Академический Документы

Профессиональный Документы

Культура Документы

Trace Wires On Main Water Lines

Загружено:

Leo Santiago ToyogonОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Trace Wires On Main Water Lines

Загружено:

Leo Santiago ToyogonАвторское право:

Доступные форматы

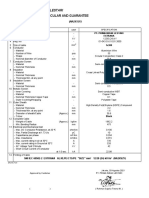

METROPOLITAN UTILITIES DISTRICT

Prepared by: Approved by:

Construction Standard

Installation of Trace Wire on Water Mains

No: Page: Supersedes: Effective:

1.14.1

1 of 5

1-22-08

Bill Travnicek Jeff Loll

10-19-11

GENERAL * This Construction Standard governs trace wire installation on water mains. A 14 gauge or larger trace wire shall be installed on all water mains. Exception: Water mains as part of a relocation project shall have trace wire installed: - If the length of the relocated section is 600 or greater - The length of the relocated section is between 200 and 600 and includes a valve (including hydrant branch valves) - The main being relocated currently has trace wire on it - All relocated PVC and HDPE water mains - Where called for on project drawings Typical hydrant branches, that are perpendicular to the water main, do not require trace wire. Trace wire shall be installed on non-typical hydrant branches (i.e. dog-legged hydrant branch). * Take care to protect the wire insulation and repair it with electrical tape if the coating is damaged. Always attach the wire to the lead end of the pipe when boring or plowing and avoid kinking or tangling the wire during installation. Because of the tremendous strain on trace wire when using directional boring equipment, three 10 or 12 gauge wires should be pulled with the main in case one or two wires break. APPROVED TRACE WIRE MATERIAL - Trace wire for direct bury installations shall be #14 AWG Copper Clad Steel wire as manufactured by Copperhead Industries, LLC #14 AWG solid Copper wire with 30 mil high molecular weight polyethylene insulation as manufactured by Agave Wire LTD, or approved equal. - Trace wire for water mains installed by directional boring shall be #12 or #10 AWG copper clad steel wire as manufactured by Copperhead Industries, or approved equal. - Blue tri-view plastic markers by Rhino w/Test Screws - 4 ft U-channel posts - Valve Box Top Sections - Direct Bury Wire Nuts (Dryconn Direct Bury Wire Nut (10444) manufactured by King Innovation, DBY-6 or DBR-6 as manufactured by 3M or approved equal). - Direct Bury Lug (Dryconn Direct Bury Lug as manufactured by King Innovation or approved equal). TRACE WIRE CONNECTIONS Joining Ends of Trace Wire: Connections into existing trace wire, connections into trace wire used during water main bores, connections between one spool of trace wire to another, and other similar connections shall be made using a direct bury wire nut. * Revised Text

METROPOLITAN UTILITIES DISTRICT

Prepared by: Approved by:

Construction Standard

Installation of Trace Wire on Water Mains

No: Page: Supersedes: Effective:

1.14.1

2 of 5

1-22-08

Bill Travnicek Jeff Loll

10-19-11

When connecting trace wire ends together, strip 5/8 of insulation from the end of each wire. Insert the two ends firmly into the direct bury wire nut. Twist the wire nut clockwise while pushing the wires firmly into the nut. Do not over torque. Tie the wires in a knot as shown in Fig 1. Joining Trace Wire - Branch to Main: Connections of trace wire at tees, crosses, and at locations where the trace wire will be brought to the surface shall be conducted using a direct bury lug. Refer to Fig 2 for this connection style.

METROPOLITAN UTILITIES DISTRICT

Prepared by: Approved by:

Construction Standard

Installation of Trace Wire on Water Mains

No: Page: Supersedes: Effective:

1.14.1

3 of 5

1-22-08

Bill Travnicek Jeff Loll

10-19-11

INSTALLATION Trace wire shall be installed in a continuous fashion. Install trace wire on top of water main and secure to main every five (5) feet with tape as shown in Fig 3.

Bring trace wire to surface at every cc box, vault, blue plastic marker with trace wire connectors, dead end hydrants, and as called out in the drawings. Trace wire shall be brought to the surface at least every one thousand (1,000) feet. Take care not to damage the wire coating. Repair damaged coating with electrical tape. Trace Wire in a Vault Trace wire shall be brought up in all vaults. Trace wire shall be brought to the surface according to Fig 4. Do not wrap the trace wire around the steps or any other place where a person entering the vault could trip on the wire.

METROPOLITAN UTILITIES DISTRICT

Prepared by: Approved by:

Construction Standard

Installation of Trace Wire on Water Mains

No: Page: Supersedes: Effective:

1.14.1

4 of 5

1-22-08

Bill Travnicek Jeff Loll

10-19-11

Trace Wire in Blue Plastic Pipe Line Marker When bringing the trace wire up in a blue plastic pipe line marker, install the trace wire according to Fig 5. Bury a four foot u-channel post two feet in the ground. Run the trace wire up through the marker and slide the blue plastic marker over the post. Bury the bottom six inches of the marker. Connect the trace wire to the brass connecting screws and label the screws with a permanent marker as shown in Fig 5. Note location of trace wire pipeline marker on as-built drawings. Note: If a marker is used only to mark the main location and not bring up the trace wire, use the blue markers without the trace wire connectors.

Trace Wire in a CC Valve Box Trace wire shall be brought up in all cc valve boxes. The trace wire shall be brought to the surface according to Fig 6.

METROPOLITAN UTILITIES DISTRICT

Prepared by: Approved by:

Construction Standard

Installation of Trace Wire on Water Mains

No: Page: Supersedes: Effective:

1.14.1

5 of 5

1-22-08

Bill Travnicek Jeff Loll

10-19-11

Trace Wire in PVC Conduit at Hydrant Trace wire shall be brought up in a PVC conduit at all dead end/end of main fire hydrants without a valve and at hydrants of a non-typical hydrant branch (i.e. dog-legged hydrant branch). Trace wire shall be brought to the surface according to Fig 7. Note location of PVC conduit in relation to the hydrant (i.e. north, east, south or west) on as-built drawings.

This Page is Intentionally Left Blank

Вам также может понравиться

- 2010-2 Service La Artcool-Gallery System 3828a20926c 20120509091718 PDFДокумент76 страниц2010-2 Service La Artcool-Gallery System 3828a20926c 20120509091718 PDFTamo NekoОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Answer Key For Activity Sheet - 14.1, Electric Current and Its EffectsДокумент8 страницAnswer Key For Activity Sheet - 14.1, Electric Current and Its EffectsalatexgamingОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Flying Scale Models Issue 176 2014-07Документ68 страницFlying Scale Models Issue 176 2014-07Peter100% (1)

- Types of Earthing-IEC 60364Документ5 страницTypes of Earthing-IEC 60364Navneet Singh100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Terra At-3000 EncoderДокумент19 страницTerra At-3000 EncoderDRAGONFLYDFОценок пока нет

- List TPPIДокумент4 страницыList TPPItechnical kmiОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Schedule of Load PreparationДокумент3 страницыSchedule of Load PreparationTeodoro Quintana100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Resistance Heating Alloys: and Systems For Industrial FurnacesДокумент24 страницыResistance Heating Alloys: and Systems For Industrial FurnacesAndrés RiosОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Combination Starters and Distribution UnitsДокумент26 страницCombination Starters and Distribution UnitsFelipe Vasquez MedinaОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- OPGW Specifications: GeneralДокумент18 страницOPGW Specifications: GeneralMubashir HussainОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- AFL Standard Compression Joints For Alumoweld and Steel Ground Wire Conductors PDFДокумент2 страницыAFL Standard Compression Joints For Alumoweld and Steel Ground Wire Conductors PDFDiego SecoОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- 3613Документ31 страница3613youuuuyОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Steel Wire Ropes in ElevatorsДокумент40 страницSteel Wire Ropes in ElevatorsDaud Jiong KIM100% (1)

- Chapter 1 Introduction To PrestressingДокумент22 страницыChapter 1 Introduction To PrestressingJoena LindaОценок пока нет

- The Complete Guide To WiringДокумент52 страницыThe Complete Guide To WiringEhab SaberОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Lucite Flower Bracelet Project From Sherri Haab Jewelry InspirationsДокумент8 страницLucite Flower Bracelet Project From Sherri Haab Jewelry InspirationsCrafterNews67% (12)

- TPG NA2XS2Y 1x300 mm2 20KVДокумент2 страницыTPG NA2XS2Y 1x300 mm2 20KVtees220510Оценок пока нет

- Slings Instruction ManualДокумент20 страницSlings Instruction ManualCris SuyamОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Megger Test FormДокумент1 страницаMegger Test FormJHON CHRISTOPHER CENTINOОценок пока нет

- Pedal Opperated Grain MillДокумент38 страницPedal Opperated Grain Millpitufito100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Data Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeДокумент10 страницData Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeRisa RidmaОценок пока нет

- 13a Socket StanderizationДокумент3 страницы13a Socket Standerizationthilanka06Оценок пока нет

- Astm 401Документ4 страницыAstm 401JOSEPH REFUERZOОценок пока нет

- Iec 439-1 Iec 947-2Документ13 страницIec 439-1 Iec 947-2zuma zaiamОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Intercom WiringДокумент2 страницыIntercom WiringjussomeguyОценок пока нет

- Pemboran 3Документ74 страницыPemboran 3Gerald PrakasaОценок пока нет

- TLE-IA6 q0 Mod8 Simple Electrical Gadgets v3Документ32 страницыTLE-IA6 q0 Mod8 Simple Electrical Gadgets v3sam yoong100% (1)

- Helukabel Range-At A GlanceДокумент52 страницыHelukabel Range-At A GlanceMalar VizhiОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Wire Gauge and Current Limits PDFДокумент3 страницыWire Gauge and Current Limits PDFShahbazОценок пока нет

- חוברת הפעלה למכונה לגילוף חוטיםДокумент22 страницыחוברת הפעלה למכונה לגילוף חוטים208020Оценок пока нет