Академический Документы

Профессиональный Документы

Культура Документы

Design Data: Material Specification

Загружено:

John AlexanderОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design Data: Material Specification

Загружено:

John AlexanderАвторское право:

Доступные форматы

DESIGN CODE =

*MAWP (MEASURED AT TOP) = 1.76MPa (18 kgf/cm

2

)

OPERTAING PRESSURE = 1.796 mpa

OPERTAING TEMPERATURE = 78 C

DESIGN PRESSURE = 1.824439291 mpa [SHT-5]

DESIGN TEMPERATURE = 78 C

RADIOGRAPHY = FULL

JOINT EFFICIENCY = 1

CORROSION ALLOWANCE = 3 mm

MEDIUM = UTILITY GAS

SPECIFIC GRAVITY OF MEDIUM = 1 (ASSUME AN HIGHER SIDE)

FLUID DENSITY = 1000 Kg/m

HEIGHT OF MEDIUM = FULL OF WATER [SHT-5]

APPLICABLE LOADING = REFER SHEET No. 4

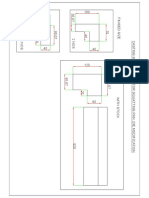

VESSEL SIZE = 1600 3MM ID x 2100 MM LG (T/L to T/L)

HEIGHT OF SKIRT = 1000 mm

MATERIAL SPECIFICATION Allowable stress(Mpa)

SHELL = SA 516 M Gr. 60 118

DISHED HEAD = SA 516 M Gr. 60

NOZZLE PIPE = SA 106M Gr. B

NOZZLE FLANGE = SA 105M

STUD BOLT = SA 193M Gr. B7 [SHT 39 TO 41]

HEX. NUT = SA 194 Gr. 2HM

MDMT = -27.6C @1.76MPa

THK OF INSULATION = 40 mm

*MAXIMUM ALLOWABLE WORKING PRESSURE

DESIGN DATA

ASME SEC VIII DIV I EDITION 2010ADDENDA 2011

a.

b.

c.

e

f

g

h

d.

INTERNAL PRESSURE (UG 21) REF. SHEET 10-14

EXTERNAL PRESSURE (UG 21) REF. SHEET -

2. VESSEL SUPPORTS SUCH AS LUGS, RINGS, SKIRTS, SADDLES AND LEGS. (AS PER APPENDIX G)

SADDLE &LUGS

APPLICABLE

1. INTERNALS (AS PER APPENDIX D ) REF. SHEET -

THE ATTACHMENT OF

LOADING TO BE CONSIDERED IN DESIGNING THE VESSEL

AS PER ASME SEC-VIII DIV.I.2010 EDITION UP TO & INCL. ADDENDA 2011 (UG-22)

TEMPERATURE GRADIENTS AND DIFFERENTIAL THERMAL EXPANSION. REF. SHEET NOT APPLICABLE

APPLICABLE

NOT APPLICABLE

WEIGHT OF THE VESSEL AND NORMAL CONTENTS UNDER OPERATING OR TEST CONDITIONS. (THIS

INCLUDES ADDITIONAL PRESSURE DUE STATIC HEAD OF LIQUIDS.) REF. SHEET 5

SUPERIMPOSED STATIC REACTIONS FROM WEIGHT OF ATTACHED EQUIPMENT SUCH AS MOTORS,

MACHINERY, OTHER VESSELS, PIPING, LININGS AND INSULATIONS. REF. SHEET

APPLICABLE

NOT APPLICABLE

CYCLIC AND DYNAMIC REACTIONS DUE TO PRESSURE OR THERMAL VARIATIONS OR FROM

EQUIPMENT MOUNTED ON A VESSEL AND MECHANICAL LOADINGS.

NOT APPLICABLE

WIND, SNOW AND SEISMIC REACTIONS, WHERE REQUIRED.REF. SHEET 11-13, 23- 33

WIND AND SEISMIC

APPLICABLE

IMPACT REACTIONS SUCH AS THOSE DUE TO FLUID SHOCK REF. SHEET NOT APPLICABLE

DESIGN PRESSURE CALCULATION

DESIGN PRESSURE CALCULATION

=

(VESSEL WITH FULL HEIGHT WATER CONSIDERED)

= mm

g DENSITY OF LIQUID = kg/

PRESSURE DUE TO LIQUID HEAD = Hg/101971.6 = 0.028 Mpa

DESIGN PRESSURE = MAWP + PRESSURE DUE TO LIQUID HEAD

= Mpa

VOLUME OF VESSEL

VOLUME OF VESSEL Vc = VOLUME OF SHELL + VOLUME OF HEAD

(2:1 ELLIPTICAL HEAD)

=

d1- I.D OF SHELL = 1600

l- LENGTH OF SHELL (T/L TO TL) = 2100

d2- I.D OF DISHED HEAD 1600

Vc = = 5.29

WEIGHT OF THE WATER DURING HYD. TEST = Vc X g X Velocity = 51914 N

*(Density of Water = 1000 kg/M

3

** Tolerance

***Assumed

1.824

H-HEIGHT OF LIQUID COLUMN

T/L TO T/L + INNER DEPTH OF BOTTOM HEAD + PROJECTION OF TOP NOZZLE

FROM UPPER T/L

1000

HEIGHT OF LIQUID COLUMN 2900

3

m

2 3

1 2

2

4 24

d L d

t t

+

3

m

2 3

1 2

2

4 24

d L d

t t

+

SL.No DESCRIPTION

1

ASME Boiler & Pressure Vessel

Code

2

ASME Boiler & Pressure Vessel

Code

3

ASME Boiler & Pressure Vessel

Code

4 Pipe Flange and Flange Fittings

5

Welded and Seamless Wrought

Steel Pipe

6 Metallic Gaskets for Pipe Flanges

7

Flange Fittings, Socket Welded and

Threaded

8

Design Loads for Buildings and

Structures

RADIOGRAPHY EXAMINATION REQUIREMENT

AS PER ASME SEC-VIII DIV.I.2007 EDITION UP TO & INCL. ADDENDA 2008 (UW-11)

APP

1

2 NOT APP

3 NOT APP

4 NOT APP

NOT APP

5 NOT APP

6 NOT APP

7 NOT APP

CONCLUSION:

FULL RADIOGRAPHY: - THE FOLLOWING WELDED JOINTS SHALL BE FULL RADIOGRAPHED.

ALL BUTT WELDS IN THE SHELL AND HEADS OF VESSEL USED TO CONTAIN LETHAL SUBSTANCES.

CODES &

- --

ASME 16.11

ASME 16.20

ASME 36.10M

ULTRASONIC EXAMINATION MAY BE SUBSTITUTED FOR RADIOGRAPHY FOR FINAL CLOSURE SEAM IF THE

CONSTRUCTION DOSE NOT PERMITS INTERPRETABLE RADIOGRAPHY.

APPLICABLE CODE, STANDARD AND REFERENCE BOOKS

ASME B 16.5

Section IX

Section II Part A and D

Section VIII Division I

YEAR & ADDENDA REMARKS

Applicable

Applicable

-

Applicable

Applicable

Applicable

Applicable

2010 Edition, Addenda

2011

2011 Edition, Addenda

2011

2012 Edition, Addenda

2011

2003 Edition

2004 Edition

2004 Edition

2001 Edition

Applicable

NOT APP

ALL BUTT JOINTS OF SEAM IN THE SHELL, HEAD TO SHELL TO BE FULLY RADIO GRAPHED AS PER CUSTOMER REQUIREMENT.

a) ALL CATEGORY A AND B WELDS CONNECTING SHELL OR HEADS SHALL BE TYPE NO.1 OR 2 OF TABLE UW-12.

b) ANY CATEGORY B AND C BUTT WELDS (EXCLUDING CATEGORY B AND C BUTT WELDS IN NOZZLES THAT

NEITHER EXCEED 250 NB NOR 29MM WALL THICKNESS) WHICH INTERSECT THE CATEGORY A BUTT WELDS IN

SHELL OR HEADS OR CONNECT SEAMLESS SHELL OR HEADS AND WHICH ARE NOT REQUIRED TO BE FULLY

RADIOGRAPHED BY POINT 1, 2, 3 OR 4 ABOVE SHELL AS A MINIMUM REQUIREMENT, BE SPOT RADIOGRAPHED.

ALL BUTT WELDS JOINED BY ELECTRO GAS WELDING WITH ANY SINGLE PASS GREATER THAN 38MM & ALL BUTT

WELDS JOINED BY ELECTRO SLAG WELDING

ALL BUTT WELDS IN THE SHELL AND HEADS OF VESSEL IN WHICH THE LEAST NOMINAL THK AT THE WELDED

JOINTS EXCEEDS 32MM AS PER UCS-57

ALL BUTT WELDS IN THE SHELL AND HEADS OF UNFIRED STEAM BOILERS HAVING A DESIGN PRESSURE

EXCEEDING 3.4bar

a) ALL BUTT WELDS IN NOZZLE ATTACHED TO SHELL OR HEAD WHICH ARE REQUIRED TO BE FULLY RADIO

GRAPHED AS PER POINT 1 OR 3 FOR EXEMPTION REF. POINT 4(b)

b) CATEGORIES B AND C BUTT WELDS IN NOZZLES AND COMMUNICATING CHAMBERS THAT NEITHER EXCEED

NPS 10 NOR 29MM WALL THICKNESS DO NOT REQUIRE ANY RADIOGRAPHIC EXEMPTION.

ALL CATEGORY A AND D BUTT WELDS IN SHELL AND HEAD WHERE DESIGN IS BASED ON JOINT EFFICIENCY 1 AS

PER UW 12(a) IN WHICH CASE.

DATA

MAWP : MAX. ALLOWABLE WORKING PRESSURE = 1.76 MPa AT 78C

MDMT : (TO BE DETERMINED AT 1.04MPa

GROUP

TO

CURVE

SHELL

P. NO.1 ; GR.

NO. 1

D

SHED HEAD

P. NO.1 ; GR.

NO. 1

D

NOZZLE

PIPE

P. NO.1 ; GR.

NO. 1

B

NOZZLE

FLANGE

P. NO.1 ; GR.

NO.2

NOT APP

UG 20(f) CONSIDERATION

1 MET

2 MET

3 MET

4 MET

5

SA 106 GR B

SA 105

18MM[SHT.10]

20MM[SHT.14]

10.16MM[SHT.18]

FOR P.NO.: 1 GROUP NO. 1 (OR) 2 MAX. THK < 12.5MM FOR MATERIAL LISTED IN CURVE A OF FIG. UCS 66 (OR) <

25.4MM FOR MATERIAL LISTED IN CURVE B,C,D OF FIG UCS 66

DETERMINATION OF COLDEST ALLOWABLE MINIMUM DESIGN METAL TEMPERATURE (MDMT)

USING UCS 66 RULES

PROVIDED THK

MATERIAL SPECN.

DESCRIPTIO

N

MATERIAL

MAX.

SA 516 Gr.60 (NORM)

SA 516 M Gr.60 (NORM)

10.16MM[SHT.18]

FOR THE VESSEL

*NOZZLE WHICH IS HAVING MAX. THK IS CONSIDERED.

**MIN. THK OF DISHED HEAD [ NOTE 1 OF FIG UCS 66.2]

THE COMPLETED VESSEL SHALL BE HYDRO TESTED AS PER UG 99(b), (c) OR (K)

DESIGN TEMP. WITHIN -29C TO 345C

THERMAL (OR) MECHANICAL SHOCK LOADING ARE NOT A CONTROLLING DESIGN REQUIREMENT

CYCLIC LOADING IS NOT A CONTROLLING DESIGN REQUIREMENT. SINCE ALL THE ABOVE THE

CONDITION ARE MET, IMPACT TEST IS NOT REQUIRED. HOWEVER CALCULATION HAS BEEN

PROCEEDED IN ORDER TO FIND OUT COLDEST ALLOWABLE MINIMUM DESIGN METAL TEMPERATURE

(MDMT)

CYCLIC LOADING IS NOT A CONTROLLING DESIGN REQUIREMENT. SINCE ALL THE ABOVE THE

CONDITION ARE MET, IMPACT TEST IS NOT REQUIRED. HOWEVER CALCULATION HAS BEEN

PROCEEDED IN ORDER TO FIND OUT COLDEST ALLOWABLE MINIMUM DESIGN METAL TEMPERATURE

(MDMT)

POST WELD HEAT TREATMENT REQUIREMENT

AS PER ASME SEC - VIII DIV. I. 2007 EDITION UP TO & INCL. ADDENDA 2008 (UCS -79)

APP

1 NOT APP

2 NOT APP

3 NOT APP

EXIST

COMPUTATION OF FIBER ELONGATION

THE EXTREME FIBER ELONGATION SHALL BE DETERMINED BY THE FOLLOWING FORMULAE.

PERCENTAGE OF EXTREME FIBER ELONGATION =

FOR DOUBLE CURVATURE(EX.HEAD) DISHED HEAD

WHERE, t = THICKNESS OF PLATE IN mm = 30

Rf = FINAL CENTERLINE RADIUS IN mm =

Ro = ORIGINAL CENTERLINE RADIUS (EQUALS INFINITY FOR FLAT PLATES) mm.

PERCENTAGE FO EXTREME FIBER ELONGATION =

*KNUCKLE RADIUS CONSIDERED SINCE MORE CRITICAL = 3.6

6 .31> 5

PERCENTAGE OF EXTREME FIBER ELONGATION

FOR SINGLE CURVE(EX.CLYLINDER) =

WHERE, t = THICKNESS OF PLATE IN mm = 30

Rf = FINAL CENTERLINE RADIUS IN mm = 803

Ro = ORIGINAL CENTERLINE RADIUS (EQUALS INFINITY FOR FLAT PLATES) MM.

FOR SHELL FOR MAN WAY

1.867995019

2.7 < 5

POST WELD HEAT TREATMENT OF VESSEL IS REQUIRED UNDER FOLLOWING CONDITIONS:

CONCLUSIONS: POST WELD HEAT TREATMENT REQ. FOR DISHED HEAD. HOWEVER STRESS RELIEVING OF EQUIPMENT AS A WHOLE IS DONE

AS PER CUSTOMER REQUIREMENT

4

WHEN A VESSEL IS USED TO CONTAIN LETHAL SUBSTANCES.

WHEN THE BUTT WELDS IN THE SHELL AND HEADS OF VESSEL IN WHICH THE LEAST NOMINAL THICKNESS AT THE

WELDED JOINTS EXCEEDS 38mm. MATERIAL OVER 32mm THROUGH 38mm NOMINAL THK WHEN PREHEAT IS

NOT APPLIED AT A MIN. TEMPERATURE OF 200F DURING WELDING (TABLE UCS 56)

WHEN THE MATERIAL REQUIRE IMPACT TESTING AS PER UCS 66 REF. SHEET

VESSEL SHELL SECTIONS, HEADS, AND OTHER PRESSURE BOUNDARY PARTS OF ALL CARBON AND LOW ALLOY

STEEL FABRICATED BY COLD FORMING SHALL BE HEAT TREATED. SUBSEQUENTLY (SEE UCS 56) WHEN THE

RESULTING EXTREME FIBER ELONGATION IS MORE THAN 5% FROM THE AS ROLLED CONDITION AND ANY ONE

OF THE FOLLOWING CONDITION EXISTS.

THE EXTREME FIBER ELONGATION MAY BE AS GREAT AS 40% WHEN NONE OF THE CONDITION LISTED ABOVE IN

1, 3, & 4 EXISTS.

FOR P.No:1 GR No.1 & 2 MATERIALS

c). THE TEMP. OF THE MATERIAL DURING FORMING IS IN THE RANGE OF 250F(120C) -900F(480C)

b). THE REDUCTION BY COLD FORMING FROM THE AS ROLLED THICKNESS IS MORE THAN 10%

a). THE THICKNESS OF THE PART BEFORE COLD FORMING EXCEEDS 16 mm

PERCENTAGE FOR EXTREME FIBER ELONGATION

75 24

= 6.31

285.2

75

(1 )

t Rf

Rf Ro

50

(1 )

t Rf

Rf Ro

DESIGN SHEET FOR CYLINDRICAL SHELL (INTERNAL PRESSURE)

AS PER ASME SEC VIII. DIV. I. 2007 EDITION UP TO & INCL. ADDENDA 2008

BASED ON OUT

SIDE RADIUS

DETERMINE SHELL THICKNESS DESIGN CONDITION

S ALLOWABLE STRESS [TABLE 1A***] = 118 Mpa

t1 25.0 mm

t2 = CALCULATED MINIMUM THK. OF SHELL [UG -16(4)] = 2.4 mm

With CORRODED ALLO. = t1+C 28.0 mm

= 28.0 mm

USE SHELL THICKNESS

USE 8mm. AS PER CUSTOMER REQUIREMENT 30 MM

REQD. THK. FOR NOZZ. REINFORCEMENT UG 37 (a)

tr = = 25.0

CONDITION

PH* - PRESSURE DUE TO LIQUID HEAD

*** OF ASME SEC II PART D 2007 EDITION UP TO & INCL. ADDENDA 2008

CONDITION FOR USING THE FORMULA

27 < 400 OK

1.8 < 45.43 OK 2) P < 0.385 SE

CYLINDRICAL SHELL UG-27(C )

INTERNAL PRESSURE DESIGN

t = REQUIRED THK. t =GREATER OF t1 OR t2 ( t + CA)

1) t < R/2

0.6

PR

SE P

0.6

PR

SE P

=

CALCULATION

CYLINDRICAL SHELL DESIGN (APPENDIX-L)

THREE CASE MUST BE INVESTIGATED TO DETERMINE THE MINIMUM SHELL THICKNESS

1. TENSILE STRESS

a) CIRCUMFERENTIAL TENSILE STRESS [UG-27(C)(1)]

b) LONGITUDINAL TENSILE STRESS [UG-27(C)(2)]

2. COMPRESSIVE STRESS [UG-23(b)]

CASE 1 (a) CIRCUMFERENTIAL TENSILE STRESS:

REQUIRED SHELL THK t MM =

P-DESIGN PRESSURE MPa = 1.824439291

R-CORRODED INNER RADIUS MM = 803

S-ALLOWABLE STRESS MPa = 118

MM = 25.19

CASE (b) LONGITUDINAL TENSILE STRESS:

REQUIRED SHELL THK t =

P-DESIGN PRESSURE MPa 1.796

R-CORRODED INNER RADIUS MM 807

S-ALLOWABLE STRESS MPa 118

MPa 141.6 * UG 23 (d)+

E- JOINT EFFICIENCY = 1

TO CALCULATED WIND MOMENT (M)

Vb-MAX WIND VELOCITY = 225 Km/hr = 62.5 m/s

[ Max. wind speed as per customer spec. GS-18 page 3]

Vz-DESIGN WIND SPEED = Vb x K1 x K2 x K3

IS 875 PART-3

K1-RISK COEFFICIENT = 1.08 [TABLE 1 PAGE No. 11]

= 1 [TABLE 1 PAGE No. 12]

K3-TOPOGRAPHY FACTOR = 1.36

SHELL DIA / SHELL LENGTH = 0.76 M

Vz = 91.8 m/s

DESIGN WIND PRESSURE Pz = 0.6 = 5056.344

SAY = 0.005 (for conversion factor see below)

DEFF = OUTSIDE DIA (Do) + 2 x INSULATION THK = (1600 +8+2x18)+ 2x40

H-OVER ALL HEIGHT = T/L TO T/L + TOP DISHED HEAD +HEIGHT + SKIRT HEIGHT .

= 2100 + (402+24)*1000 = 3526mm

H/Deff

Cf FORCE COEFFICIENT = 0.7 [TABLE 23 OF IS 875 PART-3-2007]

M-WIND MOMENT =

H 1 HEIGHT

OF VESSEL

T/L TO T/L + TOP DISHED HEAD +HEIGHT HEIGHT + SKIRT HEIGHT JUNCTION HEIGHT

= 2100 + (402.0+24)*+75.7

2600.9

K2-TERRAIN, HEIGHT AND STRUCTURE SIZE

FACTOR

( / 144)

0.6 0.6( / 144)

PR Hg R

SE P SE Hg

+

2

2 0.4

C

W W PR M

SE P R SE DSE t t

+

+

+

2

( )

Z

V

2

/ N m

2

/ N mm

3526.2

= 2.4

1723.64

=

2

1

( / 2) 1.3 Deff H Cf PZ

2

1600.9

1723.64 0.7 19.05 1.3

2

=

. N mm

M 27433927.8

t

= 5.9mm

PROVIDED THK OF SHELLt 15

= 15mm

Which is greater than the above two required thickness

1 Psi = 6894.757 Pa = 6894.757 N/m

2

= 0.00511 N/mm

2

[page 765 of ASME SEC II PART D]

WIND ALLOWANCE FACTOR FOR PIPING AND PLAT FORM EFFECT

*INNER DEPTH OF DISHED HEAD [SHT 5] + NOM.THK. OF DISHED HEAD [SHT-14]

** REF DRG. NO : 1936 /B SHT 1 OF 2

CASE (2) COMPRESSIVE STRESS

FACTOR A =

Ro OUTER RADIUS =

=

t CORRODED THK = 15mm

FACTOR A =

=

FACTOR B = 103.42 MPa * Figcs-2 of ASME SEC II PART D 2007+

ALLOWABLE COMPRESSIVE STRESS = 1.2 x 103.42= 124.1 MPa

WEIGHT OF VESSEL EXCLUDING EXTERNAL WEIGHT = 39366.7 N

WEIGHT OF EXTERNALS = 8896 N

EMPTY OF VESSEL = 48263 N SAY 49000N

WEIGHT OF LIQUID = CAPACITY OF VESSEL x DENSITY OF LIQUID

= 5.4 x 1000 x 9.81

= 52974N SAY 53000

OPERATING / TEST WEIGHT = 49000 +53000 = 102000 N

REQUIRED THK t =

=

= 0.1+ 0.162 = 0.262MM

PROVIDED THK. = 15MM [EXCLUSIVE OF CORROSION ALLO.]

CORRODED I.D OF SHELL = 2 x R

DESIGN SHEET FOR ELLIPSOIDAL HEAD (INTERNAL PRESSURE)

AS PER ASME SEC. VIII DIV.I-2007 EDITION UP TO & INCL. ADDENDA-2008

ELLIPSOIDAL HEAD UG-32(d) (BASED ON IN SIDE DIAMETER)

INTERNAL PRESSURE DESIGN

MATERIAL SA 516 M GR 485(Gr.60)

DESIGN TEMPERATURE 78C

DETERMINE HEAD THICKNESS DESIGN CONDITION

P DESIGN PRESSURE (MAWP+PH*) Mpa 1.80

CA - CORROSION ALLOWANCE MM 3

ID - INSIDE DIAMETER MM 1614**

S - ALLOWABLE STRESS [TABLE -1A ***] N/mm 103.42

E - JOINT EFFICIENCY 1

t 1 =

=

14 MM 14

t 2 = MINIMUM THK OF HEAD (UG-16) MM 2.4

REQD. THK t = GREATER OF = t1 (OR) t2 MM 14

t + CA

. N mm

2

1.796 807 27433927.8

2 124.1 1 0.4 1.796 807 124.1 1 t

= +

+

5.8 0.1 = +

0.125

where

( / ) Ro t

2

Do

1644*

= 822mm

2

0.125

(822 / 15)

0.0022 SAY 0.002

2

M W

R SE D SE t t

2

27433927.8 102000

807 124.1 1 2 807 124.1 1 t t

2 0.2

P ID

SE P

USE MIN. HEAD THICKNESS

PROVIDE THK. MM

USE NOM. HEAD THICKNESS MM 20

REQD. THK FOR NOZZLE REINFORCEMENTUG 37(a)(3)

(FOR NOZZLE LOCATED AT CENTER LINE OF HEAD ONLY)

P = DESIGN PRESSURE (MAWP. + )

Mpa 1.80

E = 0.85

K = 0.9 [TABLE UG- 37]

t 1 =

12.7 MM 12.7

* - PRESSURE DUE TO LIQUID HEAD

** CORRODED ID OF SHELL = 1600+2x3+8(TOLERANCE) = 1614MM

*** OF ASME SEC II PART D 2007 EDITION UP TO AND INCL. ADDENDA 2008.

USE 20MM MIN. AND 24MM NOM. AS PER AVAILABILITY OF MATERIAL

DESIGN SHEET FOR STD FLANGE RATTING UG -11(a) (2)

AS PER ASME SEC. VIII DIV.I-2007 EDITION UP TO & INCL. ADDENDA-2008

1. DESIGN PRESSURE : 1.796 MPa

2. DESIGN TEMPERATURE : 78 C

3. MATL. SPEC. OF FLANGE : SA 105 M [ MATERIAL GR. No. 1 & P. No.1]

4. FLANGE RATTING ASSUMED : 150 #

5. PRESSURE RATTING AT 149 F : 1.8 MPa

(AS PER TABLE -2 FOR CLASS 150 # OF ANSI B16.5 -2007)

6. DESIGN PRESSURE 1.796 MPa PRESSURE RATTING

7. SELECTED RATTING 150 # IS OK

8. ANSI B16.5 STD FLANGE USED FOR ALL FLANGED CONNECTIONS

NOTES:

** PRESSURE RATING AT 100F = 285 psi

PRESSURE RATING AT 200F = 260 psi

PRESSURE RATING AT 149F = 272.75 psi

= 1.8 MPa

*FROM TABLE 1A OF ANSI B16.5-2007

H

P

K

2 0.2

P D

SE P

2.1

Вам также может понравиться

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersДокумент30 страницWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilОценок пока нет

- Lifting Lug Calculation On Dish EndДокумент156 страницLifting Lug Calculation On Dish EndTejas Shah33% (3)

- New - Reinforcement of NozzleДокумент24 страницыNew - Reinforcement of NozzleVaniya GoelОценок пока нет

- Design Calculation Sheet: H2So4 Neutralization TankДокумент43 страницыDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunОценок пока нет

- Trunnion CalculationДокумент92 страницыTrunnion CalculationkarunaОценок пока нет

- Max Allowable Nozzle LoadДокумент1 страницаMax Allowable Nozzle Loaddskr fkshОценок пока нет

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Документ17 страницNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoОценок пока нет

- Lifting Lug Calculation For Small Horizontal VesselДокумент2 страницыLifting Lug Calculation For Small Horizontal VesselshaishavОценок пока нет

- Calculation For Sight Glass FlangeДокумент4 страницыCalculation For Sight Glass FlangeOmil Rastogi0% (2)

- Elliptical Head Design ToolДокумент1 страницаElliptical Head Design ToolSudjono BroОценок пока нет

- Stress Sample Calculation On Base EllДокумент1 страницаStress Sample Calculation On Base EllLionel TorradoОценок пока нет

- Output Data: Design CaseДокумент3 страницыOutput Data: Design CaseAnonymous RytT6uvX1Оценок пока нет

- Power Calculation For AgitatorДокумент12 страницPower Calculation For AgitatorDeepikaОценок пока нет

- MD He Tema Asme v0.1Документ31 страницаMD He Tema Asme v0.1Sharon Lambert100% (1)

- Lug - On - FlangeДокумент17 страницLug - On - Flangeshaishav100% (1)

- Blind Flange Design Calculation As Per Asme Section Vii Division - 1Документ4 страницыBlind Flange Design Calculation As Per Asme Section Vii Division - 1mukesh100% (2)

- Nozzle Calculation - Primary Reformer Stack-R0Документ22 страницыNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Section VIII CalДокумент19 страницSection VIII CalPradeep Kothapalli100% (1)

- Nozzle Design CalculationДокумент1 страницаNozzle Design CalculationSachin55860% (1)

- Mitered BendsДокумент1 страницаMitered BendsTsouki TsoukiОценок пока нет

- Design of Flanges - Loose Hub Type 2010Документ58 страницDesign of Flanges - Loose Hub Type 2010bakellyОценок пока нет

- Lifting Lug Cal PDFДокумент1 страницаLifting Lug Cal PDFveeru2906Оценок пока нет

- Longitudinal Bending Stress: M1 Allowable Limit RemarkДокумент16 страницLongitudinal Bending Stress: M1 Allowable Limit RemarkSandal JepitОценок пока нет

- 28 Roark Flat PlatesДокумент14 страниц28 Roark Flat Platesgutmont0% (1)

- Internal CoilДокумент2 страницыInternal CoilwhngomjОценок пока нет

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFДокумент4 страницыBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiОценок пока нет

- Piping Engineering - Tank Nozzle Loads 1Документ1 страницаPiping Engineering - Tank Nozzle Loads 1Nasrul AdliОценок пока нет

- N-318-5 Lug Local StressДокумент3 страницыN-318-5 Lug Local StresscohenfuОценок пока нет

- Pressure Vessel Design Calculations - by Abdel Halim Galala PDFДокумент127 страницPressure Vessel Design Calculations - by Abdel Halim Galala PDFsizmaru100% (1)

- Ibr CalculationsДокумент12 страницIbr CalculationsGopal RamalingamОценок пока нет

- External Pressure - Pressure Vessel EngineeringДокумент15 страницExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- IBR CalculationsДокумент20 страницIBR CalculationsSivi NallamothuОценок пока нет

- Design Procedure For Aes He PDFДокумент30 страницDesign Procedure For Aes He PDFRyan Goh Chuang HongОценок пока нет

- Saddle 3Документ3 страницыSaddle 3RUDHRA DHANASEKAR100% (1)

- Heat Transfer Through Pipe and InsulationДокумент1 страницаHeat Transfer Through Pipe and InsulationballisnothingОценок пока нет

- Design Calculation ReportДокумент151 страницаDesign Calculation ReportRaul Dolo QuinonesОценок пока нет

- Saddle CalcДокумент26 страницSaddle CalcVamsi S100% (2)

- Rectangular Tank SizingДокумент66 страницRectangular Tank SizinglavascudoОценок пока нет

- Volume Calculation For Pressure Vessel TankДокумент2 страницыVolume Calculation For Pressure Vessel Tanksai srikarОценок пока нет

- Tailing LugДокумент2 страницыTailing Lugjagannadha varmaОценок пока нет

- Design of Pressure Vessel (Int & Ext)Документ394 страницыDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- Appendix 2) : Optional Type Flange (Fig. 2-4 (8) )Документ18 страницAppendix 2) : Optional Type Flange (Fig. 2-4 (8) )hardik5818Оценок пока нет

- Check 18Документ6 страницCheck 18Anonymous qBwHKusОценок пока нет

- Shell and Tube HE CalculationДокумент16 страницShell and Tube HE CalculationPradip ShindeОценок пока нет

- What Is An ASME Appendix - 2 Flange Design PDFДокумент1 страницаWhat Is An ASME Appendix - 2 Flange Design PDFsurefooted1100% (1)

- Heat Exchanger DesignДокумент7 страницHeat Exchanger Designsiva sankarОценок пока нет

- ChimneyДокумент42 страницыChimneyAnand SwamiОценок пока нет

- Design As Per APIДокумент82 страницыDesign As Per APINeeraj BhallaОценок пока нет

- Design Computation Penstock 3Документ26 страницDesign Computation Penstock 3Roland TagufaОценок пока нет

- Design Tanks Menurut API 650Документ80 страницDesign Tanks Menurut API 650irbar.darmansyah.alwiОценок пока нет

- Thickness Cal. Fo DM Water Storage Tank-API 650Документ15 страницThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- API 650 10th Edition ErrataДокумент6 страницAPI 650 10th Edition ErrataJosé Ramón GutierrezОценок пока нет

- Asme Section VIII Division 1Документ15 страницAsme Section VIII Division 1JC SchwartzОценок пока нет

- Cs & Las Impact Req - Asme Sec Viii Div 2Документ16 страницCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareОценок пока нет

- Propeller PushupДокумент7 страницPropeller PushupMannMannОценок пока нет

- Filtro de Aire Metálico DL - EblackДокумент8 страницFiltro de Aire Metálico DL - EblackJavierОценок пока нет

- New - Reinforcement of NozzleДокумент31 страницаNew - Reinforcement of NozzleChagar HarshpalОценок пока нет

- LTA and Dryer Cylinders - Applying Mandatory Appendix 32Документ2 страницыLTA and Dryer Cylinders - Applying Mandatory Appendix 32GTpianomanОценок пока нет

- Footings For ColumnsДокумент9 страницFootings For ColumnsNidhi Sharma KhandelwalОценок пока нет

- Statical Calculation of 50m TowerДокумент25 страницStatical Calculation of 50m TowerAntenasmОценок пока нет

- viewNitPdf 3036481Документ4 страницыviewNitPdf 3036481John AlexanderОценок пока нет

- Sheet Metal Design-Handbook-Rev3 PDFДокумент12 страницSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- 2 Nos. WPS Signed by L&T Welding EnggДокумент20 страниц2 Nos. WPS Signed by L&T Welding EnggJohn AlexanderОценок пока нет

- Casting Work For Press PDFДокумент1 страницаCasting Work For Press PDFJohn AlexanderОценок пока нет

- Bottom Euro Type Tray: Assembly Drg. NoДокумент2 страницыBottom Euro Type Tray: Assembly Drg. NoJohn AlexanderОценок пока нет

- Icf Md-Spec-254 Rev-02Документ17 страницIcf Md-Spec-254 Rev-02John Alexander100% (1)

- Aircel Secret Codes For Checking Balance and Other OffersДокумент1 страницаAircel Secret Codes For Checking Balance and Other OffersJohn AlexanderОценок пока нет

- Laser TestДокумент2 страницыLaser TestJohn AlexanderОценок пока нет

- 3S Standard Cum Checklist Month: August 2019: by Using Broom SticksДокумент2 страницы3S Standard Cum Checklist Month: August 2019: by Using Broom SticksJohn AlexanderОценок пока нет

- Dia 500 Dish Tool-ModelДокумент1 страницаDia 500 Dish Tool-ModelJohn AlexanderОценок пока нет

- Nose 2 MMДокумент37 страницNose 2 MMJohn AlexanderОценок пока нет

- UntitledДокумент2 страницыUntitledJohn AlexanderОценок пока нет

- Beam 20031213Документ8 страницBeam 20031213John AlexanderОценок пока нет

- Iec License Guide LineДокумент33 страницыIec License Guide LineJohn AlexanderОценок пока нет

- Asme Calculation As Per Sec 8 Div1Документ11 страницAsme Calculation As Per Sec 8 Div1John AlexanderОценок пока нет

- English Through TamilДокумент90 страницEnglish Through TamilKhalifullah100% (1)

- Mplementing Strategies MbaДокумент15 страницMplementing Strategies MbaJohn AlexanderОценок пока нет

- AnalysisДокумент2 страницыAnalysisJohn AlexanderОценок пока нет

- Requested Books For Design Department in ASMEДокумент1 страницаRequested Books For Design Department in ASMEJohn AlexanderОценок пока нет

- Fastener Analysis: Scenario Mass (KG) G's Preload % # Bolts Mu FOSДокумент2 страницыFastener Analysis: Scenario Mass (KG) G's Preload % # Bolts Mu FOSJohn AlexanderОценок пока нет

- UntitledДокумент2 страницыUntitledJohn AlexanderОценок пока нет

- UntitledДокумент2 страницыUntitledJohn AlexanderОценок пока нет

- Asme Calculation As Per Sec 8 Div1Документ11 страницAsme Calculation As Per Sec 8 Div1John AlexanderОценок пока нет

- Manual ILC 151Документ132 страницыManual ILC 151Cristian PisitelloОценок пока нет

- GE Custom 8000 Horizontal Induction Motor - GEEP-124-I (1998)Документ41 страницаGE Custom 8000 Horizontal Induction Motor - GEEP-124-I (1998)Edson França Rodrigues100% (1)

- ReliabilityДокумент9 страницReliabilityWahab HassanОценок пока нет

- SOP For Handling of Rejected Raw MaterialДокумент6 страницSOP For Handling of Rejected Raw Materialanoushia alviОценок пока нет

- Simulation Exercise Manual HandbookДокумент44 страницыSimulation Exercise Manual HandbookMayte Gz100% (1)

- Autohex Ii BMW: Beyond The Edge of ImpossibleДокумент2 страницыAutohex Ii BMW: Beyond The Edge of ImpossibleJuank MrtОценок пока нет

- ANSI - Ahri Standard 550-590 (I-P) With Addendum 3Документ109 страницANSI - Ahri Standard 550-590 (I-P) With Addendum 3Afzal KhanОценок пока нет

- Astm f1554Документ3 страницыAstm f1554ingsabrinaОценок пока нет

- 120 W X 2 Channel Class D Audio Power Amplifier Using IRS20955 and IRF6645Документ43 страницы120 W X 2 Channel Class D Audio Power Amplifier Using IRS20955 and IRF6645Mazariegôs JJОценок пока нет

- GET OA Doc - Batch 2Документ3 страницыGET OA Doc - Batch 2Ganesh Sai VelidiОценок пока нет

- Vale International Pellet Plant PDFДокумент2 страницыVale International Pellet Plant PDFSrinivasanОценок пока нет

- English Today Vol 2Документ10 страницEnglish Today Vol 2StancuLucianОценок пока нет

- Id Based Multicast Secret-Key Management Scheme (SKMS) in ManetsДокумент10 страницId Based Multicast Secret-Key Management Scheme (SKMS) in ManetsSandhya RaniОценок пока нет

- 24 Plait 8ft Bullwhip RecipeДокумент9 страниц24 Plait 8ft Bullwhip RecipeTyler RiceОценок пока нет

- Speed Breaker Electric GenerationДокумент72 страницыSpeed Breaker Electric Generationparas bhogulkarОценок пока нет

- CIS Kubernetes Benchmark v1.4.1Документ254 страницыCIS Kubernetes Benchmark v1.4.1Anonymous 4uxmV5Z4oОценок пока нет

- Applications of Statistics and Probability in Civil EngineeringДокумент9 страницApplications of Statistics and Probability in Civil EngineeringAlexis CruzОценок пока нет

- Chapter 1 FinalДокумент13 страницChapter 1 FinalThahzeen KazifОценок пока нет

- ADP ObservationДокумент15 страницADP ObservationSanjay SОценок пока нет

- Patrick C Hall@yahoo - com-TruthfinderReportДокумент13 страницPatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithОценок пока нет

- Gmail - CAMPUS DRIVE NOTIFICATION - Himadri Speciality Chemical LTDДокумент2 страницыGmail - CAMPUS DRIVE NOTIFICATION - Himadri Speciality Chemical LTDShresth SanskarОценок пока нет

- Rattan Pole BendingДокумент21 страницаRattan Pole Bendingcintamore_jos355Оценок пока нет

- Information For New CustomersДокумент1 страницаInformation For New CustomersOctavian P TodirasОценок пока нет

- The Most Essential Phone Etiquette Rules To RememberДокумент4 страницыThe Most Essential Phone Etiquette Rules To Rememberpraks758Оценок пока нет

- NISSOS NIKOURIA - KYKLADES MARITIME - SpecsДокумент2 страницыNISSOS NIKOURIA - KYKLADES MARITIME - SpecsEkvazis TarsachОценок пока нет

- Deepak ResumeДокумент3 страницыDeepak ResumethiyaguyОценок пока нет

- Referencing Using The Documentary-Note (Oxford) System, Deakin UniversityДокумент9 страницReferencing Using The Documentary-Note (Oxford) System, Deakin UniversityjengadjОценок пока нет

- Foot Step Power Generation Using Piezoelectric MaterialДокумент3 страницыFoot Step Power Generation Using Piezoelectric MaterialYogeshОценок пока нет

- Walls2017 DemolitionforsustainableconstructionRGДокумент6 страницWalls2017 DemolitionforsustainableconstructionRGStefan GhidiuОценок пока нет