activated alumina based domestic defluoridation units, Journal of Hazardous Materials. Vol. 139, pp: 103107. 7. Chen X., Chen G. and Yue P.L. (2000), Separation of pollutants from restaurant wastewater by electrocoagulation, Sep. Purification Technology, Vol. 19, pp: 6576. 8. Daifullah, A.A.M., Yakout S.M. and Elreefy S.A. (2007), Adsorption of fluoride in aqueous solutions using KMnO4-modified activated carbon derived from steam pyrolysis of rice straw, Journal of Hazardous Materials. Vol. 147, pp: 633643. 9. Emamjomeh M. M., Sivakumar M. (2009), Fluoride removal by continuous flow electrocoagulation reactor, Journal of Environmental Management, Vol. 90, pp: 12041212. 10. Essadkia, A.H., Gouricha B., Vial Ch., Delmasc H and Bennajaha M. (2009), Defluoridation of drinking water by electrocoagulation/electroflotation in a stirred tank reactor with a comparative performance to an external-loop airlift reactor. Journal of Hazardous Materials. Vol. 168, pp: 13251333. 11. Ghorai, S. and Pant K.K. (2005), Equilibrium, kinetics and breakthrough studies for adsorption of fluoride on activated alumina, Sep. Purification Technology, Vol. 42, pp: 265 271. 12. Hernandez-Montoya V., Elizalde-Gonzalez M.P. and Trejo-Vazquez R. (2007), Screening of commercial sorbents for removal of fluoride in synthetic and groundwater, Environmental Technology. Vol. 28, pp: 595607. 13. Holt P.K. (2003), Electrocoagulation: unravelling and synthesising the mechanisms behind a water treatment processes, Ph.D. thesis, Faculty of Engineering, The University of Sydney. 14. Hu C.Y., Lo S.L. and Kuan W.H. (2005), Effects of the molar ratio of hydroxide and fluoride to Al (III) on fluoride removal by coagulation and electrocoagulation. J. Colloid Interf. Sci. Vol. 283, pp: 472476. 15. Hu K., Dickson J.M. (2006), Nanofiltration membrane performance on fluoride removal from water, Membrane Science, Vol. 279 pp: 529538.

32

Neha Mumtaz, Govind Pandey, Pawan Kumar Labhsetwar & Subhash P. Andey

16. IPCS (2002), Fluorides. Environmental Health Criteria 227. International Programme on Chemical Safety, World Health Organisation, Geneva, Switzerland 17. Kumar S., Gupta A. and Yadav J.P. (2007), Fluoride removal by mixtures of activated carbon prepared from Neem (Azadirachta indica) and Kikar (Acacia arabica) leaves, Indian Journal of Chemical Technology. Vol. 14, pp: 355361. 18. Mjengera H. and Mkongo G. (2003), Appropriate deflouridation technology for use in flourotic areas in Tanzania, Physical chemistry Earth, Vol. 28 pp: 10971104. 19. Pinon-Miramontes M., Bautista-Margulis R.G., Perez-Hernandez A. (2003), Removal of arsenic and fluoride from drinking water with cake alum and a polymeric anionic flocculent, Fluoride Vol. 36 pp: 122128. 20. Qianhai Zuoa, Xueming Chena, Wei Li a, Guohua Chenb (2008), Combined electrocoagulation and electroflotation for removal of fluoride from drinking water, Journal of Hazardous Materials, Vol. 159 pp: 452 457. 21. Shen F., Chen X., Ping Gao and Chen G. (2003), Electrochemical removal of fluoride ions from industrial wastewater, Chemical Engineering Science. Vol. 58, pp: 987 993. 22. State of Environment Report (2009), Ministry of Environment and Forests, Government of India. 23. Tahaikt, M., Achary I., Menkouchi Sahli M.A., Z. Amor, Taky M., Alami A., Boughriba A., Hafsi M. and Elmidaoui A. (2006), Defluoridation of Moroccan groundwater by electrodialysis: continuous operation, Desalination, Vol.189 pp: 215 220. 24. The Environmental Health Criteria document for Aluminium (WHO, 1997). 25. Toyoda, A. and Taira T. (2000), A new method for treating fluorine wastewater to reduce sludge and running costs, IEEE Transactions on Semiconductor Manufacturing, Vol. 13(3), pp: 305309. 26. Tripathy S.S., Bersillon J.L. and Gopal K. (2006), Removal of fluoride from drinking water by adsorption onto alum-impregnated activated alumina, Sep. Purification Technology, Vol.50, pp: 310317. 27. UNMDG (2005), United Nations Millennium Development Goals Report, United Nations, New York. 28. World Health Organization (2011), Guidelines for Drinking-Water Quality.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Analysis of Drinking Water QualityДокумент16 страницAnalysis of Drinking Water QualityYuvaraj Duttaragi50% (4)

- Test Reports - NBRДокумент105 страницTest Reports - NBRImtiyaz KhanОценок пока нет

- Baluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaДокумент14 страницBaluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaTJPRC PublicationsОценок пока нет

- Development and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateДокумент10 страницDevelopment and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateTJPRC PublicationsОценок пока нет

- Comparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanДокумент8 страницComparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanTJPRC PublicationsОценок пока нет

- Flame Retardant Textiles For Electric Arc Flash Hazards: A ReviewДокумент18 страницFlame Retardant Textiles For Electric Arc Flash Hazards: A ReviewTJPRC PublicationsОценок пока нет

- 2 29 1645708157 2ijtftjun20222Документ8 страниц2 29 1645708157 2ijtftjun20222TJPRC PublicationsОценок пока нет

- 2 52 1649841354 2ijpslirjun20222Документ12 страниц2 52 1649841354 2ijpslirjun20222TJPRC PublicationsОценок пока нет

- 2 4 1644229496 Ijrrdjun20221Документ10 страниц2 4 1644229496 Ijrrdjun20221TJPRC PublicationsОценок пока нет

- Self-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsДокумент8 страницSelf-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsTJPRC PublicationsОценок пока нет

- 2 33 1641272961 1ijsmmrdjun20221Документ16 страниц2 33 1641272961 1ijsmmrdjun20221TJPRC PublicationsОценок пока нет

- 2 44 1653632649 1ijprjun20221Документ20 страниц2 44 1653632649 1ijprjun20221TJPRC PublicationsОценок пока нет

- Using Nanoclay To Manufacture Engineered Wood Products-A ReviewДокумент14 страницUsing Nanoclay To Manufacture Engineered Wood Products-A ReviewTJPRC PublicationsОценок пока нет

- 2 51 1651909513 9ijmpsjun202209Документ8 страниц2 51 1651909513 9ijmpsjun202209TJPRC PublicationsОценок пока нет

- 2 51 1656420123 1ijmpsdec20221Документ4 страницы2 51 1656420123 1ijmpsdec20221TJPRC PublicationsОценок пока нет

- Dr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahДокумент12 страницDr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahTJPRC PublicationsОценок пока нет

- Covid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangДокумент8 страницCovid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangTJPRC PublicationsОценок пока нет

- 2 51 1647598330 5ijmpsjun202205Документ10 страниц2 51 1647598330 5ijmpsjun202205TJPRC PublicationsОценок пока нет

- An Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaДокумент10 страницAn Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaTJPRC PublicationsОценок пока нет

- A Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)Документ8 страницA Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)TJPRC PublicationsОценок пока нет

- Analysis of Bolted-Flange Joint Using Finite Element MethodДокумент12 страницAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsОценок пока нет

- Effectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewДокумент14 страницEffectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewTJPRC PublicationsОценок пока нет

- 2 67 1644220454 Ijmperdfeb202206Документ9 страниц2 67 1644220454 Ijmperdfeb202206TJPRC PublicationsОценок пока нет

- 2 67 1640070534 2ijmperdfeb202202Документ14 страниц2 67 1640070534 2ijmperdfeb202202TJPRC PublicationsОценок пока нет

- 2 67 1653022679 1ijmperdjun202201Документ12 страниц2 67 1653022679 1ijmperdjun202201TJPRC PublicationsОценок пока нет

- Vitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019Документ16 страницVitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019TJPRC PublicationsОценок пока нет

- Effect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementДокумент8 страницEffect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementTJPRC PublicationsОценок пока нет

- Comparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsДокумент22 страницыComparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsTJPRC PublicationsОценок пока нет

- 2 67 1641277669 4ijmperdfeb202204Документ10 страниц2 67 1641277669 4ijmperdfeb202204TJPRC PublicationsОценок пока нет

- Numerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingДокумент18 страницNumerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingTJPRC PublicationsОценок пока нет

- 2 67 1645871199 9ijmperdfeb202209Документ8 страниц2 67 1645871199 9ijmperdfeb202209TJPRC PublicationsОценок пока нет

- Next Generation'S Energy and Time Efficient Novel Pressure CookerДокумент16 страницNext Generation'S Energy and Time Efficient Novel Pressure CookerTJPRC PublicationsОценок пока нет

- Chemical Burn TraumataДокумент10 страницChemical Burn TraumatadnnivОценок пока нет

- Latsol Bahasa Inggris + PembahasanДокумент152 страницыLatsol Bahasa Inggris + PembahasanAfwega Bagas K. P.Оценок пока нет

- Final Year Project Mrs NdlovuДокумент35 страницFinal Year Project Mrs NdlovuBlessed Sibanda100% (1)

- Khaitan HazardousДокумент15 страницKhaitan HazardousKamesh TripathiОценок пока нет

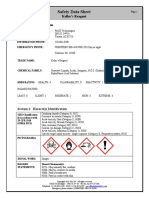

- Safety Data Sheet: Keller's Reagent Section 1: IdentificationДокумент13 страницSafety Data Sheet: Keller's Reagent Section 1: IdentificationEmmanuel ReyesОценок пока нет

- Usp31nf26s1 - m11430, USP Monographs - Calcium CarbonateДокумент1 страницаUsp31nf26s1 - m11430, USP Monographs - Calcium CarbonateEfsha KhanОценок пока нет

- Cations and Anions in Fresh Fruit Juice by Fast Ion ChromatographyДокумент8 страницCations and Anions in Fresh Fruit Juice by Fast Ion ChromatographyAravinthОценок пока нет

- Adsorption of Flouride Using Nanoparticles of Aluminium OxideДокумент15 страницAdsorption of Flouride Using Nanoparticles of Aluminium OxideIsa musaОценок пока нет

- Performance of Nickel Alloys in Hot Gaseous FluorineДокумент6 страницPerformance of Nickel Alloys in Hot Gaseous FluorineHeanjiaAlloysОценок пока нет

- RE: False and Misleading Statements Made OnДокумент8 страницRE: False and Misleading Statements Made OnDean DeYongОценок пока нет

- D 3270 - 00 - Rdmynza - PDFДокумент9 страницD 3270 - 00 - Rdmynza - PDFAnilОценок пока нет

- Fluoride: Its Metabolism, Toxicity, and Role in Dental HealthДокумент5 страницFluoride: Its Metabolism, Toxicity, and Role in Dental HealthCeida Lopez CastillaОценок пока нет

- Systemic FlouridesДокумент61 страницаSystemic FlouridesJitender Reddy100% (1)

- Terapia de Fluor AAPDДокумент4 страницыTerapia de Fluor AAPDAndy HerreraОценок пока нет

- Material Safety Data Sheet - Sodium Fluoride MSDSДокумент6 страницMaterial Safety Data Sheet - Sodium Fluoride MSDSGodIsTruthОценок пока нет

- Water Issue and Harvesting Techniques For Development in Nagaur District, RajasthanДокумент11 страницWater Issue and Harvesting Techniques For Development in Nagaur District, Rajasthanpraveenanp1234Оценок пока нет

- Medicinal Water: Special GuideДокумент28 страницMedicinal Water: Special Guide黃浚維Оценок пока нет

- ProjectДокумент26 страницProjectPrashanth S PОценок пока нет

- Dental Fluorosis and Its PreventionДокумент4 страницыDental Fluorosis and Its PreventionSachinSharmaОценок пока нет

- Q46F-D Direct Fluoride MonitorДокумент2 страницыQ46F-D Direct Fluoride Monitorjose maria sanchez hurtadoОценок пока нет

- Chlorates and FluorineДокумент29 страницChlorates and FluorineElamaran AnbazhaganОценок пока нет

- Assessment of Supply Water Quality Using GIS Tool For Selected Locations in Delhi-A Case StudyДокумент9 страницAssessment of Supply Water Quality Using GIS Tool For Selected Locations in Delhi-A Case StudyTriandoОценок пока нет

- Manuskrip Fluoride 2017Документ51 страницаManuskrip Fluoride 2017Annisa HusnaОценок пока нет

- LUSSI, 2019. The Use of Fluoride For The Prevention of Dental Erosion and Erosive Tooth Wear in Children and Adolescents PDFДокумент11 страницLUSSI, 2019. The Use of Fluoride For The Prevention of Dental Erosion and Erosive Tooth Wear in Children and Adolescents PDFJohnatan MeirelesОценок пока нет

- Hydro and Geochemical Characteristics of Ground Water Assessment in Puducherry Coastal Stretch, Puducherry RegionДокумент11 страницHydro and Geochemical Characteristics of Ground Water Assessment in Puducherry Coastal Stretch, Puducherry RegionIJRASETPublicationsОценок пока нет

- Week 13,14 Treatment of WaterДокумент55 страницWeek 13,14 Treatment of WaterWarid BangashОценок пока нет

- The Fluoride DeceptionДокумент4 страницыThe Fluoride DeceptionNayla Carole Gaspareto100% (2)

- Flour IdaДокумент12 страницFlour IdapravitasaririzkyОценок пока нет