Академический Документы

Профессиональный Документы

Культура Документы

Metric THread Charts

Загружено:

rethinamkИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Metric THread Charts

Загружено:

rethinamkАвторское право:

Доступные форматы

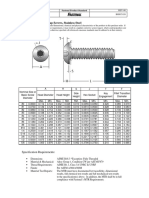

Threads

and

Materials

57

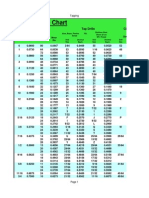

Threads and Materials

Inch Series and Metric Threads

Decarburization Limits

Threads

Per

Inch

H

Thread

Height

0.75 H

From Root

To Crest

Min.

0.1 H

At Root

Max.

Thread

Pitch

mm

H

Thread

Height

mm

80

72

64

56

48

44

40

36

32

28

24

20

18

16

14

13

12

11

10

9

8

7

6

5

4.5

4

0.008

0.009

0.010

0.011

0.013

0.014

0.015

0.017

0.019

0.022

0.026

0.031

0.034

0.038

0.044

0.047

0.051

0.056

0.061

0.068

0.077

0.088

0.102

0.123

0.136

0.153

0.006

0.007

0.008

0.008

0.010

0.011

0.011

0.013

0.014

0.017

0.020

0.023

0.026

0.029

0.033

0.035

0.038

0.042

0.046

0.051

0.058

0.066

0.077

0.092

0.102

0.115

0.001

0.001

0.001

0.001

0.001

0.001

0.002

0.002

0.002

0.002

0.003

0.003

0.003

0.004

0.004

0.005

0.005

0.006

0.006

0.007

0.008

0.009

0.010

0.012

0.014

0.015

0.35

0.4

0.45

0.5

0.7

0.8

1.0

1.25

1.5

1.75

2.0

2.5

3.0

3.5

4.0

0.215

0.245

0.276

0.307

0.429

0.491

0.613

0.767

0.920

1.074

1.227

1.534

1.840

2.147

2.454

0.75 H

From Root

To Crest

Min.

mm

0.161

0.184

0.207

0.230

0.322

0.368

0.460

0.575

0.690

0.806

0.920

1.151

1.380

1.610

1.841

58

Threads and Materials (continued)

Thread Limiting Dimensions Inch threads

Class 3A through 1, Class 2A 1 1/8 through 2 diameter

Coarse Series Threads

Nominal

Screw

Size

#2

#3

#4

#5

#6

#8

#10

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

1

1 1/8

1 1/4

1 1/2

1 3/4

2

Threads

Per

Inch

UNRC

56

48

40

40

32

32

24

20

18

16

14

13

11

10

9

8

7

7

6

5

4 1/2

Pitch

Diameter

Max. Min.

0.0744

0.0855

0.0958

0.1088

0.1177

0.1437

0.1629

0.2175

0.2764

0.3344

0.3911

0.4500

0.5660

0.6850

0.8028

0.9188

1.0300

1.1550

1.3893

1.6174

1.8528

0.0728

0.0838

0.0939

0.1069

0.1156

0.1415

0.1604

0.2147

0.2734

0.3311

0.3876

0.4463

0.5619

0.6806

0.7981

0.9137

1.0228

1.1476

1.3812

1.6085

1.8423

Major

Diameter

Max. Min.

0.0860

0.0990

0.1120

0.1250

0.1380

0.1640

0.1900

0.2500

0.3125

0.3750

0.4375

0.5000

0.6250

0.7500

0.8750

1.0000

1.1228

1.2478

1.4976

1.7473

1.9971

0.0819

0.0945

0.1069

0.1199

0.1320

0.1580

0.1828

0.2419

0.3038

0.3656

0.4272

0.4891

0.6129

0.7371

0.8611

0.9850

1.1064

1.2314

1.4794

1.7268

1.9751

Minor

Diameter

Min.

0.0612

0.0703

0.0777

0.0906

0.0953

0.1212

0.1334

0.1823

0.2374

0.2906

0.3413

0.3964

0.5029

0.6157

0.7260

0.8325

0.9300

1.0548

1.2729

1.5092

1.6900

59

Threads and Materials (continued)

Thread Limiting Dimensions Inch Series Threads

Fine Series Threads

Nominal

Screw

Size

#2

#3

#4

#5

#6

#8

#10

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

1

1 1/8

1 1/4

1 1/2

1 3/4

2

Threads

Per

Inch

UNRF

64

56

48

44

40

36

32

28

24

24

20

20

18

16

14

12

12

12

12

Pitch

Diameter

Max. Min.

0.0759

0.0874

0.0985

0.1102

0.1218

0.1460

0.1697

0.2268

0.2854

0.3479

0.4050

0.4675

0.5889

0.7094

0.8286

0.9459

1.0691

1.1941

1.4440

0.0744

0.0858

0.0967

0.1083

0.1198

0.1439

0.1674

0.2243

0.2827

0.3450

0.4019

0.4643

0.5854

0.7056

0.8245

0.9415

0.0631

1.1879

1.4376

Major

Diameter

Max. Min.

0.0860

0.0990

0.1120

0.1250

0.1380

0.1640

0.1900

0.2500

0.3125

0.3750

0.4375

0.5000

0.6250

0.7500

0.8750

1.0000

1.1232

1.2482

1.4981

0.0822

0.0949

0.1075

0.1202

0.1329

0.1585

0.1840

0.2435

0.3053

0.3678

0.4294

0.4919

0.6163

0.7406

0.8647

0.9886

1.1118

1.2368

1.4867

Minor

Diameter

Min.

0.0643

0.0742

0.0832

0.0936

0.1036

0.1259

0.1471

0.2011

0.2557

0.3180

0.3695

0.4319

0.5494

0.6650

0.7781

0.8874

1.0090

1.1338

1.2586

60

Threads and Materials (continued)

Thread Limiting Dimensions Class 4g6g Metric Threads

Nominal

Diameter

And

Thread Pitch

Tolerance

Class

Allowance

ES

M2x0.4

M2.5x0.45

M3x0.5

M4x0.7

M5x0.8

M6x1.0

M8x1.25

M10x1.50

M12x1.75

M16x2.0

M20x2.5

M24x3.0

M30x3.5

M36x3.5

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

4g6g

0.019

0.020

0.020

0.022

0.024

0.026

0.028

0.032

0.034

0.038

0.042

0..048

0.053

0.060

Major

Diameter

Max. Min.

1.981

2.480

2.980

3.978

4.976

5.974

7.972

9.968

11.966

15.962

19.958

23.952

29.947

35.940

1.886

2.380

2.874

3.838

4.826

5.794

7.760

9.732

11.701

15.682

19.623

23.577

29.522

35.465

Pitch

Diameter

Max. Min.

1.721

2.188

2.655

3.523

4.456

5.324

7.160

8.994

10.829

14.663

18.334

22.003

27.674

33.342

1.679

2.143

2.607

3.467

4.396

5.253

7.085

8.909

10.734

14.563

18.228

21.878

27.542

33.202

Minor

Diameter

(flat form)

Max.

1.548

1.993

2.439

3.220

4.110

4.891

6.619

8.344

10.072

13.797

17.252

20.704

26.158

31.610

Minor

Diameter

(rounded form)

Min.

Ref.

1.433

1.866

2.299

3.036

3.904

4.637

6.315

7.985

9.656

13.331

16.688

20.030

25.386

30.738

Applicable Specifications: ASME B1.13M, B1.3M

61

Threads and Materials (continued)

Limits for M Profile Minimum Rounded Root Radius

Pitch

Or

Thread

Spacing

0.4

0.45

0.5

0.6

0.7

0.8

1.0

1.25

1.50

1.75

2.0

2.5

3.0

3.5

4.0

Root Radius

0.125 P

Min.

0.050

0.056

0.062

0.075

0.088

0.100

0.125

0.156

0.188

0.219

0.250

0.312

0.375

0.438

0.500

Applicable Specifications: ASME B1.13M, B1.3M.

62

Threads and Materials (continued)

Tolerance Grade and Position Symbols for Classes of ISO Metric Threads

External Threads

Amount

0

Small

Large

Internal Threads

Tolerance

Grade

Tolerance

Grade

Major

Diameter

Pitch

Diameter

Tolerance

Position

(allowance)

Minor

Diameter

Pitch

Diameter

Tolerance

Position

(allowance)

----4

---

--3

4

5

----4

5

----4

5

6

--8

---

6

7

8

g

6

7

8

---

6

7

8

---

---

ISO metric internal threads are identified by the use of capital letters for the tolerance

position. ISO metric external threads are identified by the use of lower case letters for the

tolerance position.

As an example: M6 x 1.0 4g6g indicates a metric thread form M, 6 mm nominal

diameter. The fastener is externally threaded as noted by the lower case g. The

tolerance position and grade of the major diameter is listed first 4g, followed by the

tolerance position and grade of the pitch diameter-6g.

Standard Property Class 12.9 socket screw products manufactured in the United States

have 4g6g thread tolerances as the form most closely resembles the 3A thread form

used on inch series socket products. When plating or coating of threads is desired, a

thread form with greater allowance should be selected.

63

Threads and Materials (continued)

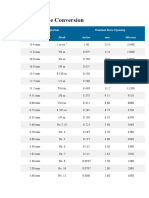

Diameter and Thread Pitch Comparison

Inch

Series

Size

#0

Nom.

Dia.

In.

0.060

Threads

Per

Inch

Metric

Size

Dia.

In.

M1.4

0.05

5

0.073

0.086

0.099

#4

0.112

0.125

#6

0.138

0.164

#10

0.190

5/16

0.3125

0.07

9

0.4

0.25

0.09

8

0.45

0.35

1/2

0.5

0.35

0.375

0.4375

51

74

5/8

0.500

0.625

0.7

0.5

36

51

3/4

0.750

M6

0.19

6

0.23

6

0.8

0.5

1.0

0.75

32

51

25

34

7/8

0.875

1.000

Pitch

In

mm

Equiv.

TPI

(app.)

M8

0.315

1.25

1.0

20

25

M10

0.393

1.5

1.25

17

20

M12

0.472

1.75

1.25

14.5

20

M14

0.551

2

1.5

12.5

17

M16

0.630

2

1.5

12.5

17

M20

0.787

2.5

1.5

10

17

M24

0.945

3

2

8.5

12.5

13

20

11

18

10

16

32

36

24

32

M5

Dia.

In.

14

20

40

44

32

40

0.15

7

Metric

Size

16

24

56

74

48

56

40

48

0.11

8

Threads

Per

Inch

20

28

18

24

64

101

7/16

M4

#8

Nom.

Dia.

In.

0.250

74

127

56

64

M3

#5

0.35

0.2

Inch

Series

Size

1/4

3/8

M2.5

#3

0.06

3

64

72

M2

#2

Equiv.

TPI

(app.)

85

127

80

M1.6

#1

Pitch

In

mm

0.3

0.2

9

14

8

12

Research has shown that there are over 100 possible inch/metric fastener mismatches

possible among commonly used sizes. Care must be taken not to mix the types together.

64

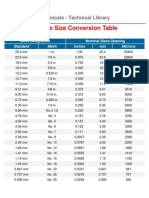

Inch and Metric Screw Threads (continued)

Common Tap Drill Sizes Inch Series Threads

Diameter

Pitch (TPI)

UNC

#2

56

Pitch (TPI)

UNF

64

#3

48

#4

40

#5

40

#6

32

#8

32

#10

24

1/4

20

5/16

18

3/8

16

7/16

14

1/2

13

5/8

11

3/4

10

7/8

1 1/4

1 1/2

56

48

44

40

36

32

28

24

24

20

20

18

16

14

12

12

12

Drill

(in.)

Decimal

0.070

0.070

0.785

0.082

0.0890

0.0935

0.1015

0.1040

0.1065

0.1130

0.1360

0.1360

0.1495

0.1590

0.2040

0.2187

0.261

0.272

0.313

0.332

0.3680

0.3906

0.4219

0.4531

0.5469

0.5781

0.6562

0.6875

0.7656

0.8125

0.875

0.9129

1.1094

1.1719

1.3437

1.4219

Wire, Letter

Fractional

#50

#50

#53

#53

#43

#42

#38

#37

#36

#33

#29

#29

#25

#21

#6

7/32

G

I

5/16

Q

U

25/64

27/64

29/64

35/64

37/64

21/32

11/16

49/64

13/16

7/8

59/64

1 7/64

1 11/64

1 11/32

1 27/64

65

Inch and Metric Screw Threads

Common Tap Drill Sizes-Metric Threads

Metric

Diameter

M2

M2.5

M3

M4

M5

M6

M8

M10

M12

M16

M20

M24

M30

M36

M42

Thread

Spacing

In mm

0.4

0.45

0.5

0.7

0.8

1.0

1.25

1.50

1.75

2.0

2.5

3.0

3.5

4.0

4.5

Drill

mm

1.6

2.05

2.5

3.3

4.2

5.0

6.7

8.5

10.2

14.0

17.5

21.0

26.5

32.0

37.5

Drilling Blind Holes: the minimum depth of a drilled hole suitable for tapping equals the

full thread depth plus the number of turns, P, for each style and size of tap.

Generally, the following minimum length thread engagements are recommended:

Hardened Steel 1 times diameter of the screw

Soft Steels or Cast Iron 1 and 1/2 times diameter of screw

Aluminum 2 times the diameter of the screw.

66

Вам также может понравиться

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreОт EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreРейтинг: 4.5 из 5 звезд4.5/5 (11)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsОт EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsРейтинг: 5 из 5 звезд5/5 (1)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosОт EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosОценок пока нет

- Mesh (Scale)Документ5 страницMesh (Scale)slifer236Оценок пока нет

- Welding Stainless Steel - Questions and Answers A Guide For Troubleshooting Stainless Steel Welding-Related Problems - AWS (2013)Документ266 страницWelding Stainless Steel - Questions and Answers A Guide For Troubleshooting Stainless Steel Welding-Related Problems - AWS (2013)arnoldbatista55100% (1)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderОт EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderРейтинг: 5 из 5 звезд5/5 (2)

- Gear InspectionДокумент7 страницGear Inspectionpangscribd100% (1)

- Types of ThreadsДокумент20 страницTypes of Threadsrethinamk50% (2)

- NEW - I Can Offer FRF / SGO 2 BIN Conversion and BIN 2 SGO / FRF For Almost ALL VAG DSG Gearboxes !! PRICES Between 50 and 100 EurДокумент1 страницаNEW - I Can Offer FRF / SGO 2 BIN Conversion and BIN 2 SGO / FRF For Almost ALL VAG DSG Gearboxes !! PRICES Between 50 and 100 Euralmia tronicsОценок пока нет

- Chapter 4 Matriculation STPMДокумент53 страницыChapter 4 Matriculation STPMJue Saadiah100% (1)

- Steel Section SizesДокумент96 страницSteel Section Sizesabbasshaikh21682Оценок пока нет

- Properties of Matter: Extensive vs IntensiveДокумент16 страницProperties of Matter: Extensive vs IntensiveCentener CalcetaОценок пока нет

- Dimensional Tolerance ChartДокумент1 страницаDimensional Tolerance Chartpushkar_k123Оценок пока нет

- History of MechatronicsДокумент20 страницHistory of MechatronicsManoj DhageОценок пока нет

- Everything About Conveyor BeltsДокумент30 страницEverything About Conveyor BeltsJatin DarveОценок пока нет

- Socket Head Cap Screws Alloy SteelДокумент5 страницSocket Head Cap Screws Alloy SteelChris MedeirosОценок пока нет

- Industrial Press Books CatalogДокумент48 страницIndustrial Press Books CatalogrethinamkОценок пока нет

- Bolting Information Pertaining To ASTM A193Документ25 страницBolting Information Pertaining To ASTM A193dirtylsu100% (2)

- Pfaudler Din Be Reactors 1Документ42 страницыPfaudler Din Be Reactors 1Nancy GarciaОценок пока нет

- Successful Serging: From Setup to Simple and Specialty StitchesОт EverandSuccessful Serging: From Setup to Simple and Specialty StitchesРейтинг: 3 из 5 звезд3/5 (1)

- Arandelas Asme b18.22.1Документ8 страницArandelas Asme b18.22.1Beto HurtadoОценок пока нет

- Computation of Earthquake Response SpectrumДокумент33 страницыComputation of Earthquake Response SpectrumAngela100% (1)

- Serger 101: From Setting Up & Using Your Machine to Creating with Confidence; 10 Projects & 40+ TechniquesОт EverandSerger 101: From Setting Up & Using Your Machine to Creating with Confidence; 10 Projects & 40+ TechniquesОценок пока нет

- ASTM Sieve Chart and TYLER Mesh SizesДокумент1 страницаASTM Sieve Chart and TYLER Mesh SizesWilder CubaОценок пока нет

- ASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesДокумент5 страницASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesPablo Antonio Valcárcel VargasОценок пока нет

- Threads - Galvanized Bolts and Nuts Need Special Thread GagesДокумент3 страницыThreads - Galvanized Bolts and Nuts Need Special Thread GagesBiaizidi Abbou SamirОценок пока нет

- Sieve Designation Nominal Sieve Opening: Standard Mesh Inches MM MicronsДокумент3 страницыSieve Designation Nominal Sieve Opening: Standard Mesh Inches MM MicronsmusaveerОценок пока нет

- How To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincДокумент15 страницHow To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincAndré BuysОценок пока нет

- Telescoping RHS & PIPE PДокумент2 страницыTelescoping RHS & PIPE PRichard WebbОценок пока нет

- Threads-Galvanized Bolts and Nuts Need Special Thread Gages 060923Документ2 страницыThreads-Galvanized Bolts and Nuts Need Special Thread Gages 060923Scott NorrisОценок пока нет

- Hammer Drive ScrewДокумент1 страницаHammer Drive ScrewNisa BN QAОценок пока нет

- Pipe Threads, General Purpose (Inch) : ASME B1.20.1-2013Документ4 страницыPipe Threads, General Purpose (Inch) : ASME B1.20.1-2013NavafОценок пока нет

- Threaded Fasteners: How To Specify FastenersДокумент19 страницThreaded Fasteners: How To Specify FastenersSudath KularathnaОценок пока нет

- Drill and Tap Chart: Clearance Hole Drills Tap Drills Screw SizeДокумент7 страницDrill and Tap Chart: Clearance Hole Drills Tap Drills Screw SizeJennifer Nicky ShakerОценок пока нет

- Week 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensityДокумент27 страницWeek 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensitySamantha NamzugОценок пока нет

- Tuberias Schedule 40 Fittings, Unions & SaddlesДокумент74 страницыTuberias Schedule 40 Fittings, Unions & SaddlesFelix SanchezОценок пока нет

- Unprotected A3702003a 6Документ1 страницаUnprotected A3702003a 6kaveh-bahiraeeОценок пока нет

- Particle Size Conversion TableДокумент3 страницыParticle Size Conversion Tableglauciasc25Оценок пока нет

- Reference Tables - Standard Tap Drills / Clearance HolesДокумент2 страницыReference Tables - Standard Tap Drills / Clearance HolesiswantmachooОценок пока нет

- Sieve SizeДокумент3 страницыSieve SizeSse SteelОценок пока нет

- Particle Size Conversion TableДокумент2 страницыParticle Size Conversion TableVivi OktaviantiОценок пока нет

- Flakiness ElongationДокумент4 страницыFlakiness ElongationrisrizОценок пока нет

- 1936 Series Cap ScrewsДокумент1 страница1936 Series Cap ScrewsStuartОценок пока нет

- Acme Screws Nuts CatalogДокумент18 страницAcme Screws Nuts CatalogparantapkayalОценок пока нет

- Thread - Drill & Tap ChartДокумент2 страницыThread - Drill & Tap ChartullwnОценок пока нет

- Nuts Bolts KeyДокумент2 страницыNuts Bolts KeysudhirggОценок пока нет

- Inch Series Dowel Pins: Mechanical PropertiesДокумент2 страницыInch Series Dowel Pins: Mechanical PropertieswilliaqОценок пока нет

- Bridge Plug Piranha Energy Cataloge BPДокумент11 страницBridge Plug Piranha Energy Cataloge BPJohnОценок пока нет

- Particle Size Conversion Table: Chemicals Technical LibraryДокумент2 страницыParticle Size Conversion Table: Chemicals Technical LibraryduhgrandoОценок пока нет

- N XD 3 2 1 XD XD XD: TurningДокумент3 страницыN XD 3 2 1 XD XD XD: TurningAlejandro Alvarez AlvaradoОценок пока нет

- Cotter PinsДокумент2 страницыCotter PinsMuthukumar MuruganОценок пока нет

- U.S. Sieve Series and Tyler Equivalents: Source by Perry's Chemical Engineer Handbook 7 EditionДокумент2 страницыU.S. Sieve Series and Tyler Equivalents: Source by Perry's Chemical Engineer Handbook 7 EditionMegaboy BwbpОценок пока нет

- Screnning by Perry PDFДокумент2 страницыScrenning by Perry PDFMegaboy BwbpОценок пока нет

- Particle Size Conversion Table: Chemicals - Technical LibraryДокумент3 страницыParticle Size Conversion Table: Chemicals - Technical LibraryMudassar KhanОценок пока нет

- MEC Threads ChartДокумент12 страницMEC Threads ChartenricoОценок пока нет

- 2.2 - Details of Shell & Tube H.EДокумент110 страниц2.2 - Details of Shell & Tube H.ENader GaafarОценок пока нет

- Armstrong ArmaCoil Brass InsertsДокумент12 страницArmstrong ArmaCoil Brass InsertsAce Industrial SuppliesОценок пока нет

- Mallas LaboratorioДокумент2 страницыMallas Laboratoriorafa0714Оценок пока нет

- Cable Gland and Box Selection ChartДокумент1 страницаCable Gland and Box Selection ChartAdrianОценок пока нет

- Cable gland and box selection chartДокумент1 страницаCable gland and box selection chartrocket-vtОценок пока нет

- Threads - Pre-Plate Vs Post Plate Class-MetricДокумент3 страницыThreads - Pre-Plate Vs Post Plate Class-MetricNaveen MaliОценок пока нет

- Conversion Table For Standard Test SievesДокумент2 страницыConversion Table For Standard Test SievesAyo OshoОценок пока нет

- 2019 Peerless Industrial Catalog LGIДокумент150 страниц2019 Peerless Industrial Catalog LGIalan camposОценок пока нет

- BHSCS SSДокумент1 страницаBHSCS SSekjrfhb,dsmОценок пока нет

- Tooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool CompanyДокумент4 страницыTooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool Companyjavier_mor69Оценок пока нет

- Ansys Tensile AnalysisДокумент9 страницAnsys Tensile AnalysisJeremiah KarrisОценок пока нет

- A574 Alloy Steel Socket Head Cap Screw Spec SheetДокумент5 страницA574 Alloy Steel Socket Head Cap Screw Spec SheetChris MedeirosОценок пока нет

- Power Stream Couplings-Specn SheetsДокумент6 страницPower Stream Couplings-Specn SheetsAmol PatkiОценок пока нет

- Drillsize CutДокумент4 страницыDrillsize CutRichard KhooОценок пока нет

- Vandhargal VendrargalДокумент188 страницVandhargal VendrargalrethinamkОценок пока нет

- Cutting Data Corrax EngДокумент5 страницCutting Data Corrax Engstanalina00Оценок пока нет

- Standard External Metric Thread and Fastener Sizes M1Документ2 страницыStandard External Metric Thread and Fastener Sizes M1rethinamkОценок пока нет

- Chapter 1Документ94 страницыChapter 1rethinamkОценок пока нет

- Yvj ThesisДокумент67 страницYvj ThesisMuhammed Noman Fazal SiddiquiОценок пока нет

- Gear Skiving ProcessДокумент8 страницGear Skiving ProcessrethinamkОценок пока нет

- Guide To Statistical Process Control TechniquesДокумент45 страницGuide To Statistical Process Control TechniquesAnonymous FFMmIJyОценок пока нет

- CMC Ready ReckonerxlsxДокумент3 страницыCMC Ready ReckonerxlsxShalaniОценок пока нет

- Ball Mill For Cement GrindingДокумент5 страницBall Mill For Cement GrindingNkosilozwelo Sibanda100% (1)

- 08 PDFДокумент23 страницы08 PDFRakesh7770Оценок пока нет

- Revision - Summary - 7T04 MP 00 TS 004 - Rev10Документ10 страницRevision - Summary - 7T04 MP 00 TS 004 - Rev10Cristi DemОценок пока нет

- Tank Installation RequirementsДокумент2 страницыTank Installation Requirementsmarkigldmm918Оценок пока нет

- Installation AND Maintenance Manual: Always A Step Ahead in TechnologyДокумент8 страницInstallation AND Maintenance Manual: Always A Step Ahead in TechnologyyoyoОценок пока нет

- PDC Lab ReportДокумент13 страницPDC Lab Reportarslan_uetanОценок пока нет

- Cold Formed Steel DesignДокумент2 страницыCold Formed Steel DesignkiplingkipОценок пока нет

- 7 - Psy - Chart - XLS Cooling CoilДокумент28 страниц7 - Psy - Chart - XLS Cooling CoilRanu JanuarОценок пока нет

- CS4002 U-Deck Recommended SparesДокумент5 страницCS4002 U-Deck Recommended SparesedwinОценок пока нет

- MULTi-V NT ENG 60HzДокумент44 страницыMULTi-V NT ENG 60HzMarco Antonio Zelada HurtadoОценок пока нет

- Machine Design Data BookДокумент19 страницMachine Design Data BookSunnyChoudharyОценок пока нет

- HPHT Completion Hardware (2023.05.05)Документ54 страницыHPHT Completion Hardware (2023.05.05)New Auto TVОценок пока нет

- Ariston Lbe 8 X 80269690000Документ80 страницAriston Lbe 8 X 80269690000frОценок пока нет

- Soldier Pile and Lagging Caltan 1990 Tedds CalcДокумент2 страницыSoldier Pile and Lagging Caltan 1990 Tedds CalcRJSQОценок пока нет

- Inst Headers Install TitianДокумент3 страницыInst Headers Install TitianhuntersgreenОценок пока нет

- Hydraulic Power Pack Minipack HPM TG2 XXX X S N N 05S C18CDДокумент1 страницаHydraulic Power Pack Minipack HPM TG2 XXX X S N N 05S C18CDjuniorОценок пока нет

- 2356 cptg007 En-Web PDFДокумент24 страницы2356 cptg007 En-Web PDF7esabat7033Оценок пока нет

- Techno-Commercial Proposal - Slitting Machine - Rev 01Документ9 страницTechno-Commercial Proposal - Slitting Machine - Rev 01Chandru ChristurajОценок пока нет

- Chapter 4 Centroid - Distr. ForcesДокумент33 страницыChapter 4 Centroid - Distr. Forceskamal touilebОценок пока нет

- Engine 310G 310SGДокумент7 страницEngine 310G 310SGANDRES BAZURTOОценок пока нет

- Weg 10018xp3e405tДокумент5 страницWeg 10018xp3e405tcorsini999Оценок пока нет