Академический Документы

Профессиональный Документы

Культура Документы

Isoloop Magnetic Coupler

Загружено:

Karthik SurabathulaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Isoloop Magnetic Coupler

Загружено:

Karthik SurabathulaАвторское право:

Доступные форматы

Isoloop Magnetic Couplers

1. INTRODUCTION

Couplers, also known as "isolators" because they electrically isolate as well as transmit data, are widely used in industrial and factory networks, instruments, and telecommunications. Every one knows the problems with optocouplers. They take up a lot of space, are slow, optocouplers age and their temperature range is quite limited. For years, optical couplers were the only option. Over the years, most of the components used to build instrumentation circuits have become ever smaller. Optocoupler technology, however, hasnt kept up. Existing coupler technologies look like dinosaurs on modern circuit boards. Magnetic couplers are analogous to optocouplers in a number of ways. Design engineers, especially in instrumentation technology, will welcome a galvanically isolated data coupler with integrated signal conversion in a single IC. My report will give a detailed study about ISOLOOP MAGNETIC COUPLERS.

Department of ECE, MRCE

Isoloop Magnetic Couplers

2. INDUSTRIAL NETWORKS NEED ISOLATION

2.1 Ground Loops

When equipment using different power supplies is tied together (with a common ground connection) there is a potential for ground loop currents to exist. This is an induced current in the common ground line as a result of a difference in ground potentials at each piece of equipment. Normally all grounds are not in the same potential. Widespread electrical and communications networks often have nodes with different ground domains. The potential difference between these grounds can be AC or DC, and can contain various noise components. Grounds connected by cable shielding or logic line ground can create a ground loop unwanted current flow in the cable. Ground-loop currents can degrade data signals, produce excessive EMI, damage components, and, if the current is large enough, present a shock hazard. Galvanic isolation between circuits or nodes in different ground domains eliminates these problems, seamlessly passing signal information while isolating ground potential differences and common-mode transients. Adding isolation components to a circuit or network is considered good design practice and is often mandated by industry standards. Isolation is frequently used in modems, LAN and industrial network interfaces (e.g., network hubs, routers, and switches), telephones, printers, fax machines, and switched-mode power supplies.

Department of ECE, MRCE

Isoloop Magnetic Couplers

3. GALVANIC COUPLERS

Optocouplers transmit signals by means of light through a bulk dielectric that provides galvanic isolation (see Figure 1).Magnetic couplers are analogous to optocouplers in a number of ways.

Figure 1: Optical

Isolator

Figure 2: Isoloop

Isolator

Department of ECE, MRCE

Isoloop Magnetic Couplers

Magnetic couplers transmit signals via a magnetic field, rather than a photon transmission, across a thin film dielectric that provides the galvanic isolation. As is true of optocouplers, magnetic couplers are unidirectional and operate down to DC. But in contrast to optocouplers, magnetic couplers offer the high-frequency performance of an isolation transformer, covering nearly the entire combined bandwidth of the two conventional isolation technologies.

Department of ECE, MRCE

Isoloop Magnetic Couplers

4. PHYSICS OF THE GIANT MAGNETORESISTANCE

4.1 Giant Magnetoresistive

Large magnetic field dependent changes in resistance are possible in thin film ferromagnet/nonmagnetic metallic multilayers. The phenomenon was first observed in France in 1988, when changes in resistance with magnetic field of up to 70% were seen. Compared to the small percent change in resistance observed in anisotropic magnetoresistance, this phenomenon was truly giant magnetoresistance. The spin of electrons in a magnet is aligned to produce a magnetic moment. Magnetic layers with opposing spins (magnetic moments) impede the progress of the electrons (higher scattering) through a sandwiched conductive layer. This arrangement causes the conductor to have a higher resistance to current flow. An external magnetic field can realign all of the layers into a single magnetic moment. When this happens, electron flow will be less effected (lower scattering) by the uniform spins of the adjacent ferromagnetic layers. This causes the conduction layer to have a lower resistance to current flow. Note that these phenomenon takes places only when the conduction layer is thin enough (less than 5 nm) for the ferromagnetic layers electron spins to affect the conductive layers electrons path.

Department of ECE, MRCE

Isoloop Magnetic Couplers

Figure 3: Nonmagnetic Conductive Layers

The resistance of two thin ferromagnetic layers separated by a thin nonmagnetic conducting layer can be altered by changing the moments of the ferromagnetic layers from parallel to antiparallel, or parallel but in the opposite direction. Layers with parallel magnetic moments will have less scattering at the interfaces, longer mean free paths, and lower resistance. Layers with antiparallel magnetic moments will have more scattering at the interfaces, shorter mean free paths, and higher resistance (see Figure 2 & 3).

Department of ECE, MRCE

Isoloop Magnetic Couplers

Figure 4: Magneto Resistive Sensor For spin-dependent scattering to be a significant part of the total resistance, the layers must be thinner than the mean free path of electrons in the bulk material. For many ferromagnets the mean free path is tens of nanometers, so the layers themselves must each be typically <10 nm (100 ). It is therefore not surprising that GMR was only recently observed with the development of thin film deposition systems. The spins of electrons in a magnet are aligned to produce a magnetic moment. Magnetic layers with opposing spins (magnetic moments) impede the progress of the electrons (higher scattering) through a sandwiched conductive layer. This arrangement causes the conductor to have a higher resistance to current flow.

4.2 Gmr Materials

There are presently several GMR multilayer materials used in sensors and sensor arrays. The following chart shows a typical characteristic for a GMR material:

Department of ECE, MRCE

Isoloop Magnetic Couplers

Figure 5: : Characteristics Of Gmr Materials

Notice that the output characteristic is omnipolar, meaning that the material provides the same change in resistance for a directionally positive magnetic field as it does for a directionally negative field. This characteristic has advantages in certain applications. For example, when used on a magnetic encoder wheel, a GMR sensor using this material will provide a complete sine wave output for each pole on the encoder thus doubling the resolution of the output signal. The material shown in the plot is used in most of GMR sensor products. It provides a 98% linear output from 10% to 70% of full scale, a large GMR effect (13% to 16%), a stable temperature coefficient (0.15%/C) and temperature tolerance (+150C), and a large magnetic field range (0 to 300 Gauss).

Department of ECE, MRCE

Isoloop Magnetic Couplers

For spin-dependent scattering to be a significant part of the total resistance, the layers must be thinner than the mean free path of electrons in the bulk material. For many ferromagnets the mean free path is tens of nanometers, so the layers themselves must each be typically <10 nm (100 ). It is therefore not surprising that GMR was only recently observed with the development of thin film deposition systems.

Department of ECE, MRCE

Isoloop Magnetic Couplers

5. CONSTRUCTION OF ISOLOOP MAGNETIC COUPLER

Figure 6: Isolator Data Travel Figure 5. In a GMR, isolator data travels via a magnetic field through a dielectric isolation to affect that resistance elements arranged in a bridge configuration.

Figure 7: Magnetic Coupler

Department of ECE, MRCE

10

Isoloop Magnetic Couplers

To put this phenomenon to work, a Wheatstone bridge configuration of four GMR sensors (see Figure 5 & 6). The manufacturing process allows thick film magnetic material to be deposited over the sensor elements to provide areas of magnetic shielding or flux concentration. Various op-amp or in-amp configurations can be used to supply signal conditioning from the bridges outputs. This forms the basis of an isolation receiver. The isolation transmitter is simply coil circuitry deposited on a layer between the GMR sensors layers and the thick film magnetic shielding layer (see Figure 5). Current through this coil layer produce the magnetic field, which overcomes the antiferromagnetic layers there by reducing the sensors resistance.

5.1 Sensor Arrays

GMR elements can be patterned to form simple resistors, half bridges, Wheatstone bridges, and even X-Y sensors. Single resistor elements are the smallest devices and require the fewest components, but they have poor temperature compensation and usually require the formation of some type of bridge by using external components. Alternatively they can be connected in series with one differential amplifier per sensor resistor. Half bridges take up more area on a chip but offer temperature compensation, as both resistors are at the same temperature. Half bridges can be used as field gradient sensors if one of the resistors is some distance from the other. They can function as field sensors if one of the resistors is shielded from the applied field. Figure 4 shows a portion of an array of 16 GMR half bridge elements with 5 m spacing. The elements are 1.5 m wide by 6 m high with a similar size element above the center tap. The bottoms of the stripes are connected to a common ground connection and the tops of the half bridges are connected to a current supply. The center taps are connected

Department of ECE, MRCE

11

Isoloop Magnetic Couplers

to 16 separate pads on the die. A bias strap passes over the lower elements to provide a magnetic field to bias the elements.

5.2 Signal Processing

Adding signal processing electronics to the basic sensor element increases the functionality of sensors. The large output signal of the GMR sensor element Introduction means less circuitry, smaller signal errors, less drift, and better temperature stability compared to sensors where more amplification is required to create a usable output. For the GMR products, we add a simple comparator and output transistor circuit to create the worlds most precise digital magnetic sensor. For these products, no amplification of the sensors output signal is necessary. A block diagram of this circuitry is shown in the figure 8.

Department of ECE, MRCE

12

Isoloop Magnetic Couplers

Figure 8: Signal Processing Circuit The GMR Switch holds its precise magnetic operate point over extreme variations in temperature and power supply voltage. This is a low cost method.

Department of ECE, MRCE

13

Isoloop Magnetic Couplers

6. WORKING OF A ISOLOOP MAGNETIC COUPLER

In the Isoloop magnetic couplers, a signal at the input induces a current in a planar coil (see figure no: 5).The current produces a magnetic field, which is proportional to the current in the planar coil. The resulting magnetic field produces a resistance change in the GMR material, which is separated from the planar coil by a high voltage insulating material. Since the GMR is sensitive parallel to the plane of the substrate, this allows a considerably more compact construction than would be possible with Hall sensors. The resistance change in GMR material, which was caused by the magnetic field, is amplified by an electronic circuit and impressed upon the output as a reproduction of the input signal. Since changes in the ground potential at the input, output or both doesnt produce a current in the planar coil, no magnetic field is created. The GMR material doesnt change. In this way safe galvanic signal isolation is achieved and at the same time a corresponding common mode voltage tolerance.

Department of ECE, MRCE

14

Isoloop Magnetic Couplers

7. ADVANTAGES OF MAGNETIC COUPLING

The advantages of magnetic coupling include high bandwidth, small footprint, excellent noise immunity, and temperature stability.

7.1 Bandwidth

IsoLoop couplers are 510 times faster than the fastest optocouplers, and have correspondingly faster rise, fall, and propagation times (see Figure 9). Shorter rise and fall times also reduce power consumption in the device and system by minimizing time in active regions.

Figure 9: Magnetic Couplers Traces

7.2 Small Footprint

IsoLoop couplers can be fabricated in <1 mm2 of die area per channel (see Figure 10). Less board real estate means both more room for other functions

Department of ECE, MRCE

15

Isoloop Magnetic Couplers

and lower prices. Furthermore, because of their small die size, IsoLoop couplers cost no more than high-performance optocouplers.

Figure 10: Four-Channel Magnetic Coupler Die

7.3 Noise Immunity

Magnetic couplers provide transient immunity up to 25 kV/s, compared to 10 kV/s for optocouplers. Transient immunity is especially important in harsh industrial and process control environments.

7.4 Temperature Stability

Because the transmission and sensing elements are not subject to semiconductor temperature variations, magnetic couplers operate to 100C and above; for most optocouplers the upper limit is 75C. Magnetic couplers are also immune to optocouplers inherent performance decay with age.

Department of ECE, MRCE

16

Isoloop Magnetic Couplers

8. DIGITAL ISOLATORS

These devices offer true isolated logic integration in a level not previously available. All transmit and receive channels operate at 110 Mbd over the full temperature and supply voltage range. The symmetric magnetic coupling barrier provides a typical propagation delay of only 10 ns and a pulse width distortion of 2 ns achieving the best specifications of any isolator device. Typical transient immunity of 30 kV/s is unsurpassed.

8.1 Dynamic Power Consumption

Isoloop devices achieve their low power consumption from the manner by which they transmit data across the isolation barrier. By detecting the edge transitions of the input logic signal and converting these to narrow current pulses, a magnetic field is created around the GMR Wheatstone bridge. Depending on the direction of the magnetic field, the bridge causes the output comparator to switch following the input logic signal. Power consumption is independent of mark-to-space ratio and solely dependent on frequency. This has obvious advantages over optocouplers whose power consumption is heavily dependent on its on-state and frequency. The maximum power supply current per channel for IsoLoop is:

Department of ECE, MRCE

17

Isoloop Magnetic Couplers

8.2 Data Transmission Rates

The reliability of a transmission system is directly related to the accuracy and quality of the transmitted digital information. For a digital system, those parameters, which determine the limits of the data transmission, are pulse width distortion and propagation, delay skew. Propagation delay is the time taken for the signal to travel through the device. This is usually different when sending a low-to-high than when sending a high-to-low signal. This difference, or error, is called pulse width distortion (PWD) and is usually in ns. It may also be expressed as a percentage: PWD% = (Maximum Pulse Width Distortion (ns) /Signal Pulse Width (ns)) x 100% Propagation delay skew is the difference in time taken for two or more channels to propagate their signals. This becomes significant when clocking is involved since it is undesirable for the clock pulse to arrive before the data has settled. A short propagation delay skew is therefore critical, especially in high data rate parallel systems, to establish and maintain accuracy and repeatability. The IsoLoop range of isolators all has a maximum propagation delay skew of 6 ns, which is five times better than any optocoupler. The maximum channel to channel skew in the IsoLoop coupler is only 3 ns, which is ten times better than any optocoupler.

Department of ECE, MRCE

18

Isoloop Magnetic Couplers

9. COMPARISON BETWEEN OPTOCOUPLER AND ISOLOOP MAGNETIC COUPLER

Unlike typical microsecond TON/TOFF times of optoisolators, The IsoLoop-isolators also have identical TON/TOFF times, which produce no pulsewidth distortion as is the case with many optoisolators having differing TON/TOFF times. Propagation delays are less than 10 ns with inter-channel skewing of less than 2 ns. Isoloop-isolators have up to four channels per package in a variety of device direction configurations. These standard devices are great for bus isolation, serial ADCs and DACs, and communication isolation. The working range of optocouplers is only between zero and ten megahertz. The IsoLoop couplers have data transmission speeds up to100 mega baud. IsoLoop devices will operate over a wide temperature range of -40 to +100C, compared with the restricted range of 0 to +70C for optoisolators. The power consumption of IsoLoop devices is solely dependent on frequency. This makes for lower power consumption than optoisolators, whose power consumption is heavily dependent on state and frequency. With data rates up to 100Mbaud, the IsoLoop technology offers rates of up to ten times that of optoisolators.

Department of ECE, MRCE

19

Isoloop Magnetic Couplers

10. CURRENT APPLICATIONS

Magnetic isolators are quickly finding their way into process control and industrial applications. Isolation of A/D interfaces is one popular use. In addition, magnetic isolators combination of speed and packaging density provides a good method of efficient data channel management when multiple A/Ds need to be interfaced on the same circuit card. A four-channel part with three channels going one way and one going the other is available for A/D interface applications. Magnetic couplers also enable higher speed factory networks such as Profibus and other protocols. These devices are great for bus isolation, serial ADCs and DACs, and communication isolation. The combination of the fast and high-density IsoLoop couplers with high packing density allows efficient data channel management where several A/D channels must be isolated on a board.

10.1 Digital Isolation Applications

ADCs DACs Multiplexed Data Transmission Data Interfaces Digital Noise Reduction Ground Loop Elimination

Department of ECE, MRCE

20

Isoloop Magnetic Couplers

11. THE FUTURE

Magnetic field detection has vastly expanded as industry has used a variety of magnetic sensors to detect the presence, strength, or direction of magnetic fields from the Earth, permanent magnets, magnetized soft magnets, and the magnetic fields associated with current. These sensors are used as proximity sensors, speed and distance measuring devices, navigation compasses, and current sensors. They can measure these properties without actual contact to the medium being measured and have become the eyes of many control systems.

Department of ECE, MRCE

21

Isoloop Magnetic Couplers

12. CONCLUSION

Magnetic couplers will in time be even faster and have more channels. More types of integrated bus transceivers will be available. Several manufacturers are planning to introduce magnetic couplers. The U.S. military is providing significant funding for advanced magnetic coupler development because of the value of their high speed and noise immunity in aircraft and other systems. It has reported prototype devices with speeds of 300 Mbaud and switching times of <1 ns. Also under development are higher-density parts (full byte-wide couplers) and more functionality (latching bus transceivers). Finally, the inherent linearity of a resistive coil and resistive sensing elements make magnetic couplers well suited for linear data protocols such as low-voltage differential signaling.

Department of ECE, MRCE

22

Isoloop Magnetic Couplers

13. REFERENCES

1. 2. J.Daughton and Y. Chen. "GMR Materials for Low Field Applications," IEEE Trans Magn, Vol. 29:2705-2710, 2003.pp.18-21 Michael J. Caruso, Tamara Bratland, C. H. Smith, and Robert Schneider, A New Perspective on Magnetic Field Sensing, Sensors Magazine, vol. 15, no. 12, (December 2002), pp. 34-46. 3. Carl H. Smith and Robert W. Schneider, Low-Field Magnetic Sensing with GMR Sensors, Part 1: The Theory of Solid-State Sensing, Sensors Magazine, vol. 16, no. 9, (September 2002), pp. 76-83. 4. Carl H. Smith and Robert W. Schneider, Low-Field Magnetic Sensing with GMR Sensors, Part 2: GMR Sensors and their Applications, Sensors Magazine, vol. 16, no. 10, (October 2002), pp. 84- 91. 5. 6. 7. 8. http://www.circuitcellar.com/library/print/0502/JEFF/4.asp http://www.sensorsmag.com/ http://www.nve.com/isoloop/news/hispdnr.php http://www.electronicstalk.com/news/rho/rho000.html

Department of ECE, MRCE

23

Вам также может понравиться

- Sfra For Condition Monitoring of Power TransformerДокумент3 страницыSfra For Condition Monitoring of Power TransformerSarojakanti SahooОценок пока нет

- Theory of Microwave Valves: International Series of Monographs on Electronics and InstrumentationОт EverandTheory of Microwave Valves: International Series of Monographs on Electronics and InstrumentationОценок пока нет

- Characterization of Atmospheric Pressure Discharges: R.Barni, S.Zanini, R.Siliprandi, P.Esena, C.RiccardiДокумент8 страницCharacterization of Atmospheric Pressure Discharges: R.Barni, S.Zanini, R.Siliprandi, P.Esena, C.RiccardiRodrigo RamosОценок пока нет

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsОт EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsОценок пока нет

- Electromagnetic Induction: (A) Electricity From MagnetismДокумент6 страницElectromagnetic Induction: (A) Electricity From MagnetismGaurav ChopraОценок пока нет

- Men of Physics Lord Rayleigh–The Man and His Work: The Commonwealth and International Library: Selected Readings in PhysicsОт EverandMen of Physics Lord Rayleigh–The Man and His Work: The Commonwealth and International Library: Selected Readings in PhysicsОценок пока нет

- Investigations On A Standing Wave Thermoacoustic RefrigeratorДокумент8 страницInvestigations On A Standing Wave Thermoacoustic RefrigeratorAli AHОценок пока нет

- Introduction To Magnetic CircuitsДокумент23 страницыIntroduction To Magnetic Circuitssharad kumarОценок пока нет

- Applications of Electromagnetic InductionДокумент6 страницApplications of Electromagnetic InductionLivombo AveloОценок пока нет

- Models - Rf.conical AntennaДокумент16 страницModels - Rf.conical AntennaMatteo TorinoОценок пока нет

- Models - Aco.piezoacoustic TransducerДокумент16 страницModels - Aco.piezoacoustic TransducerLeuca Bogdan-CostinОценок пока нет

- Models - Acdc.capacitor Fringing FieldsДокумент16 страницModels - Acdc.capacitor Fringing FieldsAnonymous pWNBPuMcf100% (1)

- Electromagnetism Part 4 StudentsДокумент16 страницElectromagnetism Part 4 StudentsSharvinder SinghОценок пока нет

- Computing CapacitanceДокумент16 страницComputing Capacitancepraveeng11100% (1)

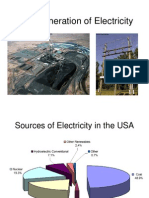

- The Generation of ElectricityДокумент42 страницыThe Generation of ElectricityNorazlin UjangОценок пока нет

- Chapter 3: Electrolytic Conductance 3.1. Specific Conductance Specific Conductance Is A Measure of The Electric Current in The Water SampledДокумент11 страницChapter 3: Electrolytic Conductance 3.1. Specific Conductance Specific Conductance Is A Measure of The Electric Current in The Water SampledBùi Hữu ĐứcОценок пока нет

- WTS 12 ElectrodynamicsДокумент28 страницWTS 12 ElectrodynamicsTondani100% (1)

- Acoustic Microbubble Dynamics With Viscous Effects 2016Документ10 страницAcoustic Microbubble Dynamics With Viscous Effects 2016Kawa Mustafa AzizОценок пока нет

- Catalogue - Probe Sonicator - Ultra Autosonic IndiaДокумент4 страницыCatalogue - Probe Sonicator - Ultra Autosonic IndiaGirish GuptaОценок пока нет

- Ultrasonics For First Year .B.Tech. StudentsДокумент9 страницUltrasonics For First Year .B.Tech. StudentsSuryasrikar Peruri100% (1)

- Resonance UnlockedДокумент5 страницResonance UnlockedgjjgОценок пока нет

- Models - Aco.piezoacoustic TransducerДокумент14 страницModels - Aco.piezoacoustic Transducerkiran kumar kОценок пока нет

- Ultrasonic Assisted Underwater Laser Micromachining of SiliconДокумент29 страницUltrasonic Assisted Underwater Laser Micromachining of SiliconBLACK SABBATHОценок пока нет

- (Done 5) Mechanical and Chemical Effects On The Frequency of UltrasonicДокумент5 страниц(Done 5) Mechanical and Chemical Effects On The Frequency of Ultrasonicاشکان صفربالیОценок пока нет

- Underwater Laser Micromachining of Silicon in Pressurized EnvironmentДокумент9 страницUnderwater Laser Micromachining of Silicon in Pressurized Environmentসুহাস মন্ডলОценок пока нет

- Ultrasonic Waves: 1. Production of UltrasonicsДокумент7 страницUltrasonic Waves: 1. Production of UltrasonicsAmit KumarОценок пока нет

- Application of Ultrasonic Technology For Water andДокумент17 страницApplication of Ultrasonic Technology For Water andMartin DarmasetiawanОценок пока нет

- Transmission LineДокумент11 страницTransmission LineDeni RistiantoОценок пока нет

- Basic Electrical EngineeringДокумент22 страницыBasic Electrical EngineeringLipi SinghОценок пока нет

- Models - Acdc.capacitor TunableДокумент12 страницModels - Acdc.capacitor TunableAnnuar BrnalОценок пока нет

- Ef Cacy of Sonically, Ultrasonically Andlaser-Activated Irrigation in Removing Abio Lm-Mimicking Hydrogel From An Isthmus ModelДокумент9 страницEf Cacy of Sonically, Ultrasonically Andlaser-Activated Irrigation in Removing Abio Lm-Mimicking Hydrogel From An Isthmus ModelBenjiОценок пока нет

- An Update On Ultrasonic Irrigant ActivationДокумент15 страницAn Update On Ultrasonic Irrigant ActivationkarishmaОценок пока нет

- Ultrasonic InterferometerДокумент5 страницUltrasonic InterferometerRadot ChandraОценок пока нет

- Atomic Structure - Discovery of Subatomic ParticlesДокумент6 страницAtomic Structure - Discovery of Subatomic ParticlesDivyansh DangiОценок пока нет

- Direct Vs Alternating Current: BelowДокумент5 страницDirect Vs Alternating Current: Belowtgs100Оценок пока нет

- IsyTech 31-10 - 31-11 - IngleseДокумент12 страницIsyTech 31-10 - 31-11 - InglesedmakaricОценок пока нет

- Introduction To Electrochemistry: The Scope of ElectrochemistryДокумент10 страницIntroduction To Electrochemistry: The Scope of ElectrochemistrymariaОценок пока нет

- Energy Efficient TRansformersДокумент19 страницEnergy Efficient TRansformersMahidhar TalapaneniОценок пока нет

- Electron ModelsДокумент13 страницElectron ModelsNooruddin SheikОценок пока нет

- Computational Aeroacoustics An Overview PDFДокумент14 страницComputational Aeroacoustics An Overview PDFVenu MadhavОценок пока нет

- Theory of SuperconductivityДокумент135 страницTheory of SuperconductivityRenjith Raveendran PillaiОценок пока нет

- VASCHE AD ULTRASUONI GB LowДокумент16 страницVASCHE AD ULTRASUONI GB Lowkaka punОценок пока нет

- (Elearnica - Ir) - An Energy Transmission System For An Artificial Heart Using Leakage InductaДокумент10 страниц(Elearnica - Ir) - An Energy Transmission System For An Artificial Heart Using Leakage Inductashizghul89b100% (1)

- Ultra Sonic Bath Instruction Manual (Labcon UBM22) PDFДокумент13 страницUltra Sonic Bath Instruction Manual (Labcon UBM22) PDFilroux100% (2)

- Computer-Controlled Sophisticated Ultrasonic Cleaner: H. Muthurajan, H.H. Kumar, and D.K. KharatДокумент4 страницыComputer-Controlled Sophisticated Ultrasonic Cleaner: H. Muthurajan, H.H. Kumar, and D.K. KharatNKJemesОценок пока нет

- Cavitation NotesДокумент4 страницыCavitation NotesFIRDAUS BIN MAHAMADОценок пока нет

- Diffraction by Ultrasonic Waves in LiquidДокумент5 страницDiffraction by Ultrasonic Waves in LiquidParmanandaОценок пока нет

- The Use of Ultrasonic Cleaning in Dairy Industry: How Does It Work?Документ3 страницыThe Use of Ultrasonic Cleaning in Dairy Industry: How Does It Work?Vetz clubОценок пока нет

- 20.1 Understanding MagnetismДокумент30 страниц20.1 Understanding MagnetismHasan AlzaghalОценок пока нет

- The Influence of The Ultrasonic Intensity On The CleaningДокумент5 страницThe Influence of The Ultrasonic Intensity On The Cleaningernesto fidel aramendiz galindoОценок пока нет

- Transformer: Rapid ElectronicsДокумент5 страницTransformer: Rapid ElectronicsMayaa KhanОценок пока нет

- Liquid Processing CatalogДокумент31 страницаLiquid Processing CatalogLina Maria RodriguezОценок пока нет

- Pressure Control Valve VRCDДокумент4 страницыPressure Control Valve VRCDFlavius Oros100% (1)

- CPX H Ultrasonic Baths DataДокумент2 страницыCPX H Ultrasonic Baths DataRodrigo Morales VeraОценок пока нет

- 8 Ultrasonics: Mechanical MethodДокумент6 страниц8 Ultrasonics: Mechanical MethodShank ManОценок пока нет

- Application of Hydrodynamic Cavitation ReactorsДокумент24 страницыApplication of Hydrodynamic Cavitation ReactorsJeffery TaylorОценок пока нет

- Sonication From Wikipedia, The Free Encyclopedia: UltrasonicДокумент4 страницыSonication From Wikipedia, The Free Encyclopedia: UltrasonicJimmyОценок пока нет

- Physics ProjectДокумент10 страницPhysics ProjectMandeep TanwarОценок пока нет

- Applications of Ultrasound in Organic SynthesisДокумент2 страницыApplications of Ultrasound in Organic SynthesisLav VarmaОценок пока нет

- Framework For Marketing Management Global 6Th Edition Kotler Solutions Manual Full Chapter PDFДокумент33 страницыFramework For Marketing Management Global 6Th Edition Kotler Solutions Manual Full Chapter PDFWilliamThomasbpsg100% (9)

- The John Molson School of Business MBA 607 Final Exam June 2013 (100 MARKS)Документ10 страницThe John Molson School of Business MBA 607 Final Exam June 2013 (100 MARKS)aicellОценок пока нет

- Update UI Components With NavigationUIДокумент21 страницаUpdate UI Components With NavigationUISanjay PatelОценок пока нет

- Shrek FSCДокумент5 страницShrek FSCMafer CastroОценок пока нет

- Saxonville CaseДокумент2 страницыSaxonville Casel103m393Оценок пока нет

- Kodak Case StudyДокумент8 страницKodak Case StudyRavi MishraОценок пока нет

- Sayyid Jamal Al-Din Muhammad B. Safdar Al-Afghani (1838-1897)Документ8 страницSayyid Jamal Al-Din Muhammad B. Safdar Al-Afghani (1838-1897)Itslee NxОценок пока нет

- The Music of OhanaДокумент31 страницаThe Music of OhanaSquaw100% (3)

- Test Statistics Fact SheetДокумент4 страницыTest Statistics Fact SheetIra CervoОценок пока нет

- Thermal Physics Questions IB Question BankДокумент43 страницыThermal Physics Questions IB Question BankIBBhuvi Jain100% (1)

- Birds (Aves) Are A Group Of: WingsДокумент1 страницаBirds (Aves) Are A Group Of: WingsGabriel Angelo AbrauОценок пока нет

- Binary SearchДокумент13 страницBinary SearchASasSОценок пока нет

- Mathematics Trial SPM 2015 P2 Bahagian BДокумент2 страницыMathematics Trial SPM 2015 P2 Bahagian BPauling ChiaОценок пока нет

- Papadakos PHD 2013Документ203 страницыPapadakos PHD 2013Panagiotis PapadakosОценок пока нет

- Sample Questions 2019Документ21 страницаSample Questions 2019kimwell samson100% (1)

- 5HP500-590 4139 - 751 - 627dДокумент273 страницы5HP500-590 4139 - 751 - 627ddejanflojd100% (24)

- Layos vs. VillanuevaДокумент2 страницыLayos vs. VillanuevaLaura MangantulaoОценок пока нет

- General Health Questionnaire-28 GHQ-28Документ3 страницыGeneral Health Questionnaire-28 GHQ-28srajanОценок пока нет

- Pediatric Autonomic DisorderДокумент15 страницPediatric Autonomic DisorderaimanОценок пока нет

- Ivler vs. Republic, G.R. No. 172716Документ23 страницыIvler vs. Republic, G.R. No. 172716Joey SalomonОценок пока нет

- 201606300437271127888362list of Prescribed Textbooks ISC 2017 PDFДокумент10 страниц201606300437271127888362list of Prescribed Textbooks ISC 2017 PDFShrimanta SatpatiОценок пока нет

- Strategic Risk ManagementДокумент46 страницStrategic Risk ManagementNuman Rox100% (1)

- Master Books ListДокумент32 страницыMaster Books ListfhaskellОценок пока нет

- Action List 50Документ4 страницыAction List 50hdfcblgoaОценок пока нет

- Capgras SyndromeДокумент4 страницыCapgras Syndromeapi-459379591Оценок пока нет

- Jurnal Politik Dan Cinta Tanah Air Dalam Perspektif IslamДокумент9 страницJurnal Politik Dan Cinta Tanah Air Dalam Perspektif Islamalpiantoutina12Оценок пока нет

- Domestic and Foreign Policy Essay: Immigration: Salt Lake Community CollegeДокумент6 страницDomestic and Foreign Policy Essay: Immigration: Salt Lake Community Collegeapi-533010636Оценок пока нет

- Reported SpeechДокумент2 страницыReported SpeechmayerlyОценок пока нет

- Chapter 3 - the-WPS OfficeДокумент15 страницChapter 3 - the-WPS Officekyoshiro RyotaОценок пока нет

- Giza: The Tesla Connection: Acoustical Science and the Harvesting of Clean EnergyОт EverandGiza: The Tesla Connection: Acoustical Science and the Harvesting of Clean EnergyОценок пока нет

- A Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceОт EverandA Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceРейтинг: 4 из 5 звезд4/5 (51)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseОт EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseРейтинг: 3.5 из 5 звезд3.5/5 (69)

- Knocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldОт EverandKnocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldРейтинг: 3.5 из 5 звезд3.5/5 (64)

- Summary and Interpretation of Reality TransurfingОт EverandSummary and Interpretation of Reality TransurfingРейтинг: 5 из 5 звезд5/5 (5)

- The End of Everything: (Astrophysically Speaking)От EverandThe End of Everything: (Astrophysically Speaking)Рейтинг: 4.5 из 5 звезд4.5/5 (157)

- Midnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterОт EverandMidnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterРейтинг: 4.5 из 5 звезд4.5/5 (410)

- A Brief History of Time: From the Big Bang to Black HolesОт EverandA Brief History of Time: From the Big Bang to Black HolesРейтинг: 4 из 5 звезд4/5 (2193)

- The Holographic Universe: The Revolutionary Theory of RealityОт EverandThe Holographic Universe: The Revolutionary Theory of RealityРейтинг: 4.5 из 5 звезд4.5/5 (77)

- The Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОт EverandThe Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОценок пока нет

- Lost in Math: How Beauty Leads Physics AstrayОт EverandLost in Math: How Beauty Leads Physics AstrayРейтинг: 4.5 из 5 звезд4.5/5 (125)

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessОт EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessРейтинг: 4 из 5 звезд4/5 (6)

- Bedeviled: A Shadow History of Demons in ScienceОт EverandBedeviled: A Shadow History of Demons in ScienceРейтинг: 5 из 5 звезд5/5 (5)

- The Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldОт EverandThe Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldРейтинг: 4.5 из 5 звезд4.5/5 (54)

- The Beginning of Infinity: Explanations That Transform the WorldОт EverandThe Beginning of Infinity: Explanations That Transform the WorldРейтинг: 5 из 5 звезд5/5 (60)

- Quantum Physics: What Everyone Needs to KnowОт EverandQuantum Physics: What Everyone Needs to KnowРейтинг: 4.5 из 5 звезд4.5/5 (49)

- Quantum Physcis for Beginners: An Easy Guide for Discovering the Hidden Side of Reality One Speck at a TimeОт EverandQuantum Physcis for Beginners: An Easy Guide for Discovering the Hidden Side of Reality One Speck at a TimeОценок пока нет

- Vibration and Frequency: How to Get What You Want in LifeОт EverandVibration and Frequency: How to Get What You Want in LifeРейтинг: 4.5 из 5 звезд4.5/5 (13)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Packing for Mars: The Curious Science of Life in the VoidОт EverandPacking for Mars: The Curious Science of Life in the VoidРейтинг: 4 из 5 звезд4/5 (1396)

- The Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectОт EverandThe Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectРейтинг: 4.5 из 5 звезд4.5/5 (20)

- Transform Your Life And Save The World: Through The Dreamed Of Arrival Of The Rehabilitating Biological Explanation Of The Human ConditionОт EverandTransform Your Life And Save The World: Through The Dreamed Of Arrival Of The Rehabilitating Biological Explanation Of The Human ConditionРейтинг: 5 из 5 звезд5/5 (2)

- Let There Be Light: Physics, Philosophy & the Dimensional Structure of ConsciousnessОт EverandLet There Be Light: Physics, Philosophy & the Dimensional Structure of ConsciousnessРейтинг: 4.5 из 5 звезд4.5/5 (57)