Академический Документы

Профессиональный Документы

Культура Документы

JSA

Загружено:

Danang WibisanaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JSA

Загружено:

Danang WibisanaАвторское право:

Доступные форматы

JOB SAFETY ANALISIS

JSA No.: Sheet: Date: Project No:

4) 8) 12)

1 of 3 26 Sep 12

Area of Work :

JSA Participants:

Lamongan Shore Base

1) 5) 9) 2) 6) 10)

Project:

CUTTING 20 CASING RL4S

3) 7) 11)

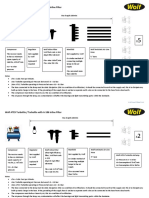

Job location and details: Lamongan Shore Base Prepared by: DNW Reviewed by: PPE Required For This Job : Standard PPE Job Step 1. Planning Hazards Identified Personnel Safety Untrained personnel Asset Damage Untrained personnel Controls & Checks Required Ensure personnel undergo appropriate HSE Training and PTW training prior to mobilisation. Utilise qualified personnel for all tasks. Supervisor to attend daily PTW / tool box meetings. Raise PTW. Good housekeeping and clear path to work site Install restricted area/access signs. Project Team Action By Project Team. Approved by: Distribution:

2. Pull oxy acetylene hose to work site

Personnel Safety - Tripping hazards Personnel Safety - Unauthorised Access to Site

JSA CUTTING

JOB SAFETY ANALISIS

3. General Cutting Personnel Safety - Blowback when first burning through could cause burns or eye injuries Personnel Safety - Hot slag could burn through oxy acetylene hose and start a fire Asset Protection - Damage to existing equipment by sparks and slag Asset Protection/Personnel Safety - Combustible gas leak/toxic gas leak from process facilities Personnel Safety - Unauthorised Access to Site Personnel Safety - Egress from scaffold platform Personnel Safety Simultaneous Activities (e.g. lifting) Same as 1 above Correct PPE to be used Keep personnel sufficiently clear of cutting area Keep hose clear of area where slag will fall Fire blanket/tarpaulins to be placed over existing equipment if there is a possibility of slag falling on it. Ensure combustible gas detectors are placed upwind and around hot work area. Ensure dedicated fire/safety watch is in place Establish portable fire extinguishers and fire hoses are located around work site. Plan lifts so that personnel are not directly under loads. Conduct daily PTW/toolbox meeting to address daily work requirements. Same as 1 above

JSA No.: Sheet: Date:

2 of 3 26 Sep 12

Project Team

4. Pull oxy acetylene hose clear of work site

Project Team

JSA CUTTING

Type of Permit Required

(please indicate by ticking box)

Additional PPE Requirements

(Please list)

Special tools or equipment required

1) 2) 3) 4) 5) 6) 7) 8)

Excavation Hot work Confined space Other.

1) 2) 3) 4)

JSA Review Process

Was the work crew involved in formulating the JSA? Did the work crew review the JSA prior to task? Was the JSA referred to during the task? Were the job steps followed? Can you suggest improvements to the JSA? (Provide details) Provide details on any incidents.

Comments

Reviewed by:

Signature:

Date:

---oo000oo---

Incident Summary

Report Number:

JSA CUTTING

Вам также может понравиться

- Mhs12-Boliers and Pressures VesselДокумент29 страницMhs12-Boliers and Pressures VesselWidya BungaОценок пока нет

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Документ5 страницPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Yosua SitumorangОценок пока нет

- 01 JSA CLEANING MgO Rev 05 017 BIДокумент7 страниц01 JSA CLEANING MgO Rev 05 017 BIMohd KhaidirОценок пока нет

- Guard House Monkey Ladder 01Документ5 страницGuard House Monkey Ladder 01razi khanОценок пока нет

- 2.03 JSA Change Rams 5 - 7Документ3 страницы2.03 JSA Change Rams 5 - 7aneshse100% (1)

- Workshop SafetyДокумент26 страницWorkshop Safetykoko prayogiОценок пока нет

- Habitat PDFДокумент8 страницHabitat PDFtungluongОценок пока нет

- HSE MS Training Feb 2019Документ17 страницHSE MS Training Feb 2019Musalim Shaikh100% (1)

- Kuisioner Kualifikasi CHESMДокумент49 страницKuisioner Kualifikasi CHESMaz03r4Оценок пока нет

- RSP - ALL - WI0573 - CC Permit To Work Management - Appendix 01Документ1 страницаRSP - ALL - WI0573 - CC Permit To Work Management - Appendix 01sani priadi100% (1)

- Checklist SkkpiДокумент27 страницChecklist SkkpiarisОценок пока нет

- Orval Hydraulic - Catalogue PDFДокумент18 страницOrval Hydraulic - Catalogue PDFtatiana hernandezОценок пока нет

- ListДокумент155 страницListarisОценок пока нет

- QP Cutting JSAДокумент6 страницQP Cutting JSAMohammed MujahidОценок пока нет

- Job Safety Analysis (Jsa) FormДокумент1 страницаJob Safety Analysis (Jsa) FormsigitОценок пока нет

- HSSE Pack - Site Training PackДокумент36 страницHSSE Pack - Site Training Packfarhan Ali100% (1)

- Wellhead Safety GE Oil Gas Pressure ControlДокумент20 страницWellhead Safety GE Oil Gas Pressure ControlCarlos A.Оценок пока нет

- Introduction DSTДокумент15 страницIntroduction DSTAnonymous CZsCLLrОценок пока нет

- WHS PPE Minimum Requirement Matrix v2Документ1 страницаWHS PPE Minimum Requirement Matrix v2DOUHAОценок пока нет

- JSA - T8420 Tank Cleaning - docFSPДокумент3 страницыJSA - T8420 Tank Cleaning - docFSPavinash100% (2)

- 459-De-SPADING of Fire Water Line For Deluge Skid and Sprinkler System SAT TestДокумент4 страницы459-De-SPADING of Fire Water Line For Deluge Skid and Sprinkler System SAT TestNasrullah JanОценок пока нет

- Allbright Industries (M) SDN BHD: Doc No.: RevДокумент10 страницAllbright Industries (M) SDN BHD: Doc No.: RevMaint100% (1)

- Cold Cutting Guideline ChecklistДокумент2 страницыCold Cutting Guideline Checklisttahatekri100% (1)

- Safety Induction: Presented By: Rizky RamadhanДокумент10 страницSafety Induction: Presented By: Rizky RamadhanMuhammad Rizky RamadhanОценок пока нет

- Health & Safety Hazard Identification/ Risk Assessment/ Operational PlanДокумент20 страницHealth & Safety Hazard Identification/ Risk Assessment/ Operational PlanRebekah SchmidtОценок пока нет

- Running Air Compressor MachineДокумент2 страницыRunning Air Compressor MachineAbdul Hakam Mohamed Yusof100% (2)

- NormДокумент16 страницNormAnnОценок пока нет

- Safety ValvesДокумент65 страницSafety Valvesserturkbudak_3448365Оценок пока нет

- Method of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryДокумент5 страницMethod of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryKarpana Devi LetchumananОценок пока нет

- Job Hazard Analysis: Generic Jha For Blasting & Painting WorksДокумент7 страницJob Hazard Analysis: Generic Jha For Blasting & Painting WorksReynaldo PesqueraОценок пока нет

- Jsa Worksheet Appendix 1: A-2401 Cooling Tower Pond CleaningДокумент4 страницыJsa Worksheet Appendix 1: A-2401 Cooling Tower Pond CleaningAmmadRehmanОценок пока нет

- USUA Reports October. 2012Документ16 страницUSUA Reports October. 2012ikehdОценок пока нет

- Dibia Ifeanyichukwu Peter Updated CV (Resume)Документ7 страницDibia Ifeanyichukwu Peter Updated CV (Resume)wizzy basseyОценок пока нет

- Confined Space: An Overview of OSHA Standards and Confined Space HazardsДокумент35 страницConfined Space: An Overview of OSHA Standards and Confined Space HazardsIssac BennyОценок пока нет

- Positive Pressure: HabitatДокумент8 страницPositive Pressure: HabitatgopuОценок пока нет

- JSA Clean Up TankДокумент1 страницаJSA Clean Up TankMaudiAyundaAyundaОценок пока нет

- De-oiling Pipelines CircularДокумент2 страницыDe-oiling Pipelines Circularnice guyОценок пока нет

- The Goa State Oil Spill Disaster Contingency PlanДокумент248 страницThe Goa State Oil Spill Disaster Contingency PlanVaishnavi JayakumarОценок пока нет

- GDN-202 - Inspection of Rig PDFДокумент27 страницGDN-202 - Inspection of Rig PDFRajesh100% (1)

- Piper Alpha Disaster SlidesДокумент26 страницPiper Alpha Disaster SlidesAzmi MohamedОценок пока нет

- Pipeline HydrotestДокумент1 страницаPipeline HydrotestNsidibe EssienОценок пока нет

- Confined SpaceДокумент16 страницConfined SpaceAbdul Moeed KalsonОценок пока нет

- Ocm1 Confined SpaceДокумент2 страницыOcm1 Confined SpacerapidsicuminteОценок пока нет

- Equipment Register - Pat Testing Original CertificateДокумент3 страницыEquipment Register - Pat Testing Original CertificateSayed AbbasОценок пока нет

- Job: Assembling of Internal Floating Roof.: Job Safety Analysis FormДокумент3 страницыJob: Assembling of Internal Floating Roof.: Job Safety Analysis FormDilshad ali100% (1)

- Why Is "Cold Cutting" Superior To Plasma Cutting?Документ9 страницWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedОценок пока нет

- Scaffold Inspection Report-Master ListДокумент2 страницыScaffold Inspection Report-Master ListMobin Thomas AbrahamОценок пока нет

- Compressed Gas Cylinders PowerPointДокумент20 страницCompressed Gas Cylinders PowerPointInspire KharianОценок пока нет

- Safety, Health & EnvironmentДокумент60 страницSafety, Health & EnvironmentGopalakrishnanОценок пока нет

- Control of Records Sample ProcedureДокумент7 страницControl of Records Sample ProcedureRafeeq rahmanОценок пока нет

- 07.03.09 Rig Move (Working at Height)Документ1 страница07.03.09 Rig Move (Working at Height)Hamdi RafiekОценок пока нет

- Risk AssesmentДокумент2 страницыRisk Assesmentsabu1995Оценок пока нет

- Hse SupervisorДокумент4 страницыHse Supervisorapi-79205155Оценок пока нет

- Safe Work Method For Hydro TestДокумент1 страницаSafe Work Method For Hydro TestEswar RaoОценок пока нет

- Safety Questions For ExaminationДокумент1 страницаSafety Questions For ExaminationAkeem Dwayne Ralph NoelОценок пока нет

- Sea Water Cooling Project Phase II Visual Inspection ReportДокумент1 страницаSea Water Cooling Project Phase II Visual Inspection ReportjahaanОценок пока нет

- Name: SignДокумент1 страницаName: SignAdel AlKhedawyОценок пока нет

- Professional Review Form For EB Staff 01 Sep 1530Документ9 страницProfessional Review Form For EB Staff 01 Sep 1530akhilОценок пока нет

- Method Statement For Excavation WorkДокумент8 страницMethod Statement For Excavation WorkWaleedMareyОценок пока нет

- Method Statement Plumbing TestДокумент4 страницыMethod Statement Plumbing TestSiraj100% (1)

- 14 inch magnetic flux leakage inspectionДокумент1 страница14 inch magnetic flux leakage inspectionDanang WibisanaОценок пока нет

- Mining Setup For TESTNETДокумент3 страницыMining Setup For TESTNETDanang WibisanaОценок пока нет

- Coated Foam PigsДокумент2 страницыCoated Foam PigsDanang WibisanaОценок пока нет

- Light, Medium & Heavy Density Bare Foam PigsДокумент3 страницыLight, Medium & Heavy Density Bare Foam PigsDanang WibisanaОценок пока нет

- Bitcoin 9000Документ13 страницBitcoin 9000Danang WibisanaОценок пока нет

- ExperimentДокумент11 страницExperimentDanang WibisanaОценок пока нет

- 10 Inch Multi Channel Caliper Inspection Vehicle: Tool Specification Operating ParameterДокумент1 страница10 Inch Multi Channel Caliper Inspection Vehicle: Tool Specification Operating ParameterDanang WibisanaОценок пока нет

- 12 Inch Multi Channel Caliper Inspection Vehicle: Tool Specification Operating ParameterДокумент1 страница12 Inch Multi Channel Caliper Inspection Vehicle: Tool Specification Operating ParameterDanang WibisanaОценок пока нет

- 10 Inch Magnetic Flux Leakage Inspection Vehicle: RS 10 SA 03Документ1 страница10 Inch Magnetic Flux Leakage Inspection Vehicle: RS 10 SA 03Danang WibisanaОценок пока нет

- Ghost: A Privacy Coin by John McafeeДокумент40 страницGhost: A Privacy Coin by John McafeeDanang WibisanaОценок пока нет

- Komodo's 2018: A Year of Innovation and GrowthДокумент13 страницKomodo's 2018: A Year of Innovation and GrowthLucas TobingОценок пока нет

- ManifoldДокумент2 страницыManifoldDanang WibisanaОценок пока нет

- 14 Inch Multi Channel Caliper Inspection Vehicle: Tool Specification Operating ParameterДокумент1 страница14 Inch Multi Channel Caliper Inspection Vehicle: Tool Specification Operating ParameterDanang WibisanaОценок пока нет

- XRC WhitepaperДокумент20 страницXRC WhitepaperDanang WibisanaОценок пока нет

- ExperimentДокумент11 страницExperimentDanang WibisanaОценок пока нет

- Mining Setup For TESTNETДокумент3 страницыMining Setup For TESTNETDanang WibisanaОценок пока нет

- Hose Handbook March 2003 PDFДокумент116 страницHose Handbook March 2003 PDFDanang WibisanaОценок пока нет

- Invoice 299af8be20647e45bb6d PDFДокумент1 страницаInvoice 299af8be20647e45bb6d PDFDanang WibisanaОценок пока нет

- 0003 PDFДокумент1 страница0003 PDFDanang WibisanaОценок пока нет

- Cam and GrooveДокумент1 страницаCam and GrooveDanang WibisanaОценок пока нет

- Smart Hose Metal PDFДокумент1 страницаSmart Hose Metal PDFDanang WibisanaОценок пока нет

- BP30SafeHandlingofTankContainers PDFДокумент80 страницBP30SafeHandlingofTankContainers PDFDanang WibisanaОценок пока нет

- Quick Coupling Products CAT 3800 Feb2014 PDFДокумент260 страницQuick Coupling Products CAT 3800 Feb2014 PDFDanang Wibisana0% (1)

- Plidco - Recomended Working PressureДокумент1 страницаPlidco - Recomended Working PressureDanang WibisanaОценок пока нет

- 3D Laser Scanning and Dimensional Control Surveys 3D Laser Scanning and Dimensional Control SurveysДокумент2 страницы3D Laser Scanning and Dimensional Control Surveys 3D Laser Scanning and Dimensional Control SurveysDanang WibisanaОценок пока нет

- Wolf Safety Lamp Company - Airlamps - Number of Connections With Filters - A-145 Issue 2Документ4 страницыWolf Safety Lamp Company - Airlamps - Number of Connections With Filters - A-145 Issue 2Danang WibisanaОценок пока нет

- Keel Cooled Commercial Marine Diesel GeneratorsДокумент2 страницыKeel Cooled Commercial Marine Diesel GeneratorsDanang WibisanaОценок пока нет

- Plidco - Recomended Working PressureДокумент1 страницаPlidco - Recomended Working PressureDanang WibisanaОценок пока нет

- Plidco CoverДокумент1 страницаPlidco CoverDanang WibisanaОценок пока нет

- 3D Laser Scanning and Dimensional Control Surveys 3D Laser Scanning and Dimensional Control SurveysДокумент2 страницы3D Laser Scanning and Dimensional Control Surveys 3D Laser Scanning and Dimensional Control SurveysDanang WibisanaОценок пока нет

- Portable Low-Frequency Acoustic Seismic System HMS-620Документ2 страницыPortable Low-Frequency Acoustic Seismic System HMS-620AntoОценок пока нет

- ApaveMare Training 2013Документ41 страницаApaveMare Training 2013fbarakaОценок пока нет

- 050, 051Документ28 страниц050, 051kefaja67% (3)

- Advanced Data Structures and ImplementationДокумент56 страницAdvanced Data Structures and ImplementationSyam Prasad Reddy BattulaОценок пока нет

- Manual 800 KvaДокумент87 страницManual 800 Kvavicvarg100% (3)

- Heat Exchanger Systems en PPL 2015-03-01Документ59 страницHeat Exchanger Systems en PPL 2015-03-01corneltincuОценок пока нет

- January2016page1to36 Layout 1Документ36 страницJanuary2016page1to36 Layout 1c737Оценок пока нет

- Design of A Fluidized Drum GranulatorДокумент6 страницDesign of A Fluidized Drum GranulatorditchcheОценок пока нет

- PML Rev-I Preferred Manufacturer List for PT Pertamina EPДокумент12 страницPML Rev-I Preferred Manufacturer List for PT Pertamina EPAndreas Schlager100% (1)

- Wacker Neuson-Dpu - 25 KNДокумент3 страницыWacker Neuson-Dpu - 25 KNMilutin BožovićОценок пока нет

- Zener DataДокумент2 страницыZener Dataapi-27149887Оценок пока нет

- ARRIMAX New Service Manual ENДокумент20 страницARRIMAX New Service Manual ENMohammed IsmailОценок пока нет

- LDX2101 Spec SheetДокумент2 страницыLDX2101 Spec SheetGaurav NarulaОценок пока нет

- 1999 System Wiring Diagrams. Chevrolet - SuburbanДокумент1 страница1999 System Wiring Diagrams. Chevrolet - SuburbanJimmy Perera BurgosОценок пока нет

- Analysis, Specification and Estimate On Road WorksДокумент71 страницаAnalysis, Specification and Estimate On Road WorksAnonymous BACdUNvPZ280% (5)

- Racecar Engineering - September 2015Документ100 страницRacecar Engineering - September 2015MrRipleiОценок пока нет

- Oil Analysis - Ruller and MPC TestДокумент81 страницаOil Analysis - Ruller and MPC Testmaidul.islamОценок пока нет

- NUSTian Final July SeptДокумент36 страницNUSTian Final July SeptAdeel KhanОценок пока нет

- Hino 500S Catalog LR PDFДокумент8 страницHino 500S Catalog LR PDFZulОценок пока нет

- Propeller DesignДокумент74 страницыPropeller DesignBambang Teguh Setiawan75% (4)

- Stressman Engineering - Brochure Norway 2018-6Документ8 страницStressman Engineering - Brochure Norway 2018-6FelipeОценок пока нет

- Lesson 7: Cylinders: Basic Hydraulic SystemsДокумент12 страницLesson 7: Cylinders: Basic Hydraulic Systemsoscar el carevergaОценок пока нет

- Strength of Pressure Vessels With Ellipsoidal HeadsДокумент8 страницStrength of Pressure Vessels With Ellipsoidal Headsنصرالدين ادريسОценок пока нет

- Product Design Recommended Reading ListДокумент3 страницыProduct Design Recommended Reading ListSai Prasath100% (1)

- Wrangling Logs With Logstash and ElasticSearch PresentationДокумент38 страницWrangling Logs With Logstash and ElasticSearch PresentationMohammad Syafiq Bin HussainОценок пока нет

- Parts List 09 636 02 02: AC Brake Motors BMG05-BMG1 Additional List: BrakeДокумент2 страницыParts List 09 636 02 02: AC Brake Motors BMG05-BMG1 Additional List: Brakeali morisyОценок пока нет

- JU P-Tool Engineering DataДокумент1 страницаJU P-Tool Engineering Dataazze bouzОценок пока нет

- Odv-065r18ejj-G DS 2-0-3Документ1 страницаOdv-065r18ejj-G DS 2-0-3Евгений Переверзев0% (1)

- Mixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Документ84 страницыMixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Masayu MYusoffОценок пока нет

- Pressure Vessel Rivets Welded Joints MDSP PrimeДокумент16 страницPressure Vessel Rivets Welded Joints MDSP PrimeIvanОценок пока нет