Академический Документы

Профессиональный Документы

Культура Документы

Seminole Checklist

Загружено:

Farah Afiqah NasihaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Seminole Checklist

Загружено:

Farah Afiqah NasihaАвторское право:

Доступные форматы

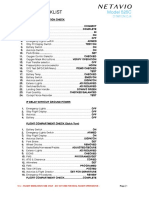

OCFC PA-44 CHECKLIST

CABIN INSPECTION

Documents (AROW) - - - - - - - - - - CHECK Hobbs Meter - - - - - - - - - - - - - - CHECK Control Lock - - - - - - - - - - - - - - REMOVE Rudder/Elevator Trim - - - - - - - - - NEUTRAL Flaps - - - - - - - - - - - CHECK OPERATION Cowl Flaps - - - - - - - - - - - - - - - - OPEN Avionics/Electrical Equipment - - - - - - - OFF Mixture - - - - - - - - - - - - - IDLE CUTOFF Landing Gear Lever - - - - - - - - - - - DOWN Emergency Gear Extend Knob - - - - - SECURE Alternate Static Source - - - - - - - - - - - OFF Magnetos - - - - - - - - - - - - - - - - - OFF Master Switch - - - - - - - - - - - - - - - - ON Fuel Quantity - - - - - - - - - - - - - - CHECK Landing Gear Lights - - - - - - - - - - CHECK Annunciator Panel - - - - - - - - - - - CHECK Heater Overheat Light - - - - - - - - - CHECK Exterior Lights - - - - - - - - - - - - - CHECK Master Switch - - - - - - - - - - - - - - - OFF Pitot/Static System - - - - - - - - - - - - DRAIN Emergency Exit - - - - CLOSED AND LOCKED

EXTERIOR INSPECTION

Baggage Door - - - - - - - - - Fuel Sumps - - - - - - - - - - Right Wing: Wheel Well, Tire, Strut, Door Hinge Wing Flap/Fuel Vents/Aileron - - Wing Tip and Leading Edge - - Wing Tie-Down - - - - - - - - Engine Fuel Quantity - - - - - - Engine Oil Level - - - - - - - - Propeller and Spinner - - - - - Tire/Strut/Brake - - - - - - - - Cowl Flap - - - - - - - - - - - Nose: Wheel Well/Doors/Strut/Tire - - - - - CLOSED - - - - DRAIN - CHECK - CHECK - CHECK - REMOVE - CHECK - CHECK - CHECK - CHECK - CHECK CHECK

- - -

(Continued on next page)

cut 9.5

EXTERIOR INSPECTION, CONTINUED

Left Wing: Tire/Strut/Brake - - - - - - - - - - - - - CHECK Cowl Flap - - - - - - - - - - - - - - - - CHECK Engine Oil Level - - - - - - - - - - - - - CHECK Propeller and Spinner - - - - - - - - - - CHECK Engine Fuel Quantity - - - - - - - - - - CHECK Wing Tie-Down - - - - - - - - - - - - REMOVE Stall Warning Vanes - - - - - - - DO NOT MOVE Pitot/Static Mast - - - - - - - - - - - - - CHECK Wing Leading Edge and Wing Tip - - - - CHECK Wing Aileron/Fuel Vents/Flap - - - - - - CHECK Wheel Well, Tire, Strut, Door Hinge - - - CHECK Fuselage and Empennage: Vertical Stabilizer Air Scoop - - - - - - - CLEAR Rudder and Horizontal Stabilator - - - - CHECK Antennas - - - - - - - - - - - - - - - - CHECK Overall Condition - - - - - - - - - - - REVIEW Wheel Chocks - - - - - - - - - - - - REMOVED Tire Check - - - - - - - - - - MOVE AIRPLANE ANNOUNCE: Preight Checklist Complete

BEFORE ENGINE START

External Power if required refer to last page. Takeoff Safety Brieng - - - - - - - - COMPLETE Seats/Seat Belts/Shoulder Harnesses - FASTEN Parking Brake - - - - - - - - - - - - - - - - SET Passenger Brieng - - - - - - - - - COMPLETE Fuel Selectors - - - - - - - - - - - - - - - - ON Primers - - - PRIME (4 strokes if cold), LOCKED Carburetor Heat - - - - - - - - - - - - - - OFF Circuit Breakers - - - - - - - - - - - - - CHECK Avionics Master Switch - - - - - - - - - - OFF Mixtures - - - - - - - - - - - - - - - - - - RICH Throttles - - - - - - - - - - - - - - - - CLOSED Master Switch - - - - - - - - - - - - - - - - ON Alternators - - - - - - - - - - - - - - - - - ON Electric Fuel Pumps - - - - - - - - - - - - - ON Magnetos - - - - - - - - - - - - - - - - - - ON ANNOUNCE: Before Start Checklist Complete

FIRST ENGINE START (Left engine, normally)

ENGINE FIRE ON GROUND CHECKLISTNEXT PAGE

Throttle - - - - - - - - - TWO FULL STROKES Warm Engine, Throttle - - - - 1/2 INCH OPEN Cold Engine, Throttle - - - - 1/4 INCH OPEN Brakes - - - - - - - - - - - - - - - - - - - SET Prop Area - - - - - - CLEAR, MAKE CALLOUT Starter - - - - - - - - (8 seconds max) ENGAGE When Engine Starts: Throttle - - - - - - - - - - - - - - - 1,000 RPM Oil Pressure - - - - - - - - - - - - - - CHECK Fuel Pump - - - - - - - OFF, CHECK PRESSURE Mixture - - - - - - - - - - - - - - - - LEANED Throttle - - - - - - - - - - - - - - - 1,000 RPM Vacuum Shuttle Valve - - - - - - - - - CHECK

SECOND ENGINE START

ENGINE FIRE ON GROUND CHECKLISTNEXT PAGE

Ammeter below 20 amps - - - - - - - - CHECK Throttle - - - - - - - - - TWO FULL STROKES Warm Engine, Throttle - - - - 1/2 INCH OPEN Cold Engine, Throttle - - - - 1/4 INCH OPEN Brakes - - - - - - - - - - - - - - - - - - HOLD Prop Area - - - - - - - - - - - - - - - - CLEAR Starter - - - - - - - - (8 seconds max) ENGAGE When Engine Starts: Throttle - - - - - - - - - - - - - - - 1,000 RPM Oil Pressure - - - - - - - - - - - - - - CHECK Fuel Pump - - - - - - - OFF, CHECK PRESSURE Mixture - - - - - - - - - - - - - - - - LEANED Throttle - - - - - - - - - - - - - - - 1,000 RPM Fuel Selectors - - - - - - CROSSFEED CHECK ATIS and ATC Clearance - - - - - - - - OBTAIN Vacuum - - - - - - - - - - - - - - - - CHECK

TAXI

Brakes - - - - - - - - - - - - - - - - CIGARS - - - - - - - - - - - CHECK

Dont drag the brakes. Use idle power and spot braking to control speed when taxiing downhill or downwind.

C THROUGH A

cut 9.5

ENGINE FIRE ON GROUND

Engine Has Not Started: Mixture - - - - - - - - - - - - - IDLE CUTOFF Throttle - - - - - - - - - - - - - - FULL OPEN Starter - - - - - - - - - - - - CRANK ENGINE If Engine Has Started: Pull re into engine - - - CONTINUE RUNNING If Fire Continues: Fuel Selectors - - - - - - - - - - - - - - - OFF Mixtures - - - - - - - - - - - - - IDLE CUTOFF ATC or Company - - - CALL FOR FIRE TRUCK Master Switch - - - - - - - - - - - - - - - OFF Parking Brake - - - - - - - - - - - - - - - - SET Evacuate Airplane - - - - DOOR or EMERG. EXIT

BEFORE TAKEOFF

Flight Controls - - - - - - - - - - - - - - CHECK Radios and Flight Instruments - - CHECK & SET Magnetic Compass - - - - - - - - - - - CHECK Fuel Selectors - - - - - - - - - - - - - - - - ON Aileron and Rudder Trim - - - - - - - - - - - SET Mixtures - - - - - - - - - - (Below 3,000') RICH Brakes - - - - - - - - - - - - - - - - - - - SET Throttles - - - - - - - - - - - - - - - 1,500 RPM Prop Feather - (500 rpm max) CHECK L then R Throttles - - - - - - - - - - - - - - - 2,000 RPM Props - - - - - - - - - (300 rpm max) EXERCISE Carburetor Heat - - - - - - - - - - - - - CHECK Annunciator Panel - - - - - - - - - - - - CHECK Suction - - - - - - - - - - - (4.8 - 5.2") CHECK Alternator Output - - - - - - - - - - - - CHECK Engine Gauges - - - - - - - - - - - - - CHECK Magnetos - - - - - - - - - - - (175/50) CHECK Throttles - - - - - - IDLE CHECK then 1,000 RPM Mixtures - - - - - - - - - - - - - - - - LEANED - - - - - - - - - - - - Final Items - - - - - - - - - - - Doors/Windows - - - - - - - - - - - - CLOSED Flaps - - - - - - - - - - - - - - AS REQUIRED Mixtures - - - - - - - - - - (Below 3,000') RICH Fuel Pumps - - - - - - - - - - - - - - - - - ON ANNOUNCE: Before Takeoff Checklist Complete then call the tower for T/O clearance.

CLEARED ONTO THE RUNWAY

Lights: strobes, landing lights - - - - - - - - ON Camera: transponder - - - - - - - - - ON ALT Action: power and off-time - - - - - - - CHECK

REACHING A SAFE ALTITUDE

Gear and Flaps Cruise Climb - Mixture - - - Fuel Pumps - Lights - - - - - - - - - - CONFIRM UP - - - - - - - ESTABLISH - - - - - - - - FULL RICH OFF, CHECK PRESSURES - - - - - - - AS DESIRED

REACHING CRUISE ALTITUDE

Mixtures - - - - - - - - - - - - - - - - LEANED Cowl Flaps - - - - - (Temp. permitting) CLOSED

BEFORE LANDING

Seat Belts and Shoulder Harnesses - FASTENED Fuel Selectors - - - - - - - - - - - - - - - - ON Heading Indicator - - - - - - - - - - - - - SET Altimeter - - - - - - - - - - - - - - - - - - SET Radios - - - - - - - - - - - - - - - - - - - SET Fuel Pumps - - - - - - - - - - - - - - - - - ON - - - - - - - -Final Items (GUMPS) - - - - - - - Landing Gear - - - - (Prefer 120k. max) DOWN Mixture - - - - - - - - - - (Below 3,000') RICH Props - - - - - - - - - - - - - FULL FORWARD Flaps - - - - - - - - - (111k. max) EXTENDED Final Approach Speed - - - - - - (minimum) 75k. ANNOUNCE: Before Landing Checklist Complete

cut 9.5

AFTER LANDING CHECKLIST

Lights: - - - - - - - - - - Camera: (Transponder) - - Action: Elevator and Rudder Trim - Flaps - - - - - - - - - - - Cowl Flaps - - - - - - - - Mixtures - - - - - - - - - - Fuel Pumps - - - - - - - - - - - - - - - OFF - - - - STANDBY NEUTRAL - - - - UP - - OPEN - LEANED - - - OFF

ENGINE SHUTDOWN

Avionics Master Switch Throttles - - - - - - - Magnetos - - - - - - Throttles - - - - - - - Left Mixture - - - - - Vacuum Shuttle Valve Right Mixture - - - - Magnetos - - - - - - Alternators - - - - - Master Switch - - - - - - - - - - - OFF - - - - - - - IDLE GROUND CHECK - - - - 1,000 RPM - - IDLE CUTOFF - - - - - - CHECK - - IDLE CUTOFF - - - - - - - OFF - - - - - - - OFF - - - - - - - OFF

SECURING

Hobbs and Tach Times Maintenance Problems Storm Window - - - - Control Locks - - - - Tie Downs - - - - - - Chocks - - - - - - - Props - - - - - - - - - - - - - - RECORD - - - - - - RECORD - - - - - - CLOSED - - - - - INSTALLED - - - - - - ATTACH - - - - - - - INSERT VERTICAL FOR FUEL

INFLIGHT ENGINE SHUTDOWN FOR TRAINING, FIRE, OR ABNORMALITY

Fuel Selector - - Throttle - - - - Prop - - - - - - Mixture - - - - Magnetos - - - Fuel Pump - - - Alternator - - - Cowl Flap - - - Electrical Load - If Fire Persists - Crossfeed - - - Fuel Management - - - - - - - - - - - - OFF - - - - - - - - - - CLOSED - - - - - - - - - FEATHER - - - - - - - IDLE CUTOFF - - - - - - - - - - - - OFF - - - - - - - - - - - - OFF - - - - - - - - - - - - OFF CLOSED, OPEN IF ON FIRE - - - - - - - - - - REDUCE - - EMERGENCY DESCENT - - - - LEVEL FLIGHT ONLY - - - REFER TO LAST PAGE

EMERGENCY DESCENT

Throttle(s) Mixture(s) Prop(s) Gear - - Bank - - (Use 12" for training) CLOSED - - - - - - - - - AS DESIRED - - - - - - - - - - FULL FWD (Use 120k. for training) DOWN - - - - - - - - - 45 Degrees

AIRSTART

Fuel Selector - - - - - - - - - - - - - - - - - ON Carb Heat - - - - - - - - - - - - - - - - - OFF Mixture - - - - - - - - - - - - FULL FORWARD Prop - - FORWARD TO CRUISE RPM POSITION Fuel Pump - - - - - - - - - - - - - - - - - - ON Alternator - - - - - - - - - - - - - - - - - - ON Magnetos - - - - - - - - - - - - - - - - - - ON Throttle - - - TWO FULL STROKES, 1/4" OPEN Airspeed - - - - - - - - - - - - 100K. MINIMUM Starter - - ENGAGE UNTIL ENGINE WINDMILLS Throttle - - - - - - - 15" UNTIL CHT IS GREEN

PROPELLER OVERSPEED

Throttle - Pitch - - - Prop - - - If necessary - - - - - DECREASE IMMEDIATELY - - - - - INCREASE IMMEDIATELY DECREASE BUT DO NOT FEATHER - - - - - - - SHUTDOWN ENGINE

SINGLE-ENGINE CHECKLISTS

cut 10.0

ENGINE FAILURE PRIOR TO LIFTOFF

Throttles - - - - Directional Control Brakes - - - - Yoke - - - - - - - - IDLE MAINTAIN - - APPLY - FULL AFT

ENGINE FAILURE BETWEEN LIFTOFF AND GEAR UP (NO-MANS LAND)

Dangerous situation - - - - - - - YOUR CHOICE Runway available - - LAND GEAR DOWN or UP Runway not available - - - - - - - - - BYE, BYE

Note: If you are properly trained for pitch management, you will be in no-mans land for only ten seconds at best. At liftoff, maintain the T-pitch attitude, retract the landing gear when a positive climb is evident, and the airplane will literally jump to VYSE. When you hear the gear clunk into the wheel wells, select the I-pitch attitude. The airplane will be at or slightly above VYSE providing you maintained the T-pitch attitude. But my instructor taught me to never raise the gear until there wasnt enough runway to land on. Thats too bad, youre compromising your safety.

ENGINE FAILURE AFTER VYSE

Throttles, Props, Mixtures - - - AS NECESSARY FULL FWD IF CLIMBING AFTER T/O OR G/A Yaw - - - - - - - - - - - - - - - - - - RUDDER Pitch - - - - - - - - - - - - - - VYSE ATTITUDE Flaps - - - - - - - - - - - - - - - - - - - - UP Landing Gear - - - - - - - - - - - - - - - - UP Identify - - - - - - - - - - - - - - DEAD FOOT Verify - - - - (Use the two nger method) THROTTLE Prop Inoperative Engine - - - - - - - - FEATHER Mixture Inoperative Engine - - - IDLE CUTOFF Cowl Flaps Inoperative Engine - - - - - CLOSE Bank - - - - - - TOWARD THE GOOD ENGINE If altitude permits - - TROUBLE SHOOT ENGINE Declare an emergency and land

LANDING GEAR UNSAFE WARNINGS

Red light will illuminate. Gear horn will sound when the throttles are at low settings or the wing aps are in the 2nd- or 3rd-notch positions.

SINGLE-ENGINE CHECKLISTS

LANDING GEAR MANUAL EXTENSION

Circuit Breakers - - - - - - Alternators - - - - - - - - - Navigation Lights - - - - - Airspeed - - - - - - - - - - Gear Selector - - - - - - - Emergency Gear Extend Knob Indicator Lights - - - - - - Emergency Gear Extend Knob - - - CHECK - - - CHECK (daytime) OFF - - 100K. MAX - - - - DOWN - - - - PULL - - 3 GREEN - LEAVE OUT

ALTERNATOR LIGHT ON

Ammeters - - - - - - - - - - - - - - - CHECK One Alternator Inoperative Alternator Switch - - - - - - - - - - - - - - OFF Electrical Loads - - - - - - - - - - - - REDUCE Alternator Circuit Breaker - - - - CHECK/RESET Alternator Switch - - - - - - - - - - - - - - - ON If Power Not Restored, Alternator Switch - - OFF Maximum Electrical Load - - - - - - MONITOR Both Alternators Inoperative Battery Switch - - - - - - - - - - - - - - - OFF Alternator Switches - - - - OFF, ONE AT A TIME Electrical Loads - - - - - - - - - - - - REDUCE Alternator Circuit Breakers - - - - CHECK/RESET Alternator Switches - - - - ON, ONE AT A TIME If Power Not Restored, Alternator Switches - OFF Land as soon as practical. Compass error may exceed 10 degrees with both alternators off. Both Alternators Restored Determine ALT showing LEAST (not zero) amps Alternator Switches - - least load ON, other OFF Maximum Electrical Load - - - - - - - 60 Amps

ELECTRICAL OVERLOAD

Alternators 30 Amps Over Known Electrical Load

Alternator Switches - - - - - - - - - - - - OFF Battery Switch - - - - - - - - - - - - - - - OFF If load reduces, battery or wiring problem exists. Reduce load, land as soon as practical. If load does not reduce, ALT off, BAT as required. Reduce load and land as soon as practical.

LANDING GEAR and ELECTRICAL

cut 10.5

EXTERNAL-POWER ENGINE START

Master Switch - - - - - - - - - - - - - - - OFF All Electrical Equipment - - - - - - - - - - OFF External Power Plug - - - INSERT IN FUSELAGE Start Engine(s) - If both engines are started, shutdown right engine after it has warmed up. External Power Plug - - - - - - - - - - REMOVE Master Switch - - - - - - ON, CHECK AMMETER Oil Pressure - - - - - - - - - - - - - - - CHECK Right Engine - - - - - - - - - - - - - RESTART

OPEN CABIN DOOR IN FLIGHT

If both upper and side latches are open, the door will trail slightly open and airspeeds will reduce slightly.

Airspeed - - - - - - - - - - - - - - - 82k. MAX Cabin Vents - - - - - - - - - - - - - - - CLOSE Storm Window - - - - - - - - - - - - - - OPEN If upper latch is open - - - - - - - - - - CLOSE If side latch is open - PULL ON ARMREST WHILE MOVING LATCH TO LATCHED POSITION If both latches are open - - LATCH SIDE LATCH THEN TOP LATCH

FUEL MANAGEMENT DURING SINGLEENGINE FLIGHT

Cruising: Using direct feed: Fuel Selector Operating Engine - - - - - - - ON Fuel Selector Inoperative Engine - - - - - OFF Fuel Pumps - - - - - - - - - - - - - - - - OFF Using crossfeed: Fuel Selector Operating Engine - - CROSSFEED Fuel Selector Inoperative Engine - - - - - OFF Fuel Pumps - - - - - - - - - - - - - - - - OFF Landing: Fuel Selector Operating Engine - - - - - - - ON Fuel Selector Inoperative Engine - - - - - OFF Fuel Pump Operating Engine - - - - - - - - ON

ENGINE DRIVEN FUEL PUMP FAILURE

Electric Fuel Pump - - - - - - - - - - - - - ON

Revised 09/12/02, Orange County Flight Center

EXT. PWR/CABIN DOOR/FUEL MANAGEMENT

Вам также может понравиться

- BE-300 - G1000 - Abbreviated ChecklistДокумент2 страницыBE-300 - G1000 - Abbreviated ChecklistFernando Méndez100% (1)

- 2000 Cessna 206H Checklist v1Документ7 страниц2000 Cessna 206H Checklist v1Kevin ArteagaОценок пока нет

- Cessna 172 N Checklist Isaac MartinezДокумент2 страницыCessna 172 N Checklist Isaac MartinezisaacvoxОценок пока нет

- Checklist b1900Документ3 страницыChecklist b1900Fabian Andres Claro ElamОценок пока нет

- QRH Pa44Документ52 страницыQRH Pa44Edgar Gamboa100% (2)

- Normal Operating Checklist B1900D Airliner: Cockpit Preparation Before Take OffДокумент2 страницыNormal Operating Checklist B1900D Airliner: Cockpit Preparation Before Take Offkevin_jordan_23Оценок пока нет

- Normal Procedures Checklist RTS Seneca V 2016 13062016 PDFДокумент14 страницNormal Procedures Checklist RTS Seneca V 2016 13062016 PDFboero115Оценок пока нет

- SFCJ E423 - Pa44 Handling NotesДокумент21 страницаSFCJ E423 - Pa44 Handling NotesEthan PoonОценок пока нет

- Effects of ControlsДокумент2 страницыEffects of ControlsRina PngОценок пока нет

- GFC 700 Training Overview2 7C03137697E94Документ15 страницGFC 700 Training Overview2 7C03137697E94Jose Luis OliverosОценок пока нет

- LW224AДокумент68 страницLW224Abujin.gym.essen100% (1)

- Thrust Flight PA44 Study GuideДокумент28 страницThrust Flight PA44 Study GuideNitsugaОценок пока нет

- Type Certificate Data SheetДокумент13 страницType Certificate Data Sheetirquadri100% (1)

- PWR Lever - Close Prop Lever - Feather Condition Lever - Cutoff Engine Fire Switch - PushДокумент11 страницPWR Lever - Close Prop Lever - Feather Condition Lever - Cutoff Engine Fire Switch - PushNienke van SchijndelОценок пока нет

- C700 CHK WTv1.5.0Документ3 страницыC700 CHK WTv1.5.0Robson MedeirosОценок пока нет

- Garmin G1000NXi Pilot's GuideДокумент576 страницGarmin G1000NXi Pilot's Guide张芷瑜Оценок пока нет

- PA-31T ChecklistДокумент11 страницPA-31T ChecklistRaph 1123Оценок пока нет

- Cessna 170 Specifications and Perfomance DataДокумент3 страницыCessna 170 Specifications and Perfomance DataAgelLowieОценок пока нет

- Featured Plane Seneca VДокумент10 страницFeatured Plane Seneca VJunior Mebude SimbaОценок пока нет

- 01 Aircraft GeneralДокумент20 страниц01 Aircraft GeneralManuel Villalba100% (1)

- Congratulations in It Is Will It, For: To of Find Flying Pilot's Gria. Airplane. To To To ofДокумент201 страницаCongratulations in It Is Will It, For: To of Find Flying Pilot's Gria. Airplane. To To To ofLuís Eduardo MansuetoОценок пока нет

- FSX Beech King Air 350Документ4 страницыFSX Beech King Air 350lkuduaviczОценок пока нет

- G550 CVR Op TestДокумент6 страницG550 CVR Op TestAdrian Lau100% (1)

- 208B (867SHP-G1000) POH Supplement 18Документ48 страниц208B (867SHP-G1000) POH Supplement 18Jose Francisco ColinaОценок пока нет

- VTBDДокумент15 страницVTBDFajar Dwi SetyawanОценок пока нет

- KAP140 Autopilot Quick Reference Card PDFДокумент1 страницаKAP140 Autopilot Quick Reference Card PDFJoe ThompsonОценок пока нет

- Approach Integrated CockpitДокумент4 страницыApproach Integrated CockpitAnonymous ib89TVОценок пока нет

- Aerobask Phenom 300 - Flight ManualДокумент31 страницаAerobask Phenom 300 - Flight ManualFloa FNОценок пока нет

- T-44C FMS GuideДокумент143 страницыT-44C FMS GuideTrung Dung100% (1)

- Piper Seminole PA44-180 Checklist: Nice AirДокумент4 страницыPiper Seminole PA44-180 Checklist: Nice AirsmedleyburlapОценок пока нет

- Maximum Permissible Takeoff WeightДокумент5 страницMaximum Permissible Takeoff WeightBasuki RahardjoОценок пока нет

- Robinson r44 SystemsДокумент15 страницRobinson r44 SystemsLuiz Fernando MibachОценок пока нет

- C182T Maneuvers GuideДокумент45 страницC182T Maneuvers GuideELAC2Оценок пока нет

- King Air Fuel System RundownДокумент4 страницыKing Air Fuel System RundownMikeОценок пока нет

- Atm QuestionsДокумент23 страницыAtm QuestionsAziz YoussoufouОценок пока нет

- Cessna 182PДокумент4 страницыCessna 182PPedro Rodrigues AlvesОценок пока нет

- STARLUX-Pilot Application Form 202001filledДокумент6 страницSTARLUX-Pilot Application Form 202001filledHeshОценок пока нет

- Organize Your Approach Brief PDFДокумент2 страницыOrganize Your Approach Brief PDFAnonymous ib89TVОценок пока нет

- Pilot's GuideДокумент410 страницPilot's GuideTuấn Vũ AnhОценок пока нет

- Taf & TrendДокумент4 страницыTaf & Trendchhetribharat08Оценок пока нет

- GTN Database Update GuideДокумент13 страницGTN Database Update GuideLenin Jose Hernandez BonillaОценок пока нет

- Hornet 460 ManualДокумент24 страницыHornet 460 ManualGildaEnxerОценок пока нет

- C172M QRH (VH-JZJ) v1.1Документ49 страницC172M QRH (VH-JZJ) v1.1alphaОценок пока нет

- Accident Prevention Program: Always Leave Yourself An OutДокумент13 страницAccident Prevention Program: Always Leave Yourself An OutHenry SalcedoОценок пока нет

- Normal Checklist: Model 525CДокумент5 страницNormal Checklist: Model 525CJose Otero De SantiagoОценок пока нет

- MJC Dh8d ManualДокумент134 страницыMJC Dh8d ManualDarek Czarnecki100% (1)

- LR35A Limit 530 ValueДокумент2 страницыLR35A Limit 530 ValueBrendanRatchfordОценок пока нет

- Cessna 182 Pilots Operating Handbook (1966)Документ31 страницаCessna 182 Pilots Operating Handbook (1966)Gustavo Adolfo Términe100% (1)

- Falcon Limitations StudyДокумент3 страницыFalcon Limitations StudyTony NicholasОценок пока нет

- MD 11 ChecklistДокумент4 страницыMD 11 ChecklistLoulitchОценок пока нет

- Sandell 3308 HSIДокумент101 страницаSandell 3308 HSISabby_89Оценок пока нет

- CL 604 Normal Checklist REV 108Документ3 страницыCL 604 Normal Checklist REV 108CLDriverОценок пока нет

- Cessna 172 Y 152 Checklist Emergency ProceduresДокумент1 страницаCessna 172 Y 152 Checklist Emergency Proceduresajcd110Оценок пока нет

- DUKE 60 Manual PDFДокумент36 страницDUKE 60 Manual PDFKevin VasquezОценок пока нет

- M67-12 TCM Overboosting of Turbocharged EngineДокумент1 страницаM67-12 TCM Overboosting of Turbocharged Enginerav100% (1)

- Indrek Paal Embraer ChecklistДокумент7 страницIndrek Paal Embraer ChecklistwolffroxОценок пока нет

- The Crash of an Alaska Airlines Boeing 727 Juneau, Alaska September 4, 1971От EverandThe Crash of an Alaska Airlines Boeing 727 Juneau, Alaska September 4, 1971Оценок пока нет

- The Alaska-Siberia Connection. The World War II Air Route (Texas A&m Univ.)Документ148 страницThe Alaska-Siberia Connection. The World War II Air Route (Texas A&m Univ.)dopeyagainОценок пока нет

- Your Boarding Pass To Jakarta - ETIHAD AIRWAYSДокумент2 страницыYour Boarding Pass To Jakarta - ETIHAD AIRWAYSKrishna Kalyan dakiОценок пока нет

- A European Sustainable Tourism Labels Proposal Using A Composite IndicatorДокумент16 страницA European Sustainable Tourism Labels Proposal Using A Composite Indicatorlylan muslimОценок пока нет

- Westside Subway Final EIR ReleaseДокумент3 страницыWestside Subway Final EIR ReleaseMetro Los AngelesОценок пока нет

- Human Resources Slide 1: Uber and Volvo Joint VentureДокумент14 страницHuman Resources Slide 1: Uber and Volvo Joint Venturedaksh tutejaОценок пока нет

- Fortune Express v. CAДокумент2 страницыFortune Express v. CAphgmbОценок пока нет

- LTS SeriesДокумент6 страницLTS SeriesKshitiz MittalОценок пока нет

- Jsa Traffic ControlДокумент2 страницыJsa Traffic ControlFirdi FirmansyahОценок пока нет

- Military Electric Vehicles WWWДокумент31 страницаMilitary Electric Vehicles WWWAlvin GohОценок пока нет

- Price ListДокумент14 страницPrice ListRavi MakhijaОценок пока нет

- Motor Vehicles Act, 1988 PDFДокумент15 страницMotor Vehicles Act, 1988 PDFDhwanit RathoreОценок пока нет

- Focus Group DiscussionДокумент4 страницыFocus Group DiscussionUsman LatifОценок пока нет

- Parts Catalogue - Yamaha Ego AvantizДокумент53 страницыParts Catalogue - Yamaha Ego AvantizHamzah Hussain60% (5)

- Especificaciones DOT SP12277 2014Документ9 страницEspecificaciones DOT SP12277 2014usamazarifehОценок пока нет

- LF Ebook PC S S H-L 2012 inДокумент330 страницLF Ebook PC S S H-L 2012 in11tata100% (1)

- EnДокумент196 страницEnAliTronic1972100% (2)

- Categories of Cargo and Types of ShipsДокумент14 страницCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- The Prepositions of DirectionДокумент5 страницThe Prepositions of DirectionBondfriendsОценок пока нет

- Applied Thermodynamics - STEAM ENGINEДокумент16 страницApplied Thermodynamics - STEAM ENGINEAbhishek BalunavarОценок пока нет

- Manual Road Side Dust Cleaning MachineДокумент11 страницManual Road Side Dust Cleaning MachineKALYAN KUMAR100% (1)

- Cable Stayed BridgeДокумент9 страницCable Stayed BridgeTanweer AyoubОценок пока нет

- Q1.Part of A Bus Route Is Along A High Street.: Motion Graphs QsДокумент18 страницQ1.Part of A Bus Route Is Along A High Street.: Motion Graphs QsAnushka NairОценок пока нет

- 912 Writing To Learn SpawnДокумент14 страниц912 Writing To Learn SpawnNicole HernandezОценок пока нет

- Supply Chain Management - Future Trends. Prihor AdinaДокумент11 страницSupply Chain Management - Future Trends. Prihor AdinaAdinaOanaPrihor100% (2)

- LPC1768 Board SchematicДокумент1 страницаLPC1768 Board Schematicshindo216100% (1)

- Linde ManualДокумент6 страницLinde ManualArnaldo AndréОценок пока нет

- Megapolis Plan Jan16 EnglishДокумент116 страницMegapolis Plan Jan16 Englishariyamanjula2914Оценок пока нет

- Loco Diesel Shed PuleraДокумент23 страницыLoco Diesel Shed PuleraAnupamОценок пока нет

- Question Bank C To BДокумент211 страницQuestion Bank C To Bsushiljp1984Оценок пока нет

- DP Requirements For Drilling and Intervention UnitsДокумент38 страницDP Requirements For Drilling and Intervention UnitsRoyОценок пока нет