Академический Документы

Профессиональный Документы

Культура Документы

Welding Inspection

Загружено:

Ahmed FathyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Welding Inspection

Загружено:

Ahmed FathyАвторское право:

Доступные форматы

Welding Inspection and Non-Destructive Test Practice in Hong Kong Ir LAM Chi-sing

On 28 June 2008, the Materials Division and Associate Members Committee jointly organized a technical seminar on Welding Inspection and Non-destructive Testing Practice in Hong Kong. The speaker Ir CK Cheung gave a brief introduction on the accreditation of welding inspection for the local construction industry. It covered inspection and approval of welding procedures and welder tests in accordance with the European Standard and Hong Kong Public Works Contract requirements. A structural steel welder is engaged to cut or join structural steel sections, steel water mains and steel gas mains by electric arc, oxy-acetylene flame or other welding processes. Welders approval is a prerequisite for the registration of structural steel welders under the Hong Kong Ordinance Chapter 583 :Construction Workers Registration Ordinance A certificate of passing of a welder test which is in conformity with BS EN 287-1:1992 standard issued by a welding inspection body accredited by the Hong Kong Accreditation Service (HKAS) under Hong Kong Inspection Body Accreditation Scheme (HKIAS) is required for the registration. The second speaker, Mr. KM Wong from A.E.S. Destructive & Non-destructive Testing Limited described Eddy Current Testing (ET) on structural steel welds. ET was electromagnetic non-destructive test and could be applied to painted or coated welds. Accordingly, it was an effective in-service test on welded structure of bridge, quay crane, offshore platform, mechanical rides in theme parks, etc. ET was also widely used in inspection of heat exchanger tubes. While there was not specific standard for preventive maintenance of such facilities so far, ET might be one of the main techniques to define the standardization in the future. ET works on the principles of electromagnetic induction, with an excited test coil inducing small, circulating current into conductive materials. Change in coil impedance due to distortion of eddy currents at regions of discontinuities and associated magnetic flux linkages, was then measured and correlated with the discontinuities. Some advantages of using ET were its convenience in use, instant results, and non-contact with test piece. However, its application was limited to conductive materials only. The seminar ended with the interactive question and answer session and had been well received by our members. Finally, on behalf of the host and the participants, we thank Ir CK Cheung and Mr. KM Wong for their valuable presentation. Words 377

Photo: Ir CK Cheung receiving souvenir from Dr WK Fung .(Materials Division)

Photo: Mr. KM Wong (Middle) receiving souvenir from Mr. Ray Ng (AMC Chairman) .Mr. Martin Siu (R)

Вам также может понравиться

- M 4 D1.1 2015 FormДокумент1 страницаM 4 D1.1 2015 FormAhmed FathyОценок пока нет

- Asme Guide Si - 1982Документ43 страницыAsme Guide Si - 1982Ahmed FathyОценок пока нет

- General Welding Fabrication and TestingДокумент24 страницыGeneral Welding Fabrication and TestingAhmed FathyОценок пока нет

- Cswip 3.1 New BookДокумент342 страницыCswip 3.1 New BookMohsin Rasul90% (52)

- Cswip 3.1 New BookДокумент342 страницыCswip 3.1 New BookMohsin Rasul90% (52)

- Basic WeldingДокумент40 страницBasic WeldingVishnu Vardhan . C100% (8)

- Asme Sec Viii-1 Quick ReferenceДокумент1 страницаAsme Sec Viii-1 Quick ReferenceManish542Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- From Bela Bartok's Folk Music Research in TurkeyДокумент3 страницыFrom Bela Bartok's Folk Music Research in TurkeyssiiuullLLОценок пока нет

- Benno Przybylski Righteousness in Matthew and His World of Thought Society For New Testament Studies Monograph Series 1981Документ198 страницBenno Przybylski Righteousness in Matthew and His World of Thought Society For New Testament Studies Monograph Series 1981alenin1Оценок пока нет

- UntitledДокумент12 страницUntitledSolomon JoysonОценок пока нет

- Why The Irish Became Domestics and Italians and Jews Did NotДокумент9 страницWhy The Irish Became Domestics and Italians and Jews Did NotMeshel AlkorbiОценок пока нет

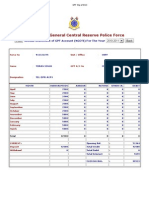

- Annual GPF Statement for NGO TORA N SINGHДокумент1 страницаAnnual GPF Statement for NGO TORA N SINGHNishan Singh Cheema56% (9)

- Problem IsДокумент5 страницProblem IsSharra Vesta Llana ValeraОценок пока нет

- People Vs CA G.R. No. 140285Документ2 страницыPeople Vs CA G.R. No. 140285CJ FaОценок пока нет

- Office 365 - Information Security Management System (ISMS) ManualДокумент18 страницOffice 365 - Information Security Management System (ISMS) ManualahmedОценок пока нет

- Ought To, Should, Must and Have ToДокумент2 страницыOught To, Should, Must and Have Topinay athena100% (1)

- Apg-Deck-2022-50 - Nautical Charts & PublicationsДокумент1 страницаApg-Deck-2022-50 - Nautical Charts & PublicationsruchirrathoreОценок пока нет

- Act 201 Chapter 02 Debit & CreditДокумент72 страницыAct 201 Chapter 02 Debit & Credittanvir ahmedОценок пока нет

- Bus. Org. OutlineДокумент73 страницыBus. Org. OutlineJAY DEEОценок пока нет

- PHILIP MORRIS Vs FORTUNE TOBACCOДокумент2 страницыPHILIP MORRIS Vs FORTUNE TOBACCOPatricia Blanca SDVRОценок пока нет

- TestbankДокумент11 страницTestbankA. MagnoОценок пока нет

- Networking and TESOL career goalsДокумент2 страницыNetworking and TESOL career goalsSadiki FltaОценок пока нет

- TAX-402 (Other Percentage Taxes - Part 2)Документ5 страницTAX-402 (Other Percentage Taxes - Part 2)lyndon delfinОценок пока нет

- Hlimkhawpui - 06.06.2021Документ2 страницыHlimkhawpui - 06.06.2021JC LalthanfalaОценок пока нет

- Taxation Reviewer.Документ176 страницTaxation Reviewer.francesОценок пока нет

- MMEP 613 - Assignment No. 1 Canoy, Niña Angelika R. - SN 2022433104Документ35 страницMMEP 613 - Assignment No. 1 Canoy, Niña Angelika R. - SN 2022433104Niña Angelika CanoyОценок пока нет

- Biswajit Ghosh Offer Letter63791Документ3 страницыBiswajit Ghosh Offer Letter63791Dipa PaulОценок пока нет

- Dunn, David Christopher vs. Methodist Hospital (Court 189)Документ1 страницаDunn, David Christopher vs. Methodist Hospital (Court 189)kassi_marksОценок пока нет

- Humility Bible StudyДокумент5 страницHumility Bible Studyprfsc13Оценок пока нет

- Bacaan Bilal Shalat Tarawih 11 Rakaat Bahasa IndonesiaДокумент4 страницыBacaan Bilal Shalat Tarawih 11 Rakaat Bahasa IndonesiaMTSs Tahfizh Ulumul Quran MedanОценок пока нет

- What Is A Pitch BookДокумент4 страницыWhat Is A Pitch Bookdonjaguar50Оценок пока нет

- 2021 Pslce Selection - ShedДокумент254 страницы2021 Pslce Selection - ShedMolley KachingweОценок пока нет

- Bob Marley - SunumДокумент5 страницBob Marley - SunumNaz SakinciОценок пока нет

- Invitation to Kids Camp in Sta. Maria, BulacanДокумент2 страницыInvitation to Kids Camp in Sta. Maria, BulacanLeuan Javighn BucadОценок пока нет

- Ysmael vs. Executive Secretary - DigestДокумент2 страницыYsmael vs. Executive Secretary - DigestVince Llamazares LupangoОценок пока нет

- Industry Analysis1Документ72 страницыIndustry Analysis1Walter InsigneОценок пока нет

- E - Commerce and IWTДокумент4 страницыE - Commerce and IWTziddirazanОценок пока нет