Академический Документы

Профессиональный Документы

Культура Документы

Wistron's Green Product Development and Environmental Management

Загружено:

xtrayangОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Wistron's Green Product Development and Environmental Management

Загружено:

xtrayangАвторское право:

Доступные форматы

Innovation

Although Wistron's products are mostly designed and developed based on our customers requirements, however, mass production also has certain impacts on the environment, highlighting our responsibility for the well-being of the Earth. We believe that taking environmental factors into consideration in our product design process will significantly reduce adverse environmental impacts caused by ICT products. In this regard, our research and development teams work closely with customers, component suppliers, technology platform suppliers and relevant research organizations to develop more environmentally friendly products through creative thinking.

Green Product Management

Green Product Design

Our product design philosophy is structured upon the lifecycle analysis concept. In this regard, we apply a comprehensive lifecycle assessment, linking every stage of a products lifecycle from proposal, planning, R&D design, to lab pilot run, engineering pilot run, production pilot run and mass production, all the way to disposal. This assessment effectively helps our R&D team understand the influence of the complex environmental factors related to our products.

2011 CS2R REPORT

116 016

Innovation

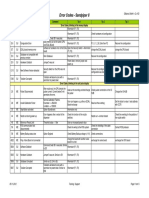

Wistron Product Development Life Cycle and Processes s

Proposal Phase

Planning Phase

R&D Design Phase

Lab Pilot Run Phase

Eng. Pilot Run Phase

Production Pilot Run Phase

Mass Production & EOL Phase

MRS-Green Requirement

Key Green Component Green Design Guide and Checklist

Green Design Green Parts Selection Pre-RoHS Check

Green Function Venfication Green Parts Spec. Approved RoHS Check

Green Parts Batch Approve &OVL Green Eng.P/R Reliability Test for Green Design Final RoHS Confirmation

Green Supplier Management Incoming Green Parts Inspection Green Parts Management Green Manufactuning Service for Green Prosuct ECR/N Process

Development Green Product Development Suppller Green Parts & Supplier Management Manufacture Green Manufactuning. Quality Control & Customer Service IT Green Information System & Application

117

2011 CS2R REPORT

118

Innovation

We expect products developed by Wistron to meet customers environmental standards and legal requirements. We also work to concretely reduce impact on the environment at every stage of a products lifecycle. A further analysis of these impacts is illustrated in the table below. In 2011, no violations of product and service standards, relevant health and safety standards or voluntary agreements were reported. Our efforts in designing sustainable products are focused on three major areas: 1) hazardous substance management, 2) material-saving recyclable design, 3) energy efficiency.

Hazardous Substance Management

Green Product Management System

In response to the EUs Restriction of Hazardous Substances Directive (RoHS), we have reviewed our product lifecycle and redefined our management system. From design, manufacturing and testing to supply chain management, we take effective control measures to establish a corresponding management system. This management system works to ensure that our products comply with regulations and customer requirements for green products at every point in our production, from research, design and material

The Impacts on Health and Safety in Each Stage of a Product / Service Life Cycle

Stages of Product Life Cycle Development of Product Concept R&D Certification Manufacturing and Production Marketing and Promotion Storage Distribution and Supply Use and Service Disposal, Reuse, or Recycling Assessment Implemented Yes Yes Yes Yes N/A (note) N/A (note) Yes Yes

procurement to product packaging and shipping. With regard to the management of hazardous substances in our products, Wistron established the Environmental Hazardous Substance Control Standards, which cover the terms of RoHS and halogen-free requirements laid out in the EU chemical policy (Registration, Evaluation, Authorization and Restriction of Chemicals; REACH). Wistron has also implemented a hazardous substance-free control SOP to ensure that all components and materials used in Wistrons products comply with the environmental criteria demanded by our customers as well as legal regulations. From R&D and design to supply chain management, we strictly demand our suppliers limit or remove controlled chemicals, aiming to reduce the impact on and pollution of the environment and the effects on human health of electronic waste.

Note: Wistron is an ODM company, not a brand marketer; therefore, the impacts from this stage are not taken into consideration.

119

2011 CS2R REPORT

120

Innovation

Since 2003, we have successfully passed annual audits by our customers and have continuously maintained an OEM Green Partner Certificate. Starting at the end of 2006, our global manufacturing sites all passed audits conducted by international certification organizations and received the IECQ QC080000 Hazardous Substance Process Management System Certificate. We have set up a Green Product Management System (GPM) which serves as an important information system for the management of environmental compliance for components. Through this system, we monitor the use of environmentally compliant components beginning from the design stage. At the same time, all of our component suppliers must pass green component certifications and comply with international environmental standards. Our manufacturing plants use the Enterprise Resource Planning System (ERP) in conjunction with the Shop Floor Control System (SFCS) to manage the use of components and prevent the penetration of non-environmentally compliant parts.

Green Product Management Information System

Green Product Management System (GPM)

Summary of the IECQ QC080000 Audit

Internal Audit for QC080000

Hsichih Office Zhongshan Plant Kunshan Plant Hsinchu Plant Mexico Plant Czech Plant

No. of Audits

0 1 2 0 NA 1

Reported Problems from Result of External the Internal Audit Audit

0 0 3 0 NA 4 Passed Passed Passed Passed NA Passed

Management of Environmentally Friendly Materials in the GPM System

121

2011 CS2R REPORT

122

Innovation

Wistron Hazardous Substance Laboratory

We have set up a professional hazardous substance laboratory at every manufacturing plant. Materials used in the plants are tested with advanced equipment to ensure that Wistrons products do not contain hazardous substances. We implement strict due diligence to minimize risks. The laboratory at Wistrons Zhongshan Plant has been certified to comply with ISO 17025 laboratory standards. It is now a full-fledged testing institution at the professional level. In 2011, over 30,000 samples were tested and the results have been stored in the laboratorys global database. Hazardous Substance Testing available at each Plant

Site

Taipei Hsinchu Plant Kunshan Plant Zhongshan Plant Mexico Plant Czech Plant N/A Lead, cadmium, mercury, total chromium, total bromine, total chlorine Lead, cadmium, mercury, total chromium, total bromine, total chlorine Lead, cadmium, mercury, chromium, bromine, chlorine, Cr6+, polybrominated biphenyls, polybrominated diphenyl ethers, phthalates Lead, cadmium, mercury, total chromium, total bromine, total chlorine Lead, cadmium, mercury, total chromium, total bromine, total chlorine

RoHS Laboratory

Extract Polybrominated Biphenyls and Polybrominated Diphenyl Ethers Through a Soxhlet Extractor

Cr6+ Color Comparison Test

Hazardous Substances

Mexico RoHS Lab

ISO 17025 Certificates

Kunshan RoHS Lab

Czech Plant RoHS Lab

123

2011 CS2R REPORT

124

Innovation

Material-Saving Recyclable Design

Currently, most materials used by Wistron are environmentally friendly materials that are compliant with RoHS standards. After taking customer demands, cost factors and legal regulations into consideration, Wistron gives priority to environmentally friendly materials; for example, plastic materials containing recyclable plastics and paper (note). Through the use of environmentally friendly materials, Wistron aims to reduce consumption and wastage of raw materials and minimize impact on the environment. Wistron manages the use of environmentally friendly materials through the GPM system described above and through selection of materials during product development. The GPM system verifies that all materials used are green components, and materials choices containing recycled plastics and paper are given priority at the product development stage. 1. All electronic components must comply with RoHS standards (except certain specified parts). 2. Product recycling complies with WEEE standards.

3. Paper cartons or user manuals are made with a certain percentage of recycled paper or are in compliance with the standards of the US Environmental Protection Agency. 4. Plastics containing a certain percentage of post-consumer material are chosen during product development. In addition, we use the customs clearance and shipping system to calculate the volume of materials used to produce the products. The following table summarizes the relevant statistics. Volume of Product Materials and Packaging Materials

Material Plant Year Volume of Material Usage (tonne) Volume of Packaging Material Usage (tonne)

2010

130,296.36 111,075.60 241,371.96

2011

200,009.87 141,643.49 341,653.36

2010

30,609.18 21,736.00 52,345.18

2011

44,986.41 13,671.60 58,658.01

Zhongshan Plant Kunshan Plant Total

Note: The amount/percentage of recycled materials used is not disclosed because of the wide variety of materials and lack of availability statistics.

125

2011 CS2R REPORT

126

Innovation

Energy Efficiency and Carbon Footprint

R&D team focuses on energy efficiency when developing a product. The team works closely with customers, technology platform suppliers, factories and component suppliers to maximize energy efficiency. During product development, the team not only strives to meet the energy efficiency requirements set forth by the ErP/EuP (EU) and Energy Star (USA), but also takes E-standby, China CECP and carbon footprint into consideration. Because Wistron is an ODM, application for environmental certifications is the responsibility of our clients. While we work closely with our clients to provide necessary product information, we are unable to monitor certification rates. In practice, in active cooperation with our technology platform provider partners we design and develop products that have a high energy conversion rate, low circuit power dissipation, excellent power management and low energy consumption in standby mode. Using the lifecycle concept, although electronic products consume the most power during normal operation, we strive to cut down energy wastage, reduce GHG emissions, upgrade product energy efficiency and develop environmentally friendly products. To achieve these goals we are proceeding in two directions: GHG inventory and product carbon footprint. Starting from these two management systems, we will launch corresponding action plans to reduce the overall GHG emissions of all units of Wistron Corporation worldwide and of the production process of every product. Product carbon footprint is assessed based on five principles: relevance, integrity, consistency, transparency and accuracy. We work with our brand customers to establish a product carbon footprint, and through this system,

we seek opportunities to minimize GHG emissions. In a carbon footprint investigation in 2011 targeting desktop computer products, we identified the components that contributed a high percentage of GHG emissions and supplied our customers with a list of such suppliers, along with a consolidated report. Joint investigation of carbon footprint is the foundation of our mission to reduce GHG emissions. Voluntary investigation will provide a valuable reference for the future development of green management and low-carbon emission designs. In addition, we have also been actively participating in discussions regarding GHG emissions issues and disclose information associated with GHG emissions and carbon reduction via the EICC Carbon Reporting System.

127

2011 CS2R REPORT

128

Вам также может понравиться

- Validation of Cleaning Programs PDFДокумент24 страницыValidation of Cleaning Programs PDFNani Z. IntriagoОценок пока нет

- Housekeeping LEEDДокумент9 страницHousekeeping LEEDsaadОценок пока нет

- Practice HSC Papers General 2Документ47 страницPractice HSC Papers General 2DarrenPurtillWrightОценок пока нет

- Example HACCP StudyДокумент9 страницExample HACCP Studycassilda_carvalho@hotmail.comОценок пока нет

- Life Cycle AssesmentДокумент34 страницыLife Cycle AssesmentMayank Joshi100% (1)

- Albaflow CIRДокумент5 страницAlbaflow CIRxtrayangОценок пока нет

- Introduction To Sustainable ManufacturingДокумент24 страницыIntroduction To Sustainable ManufacturingAnonymous f1UCK4Оценок пока нет

- Background Material: Ecodesign Information Improving Products With EcodesignДокумент18 страницBackground Material: Ecodesign Information Improving Products With Ecodesignfrank niel fajilan100% (1)

- Kris Gethin Muscle Building - Nutrition OverviewДокумент8 страницKris Gethin Muscle Building - Nutrition OverviewLuisLopezОценок пока нет

- F0358 CMM 010Документ164 страницыF0358 CMM 010MJI EUWОценок пока нет

- Industrial Process Scale-up: A Practical Innovation Guide from Idea to Commercial ImplementationОт EverandIndustrial Process Scale-up: A Practical Innovation Guide from Idea to Commercial ImplementationОценок пока нет

- Life Cycle AssessmentДокумент10 страницLife Cycle AssessmentWade Coleman100% (1)

- 34Документ11 страниц34olivier_rondouin100% (1)

- Checklist For QCДокумент12 страницChecklist For QCvistalmarlonОценок пока нет

- ISO 14001 Step by Step - A practical guide: Second editionОт EverandISO 14001 Step by Step - A practical guide: Second editionРейтинг: 5 из 5 звезд5/5 (1)

- 2006-13 - Tectilon - Erionyl - Lanaset - PolarДокумент68 страниц2006-13 - Tectilon - Erionyl - Lanaset - Polarxtrayang100% (3)

- Ecodesign Iso 14062Документ100 страницEcodesign Iso 14062Cristhian VeraОценок пока нет

- Modeling, Control, and Optimization of Natural Gas Processing PlantsОт EverandModeling, Control, and Optimization of Natural Gas Processing PlantsРейтинг: 5 из 5 звезд5/5 (1)

- Physics: OxfordДокумент224 страницыPhysics: OxfordMusic Life100% (1)

- Life Cycle Assessment of Jute ProductsДокумент47 страницLife Cycle Assessment of Jute ProductsAnastasiya Disyak QuailОценок пока нет

- Green ManufacturingДокумент9 страницGreen Manufacturingraymun c100% (1)

- Green ManufacturingДокумент21 страницаGreen Manufacturingpankaj kumar100% (1)

- Sunett Quality Info PackДокумент34 страницыSunett Quality Info Packredsky_adviseОценок пока нет

- Bluesign Standard Broschuere en Lores 01Документ21 страницаBluesign Standard Broschuere en Lores 01kent0331Оценок пока нет

- Green ElectДокумент18 страницGreen ElectvinaaykingsОценок пока нет

- Environment AssignmentДокумент2 страницыEnvironment AssignmentRaksha Dipesh AmlaniОценок пока нет

- CP Techniques Reduce Waste & CostsДокумент3 страницыCP Techniques Reduce Waste & CostsDianne VillanuevaОценок пока нет

- Environmental impact assessment and material selectionДокумент20 страницEnvironmental impact assessment and material selectionSajjad HassanОценок пока нет

- PVH's Environmental EffortsДокумент12 страницPVH's Environmental EffortsKc TsoОценок пока нет

- Ecodesign: Best Practice of ISO/TR 14062Документ100 страницEcodesign: Best Practice of ISO/TR 14062Anh PhamОценок пока нет

- Assignment 3 EiaДокумент6 страницAssignment 3 EiaWan ahmad Zahin RizzqiОценок пока нет

- Life Cycle Assessment and Its ApplicationsДокумент39 страницLife Cycle Assessment and Its ApplicationsAmol MahajanОценок пока нет

- PPL 43Документ242 страницыPPL 43Divesh GuptaОценок пока нет

- Env Mgmt-AssignmentДокумент7 страницEnv Mgmt-AssignmentKetki KadamОценок пока нет

- Save 10% on bills by unplugging unused appliancesДокумент16 страницSave 10% on bills by unplugging unused appliancesAnkit SrivastavaОценок пока нет

- Produksi Bersih (Cleaner Production) : TKK 4405 2 SksДокумент30 страницProduksi Bersih (Cleaner Production) : TKK 4405 2 SksDenny Muchammad AnwarОценок пока нет

- Amin Bin Shahrom - 2018249636 - Assignment 1Документ9 страницAmin Bin Shahrom - 2018249636 - Assignment 1Amin ShahromОценок пока нет

- Ethics 7Документ14 страницEthics 7teknikpembakaran2013Оценок пока нет

- Ecodesign The Twelve ProcedureДокумент32 страницыEcodesign The Twelve ProcedureMohamad FaifОценок пока нет

- Singapore Green Labelling SchemeДокумент6 страницSingapore Green Labelling Schemeuocmogiandi_aОценок пока нет

- PoemДокумент23 страницыPoemJaspreet Singh SidhuОценок пока нет

- Product Planning and Control, Inventory and PR OcurementДокумент12 страницProduct Planning and Control, Inventory and PR OcurementKentJustineIIОценок пока нет

- Green Supply Chain Management: by - Harsh Tiwari (21BBAC25) Vivek J (21BBAC72)Документ9 страницGreen Supply Chain Management: by - Harsh Tiwari (21BBAC25) Vivek J (21BBAC72)Aman KumarОценок пока нет

- Lca Green CouncilДокумент9 страницLca Green CouncilEngkusSutisnaОценок пока нет

- HK Green Label Scheme Criteria for All Purpose CleanersДокумент4 страницыHK Green Label Scheme Criteria for All Purpose CleanersdepriyantoОценок пока нет

- Life Cycle AssessmentДокумент15 страницLife Cycle AssessmentShamsiya KhalidОценок пока нет

- Environmental AuditДокумент6 страницEnvironmental AuditBernard GanzwaОценок пока нет

- Indira School of Business Studies: SR - No Name of Student Roll No. 1 2Документ23 страницыIndira School of Business Studies: SR - No Name of Student Roll No. 1 2Roshan RajanОценок пока нет

- Green Construction A GДокумент36 страницGreen Construction A GFlorabel Tolentino Sera JosefОценок пока нет

- International Journal of Production ResearchДокумент17 страницInternational Journal of Production ResearchbalakaleesОценок пока нет

- Bestseller Environmental RequirementsДокумент14 страницBestseller Environmental RequirementsRabiul IslamОценок пока нет

- Project Sustainable Design ManagementДокумент14 страницProject Sustainable Design ManagementNhan DoОценок пока нет

- CFP Guideline enДокумент17 страницCFP Guideline enกาลครั้งหนึ่ง ริมฝั่งโขงОценок пока нет

- NEF_QA_001_NE_France_GCO_QEM (1)Документ39 страницNEF_QA_001_NE_France_GCO_QEM (1)israel afolayan mayomiОценок пока нет

- Green Supplier Selection Model for High-Tech IndustryДокумент11 страницGreen Supplier Selection Model for High-Tech IndustrybalajimeieОценок пока нет

- Risk Management of Hazardous Substances in Selection of Green SuppliersДокумент8 страницRisk Management of Hazardous Substances in Selection of Green SuppliersMonika HusarovaОценок пока нет

- WWW - Alfa-Klima - Hu 2009 Samsung Klima en KatalogusДокумент41 страницаWWW - Alfa-Klima - Hu 2009 Samsung Klima en KatalogusAlex RizescuОценок пока нет

- Audit ReportДокумент8 страницAudit Reportanika tahsinОценок пока нет

- Factsheet1 Clean ProductionДокумент10 страницFactsheet1 Clean ProductionCharith LiyanageОценок пока нет

- REDBLISS Preliminary ResearchДокумент2 страницыREDBLISS Preliminary ResearchMariabelen DoriaОценок пока нет

- Lecture 1-4 - Basics of Sustainability and Sustainable Product Design Models and ToolsДокумент79 страницLecture 1-4 - Basics of Sustainability and Sustainable Product Design Models and ToolsMahin Ar RahmanОценок пока нет

- Sustainable ProductionДокумент12 страницSustainable ProductionSurmayee UmatheОценок пока нет

- Green Supplier Selection for Pharmaceutical IndustryДокумент13 страницGreen Supplier Selection for Pharmaceutical IndustrySomesh DasОценок пока нет

- Sgs FootwearДокумент6 страницSgs FootwearAnoosha HabibОценок пока нет

- Process ChemistryДокумент63 страницыProcess ChemistryFiruj AhmedОценок пока нет

- BEES Please QuestionnaireUserGuideДокумент13 страницBEES Please QuestionnaireUserGuide19pwmec4766Оценок пока нет

- SDC Brochure - 07 Issue - 11-08-02 - ENДокумент28 страницSDC Brochure - 07 Issue - 11-08-02 - ENxtrayangОценок пока нет

- H & M Chemical Restrictions - 2009-12-14Документ52 страницыH & M Chemical Restrictions - 2009-12-14xtrayangОценок пока нет

- SDC Brochure - 07 Issue - 11-08-02 - ENДокумент28 страницSDC Brochure - 07 Issue - 11-08-02 - ENxtrayangОценок пока нет

- 12-05-21 - 從雨林到垃圾 - 肯德基如何成為毀林幫兇 - ENДокумент16 страниц12-05-21 - 從雨林到垃圾 - 肯德基如何成為毀林幫兇 - ENxtrayangОценок пока нет

- Dirty Laundry 3 - Reloaded - en - Executive Summary - 12-03-20Документ12 страницDirty Laundry 3 - Reloaded - en - Executive Summary - 12-03-20xtrayangОценок пока нет

- Dirty Laundry - 全球服裝品牌的中國水污染調查 - EN - 11-07-13Документ116 страницDirty Laundry - 全球服裝品牌的中國水污染調查 - EN - 11-07-13xtrayangОценок пока нет

- Dirty Laundry 3 - Reloaded - en - 12-03-20Документ48 страницDirty Laundry 3 - Reloaded - en - 12-03-20xtrayangОценок пока нет

- A Lire: Le Rapport de Greenpeace "Dirty Laundry 2" (Linge Sale 2)Документ32 страницыA Lire: Le Rapport de Greenpeace "Dirty Laundry 2" (Linge Sale 2)nouvelobsОценок пока нет

- Reactive Dye Salt-Alkali Charts & Exhaust Dyeing Method For Lab Ver 2 0Документ4 страницыReactive Dye Salt-Alkali Charts & Exhaust Dyeing Method For Lab Ver 2 0xtrayangОценок пока нет

- 3-Other Dyes and Reactive DyesДокумент8 страниц3-Other Dyes and Reactive DyesxtrayangОценок пока нет

- M&S Method of Test P5A - 2007-08Документ4 страницыM&S Method of Test P5A - 2007-08xtrayang100% (1)

- Copy of Vehicle-Maintenance-Record Work BacklogsДокумент41 страницаCopy of Vehicle-Maintenance-Record Work BacklogsHughoОценок пока нет

- Routage GR.I 251-441 - GBДокумент6 страницRoutage GR.I 251-441 - GBAhmad MohammadОценок пока нет

- HVTS-70/50: Portable High-Voltage Test SystemДокумент2 страницыHVTS-70/50: Portable High-Voltage Test SystemvhendrayawanОценок пока нет

- Wave-Particle Duality FundamentalsДокумент7 страницWave-Particle Duality FundamentalsRahmatullahОценок пока нет

- Thermal Power Plant: " " NTPC (Dadri)Документ17 страницThermal Power Plant: " " NTPC (Dadri)Kulvinder SinghОценок пока нет

- Cyclotron Booklet Black Final PrintДокумент10 страницCyclotron Booklet Black Final PrintNawaf BamasoudОценок пока нет

- Aeroshell Ascender: Performance, Features & Benefits Main ApplicationsДокумент3 страницыAeroshell Ascender: Performance, Features & Benefits Main ApplicationsRicardo LacskoОценок пока нет

- 3.electromagnetic Theory NET-JRF VKSДокумент31 страница3.electromagnetic Theory NET-JRF VKSSijil SalimОценок пока нет

- Chemistry Practice Paper SA1 Class 9 CBSEДокумент2 страницыChemistry Practice Paper SA1 Class 9 CBSEgurdeepsarora8738Оценок пока нет

- Agenda Dynamics and Policy Subsystems Baumgartner1991Документ32 страницыAgenda Dynamics and Policy Subsystems Baumgartner1991Gustavo Decap AgüeroОценок пока нет

- Engineering Physics - G. AruldhasДокумент100 страницEngineering Physics - G. AruldhasJaya sankarОценок пока нет

- Ductable Fan Coil Unit: Product Selection DataДокумент26 страницDuctable Fan Coil Unit: Product Selection DataNelson MartinsОценок пока нет

- 9 Electronics TДокумент44 страницы9 Electronics TBieonWongОценок пока нет

- OMEGA Air Circuit Breaker DetailsДокумент137 страницOMEGA Air Circuit Breaker DetailsSIVA NAGA SUDHEER SIDDANIОценок пока нет

- B S T Year 5Документ9 страницB S T Year 5INCREASE & ABUNDANT SCHOOLSОценок пока нет

- SMC1500-2U: Product Data SheetДокумент3 страницыSMC1500-2U: Product Data SheetRedes ItcОценок пока нет

- Notes on Heat Transfer Methods and EquationsДокумент6 страницNotes on Heat Transfer Methods and Equationsjme733k9100% (1)

- Protection of Synchronous Machines: Application GuideДокумент44 страницыProtection of Synchronous Machines: Application GuideDerouich2019Оценок пока нет

- Master Plan For Delhi: Dr. Mayank MathurДокумент40 страницMaster Plan For Delhi: Dr. Mayank MathurJay PrakashОценок пока нет

- Produktkatalog 2019 WebДокумент280 страницProduktkatalog 2019 WebbagastcОценок пока нет

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIДокумент5 страницTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowОценок пока нет

- 66 KV Design Parameters in GujaratДокумент1 страница66 KV Design Parameters in GujaratAkhilesh SolankiОценок пока нет

- Bridge Rectifier - Definition, Construction and WorkingДокумент14 страницBridge Rectifier - Definition, Construction and WorkingRamKumarОценок пока нет

- Hypercell 1994 Engl by Hans HassДокумент126 страницHypercell 1994 Engl by Hans HassClaimDestinyОценок пока нет

- Eco NicalДокумент13 страницEco Nicalluizfellipe95Оценок пока нет