Академический Документы

Профессиональный Документы

Культура Документы

High Temperature Behaviour of Similar and Dissimilar

Загружено:

Ján KožičkaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

High Temperature Behaviour of Similar and Dissimilar

Загружено:

Ján KožičkaАвторское право:

Доступные форматы

5th International Conference on Mechanics and Materials in Design

REF: A0405.0407

HIGH TEMPERATURE BEHAVIOUR OF SIMILAR AND DISSIMILAR WELDED COMPONENTS OF STEEL GRADE P22 AND P91

P. Seliger1, and A. Thomas Siempelkamp Pruef-und Gutachter-Gesellschaft mbH P.O. 10 02 63, D-01072 Dresden, Germany Email: (1)peter.seliger@siempelkamp.com

SYNOPSIS The service of energy production plants would be impossible without the professional designing, manufacturing and monitoring of welded joints. Particularly with the increase of the steam parameters pressure and temperature the integrity of creep-exposed welded joints continues to move into the focus of the technical designers, operators and supervisors of energy-technical plants. The lifetime assessment factors of welded components, implemented in the Design Codes, must be urgently updated for the modern materials and the advanced steam parameters used in the piping construction.

INTRODUCTION Within the European research project WELDON [1] the Siempelkamp Pruef- und GutachterGesellschaft mbH (SPG) is performing component-like tests at higher temperatures. On the one hand it concerns tests at inner pressurised pipes, whose circumferential weldments are stressed additionally by external axial load. The pipes from steel grade P22 and P91 are equipped with sensors for the on-line monitoring of temperatures, deformations and strains. Metallographic investigations are monitoring the damage development in the individual zones of the weld relevant for the creep strength behaviour. Further creep-rupture tests at large tensiles are accomplished, in order to be able to examine the geometry size effect. For observance of similar axial and hoop stresses pre-calculation of specimen geometry and loading have been done before manufacture. For creep testing special test rigs were designed and built. All testing data will be implemented as inputs for the numeric FE analysis. In the context of the project the determined research results flow into a methodology for the estimation of the welding seam behaviour.

RESULTS 2 EXPERIMENTAL DETAILS 2.1 Welding of similar and dissimilar pipe materials, Forged pipes of 145 mm outer diameter and 45 mm wall thickness were produced from material grades P22 and P91 according to ASTM A 369 [2]. Similar butt welds were manufactured of P22-P22 and P91-P91 as well as dissimilar butt welds of P22-P91. The dissimilar welds were welded with P22-like electrodes (2,25 % Cr). The macro- and microstructure of the P91-P91 and P22-P91 welds are shown in Figure 1 and Figure 2.

Chapter IV: Welds at High Temperature (WELDON) in Design

Porto-Portugal, 24-26 July 2006

P9 BM 1

P9 W 1 M

P9 1 BM

10

Fig. 1 Macrostructure of similar weld P91-P91, microstructure P 91 base metal (BM)

P22 BM

P22 WM

P91 BM

10 mm

Fig. 2 Macrostructure of dissimilar weld P22-P91, microstructure P22 base metal (BM)

The microstructure of P22 pipes contains ferritic-bainitic microstructure. The microstructure of the P91 pipes show needle shaped martensite of average grain size and indicates a regular heat treatment at a sufficient austenitic temperature. All welded pipes were subjected to appropriate post weld heat treatment (PWHT). The details of welding and PWHT are presented in Table 1. After the PWHT, the pipes were examined non-destructively employing ultrasonic (UT) and Magnetic Particle Inspection (MPI) techniques, without indications for presence of welding defects or cracks.

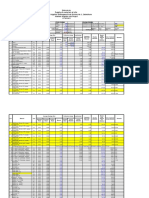

Table 1: Details of welding technology Joint type Process P22 - P22 P91 - P91 P22 - P91 SMAW SMAW SMAW Filler Material SHCromo2KS Chromo9V SHCromo2KS Process GTAW GTAW GTAW Root Material UnionICrMo910 Thermanit MTS3 UnionICrMo910 690 C/ 2h /air 760 C/ 2h/ air 725 C/ 2h/ air Post weld heat treatment

Editors: J.F. Silva Gomes and Shaker A. Meguid

5th International Conference on Mechanics and Materials in Design

2.2 Finite Element Calculation For the determination of the loading conditions finite element calculations were made. The specimen dimension and loading conditions were chosen such that the applied stresses in the hoop and axial directions (i.e. equivalent or v. Mises stress v) at the outer side will be the same for the pipe and will correspond to the axial load a applied to the large tensile specimen. An open question was concerning the level of the inner pressure and loads to reach the target test times. Therefore at first an elastic FE computation of the real component was made using ANSYS. Figure 3 illustrates the FE mesh.

1

ELEMENTS APR 3 2003 14:10:06 PLOT NO. 1

Y Z X

Figure 3: FE mesh

The reference stress was calculated in the weld cross section to compare the stresses with the creep rupture strength of the materials. As example, for the 10.000 hours feature test a reference stress of 85 MPa for P91-weld and about 106 MPa for P22 weld was chosen (Figure 4). This corresponds to a weld strength factor of about 85 % related to the mean value of the base material.

1

NODAL SOLUTION STEP=1 SUB =1 TIME=1 SEQV (AVG) DMX =.02132 SMN =72.567 SMNB=72.564 SMX =113.73 SMXB=113.736 MN APR 3 2003 12:20:14 PLOT NO. 6

1

NODAL SOLUTION STEP=1 SUB =1 TIME=1 SEQV (AVG) DMX =.132323 SMN =.588765 SMX =462.887 SMXB=845.515 APR 3 2003 12:20:03 PLOT NO. 3

MX

MN

MX

Y X

Y X Z

72.567 77.14

81.714 86.288

90.861 95.435

100.009 104.582

109.156 113.73

.588765 51.955

103.322 154.688

206.055 257.421

308.788 360.154

411.52 462.887

Figure 4: Calculation results of initial reference stress (equivalent stress; v. Mises)

Chapter IV: Welds at High Temperature (WELDON) in Design

Porto-Portugal, 24-26 July 2006

2.3 Manufacture of feature test Large tensile specimens (20 x 50 mm cross section, length 700 mm) and pipes (100 mm inner diameter, 12 resp. 15 mm wall thickness) were machined from larger welded pipes. The pretest examination of the components includes geometrical measurements, NDE (X-ray radioscopy, MPI), replica examination and hardness measurements across the weld zone surface. 2.4 Test rig for high temperature component testing The components are tested in specially designed high temperature test rigs (Figure 5).

800

Gripping device

Furnace 1850 1340 Feature pipe or large tensile

Hydraulic cylinder

Fig. 5 High temperature test rig for pipe creep tests

Fig.6-Sensor application on test pipe P22-P91

Pipes have been tested under simultaneous application of constant internal pressure using argon and an axial loading. Electrical heating elements are used for heating the component to the test temperatures. Capacitive strain gages type HT-DMS (gage length 20 mm) were installed on the pipes to measure the integral strain on different locations (base metal BM, weld metal WM, heat affected zone HAZ) and orientations (longitudinal and circumferential), as shown in Figure 6. Additionally, a number of reference marks (creep pips) were fixed on the pipe surface for intermittent extensometer measurements during test stops. The accuracy of pressure and temperature measurements during the test duration was kept within the ECCC recommendations [3] for creep tests. 3 RESULTS AND DISCUSSIONS 3.1 Creep test and Metallographic examination In P22-P91 dissimilar weld, a carbon/carbide depleted zone was formed due to carbon diffusion from P22 weld metal to the higher Cr containing P91 BM. This migration had let to the formation of a dark seam of carbides adjacent to the weld interface, as shown in Figure 7. In failed P22-P91 dissimilar weld a noticeable hardness reduction was seen which is due to the decarburised zone in P22 WM, as shown in Figure 8. More microstructure data on pre-test material characterisation of feature test components are presented in [4]. Figure 9 shows the creep curves of the two large tensile specimens of P22-P91 dissimilar weld, tested at different axial loads a. The fracture location is the decarburised zone of P22 weld metal, which corresponds to the hardness drop in figure 8.

4 Editors: J.F. Silva Gomes and Shaker A. Meguid

5th International Conference on Mechanics and Materials in Design

Fig. 7 P22-P91 dissimilar weld, Decarburised zone in P22 WM adjacent to P91 BM, dark carbide zone on fusion line

Figure 8: Hardness scan across weld, zero distance is weld interface, hardness peak in the P91 HAZ and small hardness drop in decarburised zone of P22 weld metal metal [4]

2,0 P22-P91; 550C; 125 MPa P22-P91; 550C; 105 MPa 1,6 integral strain [%]

l0

1,2

0,8

0,4

0,0 0 500 1000 1500 2000 test duration [h] 2500 3000 3500 4000

Figure 9: P22-P91 dissimilar weld, creep curves of large tensile specimens, Failure location in decarburised zone of P22-weld metal

The fracture of the large tensile specimens made from P22-P22 similar welds occurred in P22 fine grained HAZ (Type IV) after 10.191 h (a=125 MPa) and 1.276 h (a=150 MPa) of test durations, respectively. Figure 10 illustrates the measured creep curves of the different weld zones of P91-P91 similar welded test pipe. Only the primary and secondary stages of the creep curve had been monitored by the capacitive strain gages applied on the weld surface. But, the creep crack initiation and fracture had occurred on the opposite side of the test pipe, where no sensor was installed. A small necking zone was found in circumferential direction in the HAZ were the crack had initiated (Type IV cracking). For the P22-P22 test pipe the crack initiation and fracture was very well monitored by the strain gage fixed across the HAZ region, as indicated in Figure 11 and Figure 12. The creep curves of this sensor show the typical tertiary stage.

Chapter IV: Welds at High Temperature (WELDON) in Design

Porto-Portugal, 24-26 July 2006

0,4

HAZ, longitudinal WM, longitudinal BM, longitudinal BM, circumferential

0,3

integral strain [%]

0,2

0,1

0,0 0 500 1000 1500 2000 test duration [h] 2500 3000 3500 4000

Figure 10:

7,0

Pipe P91-P91 (v= 102 MPa); creep curves of different weld zones, Type IV cracking

HAZ, longitudinal 6,0 BM, longitudinal BM, circumferential 5,0 integral strain [%]

4,0

3,0

2,0

1,0

0,0 0 2000 4000 6000 test duration [h] 8000 10000 12000

Figure 11:

7,0

Pipe P22-P22 (v= 128 MPa); creep curves of different weld zones, Type IV cracking

6,0

HAZ, longitudinal BM, longitudinal BM, circumferential

5,0 integral strain [%]

4,0

3,0

2,0

1,0

0,0 0 5000 10000 test duration [h] 15000 20000 25000

Figure 12: 6

Pipe P22-P22 (v= 106 MPa); creep curves of different weld zones, Type IV cracking Editors: J.F. Silva Gomes and Shaker A. Meguid

5th International Conference on Mechanics and Materials in Design

3.2 Creep rupture strength Comparison standard (uniaxial) lab tests and pipe tests One of the main project topics was to investigate the influence of size and component type on creep rupture strength or lifetime. Figure 13 shows the results of feature tests (large tensiles/ pipes) for P22 similar weld in comparison to those of the standard uniaxial specimen, which were tested by the project partner CESI [5]. The failure points of large tensiles and standard specimens are closed together in the range of mean values of creep rupture strength. The results of the pipes seems to be better, but in the diagram the Mises-reference stress at the beginning of test is used, which leads to an overvaluation.

1000

Stress in N/mm

100

crossweld_standard_specimens crossweld_large_tensiles Pipes_butt_weld

10 100

1.000 Time in hours

10.000

100.000

Fig. 13 Creep rupture strength, uniaxial tests and pipe tests, P22-P22 at 550 C

It is well known, that the reference stress distribution is changing during service due to relaxation of high stressed areas. Therefore, the failure points of pipes in figure 13 should shift to lower stress levels. The amount of shifting depends on the test duration, the absolute stress level and the test temperature. The calculation of relaxation and redistribution was done by the project partner UNOTT and will be presented specially. The crossweld standard specimens of P91 have an expected creep rupture level at the lower scatter band, like seen in figure 14. The large tensile test results are showing a nonexplainable behaviour, but probably they do not differ from cross weld specimen so much.

1000

Stress in N/mm

100

crossweld_standard_specimens crossweld_large_tensiles Pipes_butt_welded

10 100

1.000 Time in hours

10.000

100.000

Fig. 14 Creep rupture strength, uniaxial tests and pipe tests, P91-P91 at 625 C

Chapter IV: Welds at High Temperature (WELDON) in Design

Porto-Portugal, 24-26 July 2006

For the pipes the same restrictions concerning the used reference stresses are valid like for P22-tests. The results for the dissimilar welds P22/P91 are definitely worse then for similar P22/P22tests. All the crossweld specimens have a strength level at the lower bound of the scatterband (Figure 15). The reason is the weakness of the decarburised zone in P22 weld metal, which is the failure location as well.

1000

Stress in N/mm

100

crossweld_standard_specimens crossweld_large_tensiles Pipes_butt_welded

10 100

1000 Time in hours

10000

100000

Fig. 15 Creep rupture strength, uniaxial tests and pipe tests, P22-P91 at 550 C

4 CONCLUSIONS AND OUTLOOK Within this EU 5th Framework research project WELDON, feature tests at high temperatures are performed on component-like specimens like welded pipes and large tensile specimens in addition to laboratory specimens in order to study the geometry and size effects on the damage evaluation methodology which is being developed. The observed carbide depletion in the P22 weld metal adjacent to the fusion line of P91-P22 dissimilar welds and its effect on the weld strength reduction have to be taken into account. No size effects or significant differences between standard crossweld and large crossweld results were observed. The strength level of similar P22-welds at 550 C is in the mean range of base material. On the other hand the dissimilar weld at the same temperature shows a strength at the lower bound of scatterband due to the different failure location. Also the similar welded P91-specimens have a strength level in the range of lower scatter band, but this is due the (for P91) very high temperature of 625 C. Based on the weld combinations, the component geometry and the loading conditions, the concentration of strain in the different weld regions on feature test specimens and its relation to the failure location and strain measured in standard creep testing of crossweld specimens will be investigate within the project. ACKNOWLEDGMENT The authors gratefully acknowledge the financial support provided by the European Commission to the RTD project WELDON (Contract No. G5RD-CT-2001-00596).

Editors: J.F. Silva Gomes and Shaker A. Meguid

5th International Conference on Mechanics and Materials in Design

REFERENCES 1. Weld Strength for high temperature components design and operation (WELDON). European Project No. GRD2-2000-30363. 2. ASTM A 369. Standard specification for carbon and ferritic alloy steel forged and bored pipe for high-temperature service. ASTM International, 2002 3. ECCC Recommendations. Data acceptability criteria and data generation: Recommendations for creep testing of post exposed (ex-service) materials. Volume 3 Part III [Issue 2], 2001 4. Agyakwa P. Yaghi A. Becker AA. Current state of metallurgical examination of the test welds and failed notched cross weld creep samples. Report WELDON/UNOT-009/TRP005/R0 5. S. Concari WP2 Material supply and WP5 Creep tests. CESI-Report WELDON/ CESI-011/WPR-004/00

Chapter IV: Welds at High Temperature (WELDON) in Design

Вам также может понравиться

- 1 4713 4724 4742 4762Документ4 страницы1 4713 4724 4742 4762Ján KožičkaОценок пока нет

- Lincoln GMAW Welding GuideДокумент96 страницLincoln GMAW Welding GuideМич БјукенонОценок пока нет

- Body of Knowledge: Certified Welding Inspector (CWI) Certified Welding Educator (CWE) Welding Inspector Endorsement (SIE)Документ1 страницаBody of Knowledge: Certified Welding Inspector (CWI) Certified Welding Educator (CWE) Welding Inspector Endorsement (SIE)Ján KožičkaОценок пока нет

- Welding Guide PDFДокумент24 страницыWelding Guide PDFJán KožičkaОценок пока нет

- Duplex Stainless Steel 2d Edition PracticalДокумент64 страницыDuplex Stainless Steel 2d Edition Practicalmahmoud_allam3Оценок пока нет

- Katbak - Ceramic Weld Backing: Improve Welds and Reduce Costs With Gullco KatbakДокумент4 страницыKatbak - Ceramic Weld Backing: Improve Welds and Reduce Costs With Gullco KatbakJán KožičkaОценок пока нет

- Aws SWPS B2.1-1-001Документ10 страницAws SWPS B2.1-1-001Michel Lopez100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Generic SpecsДокумент8 страницGeneric SpecsHarold Valen MagpayoОценок пока нет

- Coefficient of Friction Reference Table - Engineer's HandbookДокумент4 страницыCoefficient of Friction Reference Table - Engineer's Handbooksafaozhan100% (1)

- Plastic Extrusion Machine-Project ReportДокумент128 страницPlastic Extrusion Machine-Project ReportNHÂN LÊ HOÀNGОценок пока нет

- ADMIN Building Calculation SheetДокумент95 страницADMIN Building Calculation Sheetorode franklynОценок пока нет

- 24th Ra AbstractДокумент9 страниц24th Ra AbstractRanjan Kumar YadavОценок пока нет

- Weight Tables Mild Steel Round Bars and High Tensile Deformed BarsДокумент6 страницWeight Tables Mild Steel Round Bars and High Tensile Deformed BarsSyed ShareefОценок пока нет

- Non Ferrous Metals and Alloys CH5 DDUДокумент97 страницNon Ferrous Metals and Alloys CH5 DDUPratik ThakerОценок пока нет

- Wps & PQR Check ListДокумент2 страницыWps & PQR Check ListDimaz ragaОценок пока нет

- Section-VIII Bill of QtyДокумент48 страницSection-VIII Bill of Qtyinfra120Оценок пока нет

- INTERNSHIP REPORT MP PrintДокумент51 страницаINTERNSHIP REPORT MP PrintSACHIN MENEZESОценок пока нет

- Basilisk Self-Healing AgentДокумент3 страницыBasilisk Self-Healing AgentJordyОценок пока нет

- +GF+ Technical HandbookДокумент107 страниц+GF+ Technical HandbookBoban StanojlovićОценок пока нет

- Estimate NДокумент35 страницEstimate Nujjwal sapkotaОценок пока нет

- Ovens For Laboratories & IndustryДокумент32 страницыOvens For Laboratories & IndustryShashank TiwariОценок пока нет

- RFI For Construction of Pipe CulvertsДокумент3 страницыRFI For Construction of Pipe Culvertsaddisu moges0% (1)

- Course Metal Casting ProcessesДокумент41 страницаCourse Metal Casting Processesremy133Оценок пока нет

- DocumentДокумент23 страницыDocumentOmar Coronado ZuloetaОценок пока нет

- CIS7:2014Документ66 страницCIS7:2014Ken ChuahОценок пока нет

- Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile StrengthДокумент6 страницCarbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile StrengthGian SennaОценок пока нет

- M 15 Mix Designs As Per Is-10262-2009Документ11 страницM 15 Mix Designs As Per Is-10262-2009Rakesh ReddyОценок пока нет

- Synopsis (Shubham Shekhawat)Документ6 страницSynopsis (Shubham Shekhawat)moderate machines pvt. ltd.Оценок пока нет

- LaMOT Rupture DiscsДокумент20 страницLaMOT Rupture Discshlrich99Оценок пока нет

- Stromberg Architectural Full GlossaryДокумент49 страницStromberg Architectural Full GlossaryAna EscotoОценок пока нет

- Steam HeaderДокумент9 страницSteam Headervijayanmks100% (1)

- Caster PDFДокумент2 страницыCaster PDFRatko KečaОценок пока нет

- Impact of Silt Content of Sand On Concrete Strength and Workability - 18.01.16Документ3 страницыImpact of Silt Content of Sand On Concrete Strength and Workability - 18.01.16Jitendra SharmaОценок пока нет

- Self-Gripping Gasketing: Program 1011Документ1 страницаSelf-Gripping Gasketing: Program 1011Sofyan HadiОценок пока нет

- University of Cambridge Department of Materials Science and MetallurgyДокумент40 страницUniversity of Cambridge Department of Materials Science and MetallurgyNAVNEET PARASHARОценок пока нет

- Technical Specification For Nuts and Bolts For Over Head Distribution NetworksДокумент3 страницыTechnical Specification For Nuts and Bolts For Over Head Distribution Networksshivaanem100% (1)