Академический Документы

Профессиональный Документы

Культура Документы

Filtro Y - Marca TITAN

Загружено:

Alba Duaneth Rocabado MendietaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Filtro Y - Marca TITAN

Загружено:

Alba Duaneth Rocabado MendietaАвторское право:

Доступные форматы

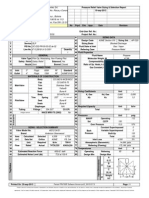

YS61-0711

TITAN

TITAN FLOW CONTROL, INC.

"Y" (WYE) STRAINER ANSI CLASS 150

FLANGED ENDS, RAISED FACE AND STAINLESS STEEL

f CARBON

Gauge Taps

NEWLY DESIGNED...

STANDARD ON ALL YS 61 MODELS IN SIZES 2" ~ 24"

MODELS:

YS 61-CS

(CARBoN

STEEL)

YS 61-SS

( S TA I N L E S S

STEEL)

FE ATURES

s

n e w d e s i g n w i t h g a u g e ta p s

5" YS 61-SS

SIzE R A NGE: 1/2" ~ 24"

T I TA N ' S y S 61 h A S C o N v E N I E N T G A U G E TA P S F U R N I S h E d W I T h A P L U G o N B oT h T h E I N L E T A N d o U T L E T S I d E S o F S I z E S 2" T h Ro U G h 24" . d E T E R M I N E W h E N S C R E E N C L E A N I N G I S N E C E S S A Ry . T h E S E TA P S A L L o W F o R E A S y I N S TA L L AT I o N o F P R E S S U R E G A U G E S To M o N I To R d I F F E R E N T I A L P R E S S U R E A N d

TECHNICAL

PRESSURE/ TEMPERATURE RATING CS - ASTM A216 GR. WCB - CLASS 150 WOG (Non-shock): 285 PSI @ 100 F Saturated Steam: 150 PSI @ 366F Maximum Liquid: 80 PSI @ 800 F PRESSURE/ TEMPERATURE RATING SS - ASTM A351 GR. CF8M - CLASS 150 WOG (Non-shock): 275 PSI @ 100 F Saturated Steam: 150 PSI @ 366 F Maximum Liquid: 20 PSI @ 1000 F

The above listed temperatures are theoretical and may vary during actual operating conditions. Carbon Steel not recommended for prolonged use above 800 F. Stainless Steel not recommended for prolonged use above 1000 F.

l a r g e s t r a i n i n g c a pa c i t y W I T h I T S L A R G E B o dy A N d S I z A B L E S T R A I N I N G E L E M E N T , T h E y S 61 P Ro v I d E S E x C E L L E N T o P E N A R E A R AT I o S T h AT A R E T y P I C A L Ly T W o - A N d - A - h A L F T I M E S L A R G E R T h A N T h E CoRRESPoNdING PIPELINE.

p r e c i s i o n m a c h i n e d s e at s P R E C I S I o N M A C h I N E d S C R E E N S E AT S I N B oT h T h E B o dy A N d C A P h E L P To E N S U R E A C C U R AT E P o S I T I o N I N G o F T h E S C R E E N d U R I N G R E A S S E M B Ly A F T E R C L E A N I N G . s e l f - c l e a n i n g c a pa b i l i t y T h E M A C h I N E d B o dy S E AT S E N A B L E F I N E R F I LT R AT I o N B y P R E v E N T I N G d E B R I S B y PA S S . ALSo,

W I T h A TA P P E d N P T B L o W - o F F C o N N E C T I o N , T h I S U N I T C A N B E F I T T E d W I T h A B L o W d o W N vA Lv E W h I C h FA C I L I TAT E S C L E A N I N G o F T h E S T R A I N I N G E L E M E N T . C o N TA C T FA C To Ry F o R M o R E I N F o R M AT I o N . PLEASE

e p ox y pa i n t e d C A R B o N S T E E L U N I T S A R E E P ox y PA I N T E d To h E L P R E S I S T R U S T A N d C o R Ro S I o N . F C I A L S o o F F E R S E P ox y C o AT I N G A S A N o P T I o N F o R T h E y S 61 . T I TA N

o p t i o n a l c ov e r d e s i g n s T I TA N ' S y S 61 I S AvA I L A B L E W I T h d I F F E R E N T C o v E R o P T I o N S I N C L U d I N G S W I N G , C L A M P , A N d h I N G E T y P E C ov E R S . oPTIoNS. P L E A S E C o N S U LT FA C To Ry F o R M o R E I N F o R M AT I o N o N T h E S E

APPLICATIONS

c a r b o n s t e e l p r o p e rt i e s : C o N T I N U o U S S E Rv I C E . hAzARdS.

C A R B o N S T E E L S T R A I N E R S A R E o F T E N U S E d I N T h E o I L A N d P E T Ro C h E M I C A L I N d U S T R I E S . S TA I N L E S S S T E E L I S C o M M o N Ly S P E C I F I E d F o R h I G h T E M P E R AT U R E S E Rv I C E , U P To S TA I N L E S S S T E E L S T R A I N E R S A R E C o M M o N Ly F o U N d I N T h E C h E M I C A L , F o o d , A N d

I T P Ro v I d E S h I G h R E S I S TA N C E To S h o C k , v I B R AT I o N , P I P I N G S T R A I N S , A N d F I R E A N d F R E E z I N G

C A R B o N S T E E L P E R F o R M S E x C E P T I o N A L Ly W E L L I N h I G h T E M P E R AT U R E S , U P To 8 0 0 F I N

s ta i n l e s s s t e e l p r o p e rt i e s :

1000 F I N C o N T I N U o U S S E Rv I C E .

P h A R M AC E U T I C A L I N d U S T R I E S .

The above data represents common market and ser vice a p p l i c a t i o n s . N o re p re s e n t a t i o n o r g u a ra n t e e , e x p re s s e d o r i m p l i e d , i s g i v e n d u e t o t h e n u m e ro u s var iat ions o f co nce ntrati o ns , temperatures and flow co ndi t i o ns t hat m ay o c c ur dur i ng ac t ual se r v i c e .

TITAN FLOW CONTROL, INC.

YOUR PIPELINE TO THE FUTURE!

Tel: 910-735-0000 s Fax: 910-738-3848 s titan@titanfci.com s www.titanfci.com 290 Corporate Drive s PO Box 7408 s Lumberton, NC 28358

YS61-0711

TITAN FLOW CONTROL, Inc.

TITAN

290 Corporate Drive Lumberton, NC 28358 Tel: 910.735.0000 BILL OF MATERIALS (1)

E-mail: titan@titanfci.com Web: www.titanfci.com Fax: 910.738.3848

WYE STRAINER YS 61-CS - (Carbon Steel) YS 61-SS - (Stainless Steel)

Flanged Ends Raised Face Carbon & Stainless Steel

(Includes Raised Face)

ANSI Class 150

A

No. 1 2 3 4 5 6 7 8

PART Body (2) Cover Straining Element (3) Gasket (3) (4) Studs Nuts NPT Plug Blow-off NPT Plug Gauge Taps (5)

YS 61-CS

(6)

YS 61-SS Stainless Steel A351 Gr. CF8M

Carbon Steel A216 Gr. WCB Carbon Steel A216 Gr. WCB Stainless Steel Stainless Steel Spiral Wound Alloy Steel Alloy Steel Carbon Steel Carbon Steel

Stainless Steel Stainless Steel Spiral Wound Stainless Steel Stainless Steel Stainless Steel Stainless Steel

D

Illustrations are representative of sizes 2" through 24" only. Please ask for certified drawings when required.

1 3 4 2

Exploded View

5 6 7

1. Bill of Materials represents standard materials. Equivalent or better materials may be substituted at the manufacturer's discretion. 2. Available in additional body materials, such as LCB, WC6, WC9, 316L, Alloy 20, and Monel. 3. Denotes recommended spare parts. 4. A wide range of gasket materials are available; contact factory for more information. 5. Part number 8 (NPT Plug - Gauge Taps) only applies to sizes 2" through 24". 6. Carbon Steel bodies are epoxy painted.

DIMENSIONS AND PERFORMANCE DATA (1) in mm in A DIMENSION FACE TO FACE (2) mm in B DIMENSION CENTER LINE TO BOTTOM mm in C DIMENSION SCREEN REMOVAL mm in D NPT Plug BLOW-OFF mm in E NPT Plug GAUGE TAPS mm ASSEMBLED WEIGHT lb APPROXIMATE kg Cv Flow Coefficient SIZE 15 6.50 166 3.50 89 5.00 127 3/8 10 N/A N/A 5.5 2.5 C/F 20 7.37 188 3.75 96 5.00 127 1/2 15 N/A N/A 10.3 4.6 C/F 1 25 7.37 188 3.75 96 5.00 127 1/2 15 N/A N/A 10.3 4.6 C/F 1 32 7.00 178 4.75 121 7.00 178 1/2 15 N/A N/A 12.0 5.4 C/F 1 40 7.12 181 4.75 121 7.00 178 1/2 15 N/A N/A 12.5 5.7 42 2 50 7.87 200 5.25 134 7.00 178 1/2 15 1/4 8 21.0 9.5 70 2 3 4 5 6 8 10 12 65 80 100 125 150 200 250 300 9.75 10.06 12.12 15.62 18.50 21.37 26.00 29.87 248 256 308 397 470 543 661 759 6.50 7.00 8.25 11.25 13.50 15.50 18.50 22.25 166 178 210 286 343 394 470 566 9.75 10.00 12.00 20.00 20.00 22.75 28.00 30.00 248 254 305 508 508 578 712 762 1 1 1 1/2 2 2 2 2 2 25 25 40 50 50 50 50 50 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 8 8 8 8 8 8 8 8 32.0 35.0 55.0 90.0 140.0 220.0 356.0 644.0 14.5 15.9 24.9 40.8 63.5 99.7 161.5 292.1 110 160 260 400 570 950 1600 2200 14 350 36.00 914 25.00 625 36.50 927 2 50 1/4 8 1000 453.6 3300 16 18 20 24 400 450 500 600 41.75 46.00 49.50 58.37 1060 1168 1257 1483 26.50 31.00 39.00 45.00 673 787 991 1143 42.00 45.50 56.00 68.00 1067 1156 1422 1727 2 2 2 2 50 50 50 50 1/4 1/4 1/4 1/4 8 8 8 8 1600 2400 2700 5000 725.7 1089 1225 2268 4900 6100 8000 11000

1. Dimensions and weights are for reference only. When required, request certified drawings. 2. Face to face dimension includes raised face. These values have a tolerance of 0.06 in (2.0 mm) for sizes 10" and lower and a tolerance of 0.12 in (3.0 mm) for sizes 12" and larger.

REFERENCED STANDARDS & CODES CODE ASME/ANSI B16.5 ASME/ANSI B16.34 DESCRIPTION Pipe Flanges and Flanged Fittings Flanged, Threaded, and Welding End

300 250

PRESSURE - TEMPERATURE RATINGS

SOURCE: ASME/ANSI B16.1

standard screen selections

Size 1/2" - 4" 5" - 8" 10" - 12" Liquid 1/16 (.0625) 1/8 (.125) 1/8 (.125) Open Area 41% 40% 40% Steam 1/32 (.033) 3/64 (.045) 30 Mesh Lined Open Area 28% 36% 44.8%

Pressure (PSI)

Carbon Steel A216 Gr. WCB ANSI Class 150 Carbon Steel not recommended for prolonged use above 800F Stainless Steel A351 Gr. CF8M ANSI Class 150 Stainless Steel not recommended for prolonged use above 1000F

200 150 100 50 0 -100

pressure - temperature rating Body Material WOG (Non-shock): Saturated Steam: Max Liquid: A216 Gr. WCB 285 PSI @ 100 F 150 PSI @ 366F 80 PSI @ 800 F A351 Gr. CF8M 275 PSI @ 100 F 150 PSI @ 366F 20 PSI @ 1000 F

100

200

300

400

500 600 Temperature (F)

700

800

900

1000

1100

Titan FCI makes every effort to ensure the information presented on our literature accurately reflects exact product specifications. However, as product changes occur, there may be short-term differences between actual product specifications and the information contained within our literature. Titan FCI reserves the right to make design and specification changes to improve our products without prior notification. When required, request certified drawings.

Stainless Steel A351 Gr. CF8M

Вам также может понравиться

- Prosertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesДокумент1 страницаProsertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesAlba Duaneth Rocabado MendietaОценок пока нет

- Prosertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesДокумент1 страницаProsertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesAlba Duaneth Rocabado MendietaОценок пока нет

- Prosertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesДокумент1 страницаProsertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesAlba Duaneth Rocabado MendietaОценок пока нет

- Daniel Measurement and Control, Inc. Emersor'4 Quality AssuranceДокумент3 страницыDaniel Measurement and Control, Inc. Emersor'4 Quality AssuranceAlba Duaneth Rocabado MendietaОценок пока нет

- TadoДокумент6 страницTadoAlba Duaneth Rocabado MendietaОценок пока нет

- CálculoKOD-Rev AДокумент28 страницCálculoKOD-Rev AGabo Montaño MendozaОценок пока нет

- Filtro Y - Marca TITANДокумент2 страницыFiltro Y - Marca TITANAlba Duaneth Rocabado MendietaОценок пока нет

- Ypfb Transporte S.A. XXXXXXXX A Hoja de Datos Flare: General DataДокумент2 страницыYpfb Transporte S.A. XXXXXXXX A Hoja de Datos Flare: General DataAlba Duaneth Rocabado MendietaОценок пока нет

- Filtro YДокумент6 страницFiltro YAlba Duaneth Rocabado MendietaОценок пока нет

- Flange Ansi - b16.5 Cl.-600Документ1 страницаFlange Ansi - b16.5 Cl.-600Selva RajОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)