Академический Документы

Профессиональный Документы

Культура Документы

Toro Equipment Anaconda, Fatflot & Sludgeway Technical Specifications

Загружено:

FilipeAntunesИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Toro Equipment Anaconda, Fatflot & Sludgeway Technical Specifications

Загружено:

FilipeAntunesАвторское право:

Доступные форматы

DISSOLVED AIR FLOTATION Product Specifications

Anaconda: Dissolved Air Flotation System for physical-chemical treatment. Advanced FADAR Flotation technology. Solid removal performance levels of up to 99%. Anaconda is made of FRP with high resistance chemical and mechanical resins. Accessibility and safety.

ANACONDA, HIGH PERFORMANCE DISSOLVED AIR FLOTATION

Anaconda FRC-2, FRC-5

Flows and Dimensions

MODEL FRC-2 FRC-5

Flow

2 m3/h

Maximum width A (mm) 1.513

Maximum height B (mm) 1.803+100

Length L (mm) 2.602

Installed power (kW) 3,3 SCP-BPS 4,5-7 VESSEL 3,9

Water inlet DN50

Water outlet DN65

Sludge outlet DN100

Drainage

Compressed air * consumption (Nl/min) 18 SCP-BPS 36 VESSEL 28

DN50

5 m3/h

2.024

1.803+100

2.960

DN80

DN100

DN125

DN65

Maximum width A (mm) 1.513 Maximum height B (mm) 1.803+100 Length L (mm) 2.602 SCP-BPS 4,5-7 Installed power (kW) 3,3 VESSEL 3,9 Water inlet DN65 Water outlet DN65 Sludge outlet DN100 Compressed air * consumption (Nl/min) 18 SCP-BPS 36 VESSEL 28

MODEL FRC-2 FRC-5

Flow

1 m3/h

Drainage DN50

3 m3/h

2.024

1.803+100

2.960

DN80

DN100

DN125

DN65

* The air pressure will be between 6-8 bar on all models.

The dimensions and product specifications might vary slightly, due to the normal development of products by the engineering department of Toro Equipment SL. More specific data can be found on our website at www.toroequipment.com.

Anaconda FRC-2, FRC-5

Anaconda FRC-2

Anaconda FRC-5

Anaconda FRC-10, FRC-20

Flows and Dimensions

MODEL FRC-10 FRC-20

Flow

10 m3/h

Maximum width A (mm) 2.360

Maximum height B (mm) 2.170+100

Length L (mm) 4.156

Installed power (kW) SCP-BPS 4,5-7 SCP-BPS VESSEL 4,5 VESSEL 5,43

Water inlet DN100

Water outlet DN125

Sludge outlet DN125

Drainage

Compressed air * consumption (Nl/min) SCP-BPS 67 SCP-BPS VESSEL 52 VESSEL 64

DN65

20 m3/h

3.050

2.108+100

5.735

4,5-7,63

DN100 DN150

DN150

DN150

DN80

83

Compressed air * consumption (Nl/min) 52 64

MODEL FSG-10 FSG-20

Flow

10 m3/h 20 m3/h

Maximum width A (mm) 2.415 2.731

Maximum height B (mm) 2.270+100 2.108+100

Length L (mm) 3.414 4.868

Installed power (kW) 4,5 5,43

Water inlet DN100 DN150

Water outlet DN125 DN150

Sludge outlet DN125 DN150

Drainage

DN65 DN80

MODEL FRC-10 FRC-20

Flow

10 m3/h

Maximum width A (mm) 2.360

Maximum height B (mm)

Length L (mm)

Installed power (kW) SCP-BPS 4,5-7 SCP-BPS 4,5-7 VESSEL 4,5 VESSEL 4,5

Water inlet

Water outlet

Sludge outlet

Drainage

Compressed air * consumption (Nl/min) SCP-BPS 67 SCP-BPS 83 VESSEL 52 VESSEL 64

2.170+100

4.156

DN100

DN125

DN125

DN65

20 m3/h

3.050

2.108+100

5.735

DN100 DN150

DN150

DN150

DN80

* The air pressure will be between 6-8 bar on all models.

The dimensions and product specifications might vary slightly, due to the normal development of products by the engineering department of Toro Equipment SL. More specific data can be found on our website at www.toroequipment.com.

Anaconda FRC-10, FRC-20

Anaconda FRC-10

Anaconda FRC-20

Anaconda FRC-30, FRC-60, FRC-90

Flows and Dimensions

MODEL FRC-30 FRC-60

Flow

30 m3/h

Maximum width A (mm) 3.642

Maximum height B (mm)

Length L (mm) SCP-BPS VESSEL 5.877 VESSEL 9.400 VESSEL 12.805

Installed power (kW) SCP-BPS 6,57 SCP-BPS 12 SCP-BPS 20 BALN 6,57 BALN 14,05 BALN 15,37

Water inlet

Water outlet

Sludge outlet

Drainage

Compressed air * consumption (Nl/min) SCP-BPS VESSEL 95 VESSEL 217 VESSEL 309

2.460+100

5.270 SCP-BPS 8.500 SCP-BPS

DN150

DN200

DN150

DN80

123 SCP-BPS 280 SCP-BPS

60 m3/h

4.414/3.503

2.460+100

DN200

DN200

DN150

2x DN80

FRC-90

90 m3/h

4.413/3.503

2.460+100

11.820

DN200

DN250

DN250

3x DN80 402

Compressed air * consumption (Nl/min) 95

MODEL FSG-30 FSG-60 FSG-90

Flow

30 m3/h

Maximum width A (mm) 3.642

Maximum height B (mm) 2.460+100

Length L (mm) 5.270

Installed power (kW) 6,57

Water inlet DN150

Water outlet DN200

Sludge outlet DN150

Drainage

DN80

60 m3/h

3.503

2.460+100

8.500

14.04

DN200

DN200

DN150

2x DN80

217

90 m3/h

3.503

2.460+100

11.820

15,37

DN200

DN250

DN250

3x DN80

309

Maximum width A (mm) 3.642 Compressed air * consumption (Nl/min) SCP-BPS 123 SCP-BPS 280 SCP-BPS 402 VESSEL 95 VESSEL 217 VESSEL 309

MODEL FRC-30 FRC-60 FRC-90

Flow

30 m3/h

Maximum height B (mm) 2.460+100

Length L (mm) SCP-BPS 5.270 SCP-BPS 8.500 SCP-BPS 11.820 VESSEL 5.877 VESSEL 9.400 VESSEL 12.805

Installed power (kW) SCP-BPS 6,57 SCP-BPS 12 SCP-BPS 20 BALN 6,57 BALN 14,05 BALN 15,37

Water inlet DN150

Water outlet DN200

Sludge outlet DN150

Drainage

DN80

60 m3/h

4.414/3.503

2.460+100

DN200

DN200

DN150

2x DN80

90 m3/h

4.413/3.503

2.460+100

DN200

DN250

DN250

3x DN80

* The air pressure will be between 6-8 bar on all models.

The dimensions and product specifications might vary slightly, due to the normal development of products by the engineering department of Toro Equipment SL. More specific data can be found on our website at www.toroequipment.com.

Anaconda FRC-30

Anaconda FRC-60

Anaconda FRC-90

Process Description

Applications

Pretreatment: Anaconda. - Sewage and industrial wastewater. In urban wastewater fat and oil reduction of up to 60% of pollution load. - Drinking and industrial water process. Physical-Chemical: Anaconda. - In sewage, the performance depends on application, volume and type of prior - In industrial water such as solid-liquid separators: Slaughterhouse Dairy Pulp & paper Precooked product Biofuel Canned fish Sludge thickening: Sludgeway. Fat and oil separation: Fatflot. equalization. Metal finishing Timber industry Mining Textile industry Vegetable oil Pharmaceutical

Options

Outfit

STANDARD

OPTIONAL

STRUCTURE: Structure AISI-304 Gangway Stairs Flanges in FRP, DIN 2501 Tramex gangway in FRP Protection cover and safety Modification regarding standard gateway Height adjuster 0-100 mm Structure elevation (1 m) Structure AISI-316 Epoxy painted structure Metallic parts in contact with water AISI-316 Metallic parts in contact with water DUPLEX Tank in other colours

OTHERS: Air sludge pre-chamber contact

In 2 & 5 In 2 & 5

others others

Reflocculation system in flotation chamber Sludge thickening lamellas Acetal scraper chain Rigid scraping system in FRP Automatic drainage Sludge level regulating system Pneumatic control box. Automatic purgator Emergency stop

FLOCCULATOR PIPE, INCLUDES: - Reagent injection 2 units - Polyelectrolyte injection 1 unit - Flock sponge system - Inlet taps samples 3 units - Legs adjuster - Manufacture inox AISI-304/PVC

PRESSURIZATION SYSTEMS: Cast iron SCP Pump + spare pump body SCP pump AISI-304, free of charge Vessel, free of charge BPS (Bach Pressurization System), free of charge Double SCP pump (1 in reserve) Double centrifugal pump (1 in reserve) SCP pump marine bronze SCP pump AISI-316 Auto-cleaning injectors system Pressurization tank FRP Pressurization tank PP Pressurization Piping PP Compressor

- Replacement in inox AISI-304-316 - Replacement in PVC-P.E.H.D. - Replacement in PVC-PP

INTEGRATION OF ELECTRICAL CABINET INCLUDE: - Electric cabinet integration - Touch-sensitive panel in colour - Dynamic PLC software

SIGNALING: Bright alarm beacon Ethernet communication Starting process by remote signal Electric box for power and control wiring (without electrical cabinet)

* Nominal flow in normal conditions of temperature and salinity. Temperature of 15 - 25, Anaconda supports up to 3,000 mg/l of solids (TSS) in FRC2 and FRC5, rest of models support up to 5,000 mg/l of solids. * Flow rates higher or lower depending on the application and rate air/solid. Contact us.

The dimensions and technical specifications may vary slightly due to the normal development of products by the technical team at Toro Equipment SL. When ordering, request the specification drawings. More specific values can be found on our website at www.toroequipment.com.

Options Structure and Materials

- Other materials can be used in the construction of Anaconda. Equipments are made of polyester resin reinforced in isophthalic fibreglass with high chemical resistance. Higher chemical resistance than stainless steel. Standard steel items are AISI 304 grade, other options being available. Working temperature up to 50 C in continuous. Other material can be use to work under higher temperature conditions. Request more information on our website, www.toroequipment.com or consult our technical staff.

Tramex gangway in FRP

Height adjuster

Ladder

Pressurization Systems

Others

Rigid scraper system in FRP

Automatic drainage

Emergency stop

Options Flocculator Pipe

The flocculator pipe manufactured by Toro Equipment is made of PVC, polypropylene, polyethylene or stainless depending of the application. The flocculator is a system that allows online dosing of chemicals in the water. Each section has a samples taking tap to control the amount of chemical injected.

FLH in PP

FLH in PVC

FLH in polyethylene

FLH in Inox

Electrical Cabinet and Signaling

Dynamic picture by graphics

Alarm light beacon

Packaging and Transport

- FRC-2 & FRC-5 fully enclosed protective wooden crate. - Protective plastic wrapping of equipment for shipping. - FRC 2/5/10/20 transportable in 20ft container. - FRC 30/60/90 transportable in 40ft container, High Cube.

FRC-2 with protective wooden crate

Wooden crate

40ft container H.C.

Equipment plasticized

Compact Plant

At the request of the customer, we supply compact plant in containers. Please request information to our commercial department.

40ft, with ground in FRP.

Containers insulated with sandwich panel. Coated steel sheet 0.4 mm. 30mm PUR foam. Conditioning by heat pump, ventilation and illumination.

Implementation

Implementing the Anaconda in a raised plant allows the sludge to fall by gravity into the TAF (Sludge Conditioning Tank), thereby saving pumping. (See TAF file). Ask for polypropylene cover and pipe options in outside installations. Consider the problems of reagent freezing and process water, especially in stopping. For hot or salt water consult the application, since the solubility of air in water decreases. The pressurization system shall be over-sized. The blowdown returns to the preliminary pumping or homogenization. It is advisable to do this through a small chamber sandbox, which collects very large dense solids. Raw water prior to flotation will have to be screened to at least a 1 mm aperture. It is advisable to install constant and adjustable flow pumping systems. This is achieved through a flow meter and a frequency inverter that operates the pump. We can as an option include it in the supply. (Diagram of pump / Frequency inverter / Magnetic flowmeter). The pre-flotation tanks shall be stirred. In many applications, stirring with air will be a great advantage for the process (see DBF file). The amount accumulated in these tanks will vary from one process to another. A minimum of 6-10 hours is recommended. It is also recommended to have a fixed or slave amount of 2-4 hours. If the preliminary tank is higher than the DAF Anaconda, an automatic shutoff valve should be available. Ask our sales department or in our website www.toroequipment.com drawing dwg.

Mobile plant

Worldwide Presence

Argentina Belgium Brazil Bulgaria Canada Chile Croatia Egypt Estonia France Germany Greece Holland Hungary India Jordan Latvia Mexico Morocco Pakistan Poland Portugal Romania Russia Saudi Arabia Spain Tunisia UAE Ukraine United Kingdom Venezuela

TORO EQUIPMENT S.L. C/ Sauce s/n. 47193 La Cisterniga Valladolid-Espaa Tel +34 983 403047 Fax +34 983 403048 toro@toroequipment.com www.toroequipment.com

TORO EQUIPMENT 2012 ANACONDA DISSOLVED AIR FLOTATION FATFLOT FAT AND OIL SEPARATOR SLUDGEWAY SLUDGE THICKENING

Вам также может понравиться

- Anaconda, Fatflot & Sludgeway Toro Wastewater EquipmentДокумент16 страницAnaconda, Fatflot & Sludgeway Toro Wastewater EquipmentDavidQueridoОценок пока нет

- Krohne OPTIFLUX 2000Документ16 страницKrohne OPTIFLUX 2000Anonymous 1LgoS05gvlОценок пока нет

- Sea WaterДокумент39 страницSea WaterArun GuptaОценок пока нет

- DC-2000/3000/5000 Air Chiller SpecsДокумент2 страницыDC-2000/3000/5000 Air Chiller SpecsmohdnazirОценок пока нет

- Catalogo ASCOДокумент4 страницыCatalogo ASCOIkaro MatosОценок пока нет

- Flo Rite FRДокумент4 страницыFlo Rite FRJorge Selim Asaff ArancibiaОценок пока нет

- Donaldson Visokotlačni FilteriДокумент86 страницDonaldson Visokotlačni FilteriViktor -stОценок пока нет

- HL-ADS compressed air dryer packagesДокумент17 страницHL-ADS compressed air dryer packagesMarcoAlbaОценок пока нет

- Flow Meter Sensor SignetДокумент6 страницFlow Meter Sensor SignetMajecco TecicoОценок пока нет

- Cyclone Separator Ultradri SG-ZДокумент3 страницыCyclone Separator Ultradri SG-ZAbu AlifОценок пока нет

- Visual Flow Indicator Guide from Flow-MonДокумент12 страницVisual Flow Indicator Guide from Flow-Mondhanu_aquaОценок пока нет

- Opti Flux 4000 Spec SheetДокумент8 страницOpti Flux 4000 Spec SheetAhmad Adel El TantawyОценок пока нет

- HTA (GIRPI) - System'O - Technical DataДокумент71 страницаHTA (GIRPI) - System'O - Technical DataTiago CostaОценок пока нет

- Burmad 400 Series-Globe Type Deluge ValveДокумент8 страницBurmad 400 Series-Globe Type Deluge Valvenastyn-1Оценок пока нет

- FD - Industrial DehumidifierДокумент8 страницFD - Industrial DehumidifierAntoniaОценок пока нет

- Aluminum Crust BreakerДокумент8 страницAluminum Crust BreakersenamotoОценок пока нет

- FD TCR Industrial 1Документ8 страницFD TCR Industrial 1HemonОценок пока нет

- Potopna Crpka PEDROLLO Top Floor BrosuraДокумент4 страницыPotopna Crpka PEDROLLO Top Floor Brosurajose03Оценок пока нет

- Pedrollo Top Multi - 60hz enДокумент4 страницыPedrollo Top Multi - 60hz enMarioAndrésRamirezC.Оценок пока нет

- Merenje ProtokaДокумент468 страницMerenje Protokasokol_poleceОценок пока нет

- Fpr300 ManualДокумент12 страницFpr300 ManualdcperfectОценок пока нет

- Deluge ValveДокумент10 страницDeluge ValvevpnrrajaОценок пока нет

- Plastic Piping System CatalogueДокумент24 страницыPlastic Piping System CataloguesardarmkhanОценок пока нет

- Ameron FRP Fittings 7000MДокумент8 страницAmeron FRP Fittings 7000MNatchimuthu Durai BalanОценок пока нет

- Polyken 1600 High TempДокумент2 страницыPolyken 1600 High TempKyaw Kyaw AungОценок пока нет

- Dura Pipe Super Flo SystemДокумент3 страницыDura Pipe Super Flo SystemSelva Kumar Selva KumarОценок пока нет

- Wika Pressure Gs08s01y01 e e Ed01Документ16 страницWika Pressure Gs08s01y01 e e Ed01Nguyễn Đăng QuýОценок пока нет

- GrundfosliteratureДокумент24 страницыGrundfosliteratureRuxandra Adriana100% (1)

- Angus (Fire Monitor)Документ2 страницыAngus (Fire Monitor)Zack LeeОценок пока нет

- R 175 UkДокумент4 страницыR 175 UkAhmed EldalyОценок пока нет

- MAXROY Series A, B & D DatasheetДокумент4 страницыMAXROY Series A, B & D Datasheetnguyenquoc1988Оценок пока нет

- Fire Protection Foam Systems CatalogДокумент52 страницыFire Protection Foam Systems CatalogAhrian BenaОценок пока нет

- ABB - FXE4000 - Medidor EletromagneticoДокумент48 страницABB - FXE4000 - Medidor Eletromagneticoalex_julieneОценок пока нет

- Multipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deДокумент2 страницыMultipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deJoshua PhillipsОценок пока нет

- Series LF25AUB-Z3 Specification SheetДокумент2 страницыSeries LF25AUB-Z3 Specification SheetWattsОценок пока нет

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationДокумент5 страницSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroОценок пока нет

- Seko Dosing PumpДокумент12 страницSeko Dosing PumptooedОценок пока нет

- (P) SRFДокумент6 страниц(P) SRFYing Kei ChanОценок пока нет

- 12S Series: High Pressure FiltersДокумент6 страниц12S Series: High Pressure FiltersPartsGopher.comОценок пока нет

- Nueva Serie de Ventiladores RitalДокумент8 страницNueva Serie de Ventiladores RitalLuis MansillaОценок пока нет

- Spirax Sarco BTM-7Документ3 страницыSpirax Sarco BTM-7Bambang Agung LaxmonoОценок пока нет

- Pulsatron Series C PDFДокумент2 страницыPulsatron Series C PDFnico samsonОценок пока нет

- Terrain Below Ground Drainage Dimensional DataДокумент16 страницTerrain Below Ground Drainage Dimensional DatamealysrОценок пока нет

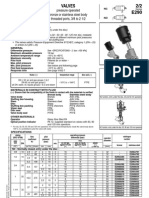

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Документ4 страницыValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuОценок пока нет

- PND1000-3 Stainless Steel FRLДокумент9 страницPND1000-3 Stainless Steel FRLPartsGopher.comОценок пока нет

- HOBAS Pressure Pipes SystemsДокумент40 страницHOBAS Pressure Pipes Systemsu_florinОценок пока нет

- Catalago PDFДокумент12 страницCatalago PDFGregory StewartОценок пока нет

- Vinci Technologies Oil & Gas Sampling EquipmentДокумент4 страницыVinci Technologies Oil & Gas Sampling EquipmentBima MahendraОценок пока нет

- GF System Specification-PROGEF Standard enДокумент23 страницыGF System Specification-PROGEF Standard enKlich77Оценок пока нет

- Technical Specification Wet LabДокумент5 страницTechnical Specification Wet Labmarfan75Оценок пока нет

- Wagner Aircoat Manual Automatic GunsДокумент11 страницWagner Aircoat Manual Automatic GunsMik AeilОценок пока нет

- Technical Proposal for Olympic Pool Filtration SystemДокумент10 страницTechnical Proposal for Olympic Pool Filtration SystemAlma DerajОценок пока нет

- Flow MeterДокумент8 страницFlow MeterDGWОценок пока нет

- RDCДокумент6 страницRDCCY LeeОценок пока нет

- Sta-Rite PRO-Storm DSS Series: Multi-Stage Sprinkler PumpsДокумент2 страницыSta-Rite PRO-Storm DSS Series: Multi-Stage Sprinkler PumpsDagoberto CerrudОценок пока нет

- 520 02 Vert Spec 130610Документ2 страницы520 02 Vert Spec 130610Yohannes S. AripinОценок пока нет

- Efficient Pumps for Wastewater and Sewage HandlingДокумент39 страницEfficient Pumps for Wastewater and Sewage HandlingpapashoОценок пока нет

- CD100 & CD160 Series Broshure 2011 PDFДокумент2 страницыCD100 & CD160 Series Broshure 2011 PDFArianto SutarnioОценок пока нет

- Conveyors WEBДокумент4 страницыConveyors WEBFilipeAntunesОценок пока нет

- October 2009: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeДокумент15 страницOctober 2009: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeVictor Macovei100% (1)

- MX 909sample Cebek300Документ18 страницMX 909sample Cebek300FilipeAntunesОценок пока нет

- ANSI Pipe and FlangesДокумент6 страницANSI Pipe and FlangesFilipeAntunesОценок пока нет

- Standard Analytical ProceduresДокумент80 страницStandard Analytical Proceduresengr_afsoomro3147Оценок пока нет

- Katalog - Bengkel Print Indonesia PDFДокумент32 страницыKatalog - Bengkel Print Indonesia PDFJoko WaringinОценок пока нет

- Scheme of Examination For Master of Computer APPLICATIONS (M.C.A.) W.E.F. Academic Session 2014-15Документ11 страницScheme of Examination For Master of Computer APPLICATIONS (M.C.A.) W.E.F. Academic Session 2014-15Siddharth JainОценок пока нет

- 7 Barriers To Implementing and Maintaining An Effective HRM FunctionДокумент13 страниц7 Barriers To Implementing and Maintaining An Effective HRM FunctionPaing Hein KyawОценок пока нет

- Molding CavityДокумент7 страницMolding CavitySudarno BaraОценок пока нет

- 2017 09Документ164 страницы2017 09sowabar100% (1)

- PronunciationДокумент5 страницPronunciationHưng NguyễnОценок пока нет

- أسئلة شاملة 1Документ25 страницأسئلة شاملة 1ibraheemalabsi99Оценок пока нет

- LMC Ans PP RM2013 GBДокумент35 страницLMC Ans PP RM2013 GBGomez GomezОценок пока нет

- Updated Official All Campuses ON CAMPUS Final Exams Schedule Spring 2021-22 Plan BДокумент11 страницUpdated Official All Campuses ON CAMPUS Final Exams Schedule Spring 2021-22 Plan BMohammad SafadiehОценок пока нет

- Filters in GeneralДокумент3 страницыFilters in GeneralJoseGarciaRuizОценок пока нет

- Physics: PAPER 3 Practical Test InstructionsДокумент8 страницPhysics: PAPER 3 Practical Test Instructionsmstudy123456Оценок пока нет

- Phase 2 (57 Selectee)Документ4 страницыPhase 2 (57 Selectee)AmarОценок пока нет

- Sem2 NanoparticlesДокумент35 страницSem2 NanoparticlesgujjugullygirlОценок пока нет

- The Monkey's PawThe Lady of The Barge and Others, Part 2. by Jacobs, W. W., 1863-1943Документ20 страницThe Monkey's PawThe Lady of The Barge and Others, Part 2. by Jacobs, W. W., 1863-1943Gutenberg.orgОценок пока нет

- Boyut AnaliziДокумент65 страницBoyut AnaliziHasan Kayhan KayadelenОценок пока нет

- Present Environment and Sustainable Development - Annual Review Report 2015Документ7 страницPresent Environment and Sustainable Development - Annual Review Report 2015catalinlungeanu758Оценок пока нет

- Gpee6.0T01Tibbgde: Technical Data SheetДокумент2 страницыGpee6.0T01Tibbgde: Technical Data SheetHope SangoОценок пока нет

- Lind 18e Chap005Документ35 страницLind 18e Chap005MELLYANA JIEОценок пока нет

- Unsaturated Polyester Resins: Chemistry and Technology: Piotr Penczek (U) Piotr Czub Jan PielichowskiДокумент2 страницыUnsaturated Polyester Resins: Chemistry and Technology: Piotr Penczek (U) Piotr Czub Jan Pielichowskiae0011979Оценок пока нет

- CSAT 2019 Spe3D Duguid - Andrew PDFДокумент111 страницCSAT 2019 Spe3D Duguid - Andrew PDFdocturboОценок пока нет

- SampleДокумент13 страницSamplemypermatakoe71Оценок пока нет

- Pulungmasle High School: Boy Scouts of The Philippines - Pulungmasle High School Chapter Work Plan For S.Y 2018-2019Документ3 страницыPulungmasle High School: Boy Scouts of The Philippines - Pulungmasle High School Chapter Work Plan For S.Y 2018-2019Rd DavidОценок пока нет

- Residual Stresses of Plate With Holes by ANSYS Analysis - Hani Aziz AmeenДокумент14 страницResidual Stresses of Plate With Holes by ANSYS Analysis - Hani Aziz AmeenHani Aziz AmeenОценок пока нет

- t-030f Spanish p35-48Документ4 страницыt-030f Spanish p35-48Juan ContrerasОценок пока нет

- Bing WorksheetДокумент3 страницыBing WorksheetFrutti MataniОценок пока нет

- Fuzzy Logic Tutorial: What Is, Application & ExampleДокумент7 страницFuzzy Logic Tutorial: What Is, Application & ExampleDe' LufiasОценок пока нет

- Certified Lead-Base White Metal AnalysisДокумент2 страницыCertified Lead-Base White Metal AnalysisIshmael WoolooОценок пока нет

- Basic Engineering & Site DataДокумент13 страницBasic Engineering & Site DataBalasubramanianОценок пока нет

- Core-Core Repulsion Integrals: E (A Z ZJJДокумент1 страницаCore-Core Repulsion Integrals: E (A Z ZJJRaditya D HmОценок пока нет