Академический Документы

Профессиональный Документы

Культура Документы

HVLS Fans

Загружено:

rijothomasv777Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HVLS Fans

Загружено:

rijothomasv777Авторское право:

Доступные форматы

E n e r g y - E f f i c i e n t Fa c t s

HIGH VOLUME LOW SPEED FANS

High volume low speed (HVLS) fans are the newest ventilation option available to dairy and livestock farmers. These large fans, which range in size from 16 to

Increasing Cow Comfort

Cow comfort is critical to a profitable dairy farm. Wetting down cows is the quickest, most cost-effective way to cool them, according to UW experts. Sprinklers should be an integrated part of a complete cow cooling system, which could include high-speed or HVLS fans. Fans increase the air velocity over the wet cow to increase evaporation, which further cools the cow. Whats the optimal air velocity for cow comfort? Theres no definitive answer, although air velocity in the 24 mph range is effective for most operations. Air velocity above 6 mph provides no additional value, according to UW experts.

24 feet, provide energy-efficient air movement throughout the barn at a fraction of the energy cost of high-speed fans.

Advantages of HVLS

The main advantage of an HVLS fan is its energy efficiency. One 20-foot fan typically moves approximately 125,000 cfm of air. It takes sixseven standard alley fans to provide similar air volume. Most HVLS fans have a 1 HP motor, moving the same volume of air for approximately one-third of the energy cost of six high-speed fans. According to a recent University of Wisconsin (UW) study, an HVLS fan costs approximately $1 per day to operate (14.5 kWh per day at $.07/kWh).

1

HVLS fans move large columns of air at a slow velocity, about 3 mph (260280 fpm). The UW study showed that HVLS systems provide more widespread air movement throughout the barn. Although high-speed fans provide more velocity, each unit impacts a small, focused area, leaving more "dead" air in the barn. High-speed fans are good for managing extreme heat, although they can cause your energy bills to increase significantly in the summer. HVLS systems are sometimes used year-round. In summer, HVLS fans provide essential cooling; in winter, the fans move drier air from ceiling to floor level and may result in a healthier environment for livestock. HVLS fans are virtually noiseless and may discourage bird and fly activity in the barn. In general, dairy farmers with HVLS systems told UW researchers they like the fans. Cows appear to be comfortable and dont bunch up. However, additional research is necessary to determine if HVLS fans have any impact on milk production.

Ideas with energy for todays farmers.

Is HVLS Right for You?

Because of their size, HVLS fans may not be appropriate for older, trussed freestall barns and stall barns with low ceiling heights. For post-and-rafter facilities with posts spaced at least 2030 feet apart, HVLS fans work well. Examples include freestall barns, holding areas and industrial-type spaces. Ideally, HVLS fans should be mounted 1618 feet from the ceiling and 5060 feet apart (measure from the center of the motor) over free stalls or the feed lane. The fans tend to wobble in the wind, so make sure the installed fans are adequately braced and provide plenty of leeway. Mounting a 24-foot fan in a 25-foot opening could eventually cause blade damage. HVLS fans cost approximately $4,200$5,000 each, including installation. While this is a large upfront investment, keep in mind that youll need six to seven high-speed fans at $200-$300 each to move the same volume of air. Energy savings over a high-speed fan system should make up the cost difference within two to three years. Barns with

A well-placed HVLS fan is approximately 16 feet off the floor in an area that isnt obstructed by a post, preferably a freestall barn or holding area. Fans should be placed approximately 60 feet apart.

The University of Kentucky College of Agriculture offers online calculators to estimate your return on investment and the number of HVLS fans your facility will need. Visit the Web site at www.ca.uky.edu and type HVLS fan into the search engine.

100200 amp electrical service may be able to install an HVLS system without rewiring. In addition, manufacturers claim that HVLS fans wont have to be replaced for at least 10 years. Because high-speed fans operate at a higher RPM, their motors could need to be replaced more quickly. Installing your HVLS fan with a control unit enables variable-speed operation, which allows you to run the fans at a slower speed on cooler days. It also reduces torque at start-up, providing a softer start thats easier on the fans motor. Control units are available for a variety of voltage requirements and can run one, three or five fans. The most common error farmers make while installing an HVLS system is to use fewer fans than recommended to save money. Spacing the fans too far apart will significantly diminish the systems benefits. Installation can be done in phases to manage the cost, but the planning needs to be done upfront so that the final system is effective.

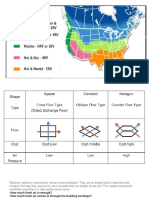

Air Velocities in feet per minute

Outside Velocity:

0 1 0 - 99 020 199 030 299 040 399 050 499 060 599 069 9 70 0+

585 fpm

Velocities Measurement Location

HVLS Fan

Alley

48'

Freestalls

26' Water

Alley

Freestalls 28' 68' 192' 68' 28'

HVLS fans create air movement (typically 23 mph) throughout the barn. By contrast, high-speed fans produce higher velocities in the area directly surrounding each fan, leaving large areas of dead air.The above velocity map shows the more even distribution of air in a barn served by three HVLS fans.The dark areas on the graph reflect the outdoor air coming in from the sidewalls and openings.

For More Information

To learn more about which ventilation system can help you reduce energy costs and improve your herds health and comfort, call Wisconsin Public Service at 1-877-444-0888. Our agricultural consultants can help you determine if an HVLS system is right for your operation.

UW researchers used smoke and soap bubbles to visualize the airflow in barns using HVLS fans.

David W. Kammel, et al.,Design of High Volume Low Speed Fan Supplemental Cooling System in Freestall Barns. For a full copy of the research, visit www.wisconsinpublicservice.com.

1

2003 Wisconsin Public Service EESFR-FS-1003A-G05 10/03

Вам также может понравиться

- Literary Review Team48Документ13 страницLiterary Review Team48Thea Marie SantarinОценок пока нет

- Water Source Heat Pump Systems: System DescriptionДокумент2 страницыWater Source Heat Pump Systems: System DescriptionsajuhereОценок пока нет

- Design of High Volume Low Speed Fan SupplementalДокумент14 страницDesign of High Volume Low Speed Fan SupplementalRupiah VNОценок пока нет

- Sizing Minimum Ventilation To Save Heating Energy in Swine HousingДокумент2 страницыSizing Minimum Ventilation To Save Heating Energy in Swine HousingaquilesreinaОценок пока нет

- High-Volume Low-Speed Fan: How HVLS Fans WorkДокумент3 страницыHigh-Volume Low-Speed Fan: How HVLS Fans WorkUlhasPolleОценок пока нет

- High Performance VAV Single Duct SystemДокумент6 страницHigh Performance VAV Single Duct Systemraghuragoo100% (1)

- Fan 1Документ5 страницFan 1HARSHAОценок пока нет

- Boiler Soot-Blowing in Power Plants - Compressed Air Best PracticesДокумент8 страницBoiler Soot-Blowing in Power Plants - Compressed Air Best PracticesRoland NicolasОценок пока нет

- HVAC - Air System BasicsДокумент2 страницыHVAC - Air System BasicsmohdnazirОценок пока нет

- Fan Selection For Poultry HousingДокумент4 страницыFan Selection For Poultry HousingImran YasinОценок пока нет

- White Paper: Hvls FansДокумент4 страницыWhite Paper: Hvls FansjaiderdelochoОценок пока нет

- Air Cooled Heat ExchangersДокумент5 страницAir Cooled Heat ExchangersRamuAlagappanОценок пока нет

- Difference Between HRV/ ERV and HRWДокумент13 страницDifference Between HRV/ ERV and HRWhbardhanОценок пока нет

- Air Cooled Heat ExchangersДокумент6 страницAir Cooled Heat ExchangersIoana PopescuОценок пока нет

- LabcairДокумент26 страницLabcairEmilia May AguinaldoОценок пока нет

- A Low-Cost, High Performance Lab HVAC DesignДокумент4 страницыA Low-Cost, High Performance Lab HVAC Designhtosar2Оценок пока нет

- Dual Duct Dual FanДокумент2 страницыDual Duct Dual FansajuhereОценок пока нет

- Chilled Beam - Engineering - GuideДокумент48 страницChilled Beam - Engineering - Guiderahulsoniin0% (1)

- EC Motor FansДокумент4 страницыEC Motor Fansrgopinath.gctОценок пока нет

- Refr Sys DesignДокумент13 страницRefr Sys Designعبدالله عمرОценок пока нет

- Reasons Engineers Are Choosing Dedicated OA SystemsДокумент3 страницыReasons Engineers Are Choosing Dedicated OA SystemsADsupermanОценок пока нет

- How Buildings Are Cooled Using AHUДокумент4 страницыHow Buildings Are Cooled Using AHUrgopinath.gctОценок пока нет

- Duct Design Myth BustersДокумент4 страницыDuct Design Myth BusterscphamfОценок пока нет

- Exhausto - Solutii VentilatiiДокумент12 страницExhausto - Solutii VentilatiialanatoraОценок пока нет

- 105 Converting Coarse Bubble Aeration To Fine BubbleДокумент3 страницы105 Converting Coarse Bubble Aeration To Fine BubbleLTE002Оценок пока нет

- BladeTec HVLS FansДокумент12 страницBladeTec HVLS Fansrijothomasv777Оценок пока нет

- Energy Efficiency Opportunity in FansДокумент23 страницыEnergy Efficiency Opportunity in Fansdhanusiya balamuruganОценок пока нет

- Cross-Ventilated Barns For Dairy Cows: New Building De-Sign With Cow Comfort in MindДокумент7 страницCross-Ventilated Barns For Dairy Cows: New Building De-Sign With Cow Comfort in MindSuseloОценок пока нет

- Energy Recovery VentilationДокумент3 страницыEnergy Recovery VentilationPrabhat KumarОценок пока нет

- A33 Si - Kitchen VentilationДокумент1 страницаA33 Si - Kitchen VentilationAhmed NabilОценок пока нет

- HvacДокумент4 страницыHvacFaiz MohОценок пока нет

- Ashrae Handbook Hvac ApplicationsДокумент9 страницAshrae Handbook Hvac Applicationsliza mae remorozaОценок пока нет

- Climate Master Com Proj LC007Документ48 страницClimate Master Com Proj LC007Daud Simon AОценок пока нет

- Fantastic Godbey JohnsonДокумент8 страницFantastic Godbey JohnsonOleg LevchiyОценок пока нет

- Commercial Building ChecklistsДокумент23 страницыCommercial Building Checklistsmnt6176Оценок пока нет

- Guide To Savings: Compressed Air SystemsДокумент8 страницGuide To Savings: Compressed Air Systemsjaime100% (1)

- Duct DesignДокумент3 страницыDuct DesignFaquruddin AliОценок пока нет

- Commercial Building ChecklistsДокумент23 страницыCommercial Building Checklistsax33m144Оценок пока нет

- By Douglas C. Hittle, PH.D., Fellow ASHRAEДокумент5 страницBy Douglas C. Hittle, PH.D., Fellow ASHRAENiong DavidОценок пока нет

- Hvac Fans Selection Parameters PDFДокумент0 страницHvac Fans Selection Parameters PDFMohamed Shobat100% (1)

- Active Passive Beams Engineering GuideДокумент48 страницActive Passive Beams Engineering GuideAshraf Adel Nashed ZakiОценок пока нет

- High Volume Low Speed (HVLS) Fans FansДокумент2 страницыHigh Volume Low Speed (HVLS) Fans FansthehvlsОценок пока нет

- Lecture 6 Zoning in HvacДокумент32 страницыLecture 6 Zoning in HvacBhaskar BhatiaОценок пока нет

- Air Release Valve Sizing Chart - How To Choose The Right ValveДокумент8 страницAir Release Valve Sizing Chart - How To Choose The Right Valvemyself_riteshОценок пока нет

- HEPA Filtration Recommendations. To Minimize The Chance of Future VirusesДокумент3 страницыHEPA Filtration Recommendations. To Minimize The Chance of Future VirusesCherrylene FranciscoОценок пока нет

- Solving Kitchen Ventilation ProblemsДокумент6 страницSolving Kitchen Ventilation ProblemsJohn DiasОценок пока нет

- Abstract Fahad Riaz 034Документ13 страницAbstract Fahad Riaz 034Saim TufailОценок пока нет

- As D CalculatorsДокумент14 страницAs D CalculatorsPatricio TamayoОценок пока нет

- Mejoras en Sistemas ACS HospitalesДокумент5 страницMejoras en Sistemas ACS HospitalesCarlos Eduardo PerezОценок пока нет

- Course Content: Fundamentals of HVAC ControlsДокумент39 страницCourse Content: Fundamentals of HVAC ControlsMuhammad AfzalОценок пока нет

- Correct Duct SizingДокумент3 страницыCorrect Duct Sizingnim_gourav1997100% (1)

- Direct or Indirect Heating?: A Look at Kitchen Ventilation Make-Up Air SystemsДокумент3 страницыDirect or Indirect Heating?: A Look at Kitchen Ventilation Make-Up Air SystemsYıldız GökОценок пока нет

- Screw Comp VS Reciproctng CompДокумент2 страницыScrew Comp VS Reciproctng CompKRUNALОценок пока нет

- Project ReportДокумент29 страницProject Reportgeetikag_23Оценок пока нет

- HvacДокумент16 страницHvacMica Tagalog DaubaОценок пока нет

- Syllabus Fans and Blowers: Types, Performance Evaluation, Efficient System Operation, FlowДокумент16 страницSyllabus Fans and Blowers: Types, Performance Evaluation, Efficient System Operation, FlowGaurav ShrivastavaОценок пока нет

- Literature Review: Forced Draft and Induced Draft FansДокумент6 страницLiterature Review: Forced Draft and Induced Draft FansAlif Nur FirdausОценок пока нет

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Small Wind: Planning and Building Successful InstallationsОт EverandSmall Wind: Planning and Building Successful InstallationsРейтинг: 5 из 5 звезд5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AОт EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AОценок пока нет

- Intelligent Fluid Management SystemДокумент8 страницIntelligent Fluid Management Systemrijothomasv777Оценок пока нет

- Armstrong Booster PumpsДокумент4 страницыArmstrong Booster Pumpsrijothomasv777Оценок пока нет

- 35 11 SG FTV BrochureДокумент8 страниц35 11 SG FTV Brochuresyed aliОценок пока нет

- Armstrong Close-Coupled Pump (Monobloc)Документ4 страницыArmstrong Close-Coupled Pump (Monobloc)rijothomasv777100% (1)

- Armstrong Vertical In-Line PumpsДокумент6 страницArmstrong Vertical In-Line Pumpsrijothomasv777Оценок пока нет

- Armstrong Design Envelope PumpsДокумент20 страницArmstrong Design Envelope Pumpsrijothomasv777Оценок пока нет

- Armstrong Fluid Technology - Complete Product Offering.Документ40 страницArmstrong Fluid Technology - Complete Product Offering.rijothomasv777Оценок пока нет

- Danfoss-Fc 051 CatalogДокумент8 страницDanfoss-Fc 051 Catalogrijothomasv777Оценок пока нет

- Now Purity, Coolness & Freshness Flow Into Your WorldДокумент2 страницыNow Purity, Coolness & Freshness Flow Into Your Worldrijothomasv777Оценок пока нет

- EasyFlex Spring HangerДокумент2 страницыEasyFlex Spring Hangerrijothomasv777Оценок пока нет

- VLT - HVAC - Basic - Drive Brochure - Hospital Alor SetarДокумент8 страницVLT - HVAC - Basic - Drive Brochure - Hospital Alor SetarNorsyafiqah RoziОценок пока нет

- High Performance Axial Fans: Model RA - Standard and High TemperatureДокумент8 страницHigh Performance Axial Fans: Model RA - Standard and High Temperaturerijothomasv777Оценок пока нет

- LabSox Brochure-Mar2015-web-6pg PDFДокумент6 страницLabSox Brochure-Mar2015-web-6pg PDFrijothomasv777Оценок пока нет

- Coatings For Extreme Applications: Perma-Z Hi-Pro-ZДокумент4 страницыCoatings For Extreme Applications: Perma-Z Hi-Pro-Zrijothomasv777Оценок пока нет

- VRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010Документ2 страницыVRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010rijothomasv777Оценок пока нет

- Cas-White Chemical Resistant and Anti SlipДокумент28 страницCas-White Chemical Resistant and Anti SlipAnonymous llBSa7Оценок пока нет

- Atex Eng PDFДокумент1 страницаAtex Eng PDFEОценок пока нет

- Siemens PICV ValvesДокумент8 страницSiemens PICV Valvesrijothomasv777Оценок пока нет

- Bluestar Organisation StructureДокумент1 страницаBluestar Organisation Structurerijothomasv777Оценок пока нет

- BladeTec HVLS FansДокумент12 страницBladeTec HVLS Fansrijothomasv777Оценок пока нет

- Tabla de Frame Motores Baldor IEC y NEMAДокумент2 страницыTabla de Frame Motores Baldor IEC y NEMAenicolas2100% (1)

- STV General Information: Threshold Amount Rs Deduction Amount Rs Deduction Amount RsДокумент3 страницыSTV General Information: Threshold Amount Rs Deduction Amount Rs Deduction Amount Rsrijothomasv777Оценок пока нет

- Encon Basement VentilationДокумент15 страницEncon Basement VentilationEngJtonuiОценок пока нет

- History of BluestarДокумент2 страницыHistory of Bluestarrijothomasv777Оценок пока нет

- Small HVAC System GuideДокумент96 страницSmall HVAC System GuideMalcolm ChanОценок пока нет

- VRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010Документ2 страницыVRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010rijothomasv777Оценок пока нет

- Física Básica II - René CondeДокумент210 страницFísica Básica II - René CondeYoselin Rodriguez C.100% (1)

- CFM56-5A-5B CO-063 Basic Engine Feb2014Документ27 страницCFM56-5A-5B CO-063 Basic Engine Feb2014Kelik Arif100% (1)

- Philips AZ 1839 Service ManualДокумент7 страницPhilips AZ 1839 Service ManualEdwardОценок пока нет

- Pre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumДокумент13 страницPre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumMc_RivОценок пока нет

- Motor Driver Board Tb6560-5axisДокумент14 страницMotor Driver Board Tb6560-5axisAli Asghar MuzzaffarОценок пока нет

- LabVIEW Project Report Complete HPK Kumar DetailedДокумент62 страницыLabVIEW Project Report Complete HPK Kumar DetailedDanny Vu75% (4)

- SYS600 System ConfigurationДокумент256 страницSYS600 System ConfigurationDang JinlongОценок пока нет

- CONTRIBN MADE by Deming, Juran and CrosbyДокумент14 страницCONTRIBN MADE by Deming, Juran and CrosbySachin Methree100% (1)

- Thread CuttingДокумент7 страницThread CuttingJulia Turpo SuarezОценок пока нет

- Ballastless TracksДокумент20 страницBallastless TracksYacoub Cheikh67% (3)

- Commodity Market (A Project Report)Документ6 страницCommodity Market (A Project Report)Manish GargОценок пока нет

- SAFMC 2023 CAT B Challenge Booklet - V14novДокумент20 страницSAFMC 2023 CAT B Challenge Booklet - V14novJarrett LokeОценок пока нет

- LX Capacity Chart Hydrogen SCFM 10-2008 PDFДокумент5 страницLX Capacity Chart Hydrogen SCFM 10-2008 PDFZack AmerОценок пока нет

- AIS - 007 - Rev 5 - Table - 1Документ21 страницаAIS - 007 - Rev 5 - Table - 1Vino Joseph VargheseОценок пока нет

- C8813 ÇДокумент39 страницC8813 ÇZawHtet Aung100% (1)

- Prince CPVC Pipes and Fittings Pricelist1Документ1 страницаPrince CPVC Pipes and Fittings Pricelist1Dee Raja38% (8)

- Optimization of Fuel Additive Utilisation at Boiler of Paiton Coal Fired Steam Power Plant Unit 1& 2Документ12 страницOptimization of Fuel Additive Utilisation at Boiler of Paiton Coal Fired Steam Power Plant Unit 1& 2fajar noviantoОценок пока нет

- Astm A325mДокумент8 страницAstm A325mChitra Devi100% (1)

- Is 15462 2004 Modified Rubber BItumen PDFДокумент16 страницIs 15462 2004 Modified Rubber BItumen PDFrajeshji_000100% (3)

- Schlafhorst Texlab: Catalogue of ServicesДокумент27 страницSchlafhorst Texlab: Catalogue of ServicesvenkatspinnerОценок пока нет

- Ad-All Ss Pressure GaugeДокумент5 страницAd-All Ss Pressure Gaugepankaj doshiОценок пока нет

- Collateral Document Management System: User'S ManualДокумент10 страницCollateral Document Management System: User'S ManualGerard DGОценок пока нет

- Westerbeke 4,5BCGTC Instruction Manual PDFДокумент53 страницыWesterbeke 4,5BCGTC Instruction Manual PDFcengiz kutukcu100% (2)

- Kinematics of MachinesДокумент2 страницыKinematics of MachinesBhavesh J MakwanaОценок пока нет

- Media Gateway SoftswitchДокумент10 страницMedia Gateway SoftswitchMahmoud Karimi0% (1)

- A88JY ManualДокумент6 страницA88JY ManualionmocanuОценок пока нет

- Aerocon BlocksДокумент5 страницAerocon BlocksLeigh Hudson100% (2)

- Atm ProjectДокумент18 страницAtm Projectsujit_ranjanОценок пока нет

- A Review of Error-Related Potential-Based Brain-Computer Interfaces For Motor Impaired PeopleДокумент16 страницA Review of Error-Related Potential-Based Brain-Computer Interfaces For Motor Impaired PeopleAkshay KumarОценок пока нет

- ALR Compact Repeater: Future On DemandДокумент62 страницыALR Compact Repeater: Future On DemandmickycachoperroОценок пока нет