Академический Документы

Профессиональный Документы

Культура Документы

Panki

Загружено:

SunОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Panki

Загружено:

SunАвторское право:

Доступные форматы

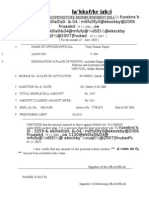

MAI/BS-157/2010/R3

ANNEXURE B BILL OF MATERIAL with Pricing: B.1 Common Development and Engineering (Applicable for both OPC & IEC Connectivity) Qty. 500 Total (Rs.) 5500000

Sl. No. Description Unit rate (Rs.) 1 Five Hundred (500) resource-days of Metso Automation for following 11000 activities: Mandays of an Expert : 50 days Mandays of Lead Engineer : 150 days Mandays of an Engineer : 300 days a Project management for the complete project. Attend design liaison meetings with UPRVUNL / UPRVUNL Consultant to b Finalization of technical scope and project schedule Finalization of software design philosophy Freeze the design basis for the engineering application, database and user interface. PS: Metso will design and develop the OPC / IEC connectivity to PI/ERP server(s), based on the requirements of UPRVUNL/ UPRVUNL Consultant Create templates. Design of libraries and OCX Design engineering for OPC / IEC database and connectivity for all plants Design engineering for user interface Review and approval of template design with UPRVUNL. PS: The template design review and approval from UPRVUNL is essential prior to the start of detailed engineering at plant level Design of manual data entry with authentication: Metso shall develop a software application with user interface which enables manual data entry with authentication of up to 300 values or parameters per unit into the OPC / IEC Server Initialization of communication protocol and testing procedures of connectivity between PI/ERP server. In case PI server is not available for testing, Metso will design the test procedure using OPC / IEC simulator Project documentation. Six (6) sets of final documentation shall be submitted by Metso Three (3) visits of 5 days each to UPRVUNL / UPRVUNL Consultant offices for implementation of the above activities. All travel and living expenses of Metso representative shall be borne by Metso TOTAL 93400 35000

c d e f

i j

lot 3

93400 105000

5698400

MAI/BS-157/2010/R3

B.2

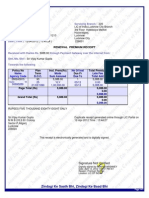

Common Engineering for Performance Calculations Qty. 350 Total (Rs.) 3733100

Sl. No. Description Unit rate (Rs.) 1 Three Hundred Fifty (350) resource-days of Metso Automation for 10666 following activities: Mandays of an Expert : 27 days Mandays of Lead Engineer : 100 days Mandays of an Engineer : 223 days a Project management for all the activities related to Performance Calculation. PS: The expertise / man-power for Performance Calculation implementation is different from that of implementing OPC / IEC Connectivity b Attend design liaison meetings with UPRVUNL / UPRVUNL Consultant for Finalization of technical scope and project schedule for implementation of Performance Calculations Finalization of software design philosophy for performance applications and user interface Create templates. Design of libraries and OCX Design engineering of database with connectivity from OPC / IEC server required for all plants Design engineering for user interface Design the Performance Calculation libraries, based on the requirement of UPRVUNL and the design data of the Boiler and Turbine manufacturers. Review and approval of template design for Performance Calculation with UPRVUNL. PS: The template design review and approval from UPRVUNL is essential prior to the start of detailed engineering at plant level Project documentation. Six (6) sets of final documentation shall be submitted by Metso Two (2) visits of 5 days each to UPRVUNL / UPRVUNL Consultant offices for implementation of the above activities. All travel and living expenses of Metso representative shall be borne by Metso TOTAL

c d e f

h i

75050 35000

lot 2

75050 70000

3878150

B.3

Equipment and software license required at each Plant Location, Common for all Units. (Applicable for both OPC & IEC Connectivity): Model No. Microsoft SFT400 HP / Equiv. TOTAL Model No. Microsoft SFT400 HP / Equiv. Qty. 1 1 1 Unit rate (Rs.) 50000 400000 100000 550000

Sl. No. Description 1 VB.Net 2 maxAPPS Software 3 Laptop (HP/Compaq nx7400 or equivalent)

B.4

Equipment and software licenses required for OPC Connectivity with MAX1 & MAX1000 System. Applicable to Units Obra 6, 7 & 8; Parichha 1 & 2 Model No. PPR101 HP / Equiv. SFT400 Model No. PPR101 HP / Equiv. SFT400 Qty. 1 1 1 Unit rate (Rs.) 671291 120000 213750 0 445500 281160 242370 36000 50000 1000 3000 2064071

Sl. No. Description 1 DPU Bus Module (refurbished) 2 maxSTATION with 22" TFT monitor, mouse & keyboard 3 max Security key (VTS4P) with following licenses: maxVUE Runtime license (SFT451) 1no. maxTOOLS license (SFT453) 1no. maxSTORIAN license (SFT455) 1no. OPC gateway + server license (SFT462) 1no. DPU4F Configurator license 1no. 4 Mounting Console 5 Redundant Switch, 8 10BT/100BTX 240Vac 6 Ethernet CAT5E cable 7 Highway cable TOTAL

MA Std. MA Std. DLINK / Equiv. DLINK / Equiv. Industry Std. Industry Std. MA Std. MA Std.

1 1 As reqd. As reqd.

MAI/BS-157/2010/R3

B.5

Equipment and software license required for OPC Connectivity with maxDNA System: Applicable to Units: Anpara 4 & 5; Harduaganj 7, 8, &9; Obra 9, 10, 11, 12 & 13; Parichha 3, 4, 5 & 6 Qty. 1 1 Unit rate (Rs.) 120000 213750 0 445500 281160 242370 36000 50000 1000 357595 1747375

Sl. No. Description Model No. Model No. 1 maxSTATION with 22" TFT monitor, mouse & keyboard HP / Equiv. HP / Equiv. 2 SFT400 SFT400 max Security key (VTS4P) with following licenses: maxVUE Runtime license (SFT451) 1no. maxTOOLS license (SFT453) 1no. maxSTORIAN license (SFT455) 1no. OPC gateway + server license (SFT462) 1no. DPU4F Configurator license 1no. 3 Mounting Console MA Std. MA Std. 4 Redundant Switch, 8 10BT/100BTX 240Vac DLINK / Equiv. DLINK / Equiv. 5 Ethernet CAT5E cable Industry Std. Industry Std. 6 Software tools for initialization and compatibility with existing maxDNA MA Std. MA Std. System TOTAL Equipment and software licenses required for IEC Connectivity with MAX1 & MAX1000 System. Applicable to Units Obra 6, 7 & 8; Parichha 1 & 2 Sl. No. Description Model No. Model No. 1 DPU Bus Module (refurbished) PPR101 PPR101 2 IEC Gateway 3 maxSTATION with 22" TFT monitor, mouse & keyboard HP / Equiv. HP / Equiv. 4 SFT400 SFT400 max Security key (VTS4P) with following licenses: maxVUE Runtime license (SFT451) 1no. maxTOOLS license (SFT453) 1no. maxSTORIAN license (SFT455) 1no. OPC gateway + server license (SFT462) 1no. DPU4F Configurator license 1no. 5 Mounting Console MA Std. MA Std. 6 Redundant Switch, 8 10BT/100BTX 240Vac DLINK / Equiv. DLINK / Equiv. B.6 7 8 Ethernet CAT5E cable Highway cable TOTAL Equipment and software license required for IEC Connectivity with maxDNA System: Applicable to Units: Anpara 4 & 5; Harduaganj 7, 8, &9; Obra 9, 10, 11, 12 & 13; Parichha 3, 4, 5 & 6 Sl. No. Description Model No. Model No. 1 IEC Gateway 2 maxSTATION with 22" TFT monitor, mouse & keyboard HP / Equiv. HP / Equiv. 3 SFT400 SFT400 max Security key (VTS4P) with following licenses: maxVUE Runtime license (SFT451) 1no. maxTOOLS license (SFT453) 1no. maxSTORIAN license (SFT455) 1no. OPC gateway + server license (SFT462) 1no. DPU4F Configurator license 1no. 4 Mounting Console MA Std. MA Std. 5 Switch, 8 10BT/100BTX 240Vac DLINK / Equiv. DLINK / Equiv. 6 Ethernet CAT5E cable Industry Std. Industry Std. 7 Software tools for initialization and compatibility with existing maxDNA MA Std. MA Std. System TOTAL B.7 Industry Std. MA Std. Industry Std. MA Std.

1 1 As reqd. 1

Qty. 1 1 1 1

Unit rate (Rs.) 671291 375000 120000 213750 0 445500 281160 242370 36000 50000 1000 3000 2439071

1 2 As reqd. As reqd.

Qty. 1 1 1

Unit rate (Rs.) 375000 120000 213750 0 445500 281160 242370 36000 50000 1000 357595 2122375

1 2 As reqd. 1

MAI/BS-157/2010/R3

B.8 Engineering and site services applicable for EACH Unit (Applicable for both OPC & IEC Connectivity options) Sl. No. Description Unit rate Qty. Total (Rs.) 1 Fifteen (15) resource-days of Metso Automation for following activities: 16670 15 250050 Mandays of an Expert : 9 days Mandays of Lead Engineer : 6 days a b Design of network architecture and implementation plan for Unit Customization of applications / data points for each Unit Customizing of templates in OPC / IEC server Configuration of Unit specific data point connectivity between the Metso supplied OPC / IEC Sever and the PI/ERP server arranged by UPRVUNL Customizing of manual points templates and commissioning of manual point software at unit level as per unit requirement and number of users Supervision of the following site activities: Supervision of installation of supplied maxDNA system hardware (like DBM and OPC Server) at Unit Supervision of laying and installation of maxDNA system cables for connectivity of existing system to new DBM and OPC servers at UPRVUNL site at Unit. System Power ON and connectivity of the Metso supplied OPC / IEC Sever with the existing Metso DCS (MAX1 / MAX1000 / maxDNA) without shutdown disturbing existing plant operation. Testing: Testing of data connectivity between the existing Metso DCS and the Metso supplied OPC / IEC Sever Testing of software and displays at plant level Testing of point manual entry software and authentication Testing of data connectivity between plant OPC / IEC Server (supplied by Metso) and the PI/ERP server. In case PI/MIS server is not available for testing, Metso will test connectivity using OPC/IEC simulator in place of PI/MIS server. f One (1) day of customer orientation at site on the Operation and Maintenance of the OPC / IEC Server and connectivity engineered by Metso Project documentation. Six (6) sets of final documentation shall be submitted by Metso One (1) visit of 5 days to each Unit site for implementation of the above activities. All travel and living expenses of Metso representative shall be borne by Metso TOTAL

g h

50000 35000

1 1

50000 35000

335050

B.9

Equipment and software license required for Performance Calculation Note1at each Plant Location (Applicable for both OPC & IEC Connectivity): Model No. SFT400 Model No. SFT400 Qty. 1 Unit rate (Rs.) 303955 242370 546325

Sl. No. Description 1 max Security key (C4) with following licenses: maxCALCS license (SFT456) + testing s/w 1no. DPU4F Configurator license 1no. TOTAL

Note 1: Performance Calculation licenses are not required in Anpara Unit 4 & 5 since already supplied with DAS project.

MAI/BS-157/2010/R3

B.10

Engineering and site services of Performance Calculations applicable for EACH Unit (Applicable for both OPC & IEC Connectivity options) Unit rate 14370 Qty. 15 Total (Rs.) 215550

Sl. No. Description 1 Fifteen (15) resource-days of Metso Automation for following activities: Mandays of an Expert : 7 days Mandays of Lead Engineer : 3 days Mandays of an Engineer : 5 days a b Design of performance calculation as per plant architecture. Installation and configuration of performance calculation package on maxDNA system. Installation of Microsoft Visual Basic software. Customization of performance calculation equations/ data points for each Unit Customizing of templates suitable to plant model. Configuration of unit specific data point inputs and outputs. Configuration of unit specific equations and curves for calculation of unit equipments efficiency. Testing: Testing performance calculation equation with three test case inputs Testing of performance calculation with online inputs and manual inputs. Testing of connectivity of results to PI/MIS server. In case PI/MIS server is not available for testing, Metso will test connectivity using OPC/IEC simulator in place of PI/MIS server. Project documentation. Six (6) sets of final documentation shall be submitted by Metso One (1) visit of 5 days to each Unit site for implementation of the above activities. All travel and living expenses of Metso representative shall be borne by Metso TOTAL

f g

50000 35000

1 1

50000 35000

300550

Вам также может понравиться

- International: April 2013 Current Affairs Study MaterialДокумент19 страницInternational: April 2013 Current Affairs Study MaterialSunОценок пока нет

- Overhauling Details January 2013Документ1 страницаOverhauling Details January 2013SunОценок пока нет

- Thermal Generation January 2013Документ1 страницаThermal Generation January 2013SunОценок пока нет

- Software Maintenance in Software Engineering Is The Modification of A Software Product After Delivery To Correct FaultsДокумент3 страницыSoftware Maintenance in Software Engineering Is The Modification of A Software Product After Delivery To Correct FaultssunuprvunlОценок пока нет

- 67603Документ4 страницы67603SunОценок пока нет

- International: March 2013 Current Affairs Study MaterialДокумент17 страницInternational: March 2013 Current Affairs Study MaterialSunОценок пока нет

- International: February 2013 Current Affairs Study MaterialДокумент15 страницInternational: February 2013 Current Affairs Study MaterialSunОценок пока нет

- Payment & Accounts Division, 'B' TPS, Obra: Priority-AДокумент2 страницыPayment & Accounts Division, 'B' TPS, Obra: Priority-ASunОценок пока нет

- Babasaheb Bhimrao Ambedkar University: Department of SociologyДокумент1 страницаBabasaheb Bhimrao Ambedkar University: Department of SociologySunОценок пока нет

- Priority BДокумент44 страницыPriority BSunОценок пока нет

- Panki Thermal Power Station (2X110 MW) : Band/Dept. EE AE Medical Office Chief Chemist Welfare Officer SAO AO AAOДокумент2 страницыPanki Thermal Power Station (2X110 MW) : Band/Dept. EE AE Medical Office Chief Chemist Welfare Officer SAO AO AAOSunОценок пока нет

- Firewall Apr2004Документ21 страницаFirewall Apr2004SunОценок пока нет

- Montana Presentation HandoutДокумент35 страницMontana Presentation HandoutSunОценок пока нет

- Group B ParichhaДокумент2 страницыGroup B ParichhaSunОценок пока нет

- La'kksf/kr Izk:i: Mobile Facility Expenditure Reimbursement BillДокумент5 страницLa'kksf/kr Izk:i: Mobile Facility Expenditure Reimbursement BillSunОценок пока нет

- Ta Bill (Dko)Документ2 страницыTa Bill (Dko)SunОценок пока нет

- 12x26 Up Department EnergyДокумент1 страница12x26 Up Department EnergySunОценок пока нет

- Group B PankiДокумент1 страницаGroup B PankiSunОценок пока нет

- LIC ReceiptДокумент1 страницаLIC ReceiptSun100% (4)

- LodaДокумент2 страницыLodaSunОценок пока нет

- Capacity Addition-11th PlanДокумент3 страницыCapacity Addition-11th PlanSunОценок пока нет

- K K Vuqefr I : To Appear in The Test For PGDBM Course, Being Organized by MDI GurgaonДокумент16 страницK K Vuqefr I : To Appear in The Test For PGDBM Course, Being Organized by MDI GurgaonSunОценок пока нет

- 6th PC ArrearДокумент1 страница6th PC ArrearSunОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Study Material On Computer Organization and ArchitectureДокумент80 страницStudy Material On Computer Organization and ArchitecturetoarnabchОценок пока нет

- CV of MD Moshiur RahamanДокумент3 страницыCV of MD Moshiur RahamanMoshiur RahamanОценок пока нет

- Instructor Materials Chapter 8: Network Troubleshooting: CCNA Routing and Switching Connecting NetworksДокумент28 страницInstructor Materials Chapter 8: Network Troubleshooting: CCNA Routing and Switching Connecting NetworksMuhammad Ridwan Adi NugrahaОценок пока нет

- CHAPTER 7 Prototyping PDFДокумент7 страницCHAPTER 7 Prototyping PDFAngeline Lagmay Visaya100% (1)

- Computer MaintenanceДокумент68 страницComputer Maintenancefronda laoyanОценок пока нет

- Epigrammatum Anthologia Palatina 1 PDFДокумент615 страницEpigrammatum Anthologia Palatina 1 PDFdrfitti1978Оценок пока нет

- Comptia Linux Guide To Linux Certification 4th Edition Eckert Test BankДокумент10 страницComptia Linux Guide To Linux Certification 4th Edition Eckert Test BankCherylRandolphpgyre100% (17)

- The Platform of EverythingДокумент51 страницаThe Platform of EverythingSi Pham QuocОценок пока нет

- WD Qdos enДокумент4 страницыWD Qdos enquanghuyvtОценок пока нет

- Model QAP For Plates1Документ3 страницыModel QAP For Plates1tarun kaushalОценок пока нет

- Revised Time Table-11.1.2014Документ136 страницRevised Time Table-11.1.2014rickyali_rocksОценок пока нет

- Acer Aspire One 522 AO522 - COMPAL LA-7072P - REV 1.0sec PDFДокумент36 страницAcer Aspire One 522 AO522 - COMPAL LA-7072P - REV 1.0sec PDFMcgregori AndradeОценок пока нет

- Cisco NCS 540Документ12 страницCisco NCS 540Samir Ben Hassen0% (1)

- Kernel (Computer Science) - Simple English Wikipedia, The Free EncyclopediaДокумент7 страницKernel (Computer Science) - Simple English Wikipedia, The Free EncyclopediaziaullahОценок пока нет

- Construction Experience ResumeДокумент6 страницConstruction Experience Resumef5dthdcd100% (2)

- Tower Foundation BOM For SST 42m 4L 290kph - HДокумент18 страницTower Foundation BOM For SST 42m 4L 290kph - Hhenjie mirasolОценок пока нет

- #Pip Install Pyttsx3 #Pip Install Speechrecognition #Pip Install WikipediaДокумент3 страницы#Pip Install Pyttsx3 #Pip Install Speechrecognition #Pip Install WikipediaTuhina SharmaОценок пока нет

- AutoProof Pro Imaging Suite - Automated Inspection SoftwareДокумент4 страницыAutoProof Pro Imaging Suite - Automated Inspection SoftwareComplete Inspection Systems, Inc.Оценок пока нет

- Cs vp11 CG Make Vacuum ContactorДокумент4 страницыCs vp11 CG Make Vacuum ContactorPushpendra KushwahaОценок пока нет

- Angry Birds - Strategic AnalysisДокумент36 страницAngry Birds - Strategic AnalysisChetanya Rajput100% (1)

- Contractor List 3Документ6 страницContractor List 3ALI KHALID0% (1)

- 1679028135898fw3TuyP3VyjUHvFh PDFДокумент4 страницы1679028135898fw3TuyP3VyjUHvFh PDFSV FilmsОценок пока нет

- SNA AssignmentДокумент42 страницыSNA AssignmentSuzan DahitОценок пока нет

- Forti WebДокумент7 страницForti WebYoussef HbilateОценок пока нет

- Charu Gupta B.Tech CS 3 Yr Roll No. 0821510020Документ27 страницCharu Gupta B.Tech CS 3 Yr Roll No. 0821510020Charu GuptaОценок пока нет

- Cybersecurity Career MasterplanДокумент280 страницCybersecurity Career Masterplan41down100% (1)

- RDB ManualДокумент160 страницRDB ManualgamunozdОценок пока нет

- UI Developer Sample ResumeДокумент4 страницыUI Developer Sample Resumerahul VikasОценок пока нет

- 7-16 DIN Female Connector For 1-5/8" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingДокумент2 страницы7-16 DIN Female Connector For 1-5/8" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingLuciano Silvério LeiteОценок пока нет

- BYTE Job Description - Class of 2024 - SRM - 8th - 9th September'23Документ2 страницыBYTE Job Description - Class of 2024 - SRM - 8th - 9th September'23SHIVANSH SRIVASTAVA (RA2011053010013)Оценок пока нет