Академический Документы

Профессиональный Документы

Культура Документы

Eco Drain condensate drain

Загружено:

Catalin FrincuОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Eco Drain condensate drain

Загружено:

Catalin FrincuАвторское право:

Доступные форматы

www.kaeser.

com

Automatic Condensate Drains ECO DRAIN Series

For compressor capacities up to 1,700 m/min

www.kaeser.com

Eco Drain series

Electronic condensate drain

Condensate is an unavoidable result of air compression. If not reliably drained off at all collection points, it can cause costly downtime and damage to the compressed air system through corrosion. Electronic Eco Drain level-sensing condensate drains are therefore the perfect choice to perform this important task.

Loss-free condensate drainage

Eco Drain condensate drains ensure safe, dependable condensate drainage without air loss, even under conditions with widely fluctuating accumulation and high particle / oil content.

Essential system component

High quality, reliable condensate drains are a key component of any compressed air system that uses premium quality compressors and treatment equipment. They should also be simple to integrate throughout the entire system so that compressor controllers (Sigma Control) and master control systems (Sigma Air Manager) can react instantaneously to their signals, thereby enhancing system reliability and performance.

The industry standard

Quality, dependability and safe operation are essential features of any industrial machinery or equipment. The Eco drain meets all of these requirements. Versions are available to suit even the most hostile operating conditions, for example: highly aggressive condensate, freezing temperatures, high pressure or vacuum.

Compressed air network

Eco Drain

www.kaeser.com

Eco Drain

Eco Drain Condensate drain

Aquamat

All collection points must be fitted with a reliable means of draining condensate. Best results are achieved with an electronically controlled condensate drain.

Dependable condensate drainage without pressure loss

Fig.: Eco Drain 31

www.kaeser.com

Eco Drain series

Dependable condensate drainage without pressure loss

Click and go

Maintenance on the Eco Drain 30 and 31 couldnt be quicker or easier. A simple click is all thats needed to detach the service unit from the electronics module. Complicated disassembly is therefore no longer necessary.

Intelligent control electronics

The control electronics operate the discharge valve with such precision that all collected condensate is discharged without any loss of compressed air. This not only maximises compressed air use but also leads to considerable energy savings. All electrical components are splash-proof.

Self-monitoring

Should an alarm situation occur (e.g. a blocked discharge line), the unit waits 60 seconds before switching to alarm mode, which allows the Eco Drain to continue to operate. A flashing LED indicates the alarm and a floating contact enables alarm signals to be relayed.

Durable level sensor

The durable level sensor forms the basis for safe, reliable condensate drainage. The drain also works perfectly under conditions with high levels of contamination, even when filled with pure oil.

www.kaeser.com

Technical Specifications

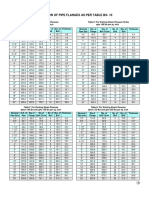

Model Pressure min. /max. Climate zone1) Max. compressor power according to climate zone 1/2/3 m3/min 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 1/2/3 3/2.5/1.5 6/5/3.5 12/10/7 12/10/7 8/6.5/4 8/6.5/4 35/30/20 35/30/20 150/130/90 150/130/90 1700/1400/1000 8/6.5/4 35/30/20 Dryer power max. 1/2/3 m3/min 6/5/3 12/10/7 24/20/14 24/20/14 16/13/8 16/13/8 70/60/40 70/60/40 300/260/180 300/260/180 3400/2800/2000 16/13/8 70/60/40 Filter power2) max. 1/2/3 m3/min 30/25/15 60/50/35 120/100/70 120/100/70 80/65/40 80/65/40 350/300/200 350/300/200 1500/1300/900 1500/1300/900 80/65/40 350/300/200 Fields of use Condensate3) a/b a/b a/b a a/b a a/b a a/b a a/b a/b a/b a/b Floating contact Dimensions WxDxH Weight

bar(g) Eco Drain 30 Eco Drain 31 Eco Drain 32 Eco Drain 32 CO Eco Drain 12 Eco Drain 12 CO Eco Drain 13 Eco Drain 13 CO Eco Drain 14 Eco Drain 14 CO Eco Drain 16 CO Eco Drain 12 CP PN 634) Eco Drain 13 CO PN 254)

1)

mm 65 x 149 x 118 74 x 165 x 127 74 x 211 x 157 74 x 211 x 157 65 x 150 x 141 65 x 150 x 141 93 x 212 x 162 93 x 212 x 162 120 x 252 x 180 120 x 252 x 180 280 x 260 x 280 65 x 150 x 141 93 x 197 x 162

kg 0.8 1 1.65 1.65 0.8 0.8 2.0 2.0 2.9 2.9 5.9 0.9 2.2

0.8/16 0.8/16 0.8/16 0.8/16 0.8/16 1.2/16 0.8/16 0.8/16 0.8/16 0.8/16 0.8/16 0.8/63 0.8/25

Climate zone: 1 = Dry/cool (Northern Europe, Canada, Northern USA, Central Asia); 2 = Temperate (Central and Southern Europe, some parts of South America, North Africa), 3 = Humid (South-East Asian coastal regions, Central America, Oceania, Amazonia and Congo regions) 2) Installed downstream from dryer 3) a = Condensate from fluid-cooled compressors, b = Aggressive condensate 4) For high pressure applications All models can be used in a temperature range from +1 C to +60 C

Eco Drain for vacuum/ low pressure 3 CO V / 3 V 6 CO V / 6 V

Condensate volume at 8 bar external control air l/h 43 228

Min. / max. working pressure bar(a) 0.1 - 1.8 0.1 - 1.8

Control pressure (external control air) bar(g) 4-8 4-8

Reverse flow volume (normal volume) l 2-3 15

Dimensions WxDxH mm 195 x 310 x 250 256 x 310 x 302

Weight kg 6.1 9.0

Electrical data Connection Max. power consumption Recommended cable diameter Recommended fusing 230 V / 1 Ph / 50-60 Hz 2 VA 3 x 0.75 mm 0.5 A

Floating contact AC DC max. 250 V / 1A min. 5 V / 10 mA

Options Heating Pipe heating Thermostatically controlled to prevent freezing of Eco Drain in ambient temperatures down to - 25 C (not suitable for 63bar high pressure version). Power supply 230 V / 1 Ph / 50 60 Hz, max. 125 W; scope of delivery: heating rod, adapter, gaskets. To be installed onsite to protect the inlet and discharge lines from freezing, temperature range - 25 C to + 60 C. Power 10 W/band metre, on-site installation. Scope of delivery: terminal box, heating band.

General design

Condensate inlet Collection chamber Level sensor Solenoid valve Valve diaphragm Balance line Valve seat Discharge line

Example: Eco Drain 31

The condensate passes through the condensate inlet (1) into the collection chamber (2). The level sensor (3) detects the presence of condensate and sends a signal to the drains control system when a preset condensate level is reached. This opens the solenoid valve (4) and also therefore the pressure balance line (6). The resulting pressure compensation causes the valve diaphragm (5) to open.

The condensate flows from the collector through the discharge line (8) from the drain. As soon as the minimum condensate level in the collection chamber is reached, the controller closes the solenoid valve. This causes a change in the pressure exerted on the diaphragm which in turn is re-closed and sealed via the spring.

Views

Eco Drain 30 / 31

G G

Eco Drain 32

Eco Drain 12

8-10 mm

13 mm

13 mm

Eco Drain 13

Eco Drain 14

Eco Drain 16

G G G G G G G G1

13 mm

13 mm

www.kaeser.com

KAESER

The world is our home

As one of the worlds largest manufacturers of rotary screw compressors, KAESER KOMPRESSOREN is represented throughout the world by a comprehensive network of branches, subsidiary companies and authorised partners in over 100 countries. With innovative products and services, KAESER KOMPRESSORENs experienced consultants and engineers help customers to enhance their competitive edge by working in close partnership to develop progressive system concepts that continuously push the boundaries of performance and compressed air efficiency. Moreover, the decades of knowledge and expertise from this industry-leading system provider are made available to each and every customer via the Kaeser groups global computer network. These advantages, coupled with KAESERs worldwide service organisation, ensure that all products operate at the peak of their performance at all times and provide maximum availability.

KAESER KompRESSoREn AG

P.O. Box 2143 96410 Coburg GERMANY Tel +49 9561 640-0 Fax +49 9561 640130 e-mail: productinfo@kaeser.com www.kaeser.com

P-741ED.14/12 Specifications are subject to change without notice

Вам также может понравиться

- Triplex Pump Part 1Документ30 страницTriplex Pump Part 1Rodolfo Castro86% (7)

- CSM MaxiДокумент8 страницCSM MaxiSomeUserОценок пока нет

- Gardner Denver - ESM30Документ8 страницGardner Denver - ESM30namnt11100% (1)

- McQuay BrochureДокумент24 страницыMcQuay BrochureAna Gil Pinto BrásОценок пока нет

- Iso 2553Документ54 страницыIso 2553lokesh38100% (2)

- Automatic Electronic Drain Valve Atlas Copco EWD 330Документ1 страницаAutomatic Electronic Drain Valve Atlas Copco EWD 330american_guy1050% (4)

- Fuel Gas System EquipmentДокумент6 страницFuel Gas System EquipmentPrasanna kumar subudhi100% (2)

- KAESER EcodrainДокумент7 страницKAESER EcodrainAlina NechitaОценок пока нет

- Geberit Piping Systems Catalogue 2010/2011Документ95 страницGeberit Piping Systems Catalogue 2010/2011Catalin Frincu0% (1)

- Baby Mait PDFДокумент2 страницыBaby Mait PDFChris LuОценок пока нет

- Csa Rotordryer PDFДокумент8 страницCsa Rotordryer PDFpeterpunk75Оценок пока нет

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentОт EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Fd60hz Secador Atlas Copco - ManualДокумент8 страницFd60hz Secador Atlas Copco - ManualEdvaldo França100% (1)

- Geberit TrapsДокумент32 страницыGeberit TrapsCatalin FrincuОценок пока нет

- FD Dryers CatalogДокумент13 страницFD Dryers CatalogmasrooorОценок пока нет

- Industrial Washing MachineДокумент10 страницIndustrial Washing MachineDiêm Công ViệtОценок пока нет

- Atlas Copco MD Dryer Brochure 2Документ12 страницAtlas Copco MD Dryer Brochure 2MistysParts100% (1)

- Elgi Screw CompressorДокумент12 страницElgi Screw CompressorRAVINDER DHINGRAОценок пока нет

- Sugar Plant Design CalculationДокумент78 страницSugar Plant Design CalculationBarlo Yñigo AlcantaraОценок пока нет

- Hankison - Secador Adsorcion HPD 300-3200 SCFM - EsДокумент8 страницHankison - Secador Adsorcion HPD 300-3200 SCFM - EsrobertohugosanchezОценок пока нет

- Catalogo ChillerДокумент8 страницCatalogo ChillerJoan Sebastian DazaОценок пока нет

- GEA Cassette-Geko DF KSДокумент64 страницыGEA Cassette-Geko DF KSCatalin FrincuОценок пока нет

- GEA Cassette-Geko DF KSДокумент64 страницыGEA Cassette-Geko DF KSCatalin FrincuОценок пока нет

- A General Review of The Causes and Acceptance of Shape ImperfectionsДокумент7 страницA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekОценок пока нет

- Bleeding Xpi Fuel System Scania XTДокумент3 страницыBleeding Xpi Fuel System Scania XTsam the fool100% (2)

- Advanced Temperature Measurement and Control, Second EditionОт EverandAdvanced Temperature Measurement and Control, Second EditionОценок пока нет

- Schuco-TH CTE220 Collector CH2-P3523Документ4 страницыSchuco-TH CTE220 Collector CH2-P3523MSEGLLCОценок пока нет

- 8573 4Документ19 страниц8573 4Catalin Frincu100% (2)

- Válvula ContrabalanceДокумент16 страницVálvula ContrabalanceMauricio Ariel H. Orellana100% (1)

- RENK MAAG Turbo GearboxesДокумент12 страницRENK MAAG Turbo Gearboxeshumayun121100% (1)

- Atlas Copco Ga - 160 - 315 - Brochure - 2013 - 0524 - LR - tcm824-3533059 PDFДокумент16 страницAtlas Copco Ga - 160 - 315 - Brochure - 2013 - 0524 - LR - tcm824-3533059 PDFimdatatasОценок пока нет

- Condensate Drains Eco Drain Series: For Compressed Air Deliveries Up To 1700 M /minДокумент3 страницыCondensate Drains Eco Drain Series: For Compressed Air Deliveries Up To 1700 M /minMihai ConstantinescuОценок пока нет

- Ecodrain ED 2000 3000 enДокумент8 страницEcodrain ED 2000 3000 enClaudio TurlherОценок пока нет

- Compressed Air Filters and Water Separators: Intelligent Air TechnologyДокумент6 страницCompressed Air Filters and Water Separators: Intelligent Air TechnologyOliver CambelОценок пока нет

- EDT GBTRДокумент4 страницыEDT GBTRAlistair Ciantar100% (1)

- Modular Water Cooled Water Chiller: Shandong Vicot Air Conditioning Co., LTDДокумент15 страницModular Water Cooled Water Chiller: Shandong Vicot Air Conditioning Co., LTDrafaelkiОценок пока нет

- Air TowerДокумент4 страницыAir Towersergio.gonzalezbaОценок пока нет

- Midea air conditioners give flexibility and economyДокумент4 страницыMidea air conditioners give flexibility and economyMohazil Ajil MohamedОценок пока нет

- Compressor GA 90 160 BrochureДокумент16 страницCompressor GA 90 160 BrochurePEDROОценок пока нет

- Total Quality Air Package: Atlas CopcoДокумент8 страницTotal Quality Air Package: Atlas CopcoCastillo PercyОценок пока нет

- Air DryerДокумент4 страницыAir Dryerrashm006ranjanОценок пока нет

- Coolers Catalog 2014Документ12 страницCoolers Catalog 2014MoriyasuNguyenОценок пока нет

- Afe Main Acc EsdДокумент2 страницыAfe Main Acc EsdEthan HuntОценок пока нет

- CD+ 25-260 Product Description EN Antwerp API 146E 46L1 Ed 00 PDFДокумент6 страницCD+ 25-260 Product Description EN Antwerp API 146E 46L1 Ed 00 PDFJesus MartinezОценок пока нет

- Refrigerant Dryer CatalogДокумент4 страницыRefrigerant Dryer CatalogManny MendozaОценок пока нет

- Acds R410a 60hz Ms0488a 0712 Npy RemoverДокумент40 страницAcds R410a 60hz Ms0488a 0712 Npy RemoverCarlos Javier PérezОценок пока нет

- At ThermostarДокумент8 страницAt ThermostarLam Ch100% (1)

- Chiller - CarrierДокумент27 страницChiller - CarrierJose Francisco Varela CruzОценок пока нет

- Ecodry - 3DK: Adiabatic CoolerДокумент12 страницEcodry - 3DK: Adiabatic CoolerMahendrajaya Gde SumawisesaОценок пока нет

- GPUSE09-04B-Product Line Up - DaikinДокумент12 страницGPUSE09-04B-Product Line Up - DaikinSiddharth KumarОценок пока нет

- Pressurization Equipment 370-383Документ14 страницPressurization Equipment 370-383Anonymous rMwYBU2Il1100% (1)

- ABAC GenesisДокумент8 страницABAC GenesisadrianrrccОценок пока нет

- Брошюра - Осушители Bd100-3000Документ8 страницБрошюра - Осушители Bd100-3000airpartОценок пока нет

- Ga 30-90Документ16 страницGa 30-90sancsa_74Оценок пока нет

- Joseph Dranetz Group 18 Final Oral PresentationДокумент20 страницJoseph Dranetz Group 18 Final Oral Presentationapi-265672374Оценок пока нет

- Compressed Air Dryer - USA - FinalДокумент14 страницCompressed Air Dryer - USA - FinalMohammad KhreibehОценок пока нет

- Inverter BrochureДокумент8 страницInverter BrochurephilОценок пока нет

- Air Compressor ASK-27TДокумент5 страницAir Compressor ASK-27TJonson CaoОценок пока нет

- Atlas Copco FX Refrigerant Air Dryers Protect Production and PipesДокумент8 страницAtlas Copco FX Refrigerant Air Dryers Protect Production and PipesjhedjesiОценок пока нет

- Citec Genesis Air Conditioner CatalogueДокумент4 страницыCitec Genesis Air Conditioner CatalogueSri WidodoОценок пока нет

- Accessories - ESD DrainДокумент2 страницыAccessories - ESD Drainmuhamad.badar9285Оценок пока нет

- FDbrochureДокумент13 страницFDbrochureAyman Mohammed Ibrahim AbdouОценок пока нет

- DryPower refrigeration dryers optimize compressed air purificationДокумент6 страницDryPower refrigeration dryers optimize compressed air purificationYanuar ZulkarnainОценок пока нет

- CSB 15 - 40 HP - enДокумент8 страницCSB 15 - 40 HP - enLeonardo RodriguezОценок пока нет

- Ga 11 - 30Документ16 страницGa 11 - 30Aji Beni LastomoОценок пока нет

- 1905 - Carrier 30 GZ 190 PDFДокумент6 страниц1905 - Carrier 30 GZ 190 PDFbilal almelegyОценок пока нет

- Trident Auto DrainДокумент10 страницTrident Auto DrainSathish KumarОценок пока нет

- Drytec - Refrigerated Compressed Air DryersДокумент8 страницDrytec - Refrigerated Compressed Air DryersJoanaRicardo FigueiredoОценок пока нет

- 30HXC CNДокумент12 страниц30HXC CNtechnokakiОценок пока нет

- N1 2Документ7 страницN1 2Vik KarОценок пока нет

- FOCSWATER.C Water Cooled Chiller - R134aДокумент8 страницFOCSWATER.C Water Cooled Chiller - R134antt_121987Оценок пока нет

- Prospekt KupplungДокумент12 страницProspekt KupplungCatalin FrincuОценок пока нет

- Obiecte Sanitare Inox ElceeДокумент52 страницыObiecte Sanitare Inox ElceeCatalin FrincuОценок пока нет

- Daikin VRV Catalogue 2012 - tcm511-256852Документ100 страницDaikin VRV Catalogue 2012 - tcm511-256852kasztakatikaОценок пока нет

- Varisco Solid Pumping SolutionsДокумент12 страницVarisco Solid Pumping SolutionsCatalin FrincuОценок пока нет

- Proprietatile Polietilenei de Inalta DensitateДокумент11 страницProprietatile Polietilenei de Inalta DensitateCatalin FrincuОценок пока нет

- Rurgaz Multisafe Tevi Polietilena Rezistente La Propagarea FisurilorДокумент8 страницRurgaz Multisafe Tevi Polietilena Rezistente La Propagarea FisurilorCatalin FrincuОценок пока нет

- Pe 100 RC Konti HidroplastДокумент16 страницPe 100 RC Konti HidroplastCatalin FrincuОценок пока нет

- Tek No Speed Pumps by LowaraДокумент20 страницTek No Speed Pumps by LowaraCatalin Frincu100% (1)

- Incledon CompanyДокумент12 страницIncledon CompanyCatalin FrincuОценок пока нет

- Tek No Speed Pumps by LowaraДокумент20 страницTek No Speed Pumps by LowaraCatalin Frincu100% (1)

- Standard Trench InstallationДокумент1 страницаStandard Trench InstallationCatalin FrincuОценок пока нет

- Geberit Shower Drainage System OverviewДокумент16 страницGeberit Shower Drainage System OverviewCatalin FrincuОценок пока нет

- 2012 - Chapter 14 - Geberit Appendix Sanitary CatalogueДокумент8 страниц2012 - Chapter 14 - Geberit Appendix Sanitary CatalogueCatalin FrincuОценок пока нет

- Devi PipeguardДокумент2 страницыDevi PipeguardCatalin FrincuОценок пока нет

- Devi PipeguardДокумент2 страницыDevi PipeguardCatalin FrincuОценок пока нет

- PressureVessels ReflexДокумент4 страницыPressureVessels ReflexCatalin FrincuОценок пока нет

- Devi PipeguardДокумент2 страницыDevi PipeguardCatalin FrincuОценок пока нет

- Geberit Concealed CisternsДокумент6 страницGeberit Concealed CisternsCatalin FrincuОценок пока нет

- Membrane Dryer Flow ConceptДокумент6 страницMembrane Dryer Flow ConceptCatalin FrincuОценок пока нет

- Course Outline (For Student)Документ3 страницыCourse Outline (For Student)hahahaОценок пока нет

- Manual Junta Giratoria Serie 3000 OPW PDFДокумент4 страницыManual Junta Giratoria Serie 3000 OPW PDFDarwin Newton TacoraОценок пока нет

- IP Ratings Chart V3 PDFДокумент1 страницаIP Ratings Chart V3 PDFsuprakashpaul93Оценок пока нет

- PIPE FLANGE DIMENSIONSДокумент5 страницPIPE FLANGE DIMENSIONSViral ParmarОценок пока нет

- Project References TableДокумент4 страницыProject References TableDiane Joy Fojas PanganibanОценок пока нет

- Schneider Electric - TeSys Contactors - Catalogue ChapterДокумент132 страницыSchneider Electric - TeSys Contactors - Catalogue ChapterdoniОценок пока нет

- Turbocharging and Supercharging ExplainedДокумент51 страницаTurbocharging and Supercharging ExplainedYoseph MershaОценок пока нет

- PowerpackДокумент26 страницPowerpackPeetОценок пока нет

- Retrofitting of Columns of An Existing Building byДокумент8 страницRetrofitting of Columns of An Existing Building bysp thipathiОценок пока нет

- Air cleaner system V2403M-T engine parts listДокумент3 страницыAir cleaner system V2403M-T engine parts listSergeyОценок пока нет

- NPTEL Fluid Mechanics MCQДокумент14 страницNPTEL Fluid Mechanics MCQVijayan SnОценок пока нет

- Bladedesign CalcДокумент55 страницBladedesign CalcMeiring PretoriusОценок пока нет

- Rotary vane vacuum pump guideДокумент6 страницRotary vane vacuum pump guideBubai111Оценок пока нет

- Full Control of A QuadrotorДокумент6 страницFull Control of A Quadrotornguyễn namОценок пока нет

- Datasheet Downhole-Fluid-Sampler en ScreenДокумент8 страницDatasheet Downhole-Fluid-Sampler en ScreenArash PourshoushtarОценок пока нет

- Clipse Ortometric Burners: Multi-Fuel Air Heating BurnersДокумент2 страницыClipse Ortometric Burners: Multi-Fuel Air Heating BurnersKarl WeierstrassОценок пока нет

- M0066206-02 (En-Us) - 00-ALLCD - 001Документ1 039 страницM0066206-02 (En-Us) - 00-ALLCD - 001Edilberto zegarra camposОценок пока нет

- Question Bank Me2401Документ13 страницQuestion Bank Me2401Anonymous p8bHAAxОценок пока нет

- Grade Markings For Steel Bolts and ScrewsДокумент3 страницыGrade Markings For Steel Bolts and Screwsrexie2canos8964Оценок пока нет

- PUNCHING STRESS CHECK COMPARISON OF ECP203 AND ACI318Документ10 страницPUNCHING STRESS CHECK COMPARISON OF ECP203 AND ACI318Abdelhamid MaymonОценок пока нет

- Amie Q Bank Thermal ScienceДокумент98 страницAmie Q Bank Thermal ScienceAurvin SinghОценок пока нет

- Ships: Related Commercial ResourcesДокумент5 страницShips: Related Commercial ResourcesMinhSon HaОценок пока нет