Академический Документы

Профессиональный Документы

Культура Документы

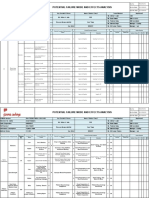

SMT Generic Control Plan

Загружено:

Pedro Lopez RodriguezОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SMT Generic Control Plan

Загружено:

Pedro Lopez RodriguezАвторское право:

Доступные форматы

Control Plan #: Part Number: Part Name/Description:

Plant: Key Contact: Prototype Pre-launch

XYZ Company, City, State, Zip Date: Production Revision: 1.0 Methods Sample Specification / Tollerance

Packing Slip Not Visibly Damaged Packing slip

WO#:

Characteristics Step # SMT Process Step Machine / Device Product

Correct Quantity 1 Receive Materials Stock Room Packaging Quality Right raw material quantity Packaging Quality Visual Check Visual Check Gross Visual Visual inspection

Process

Visual Check

Evaluation Measurement Technique

Physical Count

Size

100% 100% 1

Frequency

Each Lot Received Each Lot Each Lot Received Each Lot

Control Method

Accept/Reject Criteria

Reaction Plan

Circuit Cam, BaaN Incomming Material Procedure Incoming Inspection Procedure Incomming Material Procedure Incoming Inspection Procedure Incoming inspection procedure/Product specification

Halt Production, Notify Supervisor, Complete a PIF Segregate Non-Conforming Material, Notify Supervisor Segregate Non-Conforming Material, Notify Supervisor Segregate Non-Conforming Material, Notify Supervisor Segregate Non-Conforming Material, Notify Supervisor

Visual Check

Not Visibly Damaged

Gross Visual

100%

Moisture Sensitive Components 2 Incoming inspection Stock Room PCB out of specification

Visual Check

Per: Material Bake and Dry Storage procedure

Visual inspection

100%

Each Lot

Visual Check

According to component Optical comparator / specification / drawing caliper/surface plate

By AQL

Each lot

Segregate Non-Conforming Material, Notify Supervisor

Cosmetic verification of components

Visual Check

According to component specification / drawing

Visual inspection

By AQL

Each lot

Incoming inspection procedure

Segregate Non-Conforming Material, Notify Supervisor

Process audit ICS-WIP Serial number ICS System ICS WIP Page 100% Continuous Bar code reader in process Bar code reader in process/ process work instruction Bar code reader in process Manual

Do not put label on PCB, stop printing and notify to the Supervisor and Process/mfg Engineering Remove label that was placed wrong and place a new label. Notify Supervisor. Stop printing, and notify line supervisor if label is not legible and do not placed it on theboard. If the PCB has not been correctly oriented, it has to be removed and reoriented. Call Mfg or QE if the temperature changes out of the specified ranges (alarm) and reset the proper temperature If the expiration date has been reached, the tube has to be scrapped. Dispose of Expired Material and get a new tube form Matls. Hold the product built with the wrong paste and notify supervisor for disposition. If the stabilization period is undeterminable then a 8 hrs wait period is required and begins at time of discovery Operator checks for proper adjustment and cleanliness of stencil. Stop the machine, contact Eng or QE to take a corrective action Stop production if any of the solder paste measurements is out of the limits. Notify the technician and QE. Train the operators. Insure that the printer is password protected.

Board Labeling

Kitting Area

Board labeling

Every side of the panel (top and bottom) Bar Code legible

Visual inspection

100%

Continuous

Label legible Correct orientation of the PCB Solder Paste

Bar code reader

100%

Continuous Every change over. Continuous

Load board to loader

Manual

Conveyor width Solder paste storage temperature

Per PCB width 0-5C or per specifications shown in the Technical Data 6 months from the date of manufacture or per specifications shown in the Technical Data Sheet Per Customer Drawing

Visually

1st piece

Refrigerator

Thermometer

One reading

Alarm

Perishable Material Log Expiration date on solder paste label 100% Every tube Label on tube

Refrigerator

Solder Paste

Solder paste expiration date

Refrigerator

Type or Make or part number of solder paste

No Clean or Water Soluble Solder paste stabilization

Visual inspection

100%

Per Tube

ICS/Circuit Cam/Doc Pack

Refrigerator

Solder Paste

6 hrs minimum before production use

Perishable Materials Log

100%

Every tube

Audit log

Print solder paste Stencil Printer

Solder Paste

Paste coverage

60 % coverage of the aperture as a minimum.

Automatic vision system

4 corners 100%

Continuous

Alarm

60 % coverage of the aperture as a minimum.

Solder Paste

Solder paste shorting

-20% Screen Print verification & Setup Reference documents TCC-00004, EOP-00004 & PML00004 No overprinting or as shown in Screen Print verification & Setup Reference documents TCC-00004, EOP-00004 & PML-00004

Automatic vision system

4 corners 100%

Continuous

Alarm

Stencil Printer

Solder Paste

Correct Print Parameters

Visual

100%

Every product run

Periodic audit to insure that correct printing parameters are used.

Stencil Printer

Solder Paste

Print Registration

Visual

100%

Every product run

Verify that initial machine setup is correct. Page 1

Elcoteq SA de CV Confidential

Control Plan

Print solder paste

Control Plan #: Part Number: Part Name/Description:

Plant: Key Contact: Prototype Pre-launch

XYZ Company, City, State, Zip Date: Production Revision: 1.0 Methods Sample Specification / Tollerance Evaluation Measurement Technique

Visual 1st Article

WO#:

Characteristics Step # SMT Process Step Machine / Device Product Process

Size

Frequency

Control Method

Accept/Reject Criteria

Reaction Plan

Receive Materials

Stencil Room Stock Printer

Stencil

Correct Stencil

Solder on all intended pads

1st Article

Every run

QC first article inspection

Stop production if any pads do not have solder paste. Notify Engineering. Get correct stencil.

Elcoteq SA de CV Confidential

Control Plan

Page 2

Control Plan #: Part Number: Part Name/Description:

Plant: Key Contact: Prototype Pre-launch

XYZ Company, City, State, Zip Date: Production Revision: 1.0 Methods Sample Specification / Tollerance Evaluation Measurement Technique Size Frequency Control Method Accept/Reject Criteria Reaction Plan WO#:

Characteristics Step # SMT Process Step Machine / Device Product Process

Receive Materials

Stock Room

Component polarity

Automatic Machine Placement

By product specification and work instruction

Visual inspection

1st Article

Every run

QC first article inspection

Stop the line and report to the Supervisor and Engineer. Segregate suspect units for inspection. Modify assembly program as needed. Stop the line and report to the Supervisor and Engineer. Segregate suspect units for inspection. Modify assembly program as needed. Stop the line and report to the Supervisor and Engineer. Segregate suspect units for inspection. Modify assembly program as needed. Stop the line and report to the Supervisor and Engineer. Segregate suspect units for inspection. Modify assembly program as needed. Stop the line and report to the Supervisor and Engineer. Segregate suspect units for inspection. Modify assembly program / feeders as needed. Stop the line and verify oven parameters, separate suspect material. Notify the Supervisor / Engineer Hold Process, Notify Engineering and Supervisor Stop the line and notify Engineering. Verify material in process. Stop the process, notify to the supervisor and separate suspect material for inspection and disposition Stop the process and inspect suspect material. Verify Tip specifications Stop the process and inspect suspect material. Verify Tip specifications

Visual inspection Component alignment 6 SMT Component Placement Top / Bottom (as required) PLACEMENT MACHINES Automatic Machine Placement By product drawing and specification X-Ray Inspection

1st Article

Every run

QC first article inspection

1st Article

Every run

QC first article inspection

Component seating

Automatic Machine Placement

By product drawing and specification By bill of material and product drawing (blue print)

Visual inspection

1st Article

Every run

QC first article inspection Process audit by QC inspector. First article sheet Oven parameters, first article cheek list. Process audit by QC Per reflow oven verification procedure Product program for components location and characteristics QC in process inspection QC in process inspection QC in process inspection

Right component

Automatic Machine Placement

Visual inspection

100%

Every reel replaced and new reel

Quality of Solder 7 Reflow Relfow Oven

Per Solder Paste Type Machine Reflow Soldering as shown in the Work Order Repeatability Per reflow oven verification procedure By product program

1 time Profile device 1 time Automatic Cam inspection 100%

Every product/ new run

once per day Every lot

AOI Inspection Top / Bottom (as required)

RTI 6520 PCB Inspection System

Components location and presence

Components seating

By product drawing and specification Solder tip temperature By product specification

Visual inspection By solder Tip specification Visual inspection

100%

Every run

Second level assembly

Hand solder components

100%

Every lot

Quality of Solder

IPC-A-610 standard

100%

Every unit

10

Mechanical Assembly

Manual

Quality of assembly

By product specification

Visual inspection

100%

Every Unit

QC in process inspection

Stop the process and Notify Engineering

11

Depanelize

IPC-A-610 standard

Visual inspection

100%

Every unit

QC in process inspection

Stop the line and report to the Supervisor and Engineer the problem. Separate the suspect units for inspection. Stop the test process, notify Engineering and verify material using a golden unit.

12

Final test

Electrical test performance

By product specification

Test equipment

100%

Continuous

Test procedure and work instruction

Elcoteq SA de CV Confidential

Control Plan

Page 3

Вам также может понравиться

- PFMEA Solder Paste Printing 03 Sept 2016 (Zul)Документ129 страницPFMEA Solder Paste Printing 03 Sept 2016 (Zul)Sisma Pratama Arum PutriОценок пока нет

- Reflow and Wave Soldering Process Documentation SheetДокумент8 страницReflow and Wave Soldering Process Documentation Sheetsmtdrkd100% (3)

- Process Mapping in SMD AssemblyДокумент1 страницаProcess Mapping in SMD Assemblysmtdrkd100% (2)

- SMT Generic Control PlanДокумент2 страницыSMT Generic Control Plansmtdrkd81% (21)

- SPC SMT Defects Chart TemplateДокумент2 страницыSPC SMT Defects Chart Templatesmtdrkd100% (2)

- Assembly Line BalancingДокумент11 страницAssembly Line BalancingAyush SinghОценок пока нет

- SMT Process EngineeringДокумент4 страницыSMT Process Engineeringshaktiss24_147930359Оценок пока нет

- Area Ratio and Stencil Thickness CalculatorДокумент6 страницArea Ratio and Stencil Thickness Calculatorsmtdrkd100% (1)

- Pin-in-Paste Stencil Design SpreadsheetДокумент4 страницыPin-in-Paste Stencil Design Spreadsheetsmtdrkd100% (1)

- Wave Solder Profile Documentation SheetДокумент4 страницыWave Solder Profile Documentation SheetsmtdrkdОценок пока нет

- X-Ray Inspection BGA Glenbrook TechnologiesДокумент25 страницX-Ray Inspection BGA Glenbrook TechnologiessakthiОценок пока нет

- Solder Criteris IPC-610GДокумент17 страницSolder Criteris IPC-610GUbaldo JuarezОценок пока нет

- Chapter 5 - Control Chart For AttributesДокумент28 страницChapter 5 - Control Chart For AttributesAtirah AsnaОценок пока нет

- Incoming InspectionДокумент1 страницаIncoming InspectionGAURAV SHARMAОценок пока нет

- Stencil Aperture and Area Ratio Table For Optimum PrintingДокумент4 страницыStencil Aperture and Area Ratio Table For Optimum PrintingsmtdrkdОценок пока нет

- FMEAДокумент6 страницFMEANavnath TamhaneОценок пока нет

- PFMEA ExampleДокумент14 страницPFMEA Examplekalebasveggie100% (1)

- Process Potential Failure Mode & Effects AnalysisДокумент12 страницProcess Potential Failure Mode & Effects Analysisankit kumar100% (1)

- Wi SPCДокумент4 страницыWi SPCSujeet Kumar100% (1)

- EVERSHINE FINISHER CONTROL PLAN FOR NEEDLE CORE TEAMДокумент9 страницEVERSHINE FINISHER CONTROL PLAN FOR NEEDLE CORE TEAMManu SharmaОценок пока нет

- Capability Worksheet For CP, CR and CPKДокумент4 страницыCapability Worksheet For CP, CR and CPKsmtdrkd100% (9)

- Copy of APQP Check List - Ford (Blank)Документ9 страницCopy of APQP Check List - Ford (Blank)feiraluremaОценок пока нет

- Stencil Printing PresentationДокумент45 страницStencil Printing Presentationcdsullivan100% (1)

- Technical Devices Validation ProtocolДокумент19 страницTechnical Devices Validation ProtocolarumОценок пока нет

- 4M Change Control Management Work InstructionДокумент2 страницы4M Change Control Management Work InstructionSameer Saxena100% (2)

- APQP TemplateДокумент7 страницAPQP TemplateBob ZepfelОценок пока нет

- Aperture and Area Ratio CalculationsДокумент26 страницAperture and Area Ratio Calculationssmtdrkd100% (1)

- SMT and Through Hole DFM GuidelinesДокумент30 страницSMT and Through Hole DFM Guidelinessmtdrkd100% (5)

- ALPHA Wave Troubleshooting Guide EN 01jun20 BRДокумент20 страницALPHA Wave Troubleshooting Guide EN 01jun20 BRThe HoangОценок пока нет

- Wave Solder SPC Chart CalculatorДокумент6 страницWave Solder SPC Chart CalculatorsmtdrkdОценок пока нет

- D10414410a Fmea MachiningДокумент13 страницD10414410a Fmea MachiningSuraj RawatОценок пока нет

- Aiag Ppap4Документ75 страницAiag Ppap4tamtom75Оценок пока нет

- Manufacturing Process Data Management: IPC 175X Schema Version 2.0Документ36 страницManufacturing Process Data Management: IPC 175X Schema Version 2.0Vitalii SkrypnykОценок пока нет

- Turtle Diagram Manufacturing ProcedureДокумент1 страницаTurtle Diagram Manufacturing ProcedureBAla100% (2)

- Quality Control PlanДокумент1 страницаQuality Control PlanScha Affin100% (1)

- Change Management Matrix for Vendor Updates in May 2022Документ1 страницаChange Management Matrix for Vendor Updates in May 2022nitin rathoreОценок пока нет

- Company Process Flow and FMEA DiagramsДокумент12 страницCompany Process Flow and FMEA DiagramsDINESH SHARMA100% (1)

- Customer:: Potential Failure Mode and Effect Analysis (Process FMEA)Документ8 страницCustomer:: Potential Failure Mode and Effect Analysis (Process FMEA)Rajnish PotdarОценок пока нет

- WI-824-003 First Article InspectionДокумент2 страницыWI-824-003 First Article InspectionAndreas Schlager100% (1)

- APQP FormsДокумент23 страницыAPQP FormsJOECOOL670% (1)

- Guidelines For Temperature Profiling For Mass Soldering Processes (Reflow & Wave)Документ3 страницыGuidelines For Temperature Profiling For Mass Soldering Processes (Reflow & Wave)Selvakumar100% (2)

- Aoi SMD As Per Ipc-A-610Документ7 страницAoi SMD As Per Ipc-A-610Satadal GuptaОценок пока нет

- Fmea CastingДокумент8 страницFmea CastingSuraj RawatОценок пока нет

- Road Map For IATF 16949 R-6 UpdatedДокумент1 страницаRoad Map For IATF 16949 R-6 UpdatedRavi javali100% (1)

- 001 B Operator TrainingДокумент129 страниц001 B Operator TrainingWandyy GonçalvesОценок пока нет

- Process Management for Quality AssuranceДокумент22 страницыProcess Management for Quality AssuranceVikas0% (1)

- 4th Edition PPAPДокумент83 страницы4th Edition PPAPTerri Paleno Lebow100% (1)

- 48 Point Ppap Check SheetДокумент39 страниц48 Point Ppap Check SheetSanjay KumarОценок пока нет

- APQP Sample FormatДокумент32 страницыAPQP Sample FormatManigandan RОценок пока нет

- GM 1927 16 Process Control Plan Audit PCPAДокумент7 страницGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemОценок пока нет

- Ipc A 630 (L)Документ36 страницIpc A 630 (L)Ramesh SОценок пока нет

- PPAPДокумент116 страницPPAPevan100% (1)

- FAI - SH0071 - Rev 21 - 14oct19Документ33 страницыFAI - SH0071 - Rev 21 - 14oct19anon_958736733100% (1)

- PPAP Audit Check SheetДокумент12 страницPPAP Audit Check Sheetmahesh100% (1)

- Ppap Master TabsДокумент37 страницPpap Master TabsRaju.PalОценок пока нет

- Lead-Free Alloy Profile SupplementДокумент6 страницLead-Free Alloy Profile SupplementVimal Kumar VarmaОценок пока нет

- Your Company Name 1680995-101 1680995-101 Bushing, Guide Slot E 2/1/2003 N/A 12/23/2005 0 John Smith Amy Millimen Jane Doe Bob Miller NameДокумент20 страницYour Company Name 1680995-101 1680995-101 Bushing, Guide Slot E 2/1/2003 N/A 12/23/2005 0 John Smith Amy Millimen Jane Doe Bob Miller Namekaran11deshmukhОценок пока нет

- Supplier Audit Checklist - ZftvsДокумент3 страницыSupplier Audit Checklist - Zftvsaboo2uОценок пока нет

- IPQC General FormatДокумент17 страницIPQC General FormatMohd Isa HarunОценок пока нет

- BrochureДокумент7 страницBrochureapi-239505062Оценок пока нет

- Tata Steel Corporate PresentationДокумент49 страницTata Steel Corporate Presentationjyoti mahajanОценок пока нет

- Mastercam 2023 Lathe enДокумент3 страницыMastercam 2023 Lathe en정동현Оценок пока нет

- Eccma February2008Newsletter PDFДокумент19 страницEccma February2008Newsletter PDFprsiva2420034066Оценок пока нет

- ATFMДокумент4 страницыATFMYuranan LimpananvadeeОценок пока нет

- Project Report On Vizag Steel Plant Distribution ChannelДокумент91 страницаProject Report On Vizag Steel Plant Distribution ChannelPrisin Sudakaran0% (1)

- Chimney Sizing Chart For Fireplaces: 100 50 30 20 15 10 8 Flue Area, inДокумент1 страницаChimney Sizing Chart For Fireplaces: 100 50 30 20 15 10 8 Flue Area, inBen ZithaОценок пока нет

- Unit 8. English Daily Test For Grade 5Документ3 страницыUnit 8. English Daily Test For Grade 5NINGSIHОценок пока нет

- Slide Management ContractingДокумент3 страницыSlide Management ContractingFairus IthninОценок пока нет

- The Evolution of Cyber Espionage - Jessica BourquinДокумент0 страницThe Evolution of Cyber Espionage - Jessica BourquinVivek KhareОценок пока нет

- TechTopics58 - E-Rated Vs R Rated FusesДокумент2 страницыTechTopics58 - E-Rated Vs R Rated FusesBigBaby JulianОценок пока нет

- 01JUN TardeДокумент259 страниц01JUN TardeDanBarberaОценок пока нет

- FlowVision English BRochureДокумент2 страницыFlowVision English BRochureSanthosh LingappaОценок пока нет

- Industrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDДокумент17 страницIndustrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDAmiruddin HassanОценок пока нет

- RISK ASESSMENT For SKYLIGHTДокумент23 страницыRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- AD 302: Tightening of Ordinary Bolts: Sci Advisory DeskДокумент2 страницыAD 302: Tightening of Ordinary Bolts: Sci Advisory DeskLightninWolf32Оценок пока нет

- Rotex Poly-Norm: Torsionally Flexible CouplingsДокумент27 страницRotex Poly-Norm: Torsionally Flexible CouplingsAngelica Ochoa FlorezОценок пока нет

- Internship - BajajДокумент27 страницInternship - BajajRoyal ProjectsОценок пока нет

- VOITH MultiformvДокумент3 страницыVOITH MultiformvKristina ivanovicОценок пока нет

- Tecnotion Torque Motor Brochure Ver 10120150120Документ16 страницTecnotion Torque Motor Brochure Ver 10120150120ElectromateОценок пока нет

- Cylinders FullДокумент110 страницCylinders FulltnvishОценок пока нет

- Multi-Entity Work Process Dor: Attachment B (Sample)Документ2 страницыMulti-Entity Work Process Dor: Attachment B (Sample)Gordon LongforganОценок пока нет

- SPEC Iron Roughneck ST 80CДокумент1 страницаSPEC Iron Roughneck ST 80Csorangel_123Оценок пока нет

- Project Title: Simple Cafe Billing System: Rajokari Institute of TechnologyДокумент8 страницProject Title: Simple Cafe Billing System: Rajokari Institute of TechnologyVinodОценок пока нет

- Fidic Quality Based Consultant Selection GuideДокумент20 страницFidic Quality Based Consultant Selection GuideJuan McdanielОценок пока нет

- Eeca QB PDFДокумент6 страницEeca QB PDFJeevanandam ShanmugaОценок пока нет

- AX2012-TechDomain M05 MoveEnvironment EditedДокумент31 страницаAX2012-TechDomain M05 MoveEnvironment Editedaxapta7Оценок пока нет

- Comparing Organizational Communications - Ford vs. ToyotaДокумент17 страницComparing Organizational Communications - Ford vs. ToyotaPaul R. HayesОценок пока нет

- TFG A 020Документ81 страницаTFG A 020Sergio FontechaОценок пока нет

- Store Layout & ArchitectureДокумент76 страницStore Layout & ArchitectureGyan Singh100% (1)