Академический Документы

Профессиональный Документы

Культура Документы

78 - Triumph Stoker Brochure

Загружено:

Matias MancillaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

78 - Triumph Stoker Brochure

Загружено:

Matias MancillaАвторское право:

Доступные форматы

THOMPSON TRIUMPH

Chaingrate Stoker

An

alstom technology partner

JOHN THOMPSON TRIUMPH Chaingrate Stoker

Design Concept

Cross-feed firing, inherently smokeless Robust design and construction for long life Total package incorporates a chain-grate stoker with AC variable speed drive, FD fan, combustion controls and control panel

Combustion Efficiencies

Typical 93% for Smalls size coal Typical 97% for Peas size coal Efficiencies based upon: Smalls coal GCV 26 MJ/kg Peas coal GCV 28 MJ/kg Suitable for boiler ratings from 1 800 kg/h to 10 500 kg/h Suitable for furnace ratings from 1 000 kW to 6 000 kW

Quality

Quality system is accredited to SANS 9001: 2000 All cast iron components are produced at the JT foundry under the Meehanite process the international benchmark for guaranteed quality

Full range of support services available.

Combustion on the John Thompson Triumph Chaingrate Stoker takes place in three stages:

Firstly, the volatiles or tarry fraction is distilled off and the coal ignited, then the coke formed during the first stage is burned leaving a layer of ash on the grate, and finally the ash is transported to the ash port through a high temperature oxidizing atmosphere to burn off most of the remaining carbon. For efficient combustion to take place the air provided by the forced draught fan must be evenly distributed across the fuel bed. There are three devices inside the stoker for controlling air distribution. These are: Fixed inlet guide vanes to distribute the air evenly across its width Controllable undergrate dampers to regulate the amount of air which is allowed to flow to the tail end of the stoker Fixed vanes located at the end of the stoker to distribute the air through the carbon lean ash layer which has a low resistance to air flow. From a fundamental analysis of combustion on the stoker it follows that there are three coal characteristics which affect performance: The rate at which the coal can be ignited. This is measured to a certain extent by the volatile content but because volatiles can contain inert gases, samples are best tested in a combustion pot which is designed to measure the rate of ignition of a particular sample The particle size distribution which dictates the resistance to air flow through the fuel bed, and The ash fusion temperature. Low ash fusion temperature coals cannot be burnt at high combustion intensities without fear of slag formation on the grate.

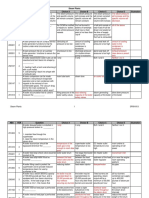

Stoker Model Number

Nominal Grate Area Overall Length Minimum Inside Diameter of Furnace Length in Furnace Approximate Mass of Complete Stoker Stoker Drive Motor FD Fan Motor

TT

m2 mm mm mm kg kW kW

180

1.4 2 661 925 1 536 1 944 0.18 1.1

320

2.3 3 891 925 2 766 2 466 0.18 2.2

500

3.1 3 660 1 240 2 385 3 250 0.18 4.0

675

4.3 4 120 1 420 2 844 4 358 0.18 7.5

800

5.0 4 270 1 610 2 915 4 459 0.18 11

1050

6.6 4 955 1 778 3 525 5 908 0.18 11

Note: All dimensions and masses are approximate only. Whilst all information is given in good faith, it should be confirmed before establishing any contractual commitment.

JOHN THOMPSON. A division of ACTOM (Pty) Ltd

Cape Town Head Office PO Box 129, Bellville, RSA, Tel:+27(0)21 959-8400, Fax:+27(0)21 959-8545, e-mail:info@johnthompson.co.za Johannesburg Office PO Box 8382, Edenglen, RSA, Tel:+27 (0)11 392-0900, Fax:+27 (0)11 392-0938, e-mail: infojhb@johnthompson.co.za Durban Office PO Box 32292, Mobeni, RSA, Tel:+27 (0)31 408-9700, Fax:+27 (0)31 408-9722, e-mail: infodbn@johnthompson.co.za

www.johnthompson.co.za

Вам также может понравиться

- Boiler Shut Down 7.10Документ7 страницBoiler Shut Down 7.10Shilca BarriosОценок пока нет

- Research Study Diesel To BiomassДокумент9 страницResearch Study Diesel To BiomassDarrel MagnoОценок пока нет

- Jfe Stoker SystemДокумент9 страницJfe Stoker SystemJose Lorenzo Toral100% (1)

- EPRF Report Com Fulton Steam BoilersДокумент13 страницEPRF Report Com Fulton Steam BoilersBlackzero68Оценок пока нет

- Project On Conservation of Steam in Electroplating in Hero CyclesДокумент7 страницProject On Conservation of Steam in Electroplating in Hero Cyclessharanjeet4uОценок пока нет

- Steam PlantsДокумент228 страницSteam PlantsMark Allen San Antonio100% (1)

- Boiler Warburton 1981Документ197 страницBoiler Warburton 1981Sai AravindОценок пока нет

- DZL 4-1.25-AiiДокумент10 страницDZL 4-1.25-AiiSamulaОценок пока нет

- Tugas BoilerДокумент33 страницыTugas BoilerAgus Dwi Nurcahyo JemberОценок пока нет

- 750 204 OM Profire D LND Apr08Документ120 страниц750 204 OM Profire D LND Apr08Rosanny Borges ChirinosОценок пока нет

- Miura Boilers Steam GeneratorsДокумент2 страницыMiura Boilers Steam GeneratorsDhonyAhmedPradjoegoОценок пока нет

- Kusile Training Teil 2 File-064 - Soot Blowers - 20170116Документ50 страницKusile Training Teil 2 File-064 - Soot Blowers - 20170116Msimanga Arnold BudalОценок пока нет

- Pump Manual - Single Plunger AmbicaДокумент24 страницыPump Manual - Single Plunger AmbicaHimTex /JaswinderОценок пока нет

- Boiler Mounting & AccessoriesДокумент14 страницBoiler Mounting & Accessoriesshiraj36100% (1)

- PRO 810354 02 Poster-SteamBoilerEquipment enДокумент1 страницаPRO 810354 02 Poster-SteamBoilerEquipment enbertan dağıstanlıОценок пока нет

- Training ReportPDF PDFДокумент42 страницыTraining ReportPDF PDFAman RajОценок пока нет

- Claver Brooks General Boiler InformationДокумент10 страницClaver Brooks General Boiler Informationnecio77Оценок пока нет

- SSGC New ConnectionДокумент19 страницSSGC New ConnectionmimranislamОценок пока нет

- C&I in CFBC-1Документ25 страницC&I in CFBC-1Prudhvi RajОценок пока нет

- Boilers and Thermic Fluid HeatersДокумент53 страницыBoilers and Thermic Fluid HeatersAamirMalikОценок пока нет

- Steam Power Plant and CoalДокумент74 страницыSteam Power Plant and CoalRahul SoniОценок пока нет

- Boiler Tuning BasicДокумент25 страницBoiler Tuning Basictrung2iОценок пока нет

- SOPДокумент29 страницSOPKeniBataraОценок пока нет

- Boiler Safety: Chapter - 13Документ10 страницBoiler Safety: Chapter - 13sunitbhaumikОценок пока нет

- Boiler Control Standard Proposal - 1Документ3 страницыBoiler Control Standard Proposal - 1Hery PrabowoОценок пока нет

- Boiler Emergencies - 2017Документ10 страницBoiler Emergencies - 2017RAJKUMAR100% (1)

- Ygnis Ingl+ S Multiflam 170.1-200.1Документ24 страницыYgnis Ingl+ S Multiflam 170.1-200.1DihorulОценок пока нет

- Cheema Boiler Limited: Presented To: MR - Deepak Bhandari (Документ32 страницыCheema Boiler Limited: Presented To: MR - Deepak Bhandari (angenious100% (1)

- Boiler Parts and DefinitionДокумент3 страницыBoiler Parts and DefinitionKarlFrederickNoblezaОценок пока нет

- Tds Contro Heat RecoverylДокумент31 страницаTds Contro Heat RecoverylHélder PascoalОценок пока нет

- Dust Explosion in CFBC BoilersДокумент5 страницDust Explosion in CFBC BoilersS V NAGESHОценок пока нет

- 400kgs Steam Boiler Oil FiredДокумент5 страниц400kgs Steam Boiler Oil FiredManikandanОценок пока нет

- Auxiliary BoilerДокумент56 страницAuxiliary BoilerNirdosh AnanthОценок пока нет

- HEI-IMS-CHEM-SOP05 HRSG and CCCW Chemical Dosing and PreparationДокумент7 страницHEI-IMS-CHEM-SOP05 HRSG and CCCW Chemical Dosing and Preparationrizwan chОценок пока нет

- P90 P91 P92 P510 P515 P520: Manual of - Installation - Operating - Maintenance Gas Burners TypeДокумент34 страницыP90 P91 P92 P510 P515 P520: Manual of - Installation - Operating - Maintenance Gas Burners TypeLucian CiudinОценок пока нет

- Thermax Combloc Multi Fuel Compact 1500 6000 KG Steam BoilerДокумент2 страницыThermax Combloc Multi Fuel Compact 1500 6000 KG Steam BoilerPRABA KARAN100% (1)

- Commissioning Manual DH-6155: Descon Engineering LTDДокумент102 страницыCommissioning Manual DH-6155: Descon Engineering LTDHammad AhmedОценок пока нет

- H2 Type Direct Fire Chiller Operation Manual PDFДокумент79 страницH2 Type Direct Fire Chiller Operation Manual PDFUmar Majeed100% (2)

- Thermal Fluid Heaters: Model HHC and VHCДокумент4 страницыThermal Fluid Heaters: Model HHC and VHCRexx MexxОценок пока нет

- Boiler Comp. For 250bhpДокумент2 страницыBoiler Comp. For 250bhpNewaz KabirОценок пока нет

- Boiler Bed MaterialДокумент3 страницыBoiler Bed MaterialWASIM MAKANDARОценок пока нет

- Basuki Boiler Chain Grate Stoker Coal Fired BoilerДокумент20 страницBasuki Boiler Chain Grate Stoker Coal Fired BoilerIza SacataniОценок пока нет

- Borderer Boiler Complete ManualДокумент228 страницBorderer Boiler Complete ManualNitrogeno MPDОценок пока нет

- Boiler ManualДокумент203 страницыBoiler ManualgaladrialОценок пока нет

- Economiser Coil - DrawingДокумент1 страницаEconomiser Coil - DrawingAnjaneya ReddyОценок пока нет

- Combustion Theory PPT OriginalДокумент30 страницCombustion Theory PPT Originalsameer betalОценок пока нет

- Boiler Dantrubin Control Rembang Dan PacitanДокумент39 страницBoiler Dantrubin Control Rembang Dan Pacitanbintang arcano lugasОценок пока нет

- 2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriДокумент51 страница2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriChanna BasavaОценок пока нет

- Vdocuments - MX Boiler Book Cleaver BrooksДокумент1 391 страницаVdocuments - MX Boiler Book Cleaver BrooksTecnico A Lazaro CardenasОценок пока нет

- Smart Soot Blower SystemДокумент8 страницSmart Soot Blower SystemidigitiОценок пока нет

- Boiler (Steam Generator) : From Wikipedia, The Free EncyclopediaДокумент20 страницBoiler (Steam Generator) : From Wikipedia, The Free EncyclopediaCarlito PantalunanОценок пока нет

- Manual of - Installation - Operation - Maintenance Dual Fuel Burners L.P.G. - Light Oil HS5 HS10 HS18Документ32 страницыManual of - Installation - Operation - Maintenance Dual Fuel Burners L.P.G. - Light Oil HS5 HS10 HS18AlvaroValdebenitoValenzuelaОценок пока нет

- Fulton ModSync Wiring DiagramДокумент3 страницыFulton ModSync Wiring DiagramjrodОценок пока нет

- Coal Consumption CalculationДокумент1 страницаCoal Consumption CalculationbrockОценок пока нет

- 3 Benefites of CFB Boiler Over Pc-Fired BoilerДокумент9 страниц3 Benefites of CFB Boiler Over Pc-Fired BoilersunitbhaumikОценок пока нет

- NATCO TurbulatorДокумент2 страницыNATCO TurbulatorshansalОценок пока нет

- Longitudinal Section B-B Transverse Section A-A: Welding Details Not To ScaleДокумент1 страницаLongitudinal Section B-B Transverse Section A-A: Welding Details Not To ScalebunkeringОценок пока нет

- 57-62 1m809 - Eng72dpiДокумент6 страниц57-62 1m809 - Eng72dpiAbhinav TewariОценок пока нет

- 78 - JT Triumph Brochure 2014Документ2 страницы78 - JT Triumph Brochure 2014Bayu Pramana PutraОценок пока нет

- 118 - Package Boiler BrochureДокумент8 страниц118 - Package Boiler BrochureBayu Pramana PutraОценок пока нет

- Amca Publication 11-03: Certified Ratings Program Operating ManualДокумент30 страницAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaОценок пока нет

- Chapter 21Документ25 страницChapter 21Matias MancillaОценок пока нет

- Amca Publication 11-03: Certified Ratings Program Operating ManualДокумент30 страницAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaОценок пока нет

- Catalago Resumen de ValvulasДокумент21 страницаCatalago Resumen de ValvulasMatias MancillaОценок пока нет

- Envirenmental EngineeringДокумент87 страницEnvirenmental Engineering4919404Оценок пока нет

- CA3000A Dodge BearingДокумент708 страницCA3000A Dodge BearingSuphi YükselОценок пока нет

- p-100 Vol2 1935 Part5Документ132 страницыp-100 Vol2 1935 Part5Matias MancillaОценок пока нет

- Refractories For Heat Treating: Industrial CeramicsДокумент6 страницRefractories For Heat Treating: Industrial CeramicsMatias MancillaОценок пока нет

- Technical Documents of The BoilerДокумент20 страницTechnical Documents of The BoilerMatias Mancilla0% (1)

- Carter Variator CatДокумент40 страницCarter Variator CatMatias MancillaОценок пока нет

- CA3000A Dodge BearingДокумент708 страницCA3000A Dodge BearingSuphi YükselОценок пока нет

- CA3000A Dodge BearingДокумент708 страницCA3000A Dodge BearingSuphi YükselОценок пока нет

- Hamada Boiler Catalogue Page 22 Coal Storage and PLC ControlДокумент1 страницаHamada Boiler Catalogue Page 22 Coal Storage and PLC ControlMatias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 47 Rotary Furnace For AMPДокумент1 страницаHamada Boiler Catalogue Page 47 Rotary Furnace For AMPMatias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 60 Coalmac 4Документ1 страницаHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 59 Coalmac 3Документ1 страницаHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 58 Coalmac 2Документ1 страницаHamada Boiler Catalogue Page 58 Coalmac 2Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 56 Heavy Duty Chain GrateДокумент1 страницаHamada Boiler Catalogue Page 56 Heavy Duty Chain GrateMatias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 57 Coalmac 1Документ1 страницаHamada Boiler Catalogue Page 57 Coalmac 1Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 59 Coalmac 3Документ1 страницаHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Документ1 страницаHamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 60 Coalmac 4Документ1 страницаHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 61 EFB Palm Waste FiringДокумент1 страницаHamada Boiler Catalogue Page 61 EFB Palm Waste FiringMatias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Документ1 страницаHamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Matias MancillaОценок пока нет

- Solid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsДокумент2 страницыSolid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsMatias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Документ1 страницаHamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 67 TVTB 3Документ1 страницаHamada Boiler Catalogue Page 67 TVTB 3Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Документ1 страницаHamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Matias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 8 Model DF Series General ViewДокумент1 страницаHamada Boiler Catalogue Page 8 Model DF Series General ViewMatias MancillaОценок пока нет

- Hamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelДокумент1 страницаHamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelMatias MancillaОценок пока нет

- 1 - Atoms, Molecules and StoichiometryДокумент80 страниц1 - Atoms, Molecules and StoichiometryHenry ChongОценок пока нет

- Glass Breakage in Buildings FireДокумент12 страницGlass Breakage in Buildings Fireoctav_laluОценок пока нет

- Us Pipeline Explosions Since 2001-Calculation of Safety SetbacksДокумент20 страницUs Pipeline Explosions Since 2001-Calculation of Safety SetbacksZecheru Ion IrimiaОценок пока нет

- BLUETEC-Diesel Emission Control SystemДокумент44 страницыBLUETEC-Diesel Emission Control SystemAbhi Shek100% (5)

- It's Raining Acid! Acid Rain in Malta and BeyondДокумент16 страницIt's Raining Acid! Acid Rain in Malta and Beyondsocialpolicy100% (1)

- Pensky MartensДокумент2 страницыPensky Martensharry_chemОценок пока нет

- Roadmap For Adaptationon Low Sulphur FuelДокумент65 страницRoadmap For Adaptationon Low Sulphur FuelHHHОценок пока нет

- Syllabus Waste Heat Recovery: Classification, Advantages and Applications, CommerciallyДокумент9 страницSyllabus Waste Heat Recovery: Classification, Advantages and Applications, Commerciallymanvendra sharmaОценок пока нет

- Chemical EngineeringДокумент120 страницChemical EngineeringPhani ChinnaОценок пока нет

- MSDS Recocool HD Premium NДокумент3 страницыMSDS Recocool HD Premium NruslanОценок пока нет

- TripticoДокумент2 страницыTripticoWeimar Saul Vargas RuizОценок пока нет

- Main Application of Fans and BlowerДокумент5 страницMain Application of Fans and Blowermissy forlajeОценок пока нет

- Piazzesi, PHD Thesis, ETH Zurich, 2006Документ164 страницыPiazzesi, PHD Thesis, ETH Zurich, 2006Alfin AdiОценок пока нет

- Welcome To Test M3 Properties, Characteristics, Safe Handling of Propane and Natural GasДокумент6 страницWelcome To Test M3 Properties, Characteristics, Safe Handling of Propane and Natural GasIbrahim FareedОценок пока нет

- 19 Jonathan Forinton ATECДокумент33 страницы19 Jonathan Forinton ATECElwathig BakhietОценок пока нет

- PC PDFДокумент3 страницыPC PDFNeel PatelОценок пока нет

- Bahan Bakar Dan PembakaranДокумент53 страницыBahan Bakar Dan PembakaranBayu Purnama RidjadiОценок пока нет

- 1 Electric Injection System - Chery Tiggo T11Документ87 страниц1 Electric Injection System - Chery Tiggo T11limadacarlosОценок пока нет

- Praxair - PropaneДокумент7 страницPraxair - Propanejaredf@jfelectric.com100% (2)

- Foundation of EnergyДокумент121 страницаFoundation of Energyapi-3765936Оценок пока нет

- Material Safety Data Sheet Nitric AcidДокумент7 страницMaterial Safety Data Sheet Nitric AcidtradeasiagroupОценок пока нет

- 763750-UOP DTS Callidus CUBP DatasheetДокумент4 страницы763750-UOP DTS Callidus CUBP DatasheetMohammad HesanОценок пока нет

- Msds Plus Weld Metal Lt1 298Документ7 страницMsds Plus Weld Metal Lt1 298Juan franОценок пока нет

- Documentatie CM... N SM... N MM... N PDFДокумент6 страницDocumentatie CM... N SM... N MM... N PDFAdam PegielОценок пока нет

- Rocket PropellantДокумент54 страницыRocket PropellantTHE CALCUTTANОценок пока нет

- MQ SP I 7015 PDFДокумент66 страницMQ SP I 7015 PDFJaseelKanhirathinkalОценок пока нет

- Modelling of Blast Loading On Aboveground Structures-Ii. Internal Blast and Ground ShockДокумент10 страницModelling of Blast Loading On Aboveground Structures-Ii. Internal Blast and Ground ShockOmer PolatОценок пока нет

- Handbook Nitrogen Oxides Pollution Prevention and ControlДокумент5 страницHandbook Nitrogen Oxides Pollution Prevention and ControlrupigapigaОценок пока нет

- Internal Combustion Engine MCQДокумент39 страницInternal Combustion Engine MCQHumphrey James B. BillonesОценок пока нет

- 30 A2020 FLC OPS FDagenda 08 18Документ22 страницы30 A2020 FLC OPS FDagenda 08 18yesidОценок пока нет

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentОт EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentРейтинг: 4.5 из 5 звезд4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050От EverandA Pathway to Decarbonise the Shipping Sector by 2050Оценок пока нет

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisОт EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsОт EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsОт EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsОценок пока нет

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerОт EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerОценок пока нет

- Handbook on Battery Energy Storage SystemОт EverandHandbook on Battery Energy Storage SystemРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Heat Transfer Engineering: Fundamentals and TechniquesОт EverandHeat Transfer Engineering: Fundamentals and TechniquesРейтинг: 4 из 5 звезд4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Guidelines for Auditing Process Safety Management SystemsОт EverandGuidelines for Auditing Process Safety Management SystemsОценок пока нет

- A Complete Guide to Safety Officer Interview Questions and AnswersОт EverandA Complete Guide to Safety Officer Interview Questions and AnswersРейтинг: 4 из 5 звезд4/5 (1)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceОт EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceОценок пока нет

- Electric Motor Control: DC, AC, and BLDC MotorsОт EverandElectric Motor Control: DC, AC, and BLDC MotorsРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Rules of Thumb for Maintenance and Reliability EngineersОт EverandRules of Thumb for Maintenance and Reliability EngineersРейтинг: 4.5 из 5 звезд4.5/5 (12)

- Smart Power Distribution Systems: Control, Communication, and OptimizationОт EverandSmart Power Distribution Systems: Control, Communication, and OptimizationОценок пока нет

- Practical Reservoir Engineering and CharacterizationОт EverandPractical Reservoir Engineering and CharacterizationРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsОт EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsОценок пока нет

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successОт EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successРейтинг: 4.5 из 5 звезд4.5/5 (3)