Академический Документы

Профессиональный Документы

Культура Документы

Confined Space Sap

Загружено:

fairusОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Confined Space Sap

Загружено:

fairusАвторское право:

Доступные форматы

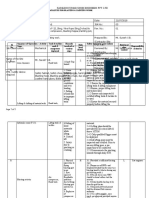

Summary of Spaces Assessed for Confined Space Survey

Alphabetical by Space Type

Space Code Space Description Hazards Space rating and controls. Signage Requirements Comments

Permit Required Confined Space

Air Handling Unit - where there is

a potential for a hazardous Permit Required Confine Space. Procedures

atmosphere exists - (e.g. to assure no toxic chemical will be No such spaces have been

hazardous chemical exhaust from Toxic chemicals. Mechanical generated in system during work are Post and/or Restrict Access to only identified or posted at this

SAP-PR-AHU3 a chemistry or biology lab). hazard from fan systems. needed, and lockout/tagout of fans. trained personnel. time.

Contract language should

inform contractor that they are

required to meet OSHA

confined space entry

procedures. Access to

elevator pits is restricted. Only

trained personnel should be

Permit Required Confined Space. Elevator Spaces are not likely to be entered permitted to enter and work in

equipment is maintained by a private without special access keys and elevator pits. Elevator pit entry

Hazard of elevator crushing contractor. UNL personnel enter for cleaning individuals entering space should procedures should be

SAP-PR-EP Elevator Pits someone in pit. and retrieving keys, etc. be trained on the safety hazards. followed.

Permit Required Confined Space -

Additional Electrical Safe Work Practices

need to be followed. Shut down of power to

the space required. Test atmosphere

Electrical Vault - Restricted Entry Atmosphere hazard. Electrical before entry and take precautions necessary A warning sign can be posted inside Utility Department personnel

SAP-PR-EV - Access through a manhole hazard. depending on the results. the cover. will post the spaces.

Generally, UNL personnel do

not enter these spaces but

work from outside the space to

remove ash, etc. Contract

language should inform

Fuel line. Hazardous contractor that they are

Atmosphere. Cleaning work in Permit Required Confined Space. Test required to meet OSHA

such a unit can create excessive atmosphere. Lock and tag out or block fuel confined space entry

SAP-PR-I Incinerators dust exposure. line. Posted procedures.

These pits are flushed and are

Livestock Pit-Under Floor of Permit Required Confined Space. Test rarely entered. Only one part

Livestock Pens - Animal Science Hazardous atmosphere. space before entry. Lock and tag out of the pit, the end near the

SAP-PR-LP Complex Engulfment hazard. flushing system. Posted drain, is deeper than four feet.

Entries most commonly involve

repair of the pump equipment.

If there is no hazardous

atmosphere, and all other

Permit Required Confined Space. Test hazards can be prevented by

atmosphere. Lock and tag out pump and lockout/tagout from outside the

Hazardous atmosphere, primarily other electrical equipment. Ventilate space space, then these spaces can

oxygen defieciency. Engulfment if necessary. If water tends to accumulate in often be reclassified as non-

Pits, including Sump Pits - greater hazard. Electrical and area quickly when pump is off, alternate permit entry for duration of

than 4 feet - AKA - Deep Sump mechanical hazards from pump pumping equipment may be necessary for entry. There are a couple of

SAP-PR-P2 Pits. equipment. work in the space to proceed. Posted exceptions, however.

Set procedures have been

established for boiler entries.

For other tank spaces, the

entry will depend on the nature

of the tank, it's contents, and

other hazards. In general,

entry by UNL staff into other

types of tanks is unlikely. For

Tanks or Vessel: Includes: Hazardous Atmosphere. Possibly Permit Required Confined Spaces. Test contractor entries, contract

Boilers, Water Tanks, Air Tanks, engulfment hazard or other atmosphere. Determine other hazards language should inform

Brine Tanks, Zeolite Tanks, Fuel hazard from failure to shut off associated with specific space. Determine contractor that they are

Tanks, and other tanks and valve systems. Possible electrical hazards to be introduced by the work in the required to meet OSHA

vessels large enough to bodily hazard. Possible high space. These hazards must be controlled or confined space entry

SAP-PR-T enter. temperature hazard. eliminated prior to entry. Post or train staff in recognition procedures.

Generally the steam tunnel

procedures can be used for

entry into these spaces.

However, the atmosphere of

these space must be tested

prior to any entry. In addition,

these spaces can be quite

warm, and work for extended

periods of time in the space

Secodary Steam Tunnels - Type Train individuals to identify confined may require a blower system

SAP-PR-ST2 II - Restricted access. Permit Required Confined Spaces. sections. for cooling.

Permit Required Confined Space - other

spaces within the Food Industry building are

not large enough for bodily entry. Note the

Spray Dryer - Food Industry blender and mixer tank are covered under

SAP-PR-SD Complex. the tank section. Post

Non-Permit Required Confined Space

SAP-NP-P Planter - Kiem Plant Science Non-Permit Required Confined Space. Build a top to prevent entry

Although Ceiling Crawl Space are "confined

spaces", these spaces have either natural or

permanent mechanical ventilation to prevent

the accumulation of a hazardous

atmosphere, and they do not present

engulfment or other serious hazards under

normal entry conditions. However, work to

be done in the space might introduce a

hazard requiring the entry to be permit entry,

and this needs to be evaluated. In addition,

if there are any obvious signs that there is a

change to the space, for example and

unusual odor coming from the space, the

situation should be evaluated by an entry

SAP-NP-CCS Ceiling Crawl Spaces supervisor befor the entry is begun. No signs required.

Summary of Spaces Assessed for Confined Space Survey

Alphabetical by Space Type

AHU - Type 3 - Whole Body Entry

required or possible in order to

change filters or perform

maintenance and access is not

restricted. These AHU have full or Non-Permit Required Confined Space See Post and/or Restrict Access to only

SAP-NC-AHU3 near full size doors. note: (2), (3) trained personnel

Non Confined Space

Air Handling Units (AHU1) - Type

I - Can not be bodily entered Does not meet the OSHA definition of a Confined Space Signs Not

SAP-NC-AHU1 (Whole Body) confined space. See note: (1) Required.

AHU- Type 2A - Whole Body

Entry required or possible to Confined Space Signs Not

change filters or perform Required. However, lockout tagout

maintenance and access is not Does not meet the OSHA definition of a of fan systems may be required for

SAP-NC-AHU2A restricted (i.e. full size doors). confined space. See note: (2) safe entry into these spaces.

Because permit required confined

spaces are located within the steam

Much of the Steam Tunnel is designed for tunnel system - recommend all

human occupancy (e.g. sections that are steam-tunnels interior accesses be

large enough to work and walk in erect posted. Exterior accesses such as

posture and natural ventilation is manhole or Bilco ® type doors do

Steam Tunnels -Type I present- and electrical lighting is not need to be posted if kept

SAP-NC-ST1 Unrestricted access. provided. See note/s: (2), (3), (6). locked.

Pits, including Sump Pit - Less

than 4 feet, AKA Shallow Sump Confined Space Signs Not

SAP-Pits1 Pits Not a Confined Space. Required.

Does not meet the OSHA definition of a

confined space. See note: (2), (3), (4)

However, that does not mean that care Confined Space Posting is not

should not be taken regarding the type of required. It would be beneficial for

Offices, Closets, Storage Rooms, work done in these spaces. The spaces walk-in coolers to post a warning

Mechanical Rooms, Walk-in may have poor ventilation, and work with that volatile materials shall not be

Coolers and Freezers, Elevator certain materials could create an stored in walk-in coolers or

SAP-N Equipment Rooms atmosphere hazard. freezers.

Вам также может понравиться

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetДокумент3 страницыAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferОценок пока нет

- Confined Space ES&H PowerPointДокумент42 страницыConfined Space ES&H PowerPointChungNguyenОценок пока нет

- Confined Space - Introduction: Canadian Government Departments Responsible For OH&S Confined Space - ProgramДокумент7 страницConfined Space - Introduction: Canadian Government Departments Responsible For OH&S Confined Space - ProgramAnge JuanОценок пока нет

- Working at Height Rescue Plan: WHS-FM-008Документ2 страницыWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoОценок пока нет

- Confined Space PresentationДокумент10 страницConfined Space PresentationNii AshiiiОценок пока нет

- Confined Spaces CardsДокумент1 страницаConfined Spaces CardsJafar KhanОценок пока нет

- Confined SpacesДокумент25 страницConfined Spaceshi2lathaОценок пока нет

- 51 Confined SpaceДокумент1 страница51 Confined SpaceAnonymous ANmMebffKRОценок пока нет

- CamScanner 03-22-2023 07.44Документ2 страницыCamScanner 03-22-2023 07.44Umar AliОценок пока нет

- Safety ProgramДокумент21 страницаSafety ProgramSits RdddОценок пока нет

- JSA For Pressure Test 2ND REVISIONДокумент10 страницJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Excavation Safety Dos and DontsДокумент4 страницыExcavation Safety Dos and DontsVidya SagarОценок пока нет

- Building De-Dusting JSAДокумент3 страницыBuilding De-Dusting JSAJayesh J PillaiОценок пока нет

- Safe Working at Heights Part 1 - KG - 310519Документ15 страницSafe Working at Heights Part 1 - KG - 310519eugene stevensОценок пока нет

- Jsa FormДокумент4 страницыJsa FormjihadspiritОценок пока нет

- WAH - Working On Roofs - 0Документ13 страницWAH - Working On Roofs - 0Rizki DarmawanОценок пока нет

- HSE Human Factors Briefing Note No. 5 Emergency Response: SourceДокумент4 страницыHSE Human Factors Briefing Note No. 5 Emergency Response: SourceMargaretta WijayantiОценок пока нет

- Risk Assess T-23 - Hilti Cartridge Tool OperationДокумент2 страницыRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- RA Excavation For Trial TrenchДокумент9 страницRA Excavation For Trial TrenchSasi KumarОценок пока нет

- Updated JSA For SAPMTofficeДокумент30 страницUpdated JSA For SAPMTofficeShaikh Abu bakarОценок пока нет

- Demolition JhaДокумент2 страницыDemolition JhaElvyn Fabellore HerreraОценок пока нет

- Workplace Inspection Checklist: General Yes No NotesДокумент4 страницыWorkplace Inspection Checklist: General Yes No NotesLakshmi BalaОценок пока нет

- Job Safety Analysis Sheet: Manual ExcavationДокумент1 страницаJob Safety Analysis Sheet: Manual ExcavationSafety ProfessionalОценок пока нет

- General Risk Assessment FormДокумент8 страницGeneral Risk Assessment FormmkmusaОценок пока нет

- Confined Space Entrant Attendant Form PDFДокумент2 страницыConfined Space Entrant Attendant Form PDFgkmlalОценок пока нет

- JHA Maintenance Tech HVACДокумент2 страницыJHA Maintenance Tech HVACMdavaОценок пока нет

- Suspended Load SafetyДокумент3 страницыSuspended Load Safetymy_agautamОценок пока нет

- TSTI FormДокумент2 страницыTSTI FormJinu ThomasОценок пока нет

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaДокумент6 страницSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerОценок пока нет

- Water Tank Cleaning TRAДокумент5 страницWater Tank Cleaning TRAyehia sayedОценок пока нет

- 23 JSA For Block WorkДокумент2 страницы23 JSA For Block WorkWakil AhmadОценок пока нет

- HIRAC - Work - at - Height - Template PDFДокумент8 страницHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariОценок пока нет

- JSA For IFRДокумент3 страницыJSA For IFRDilshad ali100% (1)

- Chemical Spill Kit ChecklistДокумент1 страницаChemical Spill Kit ChecklistPrudhvi RajОценок пока нет

- Ocm1 Confined SpaceДокумент2 страницыOcm1 Confined SpacerapidsicuminteОценок пока нет

- Safety Training: Hot WorksДокумент66 страницSafety Training: Hot WorksMuneeb Ur Rehman100% (1)

- Scaffold CampaignДокумент9 страницScaffold CampaignAdel SukerОценок пока нет

- Fan InstallationДокумент2 страницыFan InstallationKrishna PatilОценок пока нет

- Neas Miss Report (Blank Format)Документ1 страницаNeas Miss Report (Blank Format)kkalvi100% (1)

- Jha Confined SpaceДокумент6 страницJha Confined SpaceArun ArunbolluОценок пока нет

- JSA Formet New Blasting & PaintingДокумент5 страницJSA Formet New Blasting & Paintingsakthi venkatОценок пока нет

- Rescue Plan For Confined SpaceДокумент26 страницRescue Plan For Confined SpaceSARFARAZ KHANОценок пока нет

- Occupational Hazards Water Treatment ProcessesДокумент14 страницOccupational Hazards Water Treatment ProcessesMohamed Salem100% (1)

- JHA For Installation 2 Inch Nozzle..Документ6 страницJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Job Description: Date: JSA NO.: - New Revised Job Location (Plant) : JOB LOCATION (Plant) : AreaДокумент2 страницыJob Description: Date: JSA NO.: - New Revised Job Location (Plant) : JOB LOCATION (Plant) : Areahithin666Оценок пока нет

- Confind Space RCДокумент11 страницConfind Space RCIrfan ashrafОценок пока нет

- Confined Space Entry Rescue Plan 1Документ11 страницConfined Space Entry Rescue Plan 1patrick ruwonaОценок пока нет

- Nitoproof 230Документ2 страницыNitoproof 230Balasubramanian Ananth50% (2)

- JSA-Confined Space Activity - 05Документ4 страницыJSA-Confined Space Activity - 05babjihanumanthuОценок пока нет

- Confine Space at Water TankДокумент7 страницConfine Space at Water TanknaraОценок пока нет

- Pha ExcavationДокумент13 страницPha ExcavationirshadОценок пока нет

- Standard Operating Procedure: Vehicle FuelingДокумент1 страницаStandard Operating Procedure: Vehicle FuelingAnees EkОценок пока нет

- Tiling Lesson 1.5.17Документ7 страницTiling Lesson 1.5.17Daryl MurrayОценок пока нет

- HSF-PR-0063 Work at HeightДокумент32 страницыHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- Work Method Statement: Confined SpaceДокумент3 страницыWork Method Statement: Confined SpaceKarthik babu0% (1)

- OHS PROC 113 BarricadesДокумент9 страницOHS PROC 113 BarricadesPhillip L100% (1)

- OSHA Fact Sheet On Confined Space ProceduresДокумент2 страницыOSHA Fact Sheet On Confined Space ProceduresRauf HuseynovОценок пока нет

- FallprotectionpresentationДокумент128 страницFallprotectionpresentationfairusОценок пока нет

- STC 37Документ4 страницыSTC 37willdelimОценок пока нет

- Writing Policy and ProcedureДокумент4 страницыWriting Policy and ProcedurefairusОценок пока нет

- Writing PoliciesДокумент3 страницыWriting PoliciesfairusОценок пока нет

- HealthsafetysurveyДокумент32 страницыHealthsafetysurveyfairusОценок пока нет

- Guide To Writing Policy and Procedure DocumentsДокумент14 страницGuide To Writing Policy and Procedure Documentsyiah100% (11)

- The True Islam MoralsДокумент4 страницыThe True Islam MoralsfairusОценок пока нет

- AfloatfallprotectionguideДокумент107 страницAfloatfallprotectionguidefairusОценок пока нет

- Chair Selection Guide Rev8 073108Документ2 страницыChair Selection Guide Rev8 073108fairusОценок пока нет

- Workstation GuideДокумент33 страницыWorkstation GuidefairusОценок пока нет

- Acquisition Safety Executive OverviewДокумент63 страницыAcquisition Safety Executive OverviewfairusОценок пока нет

- Injury - Paper Hotel WokerДокумент19 страницInjury - Paper Hotel Wokerfairus100% (3)

- CautionzoneДокумент9 страницCautionzonefairusОценок пока нет

- Plant and Equipment Safety ProceduresДокумент19 страницPlant and Equipment Safety ProceduresfairusОценок пока нет

- HAZIDДокумент8 страницHAZIDfairusОценок пока нет

- Morality and Law in IslamДокумент18 страницMorality and Law in IslamfairusОценок пока нет

- Muslims Are Good FolksДокумент20 страницMuslims Are Good FolksfairusОценок пока нет

- HAZOPДокумент7 страницHAZOPfairusОценок пока нет

- Hazop MethodДокумент75 страницHazop Methodfairus100% (11)

- HAZOPДокумент7 страницHAZOPfairusОценок пока нет

- Working Safer and Easier For Janitors, Custodians, and HousekeepersДокумент86 страницWorking Safer and Easier For Janitors, Custodians, and Housekeepersdoc_ona100% (1)

- Introduction To MachДокумент24 страницыIntroduction To Machfairus100% (1)

- International Introduction SafetyДокумент22 страницыInternational Introduction Safetyfairus100% (2)

- Human Rights and IslamДокумент5 страницHuman Rights and IslamfairusОценок пока нет

- Hazop & HazidДокумент2 страницыHazop & Hazidfairus100% (4)

- Hotel Motel Operators Risk Assesment Tool For Housekeepers 4562docДокумент6 страницHotel Motel Operators Risk Assesment Tool For Housekeepers 4562docfairusОценок пока нет

- Incompatible MaterialsДокумент1 страницаIncompatible MaterialsfairusОценок пока нет

- Hospitality ViolenceДокумент6 страницHospitality ViolencefairusОценок пока нет

- Safety and Health For HospitalДокумент29 страницSafety and Health For HospitalfairusОценок пока нет

- Hospital Safety ManualДокумент9 страницHospital Safety Manualfairus100% (4)

- NOx Questions and Answers July 02 PDFДокумент27 страницNOx Questions and Answers July 02 PDFMannMannОценок пока нет

- Rain Water HarvestingДокумент19 страницRain Water HarvestingAbhijit DasОценок пока нет

- Baro and Karadobi Hydropower ProjectsДокумент5 страницBaro and Karadobi Hydropower ProjectsZELALEMОценок пока нет

- Chemicals Zetag DATA Powder Magnafloc LT 27 - 0410Документ2 страницыChemicals Zetag DATA Powder Magnafloc LT 27 - 0410PromagEnviro.com0% (1)

- gb5 & fb80: U.S. Installation GuidelineДокумент2 страницыgb5 & fb80: U.S. Installation GuidelineAnatoliy RozenbljumОценок пока нет

- Refining and Petrochemical Complex FEED Execution: Contract #1CD1213AДокумент12 страницRefining and Petrochemical Complex FEED Execution: Contract #1CD1213AРоман БелоусовОценок пока нет

- L7-Mass Balance Reactive CombustionДокумент15 страницL7-Mass Balance Reactive CombustionFATIN NURATHIRAОценок пока нет

- Direct Pipe Levee CrossingДокумент9 страницDirect Pipe Levee CrossingYap Wen Khong Yap Wen KhongОценок пока нет

- Energy Storage and Meta DataДокумент9 страницEnergy Storage and Meta DataDamisha DamishaОценок пока нет

- Induction Course For M&E EngineerДокумент9 страницInduction Course For M&E EngineerZol HasОценок пока нет

- AcknowledgementДокумент35 страницAcknowledgementSaba HafeezОценок пока нет

- MVMJ - Volume 23 - Issue 2 - Pages 48-52Документ5 страницMVMJ - Volume 23 - Issue 2 - Pages 48-52HebaОценок пока нет

- MABR - Membrane Aerated Biofilm Reactor: Global Water, Wastewater & Reuse Treatment SolutionsДокумент19 страницMABR - Membrane Aerated Biofilm Reactor: Global Water, Wastewater & Reuse Treatment SolutionspinaОценок пока нет

- Kathputli ColonyДокумент14 страницKathputli ColonynihaОценок пока нет

- LSN Van Ballegouy 2014Документ25 страницLSN Van Ballegouy 2014Jorge OrdóñezОценок пока нет

- Manila Standard Today - August 09, 2012 IssueДокумент12 страницManila Standard Today - August 09, 2012 IssueManila Standard Today100% (1)

- Lab 12 - MPNДокумент10 страницLab 12 - MPNMariana LacerdaОценок пока нет

- Chapter 13Документ4 страницыChapter 13Poonam CheemaОценок пока нет

- PL62X en Rev03Документ18 страницPL62X en Rev03FilipGeorgianLaurentiuОценок пока нет

- Chemicals Zetag MSDS Beads Zetag 7523 - 0710Документ7 страницChemicals Zetag MSDS Beads Zetag 7523 - 0710PromagEnviro.comОценок пока нет

- Reliable: Pipeline Coating SolutionsДокумент9 страницReliable: Pipeline Coating Solutionsshoaib1985Оценок пока нет

- Septic Tank Size TableДокумент4 страницыSeptic Tank Size Tablepersona100% (5)

- Usage of Water Lilies As Environmental Friendly CupsДокумент5 страницUsage of Water Lilies As Environmental Friendly CupsJea Ruth San AntonioОценок пока нет

- Timber SeasoningДокумент41 страницаTimber SeasoningMageshwarОценок пока нет

- Soil Improvement Technique by IIT Chennai Professor Dr. S.R.GandhiДокумент214 страницSoil Improvement Technique by IIT Chennai Professor Dr. S.R.Gandhiarpit67% (3)

- Chemical Management D0cc1a52 2a03 4d29 Ac14 E8c1544c1c82Документ4 страницыChemical Management D0cc1a52 2a03 4d29 Ac14 E8c1544c1c82Arslan Haider100% (1)

- Chapter 1 of ResearchДокумент22 страницыChapter 1 of Researchgwen calluengОценок пока нет

- Bainmount - P Auto: User ManualДокумент43 страницыBainmount - P Auto: User ManualgopiОценок пока нет

- GJESM Volume 8 Issue 2 Pages 237-250Документ14 страницGJESM Volume 8 Issue 2 Pages 237-250GJESMОценок пока нет

- VIN297 PVC Non Pressure DWV SCJ 20110926 1Документ28 страницVIN297 PVC Non Pressure DWV SCJ 20110926 1Barrasons Engineers TeamОценок пока нет