Академический Документы

Профессиональный Документы

Культура Документы

Procedure Qualification Record

Загружено:

Shaik ShahАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Procedure Qualification Record

Загружено:

Shaik ShahАвторское право:

Доступные форматы

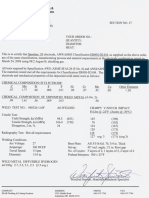

Major Tool and Machine, Inc.

1458 E. 19th Street, Indianapolis, Indiana, 46218

Procedure Qualification Record (PQR) - Details of Welding Test

Weldspec for Windows

PQR record number Date PQR328.5 12/4/03 Revision 2 WPS record number Company name Welding standard BASE METALS (QW-403) Product form Plate Welded to: and tested: Notes JOINTS (QW-402) Joint design Backing: Retainers Groove angle Root opening Root face

(deg.) (in.) (in.)

WPS328.5-PPPL Major Tool and Machine, Inc. ASME Section IX

Revision 2

Specification (type or grade) SB-443 (1) SA-240 (Type 304L)

P no. 43 8

Grp-no.

Size -

Sch. -

Thick. .375 .375

(in.) Dia.

(in.)

Plate Without PWHT

Double-bevel-groove Weld or base metal None 60 0 .06

WELDING PROCESSES Welding process Type FILLER METALS (QW-404) SFA specification AWS classification Filler metal F-number Weld metal A-number Filler metal nominal composition Filler metal trade name Filler metal size Deposited thickness Maximum pass thickness Weld deposit chemistry POSITION (QW-405) Position of groove Weld progression PREHEAT (QW-406) Preheat temperature Maximum interpass temperature GAS (QW-408) Shielding gas: Trailing gas: Backing gas: Type Flow rate Type Flow rate Type Flow rate ELECTRICAL (QW-409) Filler metal size Amperes Volts Travel speed Maximum heat input Tungsten size Tungsten type Current/polarity DC pulsing current TECHNIQUE (QW-410) String or weave Orifice/gas cup size Multi/Single pass per side Peening Initial/interpass cleaning Back gouging method Stringer .44 Multiple passes Not used Interpass cleaning requirement Grinding

(in./min) (kJ/in.) (in.) (in.) (cfh) (cfh) (cfh) (F) (F) (in.) (in.) (in.)

GTAW Manual

5.14 ERNiCrMo-3 43 NA See manufacturers data Inconel 625 0.093 0.375 <0.375

1G -

70 350

Argon 35 None None -

0.093 139 13.1 7 .093 SFA 5.12 EWTh-2 DCEN Not used

Weldspec 4.20.002 Catalog n PQR00227

(c) Copyright 2004 C-spec/TWI Software. All rights reserved worldwide. Page 1 of 3

Major Tool and Machine, Inc.

1458 E. 19th Street, Indianapolis, Indiana, 46218

Procedure Qualification Record (PQR) - Test Results (As Welded)

Weldspec for Windows

PQR record number Date PQR328.5 12/4/03 Revision 2 WPS record number Company name Welding standard TENSILE TESTS (QW-150) Specimen number 1 2 Width

(in.)

WPS328.5-PPPL Major Tool and Machine, Inc. ASME Section IX

Revision 2

Reduced section Thickness

(in.)

Area

(in)

Ultimate total load

(lb)

Ultimate unit stress

(psi)

Type of failure and location Ductile-Base Metal Ductile-Base Metal

0.757 0.758

0.381 0.377

0.288 0.286

27541 27273

95500 95400

Comments GUIDED BEND TESTS (QW-160)

Both tensile test failures occurred in the 304L base material.

Type of test 2 transverse face bends per QW-161.2 and QW-462.3(a) 2 transverse root bends per QW-161.3 and QW-462.3(a) Visual examination Radiographic Examination Comments CERTIFICATION Welder's name Clephane, Randy ID Number 743

Acceptance criteria QW-163 QW-163 QW-194 QW-191

Result Acceptable Acceptable Acceptable Acceptable

Comments see - ASME IX - QW-451.1 see - ASME IX - QW-451.1

See Additional information section for other testing performed.

Stamp number

Mechanical testing by Laboratory test number Test file number Tests conducted by

Sherry Laboratories 2003080918 Jerry L. Judt

We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in accordance with the requirements of Section IX of the ASME Code.

Signature 1 (definable in Tools-Options-Default Settings) Name Michael G. Iverson Date 12/4/2003

Weldspec 4.20.002 Catalog n PQR00227 (c) Copyright 2004 C-spec/TWI Software. All rights reserved worldwide. Page 2 of 3

Signature

Major Tool and Machine, Inc.

1458 E. 19th Street, Indianapolis, Indiana, 46218

Procedure Qualification Record (PQR) - Additional information

Weldspec for Windows

PQR record number Date PQR328.5 12/4/03 Revision 2 WPS record number Company name Welding standard WPS328.5-PPPL Major Tool and Machine, Inc. ASME Section IX Revision 2

1. 625 Inconel base material - heat number 510614L05 304L base material - heat number 896479 2a. Magnetic permeability before welding: 304L stainless steel base plate before welding = 1.058 - 1.092 625 Inconel base plate before welding = 1.000 - 1.001 2. Magnetic permeability after welding: 304L stainless steel base plate = 1.102 - 1.115 625 Inconel base plate = 1.000 - 1.001 Heat effected zone = 1.014 - 1.022 (measured on the 625 Inconel side) Heat effected zone = 1.080 - 1.105 (measured on the 304L side) 3. NDT performed on test plate: a. Radiography - MQS Inspection W.O. #371-F0004, dated 8/22/2003. b. Visual inspection - MTM NDT #6952. 4. Software error caused PQR test results to print as turned specimen rather than reduced specimen. This was eliminated by resaving the PQR. No revisions have been invoked because all information stayed the same, however, the PQR test results page now show as a reduced specimen when printed rather than a turned specimen. - 11/25/03 - Michael Iverson Welding Engineer/CWI 5. Rev 2 - Per customers comments note 4 should have caused the rev level to change to rev 1. Added Visual and Radiographic Inspection to the Test Results Page, added note 2a which records magnetic permeability of base plates prior to welding. - 12/4/03 - MGI

Weldspec 4.20.002 Catalog n PQR00227

(c) Copyright 2004 C-spec/TWI Software. All rights reserved worldwide. Page 3 of 3

Вам также может понравиться

- B-62 2507 Rev 06Документ5 страницB-62 2507 Rev 06Shaik ShahОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Astm and Iso Vocs in Coatings - Method Comparison MatrixДокумент2 страницыAstm and Iso Vocs in Coatings - Method Comparison MatrixShaik ShahОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- New Indian Model School, Dubai: EnglishДокумент2 страницыNew Indian Model School, Dubai: EnglishShaik ShahОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Astm and Iso Vocs in Coatings - Method Comparison MatrixДокумент2 страницыAstm and Iso Vocs in Coatings - Method Comparison MatrixShaik ShahОценок пока нет

- Material Approval FormДокумент1 страницаMaterial Approval FormShaik Shah50% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- WPSДокумент2 страницыWPSJuli Agus50% (2)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Norma Técnica Steel Deck Institute SDIДокумент24 страницыNorma Técnica Steel Deck Institute SDIShaik Shah100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Work Method Manual Mechanical Pump Test Run - Rev 0-28.04.10Документ14 страницWork Method Manual Mechanical Pump Test Run - Rev 0-28.04.10Iwan PrawitoОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Assessment ScheduleДокумент1 страницаAssessment ScheduleShaik ShahОценок пока нет

- Standards Information Booklet: Fabricating of Steel Structures (Plating) National/Scottish Vocational QualificationДокумент51 страницаStandards Information Booklet: Fabricating of Steel Structures (Plating) National/Scottish Vocational QualificationDanilo de JurasОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Work Method Manual Mechanical Pump Test Run - Rev 0-28.04.10Документ14 страницWork Method Manual Mechanical Pump Test Run - Rev 0-28.04.10Iwan PrawitoОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- API 541 DatasheetДокумент7 страницAPI 541 Datasheetjavier716730% (1)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- HSE QuestionnaireДокумент5 страницHSE QuestionnaireShaik ShahОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- 9 1 PDFДокумент78 страниц9 1 PDFCarlos JuárezОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- AB-522 Standard Pneumatic Test Procedure RequirementsДокумент13 страницAB-522 Standard Pneumatic Test Procedure Requirementskysuco100% (1)

- PlanetsДокумент9 страницPlanetsShaik ShahОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Positive Material Identification (Pmi)Документ2 страницыPositive Material Identification (Pmi)MurugadossRajendranОценок пока нет

- Durability of ConcreteДокумент89 страницDurability of ConcreteRamu NeupaneОценок пока нет

- Petroleum Dissertation TopicsДокумент7 страницPetroleum Dissertation TopicsEnglishPaperHelpCanada100% (1)

- One Step Extraction of Essential Oils and Pectin From Pomelo (Citrus Grandis) PeelsДокумент5 страницOne Step Extraction of Essential Oils and Pectin From Pomelo (Citrus Grandis) PeelsHuy Hoàng Lê ĐứcОценок пока нет

- CFM SPM 70-48-00Документ8 страницCFM SPM 70-48-00ZakiHaunaОценок пока нет

- 2023 Microalgae Application To Bone Repairing Process - A ReviewДокумент19 страниц2023 Microalgae Application To Bone Repairing Process - A ReviewvirgiparedesОценок пока нет

- Book by MontogomeryДокумент10 страницBook by MontogomerySubba PappuОценок пока нет

- CE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasДокумент41 страницаCE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasRickyWisaksonoОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Drill String Checklist 1 - IPMДокумент3 страницыDrill String Checklist 1 - IPMEmre CengizОценок пока нет

- ASTM D874 - 2000 - Sulfated Ash From Lubricating Oils and AdditivesДокумент5 страницASTM D874 - 2000 - Sulfated Ash From Lubricating Oils and AdditivesConstantinos ChristodoulouОценок пока нет

- Agave Biotechnology An OverviewДокумент15 страницAgave Biotechnology An Overviewadrian perezОценок пока нет

- Experimental Detemination of Crystal StructureДокумент40 страницExperimental Detemination of Crystal StructureAASHIR AHMAD JASKANIОценок пока нет

- Conjugate Acid Base Pairs WorksheetДокумент1 страницаConjugate Acid Base Pairs WorksheetFrank Massiah100% (3)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Back To Basics ... : Material Selection and Heat TreatmentДокумент8 страницBack To Basics ... : Material Selection and Heat TreatmentMuhammad Faisal FirdausОценок пока нет

- Influence of Morinda Citrifolia (Noni) On Expression of DNA Repair Genes in Cervical Cancer CellsДокумент5 страницInfluence of Morinda Citrifolia (Noni) On Expression of DNA Repair Genes in Cervical Cancer CellsAtika Nur NabilaОценок пока нет

- Biodegradable Wastes: Hospital WasteДокумент4 страницыBiodegradable Wastes: Hospital WasteFAIZA A PASCUALОценок пока нет

- Understanding Omega Fatty AcidsДокумент5 страницUnderstanding Omega Fatty Acidsdrubwang100% (1)

- For NAT Review Earth and Life ScienceДокумент2 страницыFor NAT Review Earth and Life ScienceKier CorbitaОценок пока нет

- Distortions: M. Vedani Failure and Control of Metals - AY 2020/21Документ7 страницDistortions: M. Vedani Failure and Control of Metals - AY 2020/21MarcoОценок пока нет

- A1.2.3 Method Statement 4a Redacted Version2Документ98 страницA1.2.3 Method Statement 4a Redacted Version2ChanelОценок пока нет

- Co 2Документ6 страницCo 2Sitti Nur QomariahОценок пока нет

- Enersys - DataSafe HXДокумент4 страницыEnersys - DataSafe HXRoger PerezОценок пока нет

- Effect of Flake Ice On Concrete CoolingДокумент1 страницаEffect of Flake Ice On Concrete CoolingGianni TogniОценок пока нет

- ESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root GapДокумент1 страницаESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root Gapalok987Оценок пока нет

- 1 1Документ9 страниц1 1Ankush SehgalОценок пока нет

- Praxis GuideДокумент43 страницыPraxis GuideRyan NegadОценок пока нет

- Pe Fir Handbook 1 2Документ237 страницPe Fir Handbook 1 2Salman JoОценок пока нет

- Solutios, Solutions of Non Electrolyte - 2019-2020 v2Документ80 страницSolutios, Solutions of Non Electrolyte - 2019-2020 v2hazo hazОценок пока нет

- 11 Iajps11072017Документ7 страниц11 Iajps11072017Baru Chandrasekhar RaoОценок пока нет

- Sigmafast 278Документ5 страницSigmafast 278kaleshОценок пока нет

- Semester/Concrete Technology (9021) /experiment-02 PDFДокумент14 страницSemester/Concrete Technology (9021) /experiment-02 PDFjestinvthomasОценок пока нет