Академический Документы

Профессиональный Документы

Культура Документы

Chap 18 Marlin 2002

Загружено:

Audrey Patrick KallaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chap 18 Marlin 2002

Загружено:

Audrey Patrick KallaАвторское право:

Доступные форматы

CHAPTER 18: LEVEL CONTROL

When I complete this chapter, I want to be

able to do the following.

Determine the proper location and volume

of liquid inventories in a process

Determine the dynamics of typical level

processes

Tune level controllers for two typical

control objectives

Outline of the lesson.

Levels, where are they?

Levels - good and bad aspects

Level dynamics

Level tuning

Determining inventory size

CHAPTER 18: LEVEL CONTROL

1

2

3

15

16

17

LC-1

LC-3

LC-2 dP-1

dP-2

T5

T6

TC-7

AC-1

PC-1

P3

F3

F4

F7

F8

F9

T10

L4

CHAPTER 18: LEVEL CONTROL

Where are liquid inventories?

Why do we design equipment with inventories?

CHAPTER 18: LEVEL CONTROL

Where are liquid inventories?

1

2

3

15

16

17

LC-1

LC-3

LC-2 dP-1

dP-2

T5

T6

TC-7

AC-1

PC-1

P3

F3

F4

F7

F8

F9

T10

L4

CHAPTER 18: LEVEL CONTROL

Where are liquid inventories? Why?

1

2

3

15

16

17

LC-1

LC-3

LC-2 dP-1

dP-2

T5

T6

TC-7

AC-1

PC-1

P3

F3

F4

F7

F8

F9

T10

L4

Liquid on trays, allows

liquid-vapor equilibrium

Liquid mixing

reduces effects of

composition

disturbances

Flow to tower can be

constant in spite of

fluctuation in feed

flow

Allows uninterrupted

reflux and product

flows in spite of

variable condensation

Uninterrupted

fluid flow to

pump

Liquid covers the heat

exchanger transfer

area

CHAPTER 18: LEVEL CONTROL

How do inventories affect performance of the

process containing the liquid?

Strongly Weakly Insignificant

Volume of

chemical reactors,

volume has strong

effect on

conversion

Fast material

degradation (reduce

residence time)

Equilibrium stages,

both phases must

be present, but

amount beyond

minimum does not

affect process

Heat exchangers,

must have contact

with area

Drums and tanks,

no change to

material properties

But these inventories

have strong effects

on the other processes

influenced by the flows

from these inventories

CHAPTER 18: LEVEL CONTROL

What are ++ and -- for having liquid inventories?

NEGATIVE ASPECTS POSITIVE ASPECTS

Conclusion: ??

CHAPTER 18: LEVEL CONTROL

What are ++ and -- for having liquid inventories?

NEGATIVE ASPECTS

Hazards - large inventory

Product quality - degradation

Space in plant

Cost

- Equipment costs

- Material costs (inventory)

POSITIVE ASPECTS

Provide liquid to pumps

Mixing to reduce effects of stream

property disturbances

Inventory enables flow out constant

as flow in varies

Required - process principles, e.g.,

- chemical reactors

- heat exchangers

Conclusion: We use only the minimum liquid inventory needed

to achieve the desired process performance.

CHAPTER 18: LEVEL CONTROL

To design control, we

need to understand the

process dynamics

control objectives

algorithm & tuning

level sizing

Lets determine the

dynamics for each of the

designs

CHAPTER 18: LEVEL CONTROL

Self-regulatory Non-self-regulatory

0 5 10 15 20 25 30 35 40 45

-2

-1.5

-1

-0.5

0

Time

L

e

v

e

l

0 5 10 15 20 25 30 35 40 45

0

0.5

1

1.5

2

Time

F

l

o

w

o

u

t

0 5 10 15 20 25 30 35 40 45

-2

-1.5

-1

-0.5

0

Time

L

e

v

e

l

0 5 10 15 20 25 30 35 40 45

0

0.5

1

1.5

2

Time

F

l

o

w

o

u

t

out in

F F

dt

dL

A =

F

out

does not depend on the level

out in

F F

dt

dL

A =

F

out

increases as level increases

Quick reminder of key property of dynamic process behavior

New steady state

No new steady state

CHAPTER 18: LEVEL CONTROL

0

dt

dL

) ( L K F

F F

dt

dL

A

in

out in

=

=

2 1

P P K F

F F

dt

dL

A

in

out in

=

=

P

1

= pump head + gL

2 1

P P K F

F F

dt

dL

A

in

out in

=

=

P

1

= P

3

+ gL

0

0 5 10 15 20 25 30 35 40 45

-2

-1.5

-1

-0.5

0

Time

L

e

v

e

l

0 5 10 15 20 25 30 35 40 45

0

0.5

1

1.5

2

Time

F

lo

w

o

u

t

Non-Self-regulatory

0 5 10 15 20 25 30 35 40 45

-2

-1.5

-1

-0.5

0

Time

L

e

v

e

l

0 5 10 15 20 25 30 35 40 45

0

0.5

1

1.5

2

Time

F

lo

w

o

u

t

Self-regulatory

Constant

0 5 10 15 20 25 30 35 40 45

-2

-1.5

-1

-0.5

0

Time

L

e

v

e

l

0 5 10 15 20 25 30 35 40 45

0

0.5

1

1.5

2

Time

F

lo

w

o

u

t

Non-Self-regulatory

0

Determine if each level is self-regulatory or not

To design control, we

need to understand the

process dynamics

control objectives

algorithm & tuning

level sizing

Lets determine the

control objectives

for level control

CHAPTER 18: LEVEL CONTROL

LC

F

in

F

out

What is important?

The level

The manipulated flow

CHAPTER 18: LEVEL CONTROL

LC

F

in

F

out

Control objectives

1. Since the level in unstable, we must

control it!

2. We have two different categories of objectives

A. Tight level control for levels that strongly influence process

performance (or are very small).

- Level near set point, aggressive flow adjustments

B. Averaging level control for drums and tanks, where smooth

manipulation of flows will be beneficial to other units in the

plant.

- Level far from set point (but doesnt overflow), slower flow

adjustments

To design control, we

need to understand the

process dynamics

control objectives

algorithm & tuning

Lets determine the

control objectives

for level control

To design control, we

need to understand the

process dynamics

control objectives

algorithm & tuning

level sizing

Lets determine the

algorithm & tuning

for level control

CHAPTER 18: LEVEL CONTROL

LC

F

in

F

out

1. Is the control in the figure

a. feedback

b. feedforward

c. neither

d. both

2. What makes control difficult?

CHAPTER 18: LEVEL CONTROL

LC

F

in

F

out

1. Is the control in the figure

a. feedback

b. feedforward

c. neither

d. both

2. What makes control difficult?

Dead time makes feedback

difficult, but we see that

this process has negligible

dead time!

Feedback: The flow out

has a causal effect on the

level.

Since this is feedback,

lets use the old

standard, PI control

(D isnt needed).

LC

D = F

in

MV = F

out

CV = L

CHAPTER 18: LEVEL CONTROL

Controller Tuning

Can we use the standard PI

tuning approach shown in

the schematic?

S-LOOP plots deviation variables (IAE = 608.1005)

0 5 10 15 20 25 30 35 40 45 50

0

0.2

0.4

0.6

0.8

1

Time

M

a

n

i

p

u

l

a

t

e

d

V

a

r

i

a

b

l

e 0 5 10 15 20 25 30 35 40 45 50

0

0.2

0.4

0.6

0.8

1

DYNAMIC SIMULATION

Time

C

o

n

t

r

o

lle

d

V

a

r

ia

b

le

Determine a model

using the process

reaction curve

experiment.

Kc

TI

Determine the initial

tuning constants from

a correlation.

0 20 40 60 80 100 120

0

0.5

1

1.5

S-LOOP plots deviation variables (IAE = 9.7189)

Time

C

o

n

tr

o

lle

d

V

a

r

ia

b

le

0 20 40 60 80 100 120

0

0.5

1

1.5

Time

M

a

n

ip

u

la

te

d

V

a

r

ia

b

le

Apply and fine tune

as needed.

I dt t L L

T

t L L K t F

t

SP

I

SP C out

+

(

+ =

0

' )) ' ( (

1

)) ( ( ) (

LC

D = F

in

MV = F

out

CV = L

CHAPTER 18: LEVEL CONTROL

S-LOOP plots deviation variables (IAE = 608.1005)

0 5 10 15 20 25 30 35 40 45 50

0

0.2

0.4

0.6

0.8

1

Time

M

a

n

i

p

u

l

a

t

e

d

V

a

r

i

a

b

l

e 0 5 10 15 20 25 30 35 40 45 50

0

0.2

0.4

0.6

0.8

1

DYNAMIC SIMULATION

Time

C

o

n

t

r

o

lle

d

V

a

r

ia

b

le

Cannot determine a

model using the

process reaction

curve experiment.

Kc

TI

Cannot determine

the initial tuning

constants from

Ciancone (or Ziegler-

Nichols step)

correlation.

0 5 10 15 20 25 30 35 40 45

Time

L

e

v

e

l

0 5 10 15 20 25 30 35 40 45

Time

F

l

o

w

o

u

t

Standard tuning

charts are not

applicable to a non-

self-regulating level.

The level process is

unstable. Without

control, it never

reaches a new steady

state

G

d

(s)

G

P

(s) G

v

(s) G

C

(s)

G

S

(s)

D(s)

CV(s)

CV

m

(s)

SP(s) E(s)

MV(s)

+

+

+

-

LC

D = F

in

MV = F

out

CV = L

CHAPTER 18: LEVEL CONTROL

Lets build a model of the process with the controller, i.e, the closed-

loop system. We will ignore the fast sensor and valve dynamics.

Using block diagram algebra, we obtain

A = cross

sectional

area

) ( ) ( 1

) (

) (

) (

s G s G

s G

s F

s L

P C

D

in

+

=

With G

c

(s) being either

P-only of PI

For a non-self regulating level

As

s G s G

D P

1

) ( ) ( = =

LC

D = F

in

MV = F

out

CV = L

CHAPTER 18: LEVEL CONTROL

We substitute the appropriate models

for each process and controller to

obtain the following transfer function

models, which we can solve

analytically for a step disturbance!

A = cross

sectional

area

A

K T

and

K

AT

s s

K

T

s F

s L

C I

C

I

C

I

in

) (

2

1

1 2

) (

) (

2 2

=

+ +

(

=

Proportional-only control

Proportional-integral control

1

1

) (

) (

+

|

.

|

\

|

=

s

K

A

K

s F

s L

C

C

in

|

|

.

|

\

|

+ =

+

(

+ =

s T

K s G

I dt t L L

T

t L L K t F

I

C C

t

SP

I

SP C out

1

1 ) (

' )) ' ( (

1

)) ( ( ) (

0

| |

C C

SP C out

K s G

I t L L K t F

=

+ =

) (

) ( ) (

CHAPTER 18: LEVEL CONTROL

Stable, first order

Never underdamped

Non-zero s-s offset

Stable, second order

Underdamped when < 1

(We want overdamped!)

Zero s-s offset

P-only PI

(

(

|

.

|

\

|

=

|

.

|

\

|

c

K

A

t

C

in

e

K

F t L

/

1

1

) ( '

(

(

|

.

|

\

|

=

|

.

|

\

|

c

K

A

t

in

e t

A

F

t L

2

/

) ( '

Disturbance step response Disturbance step response

| | I t L L K t F

SP C out

+ = ) ( ) (

I dt t L L

T

t L L K t F

t

SP

I

SP C out

+

(

+ =

0

' )) ' ( (

1

)) ( ( ) (

CHAPTER 18: LEVEL CONTROL

P-only Tuning

Determine the expected maximum step disturbance size (F

max

) and

calculate the K

c

to give the maximum allowed change in the level

(L

max

) .

LC

F

out

F

max

L

max

Note, level does

not return to its

set point.

When is this O.K?

K

c

= - (F

max

)/ (L

max

)

F

out

= ??

| | I t L L K t F

SP C out

+ = ) ( ) (

CHAPTER 18: LEVEL CONTROL

PI Tuning

Determine the expected maximum step disturbance size (F

max

) and

calculate the K

c

and T

I

to give the maximum allowed change in the level

(L

max

).

Set tuning so that damping coefficient, = 1.

LC

F

out

F

max

L

max

Note, level returns

to its set point.

F

out

= ??

K

c

= - 0. 736 (F

max

)/ (L

max

) T

I

= 4 (

2

) A/(-K

c

)

F

out

I dt t L L

T

t L L K t F

t

SP

I

SP C out

+

(

+ =

0

' )) ' ( (

1

)) ( ( ) (

CHAPTER 18: LEVEL CONTROL

Lets use these results for averaging and tight level control.

LC

F

in

F

out

P-only control: K

c

= - (F

max

)/ (L

max

)

PI Control: K

c

= - 0. 736 (F

max

)/ (L

max

) T

I

= 4 (

2

) A/(-K

c

)

Averaging level control, L

max

40% of maximum range

Tight level control, L

max

5% of maximum range

To design control, we

need to understand the

process dynamics

control objectives

algorithm & tuning

Lets determine the

control objectives

for level control

To design control, we

need to understand the

process dynamics

control objectives

algorithm & tuning

level sizing

Lets look again at the

process

CHAPTER 18: LEVEL CONTROL

How do we determine the proper vessel volume?

LC

F

in

F

out

V = ?

That is a good question.

Averaging level control will not

provide improvement unless the

vessel is large enough!

CHAPTER 18: LEVEL CONTROL

One key design goal: maintain the rate of change of the

manipulated flow below a maximum when using averaging

tuning. This protects the downstream units from fast

disturbances.

LC

F

out

F

max

max

(

dt

dF

out

V = ?

max

2

max

) ( 84 . 1

(

=

dt

dF

F

V

out

The equation is based on a PI controller

with the averaging tuning recommended

in this chapter.

See Chapter 18 for derivation

I dt t L L

T

t L L K t F

t

SP

I

SP C out

+

(

+ =

0

' )) ' ( (

1

)) ( ( ) (

L

max

To design control, we

need to understand the

process dynamics

control objectives

algorithm & tuning

level sizing

CHAPTER 18: LEVEL CONTROL

LC

F

in

F

out

Now, we understand control of a single level!

How small can we make the levels?

Do we have a guideline?

CHAPTER 18: LEVEL CONTROL

Process plants have many units in series. Inventory control behaves

similar to a series of tanks. How should they be controlled?

F

0

LC LC

LC

F

1

F

2

F

3

Feed push with levels adjusting flows out

F

0

LC LC

LC

F

1

F

2

F

3

Product pull with levels adjusting flows in

CHAPTER 18: LEVEL CONTROL

For a series of levels, what is the importance of damping?

F

0

LC LC

LC

F

1

F

2

F

3

Step

change

We see that flow variation increases with

number of levels in series

P-only control is not oscillatory

PI (=1) experiences overshoot

PI (=0.5) experiences large oscillations

P-only

PI (=1)

PI (=0.5)

Best

Not acceptable

CHAPTER 18: LEVEL CONTROL WORKSHOP 1

We can have a liquid inventory that is not controlled, if the

vessel is large enough. Lets look at an example.

What is the minimum volume for

the storage tank?

Plot the level vs. time.

L

F

in

F

out

Time (days)

F

l

o

w

r

a

t

e

The flow in involves batches of 24,000 m

3

delivered over 12 hours, with a batch

delivered every five days.

The flow out is the feed to the plant. It must

be continuous and have a constant value.

1/2

5

CHAPTER 18: LEVEL CONTROL WORKSHOP 2

The principles we have learned for liquid level control

apply to solid and gas inventories as well.

1. Think of an example in a process plant in which we need to have

an inventory of

a. (granular) solids

b. gas

2. Describe the storage equipment for each.

3. Select a sensor to measure the inventory for each

4. Determine whether the inventory is self-regulating or non-self-

regulating.

5. Sketch the process with control.

CHAPTER 18: LEVEL CONTROL WORKSHOP 3

Discuss how you determine the proper liquid

inventories for the following unit operations.

1. Liquid on the shell side of a

shell and tube heat exchanger.

2. Liquid on a distillation tray

cooling

medium

TC

10

FC

1

Bypass and

adjustable 3-way

mixing valve

1

2

3

15

16

17

LC-1

LC-3

AC-1

PC-1

F4

F7

F8

AC-1

CHAPTER 18: LEVEL CONTROL WORKSHOP 3

3. Liquid in a flash drum

4. Liquid in a CSTR

Feed

Vapor

product

Liquid

product

Process

fluid

Steam

F1

F2 F3

T1

T2

T3

T5

T4

T6 P1

LC

A1

L. Key

Discuss how you determine the proper liquid

inventories for the following unit operations.

L

F

T

A

CHAPTER 18: LEVEL CONTROL WORKSHOP 4

Calculate the level tuning for the situation described below.

Determine the tuning for tight and for averaging control.

LC

F

in

F

out

V = 50 m

3

A = 25 m

2

F = 1.5 m

3

/min

F

max

= 1.0 m

3

/min

For each tuning, what would be the maximum rate of change of the

manipulated flow for a step disturbance of F

max

= 1.0 m

3

/min?

Lots of improvement, but we need some more study!

Read the textbook

Review the notes, especially learning goals and workshop

Try out the self-study suggestions

Naturally, well have an assignment!

CHAPTER 18: LEVEL CONTROL

When I complete this chapter, I want to be

able to do the following.

Determine the location and volume of liquid

inventories in a process

Determine the dynamics of various level processes

Tune level controllers for both typical control

objectives

CHAPTER 18: LEARNING RESOURCES

SITE PC-EDUCATION WEB

- Instrumentation Notes - Level sensors!

- Interactive Learning Module (Chapter 18)

- Tutorials (Chapter 18)

The Textbook, naturally, for many more examples.

An entire book on inventory control? Sure, it is an

important issue in corporate-wide production

management.

Nahmias, S., Production and Operations Analysis,

McGraw-Hill Irwin, New York, 2001.

CHAPTER 18: SUGGESTIONS FOR SELF-STUDY

1. Storing hazardous materials increases the risk in case of

an accident. Search the WEB for information on the

incident at Bhopal, India. Discuss the effect of the

storage volume of methyl isocyanate on the number of

deaths. A good place to start is

http://www.unu.edu/unupress/unupbooks/uu21le/uu21le00.htm#Contents

2. You are designing a reflux drum for a distillation tower

that operates at 10 atm. How does the cost of a carbon

steel, horizontal drum depend on the volume?

3. Discuss how you would monitor the performance of

averaging level control. Based on plant data, define

rules for fine tuning the controller.

CHAPTER 18: SUGGESTIONS FOR SELF-STUDY

4. Inventories are provided for all essential materials.

Discuss how you would determine the proper storage

inventory for some key materials, such as

a. Blood for transfusions

b. Food, e.g., grains and rice

c. Water for a city

5. Describe the physical principles for sensors to measure

the inventory of liquids, gases, and solids.

Вам также может понравиться

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Pid Controller: Ashok.S 500017496 M.Tech Pde R670211016Документ40 страницPid Controller: Ashok.S 500017496 M.Tech Pde R670211016Ashik Jacob Oommen100% (1)

- Process Control: Designing Process and Control Systems For Dynamic PerformanceДокумент42 страницыProcess Control: Designing Process and Control Systems For Dynamic PerformanceMercy JohnОценок пока нет

- Chap 15 Marlin 2002Документ49 страницChap 15 Marlin 2002Audrey Patrick KallaОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- CH 16 (1-27-05) PDFДокумент29 страницCH 16 (1-27-05) PDFDavid AlexanderОценок пока нет

- Projects With Microcontrollers And PICCОт EverandProjects With Microcontrollers And PICCРейтинг: 5 из 5 звезд5/5 (1)

- CH 16 (1-27-05)Документ29 страницCH 16 (1-27-05)David AlexanderОценок пока нет

- ExercisesДокумент18 страницExercisescetec1234Оценок пока нет

- Digital Pid Controller Using Microcontroller: Nishant Mishra 02913204914 EEEДокумент37 страницDigital Pid Controller Using Microcontroller: Nishant Mishra 02913204914 EEENishant MishraОценок пока нет

- Ansoft Simplorer: Model Derivation and Control Design of A Buck Converter UsingДокумент25 страницAnsoft Simplorer: Model Derivation and Control Design of A Buck Converter Usingc_u_r_s_e_dОценок пока нет

- Chap 08 Marlin 2002Документ37 страницChap 08 Marlin 2002Audrey Patrick KallaОценок пока нет

- Chapter 7 - Feedback ControllersДокумент44 страницыChapter 7 - Feedback ControllersPravin Nair50% (2)

- Root Locus DesignДокумент10 страницRoot Locus DesignirosenofОценок пока нет

- Aircraft Pitch - G1 ReportДокумент79 страницAircraft Pitch - G1 ReportTrabajo AviaciónОценок пока нет

- Process ControlДокумент26 страницProcess ControlMeenaОценок пока нет

- Simo MisoДокумент13 страницSimo MisoAndres RodriguezОценок пока нет

- PID ControlДокумент56 страницPID ControlSyafRizal100% (1)

- Pid-Applied Control Systems (Proportional Plus Integral Plus Derivative Control)Документ28 страницPid-Applied Control Systems (Proportional Plus Integral Plus Derivative Control)hiltoneng100% (1)

- Pid TuningДокумент19 страницPid TuningAsuh Rifqi Prihandana100% (1)

- Feedback Controller TuningДокумент23 страницыFeedback Controller Tuningso cool100% (1)

- Proportional-Integral-Derivative (PID) Control: Velocity ResponseДокумент34 страницыProportional-Integral-Derivative (PID) Control: Velocity ResponseFadi AlbatshОценок пока нет

- Advanced Control StrategiesДокумент27 страницAdvanced Control StrategiesmanueldidyОценок пока нет

- Lect. 17 Che 185 - Pid ControlДокумент36 страницLect. 17 Che 185 - Pid ControlAhmad Adel El TantawyОценок пока нет

- Chap 07 Marlin 2002Документ32 страницыChap 07 Marlin 2002Audrey Patrick KallaОценок пока нет

- 15.el Algoritmo de Control PIDДокумент44 страницы15.el Algoritmo de Control PIDYulieth BravoОценок пока нет

- Traditional Advanced Control StrategiesДокумент48 страницTraditional Advanced Control Strategiescape iipeОценок пока нет

- Controller PrincipleДокумент24 страницыController PrinciplePortia ShilengeОценок пока нет

- Advanced Control Seborg Chapter 15 16Документ43 страницыAdvanced Control Seborg Chapter 15 16Akhil Tiwari0% (1)

- PDC Chapter 8Документ49 страницPDC Chapter 8satya sagarОценок пока нет

- Centum VP 5 ENG Control Pgms - GlobalДокумент36 страницCentum VP 5 ENG Control Pgms - GlobalNikhilesh Muraleedharan100% (2)

- Basic Con Trol Act Ions AND Controll ERS: By: Yatendra KumarДокумент82 страницыBasic Con Trol Act Ions AND Controll ERS: By: Yatendra KumarNavdeepОценок пока нет

- Feedback Control PID Control: HadiyantoДокумент64 страницыFeedback Control PID Control: HadiyantoNuzul RamadhaniОценок пока нет

- Automation Exam Formula SheetДокумент10 страницAutomation Exam Formula SheetRobert LoweОценок пока нет

- Assignment 2 - Adv CTL 2020Документ7 страницAssignment 2 - Adv CTL 2020Thành Trung Nguyễn QuáchОценок пока нет

- Control of Continuous Process: Lecturer: Dr. Shallon StubbsДокумент32 страницыControl of Continuous Process: Lecturer: Dr. Shallon StubbsLuther King Ferguson100% (1)

- SOPDTДокумент31 страницаSOPDTAldiansyah NofaОценок пока нет

- Control StrategyДокумент44 страницыControl StrategyAyunie FazlinОценок пока нет

- Cascade ControlДокумент38 страницCascade ControlSun LwinОценок пока нет

- Automatic Voltage RegulatorsДокумент35 страницAutomatic Voltage RegulatorsAlejandroHerreraGurideChileОценок пока нет

- Pid Controls PLC EnvironДокумент22 страницыPid Controls PLC EnvironAbhinav GuptaОценок пока нет

- 6 - Tuning and Control SchemesДокумент34 страницы6 - Tuning and Control SchemesZahidОценок пока нет

- Control Tutorials For MATLAB and Simulink - Introduction - PID Controller DesignДокумент15 страницControl Tutorials For MATLAB and Simulink - Introduction - PID Controller DesignSengottu VelusamyОценок пока нет

- Workshop#10 Report - Cascade Control of Jacketed Reactor - Roy - StewartДокумент14 страницWorkshop#10 Report - Cascade Control of Jacketed Reactor - Roy - Stewartdevbones18Оценок пока нет

- Unit-3 PDCДокумент59 страницUnit-3 PDCNirmal Kumar PandeyОценок пока нет

- Task2 1 Specific Training-EnДокумент35 страницTask2 1 Specific Training-EnSantiago LarrazОценок пока нет

- PID Control - Simple Tuning Methods: Ulf HolmbergДокумент39 страницPID Control - Simple Tuning Methods: Ulf HolmbergSan BanОценок пока нет

- Control Chapter07 - GearTeamДокумент71 страницаControl Chapter07 - GearTeamNabilaSalsaОценок пока нет

- Ingeniería Automotriz: Teoria de ControlДокумент25 страницIngeniería Automotriz: Teoria de ControlPablo SandovalОценок пока нет

- PID Control Tuning Methods and Intro To NonlinearДокумент36 страницPID Control Tuning Methods and Intro To NonlinearKuanysh YessenzhanovОценок пока нет

- 3P04 Tutorial 7 SingleLoop 2008Документ19 страниц3P04 Tutorial 7 SingleLoop 2008Khaled KamalОценок пока нет

- CHE3162.Lecture8 Feedback PIDДокумент33 страницыCHE3162.Lecture8 Feedback PIDPhan NeeОценок пока нет

- Cascade ControlДокумент17 страницCascade Controlمحمد سلامОценок пока нет

- Prepared By: United Arab Emirates University College of Engineering Electrical Engineering DepartmentДокумент87 страницPrepared By: United Arab Emirates University College of Engineering Electrical Engineering DepartmentpadmajasivaОценок пока нет

- Introduction: PID Controller Design: SystemДокумент14 страницIntroduction: PID Controller Design: SystemRantharu AttanayakeОценок пока нет

- Starting: Chapter 7: PID ControlДокумент13 страницStarting: Chapter 7: PID ControlKishodarran Rajendran KicchoОценок пока нет

- 13 Cascade ControlДокумент39 страниц13 Cascade ControlMansour AbdulazizОценок пока нет

- 5 StereoisomersДокумент37 страниц5 StereoisomersAudrey Patrick KallaОценок пока нет

- AbsorptionStripping PDFДокумент25 страницAbsorptionStripping PDFJuan Camilo HenaoОценок пока нет

- Safety and Security Emergency Plan For EVENTДокумент11 страницSafety and Security Emergency Plan For EVENTAudrey Patrick KallaОценок пока нет

- Chapter 1 - Process DiagramsДокумент36 страницChapter 1 - Process Diagramsmrajim93Оценок пока нет

- .Cost EstimationДокумент15 страниц.Cost EstimationAudrey Patrick KallaОценок пока нет

- Chemical Process DesignДокумент93 страницыChemical Process DesignAudrey Patrick Kalla50% (2)

- Unit Operations and Processes in Environmental EngineeringДокумент815 страницUnit Operations and Processes in Environmental EngineeringAudrey Patrick Kalla89% (28)

- Ammonia StorageДокумент6 страницAmmonia Storagemsathishkm3911Оценок пока нет

- Ads or PtionДокумент141 страницаAds or PtionAudrey Patrick KallaОценок пока нет

- Absorption ColumnsДокумент55 страницAbsorption ColumnsAudrey Patrick KallaОценок пока нет

- Chapter 10 - QДокумент32 страницыChapter 10 - Qmohammedakbar88Оценок пока нет

- EiaДокумент16 страницEiaAudrey Patrick KallaОценок пока нет

- Paint Production Process DiagramДокумент4 страницыPaint Production Process DiagramQasim SarwarОценок пока нет

- Heat ExchangerДокумент16 страницHeat ExchangerAudrey Patrick KallaОценок пока нет

- Aerosol Paints Know How Plant Setting FormulationsДокумент1 страницаAerosol Paints Know How Plant Setting FormulationsAudrey Patrick Kalla67% (3)

- Magnetic Fields: PHYS102 Previous Exam ProblemsДокумент11 страницMagnetic Fields: PHYS102 Previous Exam ProblemsAudrey Patrick KallaОценок пока нет

- 09.electromagntic and Faraday Law - InductionДокумент53 страницы09.electromagntic and Faraday Law - InductionAudrey Patrick KallaОценок пока нет

- Paint and Coating ProcessesДокумент65 страницPaint and Coating ProcessesAudrey Patrick Kalla100% (1)

- 84 enДокумент6 страниц84 enNomaan AsimОценок пока нет

- Paint Testing ChartДокумент39 страницPaint Testing ChartAudrey Patrick Kalla0% (1)

- DRAFT CIOB Code of Quality ManagementДокумент98 страницDRAFT CIOB Code of Quality ManagementKeith Cubero100% (1)

- 001-0001-12 Quality System ManualДокумент12 страниц001-0001-12 Quality System ManualPramod AthiyarathuОценок пока нет

- BTS3900&BTS5900 V100R013C00SPC150 NodeBFunction Performance Counter Reference PDFДокумент762 страницыBTS3900&BTS5900 V100R013C00SPC150 NodeBFunction Performance Counter Reference PDFSwandito HaryoyudantoОценок пока нет

- How Do I Coordinate DesignДокумент8 страницHow Do I Coordinate DesignjvwzyxktuvnjohdkbjОценок пока нет

- Standardization Uv Flexo ManualДокумент73 страницыStandardization Uv Flexo ManualMilos Papic100% (3)

- Bakso - Wikipedia, The Free EncyclopediaДокумент3 страницыBakso - Wikipedia, The Free EncyclopediaTyas Te PyОценок пока нет

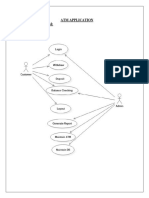

- Atm Application Use Case DiagramДокумент58 страницAtm Application Use Case DiagramS. Mohd TharikОценок пока нет

- Lifefitness Produktkatalog 2020Документ43 страницыLifefitness Produktkatalog 2020Gabriel SilvaОценок пока нет

- Course of Study - Högskolan I GävleДокумент1 страницаCourse of Study - Högskolan I GävlekamranОценок пока нет

- 08-Regulations Governing Business Trip A..ty - Higher School of EconomicsДокумент13 страниц08-Regulations Governing Business Trip A..ty - Higher School of EconomicsCha Icha NathaОценок пока нет

- Edmund John Balboa Bsa: Let's CheckДокумент3 страницыEdmund John Balboa Bsa: Let's CheckEj MacadatuОценок пока нет

- Uppercase Letter TracingДокумент27 страницUppercase Letter TracingElvis AungОценок пока нет

- Six Principles of Finance ManagementДокумент5 страницSix Principles of Finance ManagementAqib javed100% (1)

- Chat Summarization and Sentiment Analysis Techniques in Data MiningДокумент5 страницChat Summarization and Sentiment Analysis Techniques in Data MiningPersoAccoОценок пока нет

- الحلل السندسية في الأخبار التونسيةДокумент381 страницаالحلل السندسية في الأخبار التونسيةchohra khaledОценок пока нет

- Cereals and Pasta CookeryДокумент48 страницCereals and Pasta CookeryJoshua Guiriña100% (3)

- Class 10 AI NOTES CHAPTER 1Документ7 страницClass 10 AI NOTES CHAPTER 1Vinayak Chaturvedi100% (4)

- Theory of Structures - IiДокумент4 страницыTheory of Structures - IiAjmal MuhammedОценок пока нет

- Create RDP Using Digital OceanДокумент3 страницыCreate RDP Using Digital OceanZay Min HtetОценок пока нет

- B - 01 - TDD-LTE Protocol and InterfaceДокумент31 страницаB - 01 - TDD-LTE Protocol and Interfaceaslam_326580186Оценок пока нет

- Shantae ManualДокумент19 страницShantae ManualJonathan Lesomthing100% (1)

- YEF Final ReportДокумент12 страницYEF Final ReportNidhi SharmaОценок пока нет

- Financial Performance of State Bank of India: Dr.G. KanagavalliДокумент13 страницFinancial Performance of State Bank of India: Dr.G. KanagavalliANKIT GUPTAОценок пока нет

- LDRRMP - Vi Monitoring and EvaluationДокумент19 страницLDRRMP - Vi Monitoring and EvaluationMohrein H. Ismael VI100% (1)

- Bearing Phase OutДокумент12 страницBearing Phase OutAndrés UguñaОценок пока нет

- Tawitawi Public ConsultationДокумент5 страницTawitawi Public ConsultationbpdmacapendegОценок пока нет

- Ortiz, Domingo, Cachero, Tabio - Exp 8 - Fluids in MotionДокумент4 страницыOrtiz, Domingo, Cachero, Tabio - Exp 8 - Fluids in Motionortiz.kylleОценок пока нет

- Doc13 PDFДокумент6 страницDoc13 PDFBladeОценок пока нет

- Karlos KarlinaДокумент2 страницыKarlos KarlinaTip RendahОценок пока нет

- Topic: A Study On Awareness and Accessing Behavior Of: DEMAT Account in Rajpipla CityДокумент19 страницTopic: A Study On Awareness and Accessing Behavior Of: DEMAT Account in Rajpipla CityBhavesh VasavaОценок пока нет

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherОт EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherОценок пока нет

- The Importance of Being Earnest: Classic Tales EditionОт EverandThe Importance of Being Earnest: Classic Tales EditionРейтинг: 4.5 из 5 звезд4.5/5 (44)

- A**holeology The Cheat Sheet: Put the science into practice in everyday situationsОт EverandA**holeology The Cheat Sheet: Put the science into practice in everyday situationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedОт EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedРейтинг: 4.5 из 5 звезд4.5/5 (5)

- 1,001 Facts that Will Scare the S#*t Out of You: The Ultimate Bathroom ReaderОт Everand1,001 Facts that Will Scare the S#*t Out of You: The Ultimate Bathroom ReaderРейтинг: 3.5 из 5 звезд3.5/5 (48)

- The Book of Bad:: Stuff You Should Know Unless You’re a PussyОт EverandThe Book of Bad:: Stuff You Should Know Unless You’re a PussyРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Sex, Drugs, and Cocoa Puffs: A Low Culture ManifestoОт EverandSex, Drugs, and Cocoa Puffs: A Low Culture ManifestoРейтинг: 3.5 из 5 звезд3.5/5 (1429)

- The Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolОт EverandThe Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolРейтинг: 4 из 5 звезд4/5 (14)

- Sorry I'm Late, I Didn't Want to Come: One Introvert's Year of Saying YesОт EverandSorry I'm Late, I Didn't Want to Come: One Introvert's Year of Saying YesРейтинг: 4.5 из 5 звезд4.5/5 (400)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtОт EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtРейтинг: 4 из 5 звезд4/5 (60)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)