Академический Документы

Профессиональный Документы

Культура Документы

Coal Tar PDF

Загружено:

Mohammadreza AsheghОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Coal Tar PDF

Загружено:

Mohammadreza AsheghАвторское право:

Доступные форматы

Protective & Marine Coatings

Revised 8/12

TARGUARD

COAL TAR EPOXY

PART A PART A PART B B69B60 B69R60 B69V60 HARDENER

4.72

BLACK RED

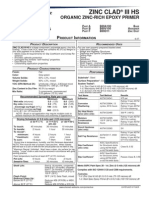

PRODUCT DESCRIPTION

TARGUARD COAL TAR EPOXY is a high build, polyamide epoxy coal tar coating. Meets the following specications: Corps of Engineers Formula C-200a SSPC Paint 16 Specication

RECOMMENDED USES

For use over prepared substrates such as steel and concrete in industrial environments. Penstocks Liner for clariers Dam gates Marine applications Petroleum storage tanks Offshore drilling rigs Heavy duty structural coating Non-potable water tank and pipe coating Acceptable for use with cathodic protection systems

PRODUCT CHARACTERISTICS

Finish: Color: Volume Solids: Weight Solids: VOC (calculated):

mixed

Semi-Gloss Black, Red 74% 2%, mixed 82% 2%, mixed

Unreduced: Reduced 10%: <250 g/L; 2.08 lb/gal <300 g/L; 2.5 lb/gal

PERFORMANCE CHARACTERISTICS

Substrate*: Steel Surface Preparation*: SSPC-SP6/NACE 3 System Tested*: 1 ct. TarGuard Coal Tar Epoxy @ 10.0 mils (250 microns) dft

*unless otherwise noted below

Mix Ratio:

2 component, premeasured 4:1 5 gallons mixed

Test Name Abrasion Resistance Adhesion Direct Impact Resistance Dry Heat Resistance (quench test only) Moisture Condensation Resistance Pencil Hardness Salt Fog Resistance Thermal Shock Wet Heat Resistance

Recommended Spreading Rate per coat:

Wet mils (microns) Dry mils (microns) ~Coverage sq ft/gal (m2/L)

Theoretical coverage sq ft/gal (m2/L) @ 1 mil / 25 microns dft *See Performance Tips section

Minimum 11.0 (275) 8.0* (200) 74 (1.8) 1184 (29)

Maximum 22.0 (550) 16.0* (400) 148 (3.6)

Test Method ASTM D4060, CS17 wheel, 1000 cycles, 1 kg load ASTM D4541 ASTM D2794 ASTM D2485 ASTM D4585, 100F (38C), 3000 hours ASTM D3363 ASTM B117, 3000 hours ASTM D2246, 100 cycles Non-immersion

Results 137 mg loss 1000 psi 36 in. lb. 350F (177C)

NOTE: Brush or roll application may require multiple coats to achieve maximum lm thickness and uniformity of appearance.

Excellent F Excellent Excellent 120F (49C)

Drying Schedule @ 11.0 mils wet (275 microns):

@ 50F/10oC @ 77F/25C 50% RH @ 100F/38C

To touch: To recoat: minimum: maximum: To cure:

14 hours 48 hours 72 hours 7-10 days

8-10 hours 18 hours 72 hours 7-10 days

2 hours 5 hours 12 hours 2 days

If maximum recoat time is exceeded, abrade surface before recoating. Drying time is temperature, humidity, and lm thickness dependent.

Pot Life: Sweat-in-time: Shelf Life:

2.5 hours 15 minutes

2 hours 10 minutes

1 hour none

Flash Point: Reducer/Clean Up: In California:

Part A: 8 months, unopened Part B: 36 months, unopend Store indoors at 40F (4.5C) to 100F (38C). 82F (28C), PMCC, mixed Xylene, R2K4 Reducer R7K111 or Oxsol 100

www.sherwin-williams.com/protective

continued on back

Protective & Marine Coatings

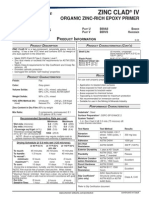

RECOMMENDED SYSTEMS

Dry Film Thickness / ct. Mils (Microns) Concrete, atmospheric or immersion: 2 cts. TarGuard Coal Tar Epoxy 8.0-16.0 (200-400) Steel, atmospheric or immersion: 2 cts. TarGuard Coal Tar Epoxy Steel, atmospheric or immersion: 1 ct. Copoxy Shop Primer 2 cts. TarGuard Coal Tar Epoxy

TARGUARD

COAL TAR EPOXY

PART A PART A PART B B69B60 B69R60 B69V60 HARDENER BLACK RED

PRODUCT INFORMATION

SURFACE PREPARATION

4.72

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Refer to product Application Bulletin for detailed surface preparation information. Minimum recommended surface preparation: Iron & Steel: Atmospheric: SSPC-SP6/NACE 3, 2 mil (50 micron) prole Immersion: SSPC-SP10/NACE 2, 3 mil (75 micron) prole Aluminum: Brush Blast, 2 mil (50 micron) prole Galvanizing: Brush Blast, 2 mil (50 micron) prole Concrete & Masonry: Atmospheric: SSPC-SP13/NACE 6, or ICRI No. 310.2, CSP 1-3 Immersion: SSPC-SP13/NACE 6-4.3.1 or 4.3.2, or ICRI No. 310.2, CSP 1-3

Surface Preparation Standards

Condition of Surface ISO 8501-1 BS7079:A1 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

8.0-16.0

(200-400)

3.0-5.0 8.0-16.0

(75-125) (200-400)

Steel, zinc rich primer, atmospheric only: 1 ct. Zinc Clad II Plus 3.0 2 cts. TarGuard Coal Tar Epoxy 8.0-16.0 Aluminum, atmospheric only: 2 cts. TarGuard Coal Tar Epoxy Galvanized Metal, atmospheric only: 2 cts. TarGuard Coal Tar Epoxy

(75) (200-400)

8.0-16.0

(200-400)

8.0-16.0

(200-400)

White Metal Near White Metal Commercial Blast Brush-Off Blast Hand Tool Cleaning Rusted Rusted Pitted & Power Tool Cleaning Rusted Rusted Pitted &

The systems listed above are representative of the product's use, other systems may be appropriate.

TINTING

Do not tint.

APPLICATION CONDITIONS

Temperature: 50F (10C) minimum, 100F (38C) maximum (air, surface, and material) At least 5F (2.8C) above dew point 90% maximum

Relative humidity:

Refer to product Application Bulletin for detailed application information.

ORDERING INFORMATION

Packaging: Part A: Part B: Weight: 5 gallons (18.9L) mixed 4 gallons (15.1L) in a 5 gallon (18.9L) container 1 gallon (3.78L) 10.7 0.2 lb/gal ; 1.3 Kg/L, mixed

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

Protective & Marine Coatings

Revised 8/12

TARGUARD

COAL TAR EPOXY

PART A PART A PART B B69B60 B69R60 B69V60 HARDENER

4.72

BLACK RED

APPLICATION BULLETIN

SURFACE PREPARATIONS

Temperature:

APPLICATION CONDITIONS

50F (10C) minimum, 100F (38C) maximum (air, surface, and material) At least 5F (2.8C) above dew point 90% maximum

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Iron & Steel, Immersion Service: Remove all oil and grease from surface by Solvent Cleaning per SSPC-SP1. Minimum surface preparation is Near White Metal Blast Cleaning per SSPC-SP10 or SSPC-SP12/NACE No. 5. For SSPCSP10, blast clean all surfaces using a sharp, angular abrasive for optimum surface prole (3 mils / 75 microns). For SSPC-SP12/ NACE No. 5, all surfaces to be coated shall be cleaned in accordance with WJ-2. Pre-existing prole should be approximately 3 mils (75 microns). Remove all weld spatter and round all sharp edges by grinding. Prime any bare steel the same day as it is cleaned. Iron & Steel, Atmospheric Service: Minimum surface preparation is Commercial Blast Cleaning per SSPC-SP6/NACE 3 or SSPC-SP12/NACE 5. For surfaces prepared by SSPC-SP6/NACE 3, rst remove all oil and grease from surface by Solvent Cleaning per SSPC-SP1. Blast clean all surfaces using a sharp, angular abrasive for optimum surface prole (2 mils / 50 microns). For surfaces prepared by SSPC-SP12/NACE No. 5, all surfaces shall be cleaned in accordance with WJ-3. Pre-existing prole should be approximately 2 mils (50 microns). Prime any bare steel the same day as it is cleaned. Galvanized Steel/Aluminum Allow to weather a minimum of six months prior to coating. Remove all oil and grease from surface by Solvent Cleaning per SSPC-SP1 (recommended solvent is VM&P Naphtha). Lightly brush blast per SSPC-SP 7 to provide a 2 mil (50 micron) prole. Concrete and Masonry For surface preparation, refer to SSPC-SP13/NACE 6, or ICRI No. 310.2, CSP 1-3. Surfaces should be thoroughly clean and dry. Concrete and mortar must be cured at least 28 days @ 75F (24C). Remove all loose mortar and foreign material. Surface must be free of laitance, concrete dust, dirt, form release agents, moisture curing membranes, loose cement and hardeners. Fill bug holes, air pockets and other voids with Steel-Seam FT910. Follow the standard methods listed below when applicable: ASTM D4258 Standard Practice for Cleaning Concrete. ASTM D4259 Standard Practice for Abrading Concrete. ASTM D4260 Standard Practice for Etching Concrete. ASTM F1869 Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete. SSPC-SP 13/Nace 6 Surface Preparation of Concrete. ICRI No. 310.2 Concrete Surface Preparation. Concrete, Immersion Service: For surface preparation, refer to SSPC-SP13/NACE 6, Section 4.3.1 or 1.3.2 or ICRI No. 310.2, CSP 1-3. Relative humidity:

APPLICATION EQUIPMENT

The following is a guide. Changes in pressures and tip sizes may be needed for proper spray characteristics. Always purge spray equipment before use with listed reducer. Any reduction must be compliant with existing VOC regulations and compatible with the existing environmental and application conditions. Reducer/Clean Up ...........Xylene, R2K4 In California ....................Reducer R7K111 or Oxsol 100 Airless Spray Pressure.........................3000 psi Hose...............................3/8" - 1/2" ID Tip ...................................017" - .025" Filter ............................... None Reduction .......................As needed up to 10% by volume Conventional Spray (bottom feed tank recommended) Gun ................................Binks 95 Fluid Nozzle ...................66 Air Nozzle.......................63PB Atomization Pressure .....60 psi Fluid Pressure ................40 psi Reduction .......................As needed up to 10% by volume Brush Brush..............................Small areas only; natural bristle Reduction .......................Not recommended Roller Cover .............................Small areas only; 3/8" - 1/2" woven with solvent resistant core Reduction .......................Not recommended

If specic application equipment is not listed above, equivalent equipment may be substituted.

Surface Preparation Standards

Condition of Surface White Metal Near White Metal Commercial Blast Brush-Off Blast Hand Tool Cleaning Rusted Rusted Pitted & Power Tool Cleaning Rusted Rusted Pitted & ISO 8501-1 BS7079:A1 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

www.sherwin-williams.com/protective

continued on back

Protective & Marine Coatings

APPLICATION PROCEDURES

Surface preparation must be completed as indicated. Mix contents of each component thoroughly with low speed power agitation. Make certain no pigment remains on the bottom of the can. Then combine four parts by volume of Part A with one part by volume of Part B. Thoroughly agitate the mixture with power agitation. Allow the material to sweat-in as indicated. Re-stir before using.

TARGUARD

COAL TAR EPOXY

PART A PART A PART B B69B60 B69R60 B69V60 HARDENER BLACK RED

APPLICATION BULLETIN

PERFORMANCE TIPS

4.72

Stripe coat all crevices, welds, and sharp angles to prevent early failure in these areas. When using spray application, use a 50% overlap with each pass of the gun to avoid holidays, bare areas, and pinholes. If necessary, cross spray at a right angle.

Spreading rates are calculated on volume solids and do not include an application loss factor due to surface prole, roughness or porosity of the surface, skill and technique of the applicator, method If reducer solvent is used, add only after both components have of application, various surface irregularities, material lost during been thoroughly mixed, after sweat-in. mixing, spillage, overthinning, climatic conditions, and excessive Apply paint at the recommended lm thickness and spreading lm build. rate as indicated below: Excessive reduction of material can affect lm build, appearance, and adhesion. Recommended Spreading Rate per coat: Wet mils (microns) Dry mils (microns) ~Coverage sq ft/gal (m2/L)

Theoretical coverage sq ft/gal (m2/L) @ 1 mil / 25 microns dft *See Performance Tips section

Minimum 11.0 (275) 8.0* (200) 74 (1.8) 1184 (29)

Maximum 22.0 (550) 16.0* (400) 148 (3.6)

Do not apply the material beyond recommended pot life. Do not mix previously catalyzed material with new. In order to avoid blockage of spray equipment, clean equipment before use or before periods of extended downtime with Xylene, R2K4. In California use Reducer R7K111 or Oxsol 100. Coating must be fully cured before placing into immersion service. For Immersion Service: (if required) Holiday test in accordance with ASTM D5162 for steel, or ASTM D4787 for concrete. Quik-Kick Epoxy Accelerator is acceptable for use. See data page 4.99 for details. When coating over aluminum and galvanizing, recommended dft is 2-4 mils (50-100 microns).

NOTE: Brush or roll application may require multiple coats to achieve maximum lm thickness and uniformity of appearance.

Drying Schedule @ 11.0 mils wet (275 microns):

@ 50F/10 C

o

@ 77F/25C 50% RH

@ 100F/38C

To touch: To recoat: minimum: maximum: To cure:

14 hours 48 hours 72 hours 7-10 days

8-10 hours 18 hours 72 hours 7-10 days

2 hours 5 hours 12 hours 2 days

If maximum recoat time is exceeded, abrade surface before recoating. Drying time is temperature, humidity, and lm thickness dependent.

Pot Life: Sweat-in-time:

2.5 hours 15 minutes

2 hours 10 minutes

1 hour none

Refer to Product Information sheet for additional performance characteristics and properties.

Application of coating above maximum or below minimum recommended spreading rate may adversely affect coating performance.

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

CLEAN UP INSTRUCTIONS

Clean spills and spatters immediately with Xylene, R2K4. Clean tools immediately after use with Xylene, R2K4. In California use Reducer R7K111 or Oxsol 100. Follow manufacturer's safety recommendations when using any solvent.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

www.sherwin-williams.com/protective

Вам также может понравиться

- Zinc Clad IIIДокумент4 страницыZinc Clad IIIScott Van PeltОценок пока нет

- Duraplate Uhs EnglishДокумент4 страницыDuraplate Uhs EnglishLuis JaraОценок пока нет

- Acrolon 218 HSДокумент4 страницыAcrolon 218 HSAndres MoralesОценок пока нет

- 7) PPG Amercoat 385 - Pds - AiДокумент4 страницы7) PPG Amercoat 385 - Pds - AididbeauОценок пока нет

- Fast Clad Urethane Spec SheetДокумент4 страницыFast Clad Urethane Spec SheetScott Van PeltОценок пока нет

- Plasite 9133 Product Data SheetДокумент3 страницыPlasite 9133 Product Data SheetChris StroudОценок пока нет

- Carbomastic 15 PDS 2013Документ2 страницыCarbomastic 15 PDS 20134508366279Оценок пока нет

- Carbo Guard 893 SGДокумент2 страницыCarbo Guard 893 SGsuzilamatsallehОценок пока нет

- SigmaCover 280Документ5 страницSigmaCover 280ajuhaseenОценок пока нет

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetДокумент7 страницAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheОценок пока нет

- Amercoat 370Документ3 страницыAmercoat 370Victor Hugo Bustos Beltran100% (1)

- DP B58W00610Документ4 страницыDP B58W00610tangouzeОценок пока нет

- Carboguard 890 PDSДокумент2 страницыCarboguard 890 PDSLinnie McleodОценок пока нет

- Sikagard 63 N PDSДокумент7 страницSikagard 63 N PDSAhmed TahaОценок пока нет

- Zinc Clad IVДокумент4 страницыZinc Clad IVvitrolaОценок пока нет

- Dura-Plate UHS Epoxy - JSP PDFДокумент4 страницыDura-Plate UHS Epoxy - JSP PDFNageswara Rao BavisettyОценок пока нет

- Interseal 670 HS EN O-FДокумент4 страницыInterseal 670 HS EN O-Fapde06Оценок пока нет

- ZRC Zero VocДокумент2 страницыZRC Zero Vochksn77Оценок пока нет

- Phenoline 1205 PDS 9-06 PDFДокумент2 страницыPhenoline 1205 PDS 9-06 PDFttr_1947Оценок пока нет

- 323 Data Sheet and Application GuideДокумент4 страницы323 Data Sheet and Application Guidejast111Оценок пока нет

- Amerlock 400Документ4 страницыAmerlock 400eternalkhutОценок пока нет

- Carboguard 89dfsfs0 PDSДокумент2 страницыCarboguard 89dfsfs0 PDSMayur PatelОценок пока нет

- Amerlock® 400 Voc: Product Data SheetДокумент8 страницAmerlock® 400 Voc: Product Data SheetCris gomezОценок пока нет

- TDS - Jotamastic 87 Aluminium - English (Uk) - Issued.08.01.2013Документ5 страницTDS - Jotamastic 87 Aluminium - English (Uk) - Issued.08.01.2013RedzuanОценок пока нет

- Carbothane+134+HG+PDS+3 11Документ2 страницыCarbothane+134+HG+PDS+3 11James Everett AbdulОценок пока нет

- Acrolon 890 EN 20130206Документ2 страницыAcrolon 890 EN 20130206hainguyenbkvhv0% (1)

- Description Packaging Product Data SheetДокумент2 страницыDescription Packaging Product Data SheetRonald Fernandez ManubuluОценок пока нет

- ChemflakeДокумент5 страницChemflakeManohar SeetharamОценок пока нет

- Solder Paste SC Blf03: Lead-FreeДокумент2 страницыSolder Paste SC Blf03: Lead-FreeluismcmcОценок пока нет

- Carboguard 891: Selection & Specification DataДокумент4 страницыCarboguard 891: Selection & Specification DataPrakashОценок пока нет

- Solder Paste SC 170: Physical PropertiesДокумент2 страницыSolder Paste SC 170: Physical PropertiesluismcmcОценок пока нет

- Pds Psx700 Jan 2008Документ3 страницыPds Psx700 Jan 2008mjayhawk28Оценок пока нет

- Carbo Zinc 11 HsДокумент2 страницыCarbo Zinc 11 Hstyto_rmzОценок пока нет

- Carboguard 635: Selection & Specification DataДокумент5 страницCarboguard 635: Selection & Specification DataPrakashОценок пока нет

- TDS - Resist 78 - English (Uk) - Issued.02.04.2010Документ4 страницыTDS - Resist 78 - English (Uk) - Issued.02.04.2010PaulSwinbankОценок пока нет

- Carbomastic 15 PDSДокумент2 страницыCarbomastic 15 PDSAnonymous 4fVUDODОценок пока нет

- Azko Coating Hjf14r r4 Es eДокумент4 страницыAzko Coating Hjf14r r4 Es eKrishna KumarОценок пока нет

- Carboguard 635 Thinned 50% - Sealer PDSДокумент5 страницCarboguard 635 Thinned 50% - Sealer PDSjakeОценок пока нет

- Om 340Документ3 страницыOm 340RОценок пока нет

- Pds Hempadur Mastic 45881Документ3 страницыPds Hempadur Mastic 45881kasosei0% (1)

- TDS MarathonДокумент5 страницTDS MarathonSyamsul MaripОценок пока нет

- TDS MarathonДокумент5 страницTDS MarathonSyamsul MaripОценок пока нет

- ZRC 3 07Документ2 страницыZRC 3 07groelzjОценок пока нет

- Plasite 7159 PDS 1-07 PDFДокумент2 страницыPlasite 7159 PDS 1-07 PDFFabricio Jiménez TОценок пока нет

- 7430 - Sigmacover 630Документ0 страниц7430 - Sigmacover 630eraswastaОценок пока нет

- K267 - PDS - en - GBДокумент2 страницыK267 - PDS - en - GBJennifer BradleyОценок пока нет

- Working Procedure Ls1-Ls4Документ9 страницWorking Procedure Ls1-Ls4Tuğrulhan ÖzdemirОценок пока нет

- 3K PRO ME CNS P02 001 010 033 240 Rev A PDFДокумент19 страниц3K PRO ME CNS P02 001 010 033 240 Rev A PDFErol DAĞОценок пока нет

- Amercoat® 385: Product Data SheetДокумент8 страницAmercoat® 385: Product Data SheetSampath GaneshОценок пока нет

- Carboguard 888 PDSДокумент3 страницыCarboguard 888 PDSsalamrefighОценок пока нет

- PPG PDS Amercoat 370Документ7 страницPPG PDS Amercoat 370sanguripОценок пока нет

- TDS - Jotamastic 80 - English (Uk) - Issued.26.03.2009Документ4 страницыTDS - Jotamastic 80 - English (Uk) - Issued.26.03.2009Joni EfwanОценок пока нет

- Sigmacover 240 Data SheetДокумент7 страницSigmacover 240 Data Sheetantonio larottaОценок пока нет

- Pds Hempadur 15570 En-GbДокумент3 страницыPds Hempadur 15570 En-GbdcsamaraweeraОценок пока нет

- Amercoat® 385: Product Data SheetДокумент8 страницAmercoat® 385: Product Data SheetNizar BouchaalaОценок пока нет

- Product Data Sheet SP-8888Документ7 страницProduct Data Sheet SP-8888pablo gonzalezОценок пока нет

- Sigmacover 522Документ4 страницыSigmacover 522Asela BollegalaОценок пока нет

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyОт EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinОценок пока нет

- Fence Fittings: Standard Specification ForДокумент4 страницыFence Fittings: Standard Specification ForAdán Cogley CantoОценок пока нет

- PIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)Документ8 страницPIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)fkhajehОценок пока нет

- Stealth Illuminator Stealth Illuminator: IR High Output Vehicle Light IR High Output Vehicle LightДокумент3 страницыStealth Illuminator Stealth Illuminator: IR High Output Vehicle Light IR High Output Vehicle LightScott HendersonОценок пока нет

- Inhibitors Cathodic Protection Galvanizing and Tinning Electroplating Metal Cladding Coating ProcessesДокумент95 страницInhibitors Cathodic Protection Galvanizing and Tinning Electroplating Metal Cladding Coating Processesanurag prernaОценок пока нет

- Global Water Storage Tanks BrochureДокумент44 страницыGlobal Water Storage Tanks Brochureعبد السميع بن أحمد100% (1)

- HIT-RE 500 V3 With AnchorДокумент22 страницыHIT-RE 500 V3 With Anchoredward the iiiОценок пока нет

- Spring SupportДокумент51 страницаSpring SupportYinka AkinkunmiОценок пока нет

- Building SSR 2009 10Документ477 страницBuilding SSR 2009 10Raja ShekharОценок пока нет

- Rittal PS 4000Документ16 страницRittal PS 4000Rey-an A. MorenoОценок пока нет

- INS-000-SPE-0002 Rev.3 Specification For Painting and Coating, Structural Steel of Marine FacilitiesДокумент25 страницINS-000-SPE-0002 Rev.3 Specification For Painting and Coating, Structural Steel of Marine FacilitiesenriqueОценок пока нет

- Torque Control Guide: Tightening Torque and Tensile LoadДокумент5 страницTorque Control Guide: Tightening Torque and Tensile Loadaa aОценок пока нет

- Flux Skimming PDFДокумент6 страницFlux Skimming PDFpbp2956Оценок пока нет

- Anchor SupportsДокумент7 страницAnchor Supportstejasp8388Оценок пока нет

- Power PlantДокумент34 страницыPower Plantmiguel0581Оценок пока нет

- Bircosir - NW 150: Stability and DiversityДокумент5 страницBircosir - NW 150: Stability and Diversityjagath2005ukОценок пока нет

- Ramset Anchoring Chemicals CatalogueДокумент156 страницRamset Anchoring Chemicals CatalogueSuci YatiningtiyasОценок пока нет

- Welding Galvanized SteelДокумент6 страницWelding Galvanized SteelmperelmuterОценок пока нет

- Corrosion Protection - PylonsДокумент51 страницаCorrosion Protection - Pylonssnitin26Оценок пока нет

- Plating Specification ListДокумент11 страницPlating Specification Listsursh60% (5)

- Snap Track Catalog 2017 (Aluminum Only)Документ76 страницSnap Track Catalog 2017 (Aluminum Only)Brandon TrocОценок пока нет

- Metaltech CatalogДокумент68 страницMetaltech CatalogFabian MedranoОценок пока нет

- Hot Dip GalvanizedДокумент6 страницHot Dip GalvanizedNestor GalianoОценок пока нет

- D-01 Model 7041 Flange Adapter-Ansi Class 125150Документ4 страницыD-01 Model 7041 Flange Adapter-Ansi Class 125150Daniel SanОценок пока нет

- VW TL 217 2009-08 enДокумент7 страницVW TL 217 2009-08 enjoaopedrosousaОценок пока нет

- BDL Project Supply Range and Specification For Piping Materials PDFДокумент49 страницBDL Project Supply Range and Specification For Piping Materials PDFEngr Arfan Ali DhamrahoОценок пока нет

- Marine CoatingsДокумент145 страницMarine CoatingsAlexander MaksaevОценок пока нет

- Accessories: Aluminium Products WindguardsДокумент1 страницаAccessories: Aluminium Products WindguardsBoy AlfredoОценок пока нет

- HighCapChainHoists SectionДокумент21 страницаHighCapChainHoists SectionMuhammad Rifqi AninditoОценок пока нет

- CBIP Publication No 295Документ422 страницыCBIP Publication No 295Pravin Narkhede100% (7)