Академический Документы

Профессиональный Документы

Культура Документы

Hydra

Загружено:

MagesssОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hydra

Загружено:

MagesssАвторское право:

Доступные форматы

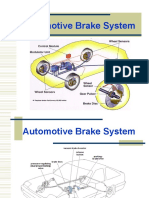

ydraulic and Pneumatic Braking System

Hydraulic and Pneumatic.pdf (Size: 83.87 KB / Downloads: 5) Introduction: Hydraulic Brakes This system uses a brake fluid (Preferably ethylene glycol) to transfer the pressure applied by the operator from the controlling unit to the actual brake mechanism, which is usually at or near the wheel of the vehicle. Most vehicles in India prefer to have drum brakes on rear wheels while disk brakes on the front wheels attached to the hydraulic controlling unit

Construction Brake pedal or lever A pushrod (also called an actuating rod) A master cylinder assembly containing a piston assembly (made up of either one or two pistons, a return spring, a series of gaskets/ O-rings and a fluid reservoir) Reinforced hydraulic lines Brake caliper assembly consisting of one or two hollow aluminum or chrome-plated steel pistons (called caliper pistons), a set of thermally conductive brake pads and a rotor (also called a brake disc) or drum attached to an axle The system is filled with a glycol-ether based brake fluid

Important Considerations Hydraulic systems are smaller and less expensive than the air brake systems Hydraulic fluid should be in-compressible. Also the hydraulic system should be air tight such that no vapor is introduced in the system Hydraulic fluid must resist vaporization at high temperatures The fluid that is used should be non-corrosive for the surrounding material Elimination of Brake Fade

Introduction

A Pneumatic Brake employs use of compressed air to execute retardation or stopping motion in the vehicles. Trains, buses and trailers use air-brake systems to overcome the deficit of the hydraulic fluid in car braking systems, which can run out in the event of a leak, leading to unsafe scenarios

Components of the system Air compressor: Pumps the air into storage tanks to be used in the brake system Air compressor governor: Controls the cut-in and cut-out point of the air compressor to maintain a set amount of air in the tank or tanks Air reservoir tanks: Hold compressed air to be used by the braking system Drain valves: Used to drain the air when the vehicle isn't in use Foot valve (brake pedal): When depressed, air is released from the reservoir tanks Brake chambers: Cylindrical container that houses a slack adjuster that moves a diaphragm or cam mechanism Push rod: A steel rod (piston) connecting the brake chamber to the slack adjuster. When depressed, the brakes are released. If extended, the brakes are applied. Slack adjusters: An arm connects the push rod to the brake s-cam to adjust the distance between the brake shoes Brake S-cam: An s-shaped cam that pushes brake shoes apart and against the brake drum Brake shoe: Steel mechanism that causes friction against the brake drum Return spring: A stiff spring connected to each of the brake shoes that returns the shoes to the open position when not spread by the s-cam or diaphragm.

Вам также может понравиться

- Terex 860 Workshop ManualДокумент20 страницTerex 860 Workshop Manualrichard100% (56)

- Arctic Cat 2008 Prowler XT XTX Service ManualДокумент174 страницыArctic Cat 2008 Prowler XT XTX Service ManualMyBriggs67% (3)

- Piaggio Fly 125-150 I.E. MY 2012 (EN)Документ252 страницыPiaggio Fly 125-150 I.E. MY 2012 (EN)Manualles67% (6)

- Automotive Brake System PDFДокумент61 страницаAutomotive Brake System PDFwanaw100% (2)

- Chapter 28-BennetДокумент63 страницыChapter 28-BennetsengottaiyanОценок пока нет

- Hydraulic Brake Power-Assist SystemsДокумент56 страницHydraulic Brake Power-Assist Systemsmewiw shortОценок пока нет

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionОт EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionРейтинг: 4 из 5 звезд4/5 (1)

- Workshop Manual Ibiza SC TrophyДокумент29 страницWorkshop Manual Ibiza SC Trophysalekojic53320% (1)

- 18263446-Jaguar XJR 1997-2003 Workshop Service Repair Manual PDFДокумент2 490 страниц18263446-Jaguar XJR 1997-2003 Workshop Service Repair Manual PDFAdan Flores CorreaОценок пока нет

- XKWorkshopManual PDFДокумент3 165 страницXKWorkshopManual PDFKereem MitchellОценок пока нет

- Hydraulic Pneumatic BrakesДокумент14 страницHydraulic Pneumatic Brakesabyzen100% (1)

- Air Brakes Slides 2 - 095652Документ97 страницAir Brakes Slides 2 - 095652honore UWIHANGANYEОценок пока нет

- Breaking SystemДокумент30 страницBreaking SystemLokeshОценок пока нет

- EyoelДокумент21 страницаEyoelefrem atsbahaОценок пока нет

- HaylshДокумент7 страницHaylshefrem atsbahaОценок пока нет

- Hydraulic Braking System: Prepared by Roshan Kumar Bisoyi Branch-Mechanical 4 SemДокумент10 страницHydraulic Braking System: Prepared by Roshan Kumar Bisoyi Branch-Mechanical 4 SemRoshan kumar BisoyiОценок пока нет

- Unit 6: Braking Systems and ClutchesДокумент34 страницыUnit 6: Braking Systems and ClutchesMarthandeОценок пока нет

- Brakes and Logistics Meeting ReportДокумент8 страницBrakes and Logistics Meeting ReportDhanush PrabhakarОценок пока нет

- Intro To Brakes PresentationДокумент77 страницIntro To Brakes PresentationMadhav RajpurohitОценок пока нет

- Air Brake HandbookДокумент59 страницAir Brake HandbookBinny Sharma100% (1)

- MELT Air Brakes Single UnitДокумент78 страницMELT Air Brakes Single UnitChristopher LiretteОценок пока нет

- Lecture 17 Notes The Braking SytemДокумент22 страницыLecture 17 Notes The Braking SytemMatthew JumaОценок пока нет

- IHP Micro ProjectДокумент13 страницIHP Micro ProjectROHANОценок пока нет

- Truck Brake Systems PDFДокумент63 страницыTruck Brake Systems PDFLazarusОценок пока нет

- Lecture - 7 - Aircraft Break SystemДокумент19 страницLecture - 7 - Aircraft Break Systemhvinith60Оценок пока нет

- Hydraulic Brake: This Article Is Missing - Please Help AddДокумент5 страницHydraulic Brake: This Article Is Missing - Please Help AddthatsopurvaОценок пока нет

- Air Brake System Operation and TroubleshootingДокумент65 страницAir Brake System Operation and Troubleshootingعبدالغني القباطي100% (2)

- AE Unit 2 Steering and Suspension SystemДокумент42 страницыAE Unit 2 Steering and Suspension Systemsemmat1802Оценок пока нет

- AutomotiveДокумент259 страницAutomotiveNavasca RandeeОценок пока нет

- BrakesДокумент27 страницBrakesNiño Jhim AndrewОценок пока нет

- 2-Auto SystemsДокумент32 страницы2-Auto Systemsallan747Оценок пока нет

- Palli Goutham Reddy 17BME0720: Hydraulic BrakesДокумент2 страницыPalli Goutham Reddy 17BME0720: Hydraulic BrakesGoutham ReddyОценок пока нет

- Unit 4 Suspension SystemsДокумент28 страницUnit 4 Suspension SystemsMarthandeОценок пока нет

- Chapter 29Документ40 страницChapter 29SudhakarLingarajuОценок пока нет

- M.P.Khond: Brakes Lecture11,12,13Документ55 страницM.P.Khond: Brakes Lecture11,12,13Pranav MakarandОценок пока нет

- D-WATCH 322 - Prelim Week 1Документ139 страницD-WATCH 322 - Prelim Week 1Jeth Ro UmbaoОценок пока нет

- Experiment No.:2: ObjectiveДокумент6 страницExperiment No.:2: ObjectiveFawad MushtaqОценок пока нет

- UNIT-1 Hydraulic and Pneumatic DrivesДокумент56 страницUNIT-1 Hydraulic and Pneumatic DrivesChetuОценок пока нет

- Suspension Systems Frames: Two TypesДокумент88 страницSuspension Systems Frames: Two TypesRaja Sekaran SajjaОценок пока нет

- Braking Systems in Railway Vehicles: Types of Air Brake SystemДокумент5 страницBraking Systems in Railway Vehicles: Types of Air Brake SystemSurya Teja KondetyОценок пока нет

- Hydraulic Brake School SubmissionДокумент24 страницыHydraulic Brake School SubmissionAjay KumarОценок пока нет

- Palli Goutham Reddy 17BME0720: Hydraulic BrakesДокумент3 страницыPalli Goutham Reddy 17BME0720: Hydraulic BrakesGoutham ReddyОценок пока нет

- Hydro-Pneumatics Suspension System: Submitted By: Melanie P. Mandipol Submitted To: Prof. Antonio M. MercaДокумент4 страницыHydro-Pneumatics Suspension System: Submitted By: Melanie P. Mandipol Submitted To: Prof. Antonio M. MercaAdhelM.TantaoОценок пока нет

- Automobile Engineering: Prepared by Dr.T.Yuvaraj Asp / MechДокумент173 страницыAutomobile Engineering: Prepared by Dr.T.Yuvaraj Asp / MechGetachew TikueОценок пока нет

- Ae 1 90Документ90 страницAe 1 90Er Dinesh ChauhanОценок пока нет

- Hydro Pneumatic Braking SytemДокумент11 страницHydro Pneumatic Braking Sytempramo_dass100% (1)

- Aircraft Pneumatic SystemsДокумент46 страницAircraft Pneumatic SystemsSasiKumar100% (1)

- Braking SystemДокумент39 страницBraking SystemNikhil SharmaОценок пока нет

- Unit-I Vehicle Structure and EnginesДокумент31 страницаUnit-I Vehicle Structure and EnginesSirajAyeshaОценок пока нет

- ActuatorДокумент42 страницыActuatorNyandaMadili MalashiОценок пока нет

- Topic 3 and 4 ElectiveДокумент17 страницTopic 3 and 4 ElectiveMeme ReviewОценок пока нет

- Accessory Gear Box: Accessory Drive Is A Gearbox That Forms Part of A GasДокумент22 страницыAccessory Gear Box: Accessory Drive Is A Gearbox That Forms Part of A GasFaisal AwaisОценок пока нет

- Steering System and TyresДокумент32 страницыSteering System and TyresFraolОценок пока нет

- MeluДокумент9 страницMeluefrem atsbahaОценок пока нет

- D WATCH 322 Prelim Week 1Документ80 страницD WATCH 322 Prelim Week 1Berly FreemanОценок пока нет

- Chp2 BДокумент43 страницыChp2 BahmedОценок пока нет

- Pneumatic Three Axis Modern TrailerДокумент14 страницPneumatic Three Axis Modern Trailern_amarsinh9938Оценок пока нет

- Brake SystemДокумент40 страницBrake SystemNico BrotonsОценок пока нет

- BVA2124 Steering Systems (Lecture 1)Документ31 страницаBVA2124 Steering Systems (Lecture 1)AdnannnОценок пока нет

- Projet de Systeme de Freinage Hydrolique AnglaisДокумент9 страницProjet de Systeme de Freinage Hydrolique AnglaisAdje EKLOUОценок пока нет

- Automotive Drivetrains: ClutchesДокумент44 страницыAutomotive Drivetrains: ClutchespapagunzОценок пока нет

- Darylll Jane CatbaganДокумент16 страницDarylll Jane CatbaganSleepy SpettoОценок пока нет

- Automobile History: IdeasДокумент38 страницAutomobile History: IdeasmajaklipaОценок пока нет

- BRAKESДокумент46 страницBRAKESDianna MadejaОценок пока нет

- Coomassie Blue Staining Method: ReagentsДокумент1 страницаCoomassie Blue Staining Method: ReagentsMagesssОценок пока нет

- Vendaikaai More KulambuДокумент1 страницаVendaikaai More KulambuMagesssОценок пока нет

- 5 Minutes 40 Minutes 2 Servings: Preparation Time: Cooking Time: ServesДокумент5 страниц5 Minutes 40 Minutes 2 Servings: Preparation Time: Cooking Time: ServesMagesssОценок пока нет

- Ingredients:: For SeasoningДокумент6 страницIngredients:: For SeasoningMagesssОценок пока нет

- Punjabi Dum AlooДокумент5 страницPunjabi Dum AlooMagesssОценок пока нет

- 17 MCBДокумент2 страницы17 MCBMagesssОценок пока нет

- M My Yc Co Ob Ba Ac Ctte Erriiu Um M A Av Viiu Um M: S.E. Hoffner, N. Heurlin, B. Petrini, S.B. Svenson, G. KälleniusДокумент4 страницыM My Yc Co Ob Ba Ac Ctte Erriiu Um M A Av Viiu Um M: S.E. Hoffner, N. Heurlin, B. Petrini, S.B. Svenson, G. KälleniusMagesssОценок пока нет

- CalameoДокумент1 страницаCalameoMagesssОценок пока нет

- 04 06 Assembly LIT 11666 17 50Документ26 страниц04 06 Assembly LIT 11666 17 50sixty_fourОценок пока нет

- Grade 9 Brake System TagingДокумент6 страницGrade 9 Brake System TagingAmor BayawaОценок пока нет

- Internal Expanding BrakeДокумент11 страницInternal Expanding BrakeGirish Sahare100% (1)

- Modeling and Analysis of Regenerative Braking System For Electric Vehicle Based On AmesimДокумент6 страницModeling and Analysis of Regenerative Braking System For Electric Vehicle Based On AmesimLe Huy HoangОценок пока нет

- Automotive Brake SystemДокумент39 страницAutomotive Brake Systemjubaer ahmed50% (4)

- Differential SystemДокумент75 страницDifferential SystemNARAVENI RAM MOHAN100% (1)

- Report On Hydraulic Disk BrakeДокумент7 страницReport On Hydraulic Disk Brakesriram PremОценок пока нет

- 3 Forces&Pressure T PDFДокумент47 страниц3 Forces&Pressure T PDFnyshahidaОценок пока нет

- WMIbiza SCДокумент29 страницWMIbiza SCVicente Talavera UsanoОценок пока нет

- Suspension: 1) Wheelbase and TrackwidthДокумент8 страницSuspension: 1) Wheelbase and TrackwidthRaneem khaledОценок пока нет

- GM STG 15004 50 2 Introduction To ABSДокумент116 страницGM STG 15004 50 2 Introduction To ABSBill NucleusОценок пока нет

- Ebike Design ReportДокумент15 страницEbike Design ReportKanishka Mathur100% (1)

- Hydraulic BrakesДокумент6 страницHydraulic BrakesCarlos VelázquezОценок пока нет

- New Beetle Disc & DrumДокумент54 страницыNew Beetle Disc & DrumPKDОценок пока нет

- 5 BrakeДокумент69 страниц5 BrakeAtalelew ZeruОценок пока нет

- My PPT AbsДокумент27 страницMy PPT AbsTigerSrinivasanОценок пока нет

- SWB A5 m01 FinalДокумент19 страницSWB A5 m01 Finalharshal161987Оценок пока нет

- Index PagesДокумент50 страницIndex PagesMTK2016Оценок пока нет

- S1-Yfce18k 2Документ717 страницS1-Yfce18k 2adipramono8888Оценок пока нет

- Brake BleedingДокумент2 страницыBrake BleedingNelly NelsonОценок пока нет

- 1 2 PressureДокумент22 страницы1 2 PressuretrojanfrpОценок пока нет

- Report 5 Landing GearДокумент36 страницReport 5 Landing GearHalf Peace Jeans100% (3)

- 206-06 Hydraulic Brake Actuation PICKUP JMCДокумент7 страниц206-06 Hydraulic Brake Actuation PICKUP JMCRusonegroОценок пока нет

- Chapter 2 - Basic Pneumatic and Hydraulic SystemДокумент40 страницChapter 2 - Basic Pneumatic and Hydraulic SystemRaziff HamsanОценок пока нет