Академический Документы

Профессиональный Документы

Культура Документы

Ramsey Weiight Scale

Загружено:

Ikram Hisan AkbarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ramsey Weiight Scale

Загружено:

Ikram Hisan AkbarАвторское право:

Доступные форматы

The Ramsey Series 17 Belt Scale System is specically designed for plant and process operations that run

at high rates of speed or require the better-than-normal accuracy of 0.25%. The Ramsey Series 17 lets you monitor production output and inventory, or regulate product loadout, while providing vital information for the effective management and efcient operation of your business.

Product Specications

Ramsey Series 17 Belt Scale System

Accurate conveyor weighing of bulk materials

The Ramsey Series 17 Belt Scale System from Thermo Electron Corporation combines the time-proven reliability of the Ramsey 10-17 Weighbridge and the Ramsey 60-12 Belt Speed Sensor with the power and versatility of the advanced electronics in the Ramsey Micro-Tech 2000 and Ramsey Micro-Tech 3000 series of electronic integrators. The long weighbridge design of the Ramsey Series 17 allows this model to be offered as a highly accurate 0.25% scale system. The longer weighbridge permits more scale-borne time, which minimizes alignment errors. This translates into better accuracy.

This belt scale system is available in two or four idler versions. For more information about the Ramsey Micro-Tech series of electronic integrators, please refer to catalog PI8011.0703. Applications The Ramsey Series 17 Belt Scale System is designed for plant and process operations that run at higher rates of speed or require better-than-normal belt scale accuracy. The system can monitor production output, control product loadout, and keep track of inventory while providing vital information for the effective management and efcient operation of your business.

Formerly Thermo Ramsey

Analyze Detect Measure ControlTM

Features & Benets

Four Idler Ramsey 10-17 Weighbridge Ramsey Micro-Tech 2001 Field Mount Unit Belt Speed Sensor

The Weighbridge The Ramsey Series 17 Belt Scale System from Thermo Electron incorporates the low deection, rm and strong Ramsey 10-17 Weighbridge. It is available in all belt widths and idler spacings. The Belt Speed Sensor Thermos Ramsey 60-12 Digital Belt Speed Sensor is the most reliable and accurate speed-sensing device ever developed for belt scale service. Direct-coupling the sensor to the conveyor tail pulley, snubbing roll, or a large diameter return roller ensures an accurate belt-travel readout. No wheels ride on the belt, which eliminates problems related to material build-up and slippage. Weighbridge Advantages Frictionless, trunnion-type sealed pivots are completely impervious to vibration, moisture and material accumulations Long weigh span minimizes belt affects (four idler standard; two idler optional) Rigid mechanical tube construction Two super-precision strain gauge load cells mounted in tension for stability and fewer misalignment errors Total deection of idler(s) less than 0.127 mm (0.005 in) Slim prole to minimize material build-up problems Fits any standard conveyor with no space required above belt line

Belt Speed Sensor Advantages Rugged, cast-aluminum housing suitable for outdoor installations A.C. pulse generator means no brushes to adjust or replace Performance Guarantee On factory-approved installations, we warrant that the Ramsey Series 17 Belt Scale System will weigh and totalize to a value within 0.25% of the test value when calibrated against a known test weight, chain, or Thermos standard electronic calibration.

Ramsey Series 17 Belt Scale System

Ramsey Series 17 Belt Scale Four Idler Weighbridge Dimensions

5,334 mm (210 in) Deckplate Cutout 5,283 mm (208 in) Overall Length 4,877 mm (192 in) 2,235 mm (88 in) 20.6 mm x 25.4 mm (0.8125 in x 1.0 in) Slots (12 places)

C + 76.2 mm (3 in) C

216 mm (8.50 in)

203 mm (8.00 in) Loadcell Junction Box 1,524 mm (5 ft) Flexible Conduit 254 mm (10 in)

D (Min. Clearance)

Belt Travel

127 mm (5 in)

*1,219 mm (48 in) idler spacing shown

Ramsey Series 17 Belt Scale Two Idler Weighbridge Dimensions

2,692 mm (106 in) Deckplate Cutout 2,642 mm (104 in) Overall Length 203 mm (8 in) 20.6 mm x 25.4 mm (0.8125 in x 1.0 in) Slots (8 places) C + 76.2 mm (3 in) C 216 mm (8.50 in)

2,235 mm (88 in)

203 mm (8.00 in) Loadcell Junction Box 1,524 mm (5 ft) Flexible Conduit 254 mm (10 in)

D (Min. Clearance)

127 mm (5 in)

Belt Travel

*1,219 mm (48 in) idler spacing shown

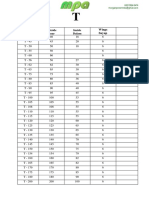

Ramsey Series 17 Belt Scale Variable Belt Width Dimensions

BELT WIDTH A LENGTH (mm) B C D WEIGHT* (kg) 2 IDLER 4 IDLER BELT WIDTH A LENGTH (in) B C D WEIGHT* (lb) 2 IDLER 4 IDLER

610 mm 641 838 762 mm 794 991 914 mm 946 1143 1067 mm 1099 1295 1219 mm 1251 1448 1372 mm 1403 4600 1524 mm 1556 1753 1829 mm 1861 2057 2134 mm 2165 2362 *approximate weight without idlers

902 1054 1207 1359 1511 1664 1816 2121 2426

756 908 1060 1213 1365 1518 1970 1975 2280

197 204 210 216 223 229 235 248 261

288 295 301 307 313 320 326 339 352

24 in 30 in 36 in 42 in 48 in 54 in 60 in 72 in 84 in

25.25 31.25 37.25 43.25 49.25 55.25 61.25 73.25 85.25

33 39 45 51 57 63 69 81 93

35.50 41.50 47.50 53.50 59.50 65.50 71.50 83.50 95.50

29.75 35.75 41.75 47.75 53.75 59.75 65.75 77.75 89.75

435 450 463 477 491 505 518 547 575

635 650 663 677 691 705 718 747 775

Ramsey 61-12 Speed Sensor Dimensions

9.53 mm (0.375 in)

12.7 mm (0.5 in)

spring hole 338 mm (13.31 in) Mechanical Stop 178 mm (7.00 in)

Retaining Spring

70 mm (2.75 in)

127 mm (5.00 in)

13 mm (0.50 in)

6 mm (0.25 in)

64 mm (2.50 in) 43 mm (1.69 in) 130 mm (5.13 in) Shaft Rotation

Specications

Ramsey Series 17 Belt Scale System

Specication

Ramsey 10-17 Weighbridges Weigh Span Frictionless Pivots Weighbridge Construction Load Cells Total Deection Clearance Requirements Load Cells Quantity Enclosure Mounting Excitation Output Non-Linearity Non-Repeatability Hysteresis Operating Temperature Temperature Sensitivity Four idler standard minimizes belt effects; Two idler version optional for 0.5% accuracy Trunnion-type; Sealed units are completely impervious to vibration, moisture, and material build-up Rigid mechanical tube construction Two super-precision strain gauge load cells mounted in tension for stability and reduction of misalignment errors Less than 0.127 mm (0.005 inches) Fits any standard conveyor; No space required above belt line

Two (2) in parallel Environmentally-protected S type cell Tension 10 VDC 5% 3 mV/V 0.1% < 0.03% FS 0.01% FS < 0.02% FS -54C to +93C (-65F to +200F) Span 0.0014% FS/C (0.0008% FS/F) Zero 0.0027% FS/C (0.0015% FS/F) Overload Safe to 150% of load cell capacity; Ultimate to 300% FS; Sideload 50% FS Rating FM Approved for Class II, Div 1 & 2, Groups E, F & G; NTEP Type III, 5000 divisions; OIML R60 Ramsey 60-12 Digital Speed Sensor Type Digital, brushless Mounting Direct to 15.88 mm (0.625 in) diameter stub shaft on tail pulley, bend pulley, or return roll Housing Weather-tight, epoxy nish, cast aluminum Mounting Hardware Supplied with coupling, restraint arm and restraint spring Shipping Weight 3.6 kg (8 lb)

2004 Thermo Electron Corporation. All rights reserved. Specications, terms and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representatives for details. Literature Code PI.8018.1103

Germany South Africa USA Australia +49 (0) 208-824930 +27 (0) 11-609-3101 +1 (877) 290-7422 +1 61 (0) 8 8150 5300 +1 61 (0) 8 8234 5882 fax +49 (0) 208-852310 fax +27 (0) 11-609-3120 fax +1 (763) 783-2525 fax Canada +1 (905) 888-8808 +1 (905) 888-8828 fax Process Instruments China +86 (0) 516-7793650 +86 (0) 516-7793652 fax Italy +39 02-959514-1 +39 02-953200-15 fax Spain +34 01-657-3900 +34 91-661-5572 fax www.thermo.com

Netherlands United Kingdom +31 (0) 33-454-9000 +44 (0) 1788-820300 +31 (0) 33-454-9009 fax +44 (0) 1788-820301 fax

Вам также может понравиться

- MasteringPhysics Pearson-Intro To Mastering and Math ReviewДокумент57 страницMasteringPhysics Pearson-Intro To Mastering and Math ReviewShristi Singh80% (10)

- Hyundai R210-7 Specifications Machine - Market192327 PDFДокумент11 страницHyundai R210-7 Specifications Machine - Market192327 PDFAldhi BrajamustiОценок пока нет

- Mikalor Clamp TableДокумент2 страницыMikalor Clamp TableRini Agnesty SkbОценок пока нет

- Tabel Volume TankiДокумент1 страницаTabel Volume Tankirudi 01Оценок пока нет

- Procuretment List Premire Oil 2020Документ2 страницыProcuretment List Premire Oil 2020Fahryan RozakОценок пока нет

- Sikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutДокумент4 страницыSikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutChandra Yk100% (1)

- Wondershare Filmora Effect Packs Link DownloadДокумент2 страницыWondershare Filmora Effect Packs Link DownloadRollensa PicturesОценок пока нет

- EmbankmentДокумент5 страницEmbankmentAmila Priyadarshana Dissanayake100% (1)

- PNA Chemistry Expedite 8900 User's GuideДокумент114 страницPNA Chemistry Expedite 8900 User's GuideJohnОценок пока нет

- System Modelling and SimulationДокумент260 страницSystem Modelling and SimulationArvind Kumar100% (13)

- Heat Transfer Chapter 1 IntroductionДокумент68 страницHeat Transfer Chapter 1 IntroductionsubratorajОценок пока нет

- Rubber Coupling Type and SizeДокумент4 страницыRubber Coupling Type and SizeErick Parlindungan MorganОценок пока нет

- Pertamina EP Cepu 2022 Procurement ListДокумент2 страницыPertamina EP Cepu 2022 Procurement Listmarketing kinaryaОценок пока нет

- Brosur RX 40Документ3 страницыBrosur RX 40Ardi TjОценок пока нет

- Construction of 40m High Galvanized Steel TowerДокумент6 страницConstruction of 40m High Galvanized Steel TowerDeni MaulanaОценок пока нет

- Laporan Harian Timbangan TBS 021222Документ8 страницLaporan Harian Timbangan TBS 021222AchoUsman Saqina MelanОценок пока нет

- Asphalt-based vapor barrier mastic for low-temperature insulationДокумент1 страницаAsphalt-based vapor barrier mastic for low-temperature insulationHung Mai Van100% (2)

- Brosur Lampu PJU SHT 30WДокумент1 страницаBrosur Lampu PJU SHT 30WRahmat HidayatОценок пока нет

- Rab MessДокумент67 страницRab Messdimas wahyuОценок пока нет

- Contoh Anggaran Capex PKS Tahun 2012Документ2 страницыContoh Anggaran Capex PKS Tahun 2012Malik100% (1)

- 017 - Test Report of Quality TGL 25 Sept 2023 - BIOSOLAR B35Документ1 страница017 - Test Report of Quality TGL 25 Sept 2023 - BIOSOLAR B35moehammadsaliem7Оценок пока нет

- Pemeliharaan Gedung&Halaman 2020 Reviu FinalДокумент52 страницыPemeliharaan Gedung&Halaman 2020 Reviu FinalCallista Canary BFОценок пока нет

- EDG Deisel ConsumptionДокумент2 страницыEDG Deisel ConsumptionANUTEJ CHITIMELAОценок пока нет

- AMC-SCHOU Cylindrical Grinders ProfileДокумент28 страницAMC-SCHOU Cylindrical Grinders Profilem_najmanОценок пока нет

- TamCem 6R V1ID 13Документ2 страницыTamCem 6R V1ID 13Arfan Rahim100% (1)

- PT Davidi International Company Info - Engineering, Fabrication, Construction ServicesДокумент28 страницPT Davidi International Company Info - Engineering, Fabrication, Construction ServicesChaidir TransmissionОценок пока нет

- MODENA Product Brochure (Cooking)Документ21 страницаMODENA Product Brochure (Cooking)Idham SyahОценок пока нет

- Perhitungan RAB Quary Kema Ko AnДокумент6 страницPerhitungan RAB Quary Kema Ko Anmdo pt likmah berkah mandiriОценок пока нет

- Prinsip Dasar M-RSДокумент45 страницPrinsip Dasar M-RSIkhsan ArifОценок пока нет

- Boq PertashopДокумент4 страницыBoq PertashopMust HarryОценок пока нет

- Jotamastic 80: Technical Data SheetДокумент14 страницJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANОценок пока нет

- Penawaran Barrier Gate KarcisДокумент2 страницыPenawaran Barrier Gate KarcisDuwiОценок пока нет

- DPS Perkins-200 kVA - 1106A-70TAG4Документ1 страницаDPS Perkins-200 kVA - 1106A-70TAG4manthoexОценок пока нет

- Kep Dirjen Migas No-84-K 38 DJM 1998Документ21 страницаKep Dirjen Migas No-84-K 38 DJM 1998krisnandar74100% (4)

- Nonwoven geotextile technical data sheetДокумент2 страницыNonwoven geotextile technical data sheetjogja raya100% (1)

- Witness Inspection and Test PlanДокумент5 страницWitness Inspection and Test PlansanketОценок пока нет

- Digital Pipeline Leak Detection: Remote MonitoringДокумент3 страницыDigital Pipeline Leak Detection: Remote MonitoringSARFRAZ ALIОценок пока нет

- Fixed Fire Fighting SystemsДокумент46 страницFixed Fire Fighting SystemsAsst. Engineer 1 I & C, 450MW SouthОценок пока нет

- Time Sheet Unit: Pelaksanaan Perawatan Harian (P2H)Документ1 страницаTime Sheet Unit: Pelaksanaan Perawatan Harian (P2H)Endrew ChristianОценок пока нет

- List Training Oil and Gas Di BatamДокумент1 страницаList Training Oil and Gas Di BatamSyahirul AlimОценок пока нет

- Authorized Service Center Locations ListДокумент35 страницAuthorized Service Center Locations ListKevin ReynaldoОценок пока нет

- Tws101 Emergency BatternДокумент2 страницыTws101 Emergency BatternIkie Barie0% (1)

- Safety Data Sheet for MasterGlenium ACE 8595 Concrete AdmixtureДокумент11 страницSafety Data Sheet for MasterGlenium ACE 8595 Concrete Admixturefadlan effendiОценок пока нет

- AMP AZP - 1000 Full Optimal 1Документ3 страницыAMP AZP - 1000 Full Optimal 1J EquipОценок пока нет

- Co2 Extinguishing System: Co2 System Setup Type A, With Solenoid Actuated Pilot CylinderДокумент2 страницыCo2 Extinguishing System: Co2 System Setup Type A, With Solenoid Actuated Pilot CylindersulaimanОценок пока нет

- Tabel Perhitungan Debit Dengan Alat Ukur ThompsonДокумент3 страницыTabel Perhitungan Debit Dengan Alat Ukur Thompsonmaslele720% (1)

- Penguard Clear SealerДокумент4 страницыPenguard Clear SealerInaam Ullah MughalОценок пока нет

- Brosur Rangka Dan Atap Baja RinganДокумент45 страницBrosur Rangka Dan Atap Baja RinganJack HugmanОценок пока нет

- Zenitel TKIS 2 1008131020Документ4 страницыZenitel TKIS 2 1008131020Veloso FernandesОценок пока нет

- En Censtar ComДокумент4 страницыEn Censtar ComSandy NugrahaОценок пока нет

- Rampe - Articulated Truck CAT 745CДокумент3 страницыRampe - Articulated Truck CAT 745CFarouk AzzouhriОценок пока нет

- Red Oxide Primer QD JotunДокумент4 страницыRed Oxide Primer QD JotunDebОценок пока нет

- Compro Borneo HoldingsДокумент16 страницCompro Borneo HoldingsWibowo BowoОценок пока нет

- P3FH-RPT-QAQC-00-004-A3 B: Fabrication Procedure For Machinery & Mechanical EquipmentДокумент55 страницP3FH-RPT-QAQC-00-004-A3 B: Fabrication Procedure For Machinery & Mechanical EquipmentFriska ThaniaОценок пока нет

- Meditran SX Plus SAE 15W-40Документ2 страницыMeditran SX Plus SAE 15W-40JohnyОценок пока нет

- Forward Minimum Maximum Calibration Flow Certification DatesДокумент3 страницыForward Minimum Maximum Calibration Flow Certification Datesteo2005Оценок пока нет

- HILUX 2.4G / 2.8G (Diesel Auto) : Model Code: GUN125, 126Документ10 страницHILUX 2.4G / 2.8G (Diesel Auto) : Model Code: GUN125, 126Stanley WongОценок пока нет

- Daily Checklist ExcavatorДокумент3 страницыDaily Checklist ExcavatorDimas Adi PratamaОценок пока нет

- PolykenДокумент7 страницPolykenJanllo83Оценок пока нет

- Thermo Scientific Ramsey Series 20: A Belt Scale System For Conveyor Weighing of Bulk MaterialsДокумент4 страницыThermo Scientific Ramsey Series 20: A Belt Scale System For Conveyor Weighing of Bulk MaterialsAlex MtОценок пока нет

- ServoClass RohsДокумент8 страницServoClass RohsManel MontesinosОценок пока нет

- Pti30000 A MSPДокумент2 страницыPti30000 A MSPStalin Paul Rodriguez LeonОценок пока нет

- Torsion Testers: Bulletin 137Документ4 страницыTorsion Testers: Bulletin 137afaq AhmadОценок пока нет

- Thermo Scientific Ramsey Series 17: Belt Scale System For Conveyor Weighing of Bulk MaterialsДокумент4 страницыThermo Scientific Ramsey Series 17: Belt Scale System For Conveyor Weighing of Bulk MaterialsFloyd Mejia GamarraОценок пока нет

- Literature SurveyДокумент6 страницLiterature SurveyAnonymous j0aO95fgОценок пока нет

- Numerical Programming I (For CSE) : Final ExamДокумент7 страницNumerical Programming I (For CSE) : Final ExamhisuinОценок пока нет

- Maximum Material Boundary (MMB) and Its Advantages in GD&T Analysis PDFДокумент6 страницMaximum Material Boundary (MMB) and Its Advantages in GD&T Analysis PDFSangeethaОценок пока нет

- 4363 111 Machine Design IДокумент6 страниц4363 111 Machine Design Iyogesh_b_k100% (2)

- Art AnalysisДокумент3 страницыArt AnalysisCheeny VelascoОценок пока нет

- BelowsДокумент35 страницBelowstejassidhpuraОценок пока нет

- Norma Japonesa Aij-Rlb-1996Документ36 страницNorma Japonesa Aij-Rlb-1996AnaApcarianОценок пока нет

- SPE 122225 Gas Condensate Productivity Improvement by Chemical Wettability AlterationДокумент12 страницSPE 122225 Gas Condensate Productivity Improvement by Chemical Wettability AlterationGabriel EduardoОценок пока нет

- Engineering Mechanics by TimoshenkoДокумент607 страницEngineering Mechanics by TimoshenkoJagadish50% (2)

- BS 476.6 PDFДокумент10 страницBS 476.6 PDFJmc NarelaОценок пока нет

- Maxwell Stress Tensor ExplainedДокумент6 страницMaxwell Stress Tensor ExplainedSyeda Tehreem IqbalОценок пока нет

- How To Build With CobДокумент33 страницыHow To Build With CobmandritsopoulosОценок пока нет

- Interactions and Incompatibilities of Pharmaceutical ExcipientsДокумент24 страницыInteractions and Incompatibilities of Pharmaceutical ExcipientsEmmanuel Vachon LachanceОценок пока нет

- WMM Plant CalibrationДокумент5 страницWMM Plant CalibrationAnonymous zyIPjL9vОценок пока нет

- 03 Modern Photoelectric Effect LabДокумент3 страницы03 Modern Photoelectric Effect LabJuan David ParraОценок пока нет

- FLUIDME Quiz 02 AnswersДокумент5 страницFLUIDME Quiz 02 AnswersSam Denielle TugaoenОценок пока нет

- RCE2018 math and geometry problems solutions under 40 charactersДокумент1 страницаRCE2018 math and geometry problems solutions under 40 charactersArwin VillegasОценок пока нет

- Wiki Unified Soil Classification SystemДокумент2 страницыWiki Unified Soil Classification SystemGIRISHA001Оценок пока нет

- Astronomy Unit Resources SchoolpointeДокумент17 страницAstronomy Unit Resources SchoolpointeShekel DeninoОценок пока нет

- Resistivity and Saturation in ShalesДокумент6 страницResistivity and Saturation in ShalesAngelMesoОценок пока нет

- Agco Type81sek PDFДокумент15 страницAgco Type81sek PDFMargaret DaughertyОценок пока нет

- Anti Derivative Chain RuleДокумент4 страницыAnti Derivative Chain Ruletutorciecle123Оценок пока нет

- Introduction to Catalysis LectureДокумент22 страницыIntroduction to Catalysis LectureVhyiitrii Shanqk Peñjhaqa Haatii100% (1)

- Interference PatternsДокумент8 страницInterference PatternsAsa mathewОценок пока нет

- Linear Differential Equations Standard Form and Operator FormДокумент10 страницLinear Differential Equations Standard Form and Operator FormJoSaОценок пока нет

- Elders Ray SYstemsДокумент7 страницElders Ray SYstemssagarmkale4395Оценок пока нет