Академический Документы

Профессиональный Документы

Культура Документы

Production of G-Alumina From Waste Aluminium Dross

Загружено:

böhmitАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Production of G-Alumina From Waste Aluminium Dross

Загружено:

böhmitАвторское право:

Доступные форматы

Minerals Engineering 20 (2007) 252258 This article is also available online at: www.elsevier.

com/locate/mineng

Production of g-alumina from waste aluminium dross

B.R. Das, B. Dash, B.C. Tripathy *, I.N. Bhattacharya, S.C. Das

Regional Research Laboratory, Bhubaneswar 751 013, India Received 31 May 2006; accepted 11 September 2006 Available online 31 October 2006

Abstract Processing of aluminium dross is one of the most challenging tasks because of its toxic nature. The dross generated while melting at various facilities is generally remelted with salts to recover residual metal values. The remaining residue dross contains mostly aluminium oxide, alloying elements and salts such as NaCl or KCl. This residue dross while stock piling creates pollution of the adjoining area as salts leach out to water stream and also emits harmful gases. In the present study domestic aluminium dross was treated for developing a suitable process ow sheet to obtain g-alumina a high valued product. Initially H2SO4 leaching was carried out for both un-washed and washed dross. With un-washed dross the leaching eciency achieved was $71% but washing of dross followed by leaching raised the recovery to $84%. Washing of dross is essential to have higher alumina recovery and also to recover salt for recycling. The liquor obtained after treatment of the dross with acid was further processed to obtain aluminium hydroxide of amorphous nature by hydrolyzing aluminium sulphate with aqueous ammonia. The aluminium hydroxide was then subjected to calcinations which resulted in the formation of g-alumina at 900 C. 2006 Elsevier Ltd. All rights reserved.

Keywords: Hydrometallurgy; Leaching; Reclamation; Recycling; Waste processing

1. Introduction Disposal and recycling of dross produced during aluminium melting is a worldwide problem. Majority of dross is disposed o in landll sites, which is likely to result in leaching of toxic metal ions into ground water causing serious pollution problems (Unger and Beckmann, 1992). In addition to this when aluminium dross comes in contact with water it emits harmful gases such as NH3, CH4, PH3, H2, H2S, etc. (Unger and Beckmann, 1992). In India, a rough estimate shows that $75,000 tons of dross is generated annually and most of it is used for making crackers, impure chemicals and low quality refractory bricks or stock piled due to want of proper treatment options. Aluminium dross is formed by natural oxidation of molten aluminium. The metal when comes in contact with air

Corresponding author. Tel.: +91 0986 1085358; fax: +91 0674 258 1637. E-mail address: bankimtripathy@gmail.com (B.C. Tripathy). 0892-6875/$ - see front matter 2006 Elsevier Ltd. All rights reserved. doi:10.1016/j.mineng.2006.09.002

*

forms oxide of aluminium at the outer surface of the melt. The residual metal part in the dross is removed by remelting it by adding salt ux to minimize the oxidation. The oxide in the dross exhibits the form of a long continuous net where aluminium stays entrapped. The molten ux also breaks this framework and facilitates the coalescence of aluminium drops that sinks to the aluminium bath (Tenorio and Espinosa, 2002). In majority of the cases salt bath is used to maximize the recovery of aluminium. By this process though oxide generation is less the dross becomes toxic because of its salt content and makes the disposal of dross and recovery of aluminium from the dross more complex. The increasing demand of valuable materials and environmental standard enforcement has forced the development of suitable treatment facilities for industrial wastes. Further, for sustainable development, replacement of primary resources with secondary resources has also become very essential. Scanning of literature shows that attempts have already been made to utilize aluminium dross by adopting either

B.R. Das et al. / Minerals Engineering 20 (2007) 252258

253

pyro- or hydrometallurgical methods. The conventional dross oxide treatment consists of grinding the dross, sieving to recover the metal value followed by water leaching to dissolve the salt in water from residue oxide. The salt is recovered back by ltering and evaporation technique. The residue which contains primarily alumina and other alloying elements is then calcined. In another process aluminium is mechanically separated from the oxide part and the remaining oxide nes are blended into a product that can be used for steel industries. In recent times Portland cement industries use certain quantities of alumina for the production of cement (Zuck, 1995). As the requirement of aluminium oxide is around 5%, many producers in US utilize this dross oxide for production of cement. Alcan (Lavoie et al., 1991; Lavoie and Lachance, 1995), since 1990 has been using plasma dross processing facility for its treatment plant where aluminium recovery is said to improve to around 90%. The dross generated is utilized for manufacture of other products like sodium aluminate (Na2Al2O4) spinel based ceramic, brown alumina, calcium aluminate etc. In a Korean process (Park et al., 1999), the dross was leached with NaOH to extract the aluminium as sodium aluminate and then precipitated in the form of aluminium hydroxide. The residue in the leaching was roasted to oxidize the remaining metals to oxide. This roasted oxide is used for making high castable refractories by mixing with aggregates and alumina cement. El-Katatny et al. (2003) described a process where aluminium is recovered from the dross by precipitating out aluminium hydroxide using NaOH solution. This aluminium hydroxide powder is then activated at 600 C to obtain c-Al2O3. Various studies (Osborne, 1995; Garret, 1982; Huckabay, 1984; Huckabay and Skiathas, 1982; Amer, 2002) have been undertaken where H2SO4 was utilized for manufacture of aluminium sulphate. In most of the works (Osborne, 1995; Garret, 1982; Huckabay, 1984; Huckabay and Skiathas, 1982) aluminium sulphate produced was having various contaminants, thus making the sulphate impure. Amer (2002) produced two types of alums (aluminium sulphate) by dividing the alumina leaching process in to two steps. In the rst step leaching was carried out with dilute H2SO4 to remove impurities and in the second step alumina was extracted from the puried dross tailings using concentrated H2SO4. In India no signicant eort has been made to reclaim the dross and add value to the waste. The dross is treated mostly in unorganized sectors for preparation of impure chemicals, crackers and castable refractories as mentioned earlier. In the present study an attempt has been made to develop a process ow sheet to recover salt and alumina value to produce g-alumina. 2. Experimental Aluminium dross is a waste material obtained from aluminium melting plants whose composition diers due

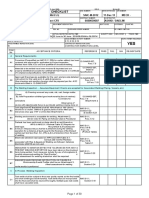

to the various alloying elements used during melting. The dross used in this work was collected from a domestic dross producer, which contains mainly $65% alumina, 4% SiO2 and oxides of Mg, Ca and Fe along with some salts such as NaCl and KCl. This dross contains bigger particles of size 25 mm, which are mostly aluminium or its alloy and the ner fractions are mostly alumina (Al2O3). Screening of the above material was undertaken to separate out the aluminium part from the oxide. The <850 lm (Tyler 20) size particles were taken for the study. The analysis of this fraction is given in Table 1. Philips X-ray Fluorescence (XRF) analytical equipment was used for the dross analysis. The X-ray diraction analysis (XRD) was carried out on a Philips Powder diractometer Model PW 1830 Xpert system. The XRD pattern of the dross is shown in Fig. 1 with the possible phases present. Carbon and sulphur were analysed on a LECO instrument. The XRF and X-ray diraction analysis of the dross indicated the presence of a-Al2O3, CaF2, MgAl2O4, Fe2O3, CaO, carbon, sulfur and salts like KCl and NaCl. The dissolution experiments of dross in H2SO4 medium were carried out in a at-bottomed glass reactor, which was placed on a Remi make hot plate cum magnetic stirrer. During leaching the temperature was maintained at around 90 C. A similar system was used for washing of dross with water. As the dissolution reaction is exothermic, the temperature of the leaching medium automatically increases up to 8085 C without any input of heat from out side. The hot plate was utilized to maintain the temperature at 90 2 C. For each experiment 10 g of dross was taken unless otherwise specied. Each experiment was carried out for 3 h followed by alumina analysis of the leached liquor by conventional EDTA ZnSO4 method. The leach solution obtained after ltration was subjected to iron removal followed by aluminium hydroxide precipitation using 10% solution of aqueous ammonia that was added drop wise into the solution using a burette. The product aluminium hydroxide was heat treated at various temperatures from 200 to 1100 C in a mue furnace to observe the phase transformation and to identify the temperature for g-alumina transformation.

Table 1 Chemical composition of aluminium dross Compound/element Al2O3 CaO SiO2 Fe2O3 MgO Na2O K2O Cl C S Percent (w/w) 64.8 0.93 4.0 1.5 3.2 2.75 0.51 3.9 1.25 0.22

254

B.R. Das et al. / Minerals Engineering 20 (2007) 252258

95

Alumina recovery, %

85

75

15 %

65

20 % 30 % 40 %

Fig. 1. XRD pattern of original dross of particle size less than 850 lm (Tyler 20).

55 10

20

30

40

50

60

3. Results and discussion 3.1. Dissolution of dross oxide Leaching of both un-washed and washed dross oxide in sulfuric acid medium was carried out to evaluate the leaching behavior. 3.1.1. Dissolution of un-washed dross After screening, the <850 lm size dross was subjected to sulphuric acid leaching. During sulphuric acid leaching of the dross following reactions take place and water-soluble aluminium sulphate is formed. Al2 O3 + 3H2 SO4 = Al2 (SO4 )3 + 3H2 O 2Al + 3H2 SO4 = Al2 (SO4 )3 + 3H2 2Al + 6H2 SO4 = Al2 (SO4 )3 + 3SO2 + 6H2 O 1 2 3

Volume of H2SO4, mL

Fig. 2. Variation of alumina recovery as a function of H2SO4 amount at various acid concentrations.

Fig. 2 shows variation of alumina recovery as a function of amount of H2SO4 at dierent percentage of its concentrations. Here at each level of H2SO4, 10 g of dross was taken. The amount of acid added varied between stoichiometric amount to almost three times of the stoichiometric amount. The temperature during leaching was maintained at around 90 C. The experiments mentioned were carried out to know the exact amount (mL) and concentration of acid (%) required for the maximum recovery of alumina from the dross. This is required because solubility of aluminium sulphate is limited to concentrated H2SO4 solution. Fig. 2 also shows the alumina recovery at a xed percentage of acid with change in acid quantity. The dierent percentages of acid used were 15%, 20%, 30% and 40%, whereas its amount varied from 15 to 50 mL. With 15% acid marginal improvement in recovery was observed when amount of acid increased to 20 mL but the recovery remained almost constant ($75%) with further increase in acid quantity. The recovery was found to be $74% with 15 mL of 20% acid. On increasing the acid quantity to

30 mL maximum recovery of 78% was obtained but with further increase in the acid quantity the recovery started falling. Similar observation was made for 30% acid where 30 mL acid showed maximum recovery of 88% and with further increase in acid quantity recovery showed a declining trend. However with 40% acid the maximum recovery was obtained at 40 mL of acid amount. The reason behind decrease in recovery with increase in acid is exactly not known. Though the decrease in recovery is not appreciable but it happened in all the cases. Generally in any dissolution/leaching operation stoichiometric quantities of leachant does not show the optimum level of recovery. Invariably some more acid would be required to have the optimum value. In this case the role of acid quantity, quantity of water, salts like KCl and NaCl, formation of aluminium sulphate etc. will inuence the leaching behaviour. It has been mentioned that where washed dross is taken for dissolution studies, with stoichiometric quantity of acid, alumina recovery is higher. It has been found, therefore that the optimum recovery of alumina for original dross is 88%, with 30 mL of 30% acid. But this 30 mL of acid is almost double the stoichiometric amount that is required for 100% solubilisation of available alumina. Fig. 3 shows percentage of recovery of alumina plotted as a function of solids (dross) concentration at various acid quantities. It has been found that solid concentration of 10% showed maximum recovery. Similar results were also obtained with other percentages of acid considered in the present study. Therefore, pulp density of 10% may be taken as the optimum solid concentration to obtain maximum alumina recovery. It has been observed from the above results that maximum recovery of 88% can be achieved with 30 mL of

B.R. Das et al. / Minerals Engineering 20 (2007) 252258

255

90

80

70

60 0 5 10 15 20 25 Solid (dross) Concentration , %

Fig. 3. Eciency of alumina recovery as a function of pulp density at 30% acid concentration.

30% acid for 10 g of dross. However as mentioned earlier, this 30% acid is almost double of the stoichiometric amount. With 30% acid leaching, the concentration of acid in the leach liquor would be too high and would require signicant amount of alkali for its neutralization during hydroxide precipitation. Considering this aspect it was decided to use stoichiometric quantity of acid i.e. 15% but in this case the recovery would be limited to $70%. 3.1.2. Washing of dross followed by leaching of washed dross The leaching of original dross with stoichiometric amount of acid resulted in only $70% alumina dissolution. In addition the salts will contaminate the leach liquor. These salts in the leach liquor will contaminate the hydroxide in the precipitation stage and thus the ultimate product. In order to improve the leaching eciency and prevent contamination of leach liquor from the soluble salts, some leaching experiments were carried out after washing the dross. This has improved the leaching eciency as well as brought almost all the salts into the washed solution. It was then decided to introduce a washing step to remove the soluble salts followed by its recovery. So a detailed study on water washing of the dross followed by leaching was taken up. 3.1.2.1. Washing of dross and recovery of salts for recycling. As discussed earlier the salts used in the dross during melting are water-soluble salts like KCl and NaCl. The total quantity of the salt present in the dross was found to be around 8%. Prior to acid leaching the dross was subjected to water washing for salt recovery. The variables considered in these

set of experiments were time and washing temperature. All these experiments were carried out under stirring condition with 20 g of dross maintaining a solid to liquid ratio of 10%. The eect of time on washing was carried out from 1 to 24 h. Washing at room temperature for 1 h yielded about 65% of the total salt present in the dross. Further increase in the washing time up to 24 h has practically no eect. However when the residue obtained after 1 h washing was again washed with fresh water for 1 h the salt recovery was improved by another 57%. To improve the salt recovery eciency, washing of the dross was carried out at 80 2 C. It has been found that kinetics of salt recovery was enhanced with rise in temperature. At 80 C around 90% salt is washed with water in 1 h. Similar to room temperature washing, the residue obtained after 1 h washing at 80 C if washed with fresh water for another 1 h at 80 C the recovery improved by further $10%. Thus almost 100% recovery of salt could be possible in two step washing at 80 C. This washed solution was evaporated to obtain KCl and NaCl crystals, which can be recycled during melting of dross. Fig. 4 shows the XRD phase analysis of recovered salt. In actual plant operation a washing scheme has to be involved so as to obtain a wash solution of high salt content for economical recovery of salts. 3.1.2.2. Leaching of washed dross. Acid leaching studies were carried out with both washed dross, and washed and dried dross. In these cases, 10 g dross was taken each time and was washed with 100 mL of demineralised (DM) water under optimum conditions to recover salts. The slurry was ltered and the residue was taken for leaching with 15% acid under the conditions established above. In another case the residue obtained after washing and ltration was dried and the dried residue was taken for leaching under the same conditions. The acid leaching eciencies (recovery of Al2O3) of the three dierent drosses i.e. original, washed and washed & dried were compared. It was found that the alumina recovery eciency has improved considerably with washing. The washed dross showed maximum recovery of $84% with 15% (v/v) acid and 10% dross (w/v). The improvement in leaching eciency for washed dross may be due to the removal of salts from the alumina surfaces. This nding has good implication, as inclusion of a washing step is essential to recover the salts from the ltrate as well as removal of washable impurities, which might otherwise end up with the nal product. X-ray diraction data (Fig. 1) showed original dross contains mainly a-Al2O3, MgO Al2O3, SiO2, CaF2, KCl, NaCl etc. There is also possibility of formation of sillimanite (Al2O3, SiO2) as 100% relative intensity is observed at 26.5 (2h) as well as at $38.5 (2h) coincides with certain aalumina reections. Probably these ceramic oxides do not respond to the present leaching conditions thus limiting the alumina recovery to $84%.

Alumina Recovery , %

256

B.R. Das et al. / Minerals Engineering 20 (2007) 252258

Fig. 4. X-ray diraction pattern of salts obtained from dross after water washing.

3.2. Aluminium hydroxide precipitation The leach liquor obtained from sulphuric acid leaching contains 1012 g/L of Al2O3 as aluminium sulphate. It also contains considerable amount of iron i.e. around 250 300 mg/L. Since presence of iron in the aluminium hydroxide imparts colour and contaminates the nal product, it was removed by controlled addition of aqueous ammonia at pH 4.4. Aluminium hydroxide was then precipitated by raising the pH of the iron free solution to 7.0. The aluminium hydroxide thus obtained is rich in water content Al2 O3 : 42%; H2 O and SO2: 58%. 4 3.3. Production of activated alumina The amorphous aluminium hydroxide during calcination undergoes phase transformation and produces dierent forms of transition oxides. The phase transformation depends on the precursor material. The dierent transition aluminas available are v, g, c and q alumina in low temperature range (250900 C) and d, j and h at higher temperature range (Goodboy and Downing, 1990). These oxides

form a large group of activated aluminas. In the present study the precipitated hydroxide is subjected to calcinations in the range of 2001100 C. This temperature range was chosen because major transformations are obtained in this range only. The activated alumina is obtained from aluminium hydroxide by controlled heating to eliminate most of the water of constitution. The XRD study of the product aluminium hydroxide carried out at dierent temperatures showed amorphous behaviour till 800 C but at 900 C it transformed to g-alumina (Fig. 5) and at 1100 C a-alumina was obtained. A similar observation was also made in our previous study (Bhattacharya et al., 2004) where aluminium hydroxide precipitated from pure aluminium sulphate was transformed to g-alumina at 900 C. TGA study of the precipitated aluminium hydroxide indicated two distinctive high rates of weight loss zones i.e. at 250 C and 900 C. The rst zone was referred to as due to dehydration or dehydroxylation and the second zone due to desulphurisation reaction. These eects result in the increased porosity. It was also observed that BET surface area of the calcined product at 900 C was maxi-

Fig. 5. X-ray diraction pattern of g-alumina.

B.R. Das et al. / Minerals Engineering 20 (2007) 252258

257

Fig. 6. Typical ow sheet for aluminium dross processing.

mum (112 m2/g). Higher surface area and increased porosity of g-alumina indicated that this can be used as a very good adsorbent and also as catalytic material. The surface area can further be increased by treating/doping the material with inorganic acids and/or various metal ions. 4. Processing routes Fig. 6 represents a ow sheet proposed from the present study for aluminium dross processing to recover aluminium value and processing of leach liquor for producing value added product like g-alumina. 5. Conclusions The process developed for the treatment of aluminium dross is unique in nature. The treatment options available mostly aimed to optimize the recovery of metal part from oxide part and rest was land lled. In this study only alumina part was subjected to the treatment after recovering the metal part by screening. A ow sheet has been developed where initially water-soluble salt is recovered by water washings. H2SO4 dissolution process has been optimized and found that 30% acid at 10% pulp density of dross will leach out 88% Al2O3 and 15% acid at 10% solid concentration showed around 71% recovery. Alternatively, it was found that when the leaching was carried out with washed dross and 15% acid around 84% recovery was obtained. The aluminium containing leached solution was further treated with aqueous ammonia to obtain amor-

phous aluminium hydroxide. This aluminium hydroxide was heat treated at 900 C to obtain g-Al2O3, which is a high valued activated alumina and can be used as an adsorbent or can be used for catalytic purpose. Acknowledgements The authors are grateful to Ministry of Environment and Forests, Govt. of India, New Delhi, for the nancial support to carry out the work. They are also grateful to M/s Agarvanshi Aluminium, Secunderabad for supplying the aluminium dross. The authors also like to thank the Director, Regional Research Laboratory, for permission to publish this paper. They are also thankful to Dr. P.S. Mukherjee and Dr. Rajeev for XRD/XRF analyses. References

Amer, A.M., 2002. Extracting aluminum from dross tailings. J. Metals 54, 7275. Bhattacharya, I.N., Gochhayat, P.K., Mukherjee, P.S., Paul, S., Mitra, P.K., 2004. Thermal decomposition of precipitated low bulk density basic aluminium sulfate. Mater. Chem. Phys. 88, 32. El-Katatny, E.A., Halany, S.A., Mohamed, M.A., Zaki, M.I., 2003. Surface composition, charge and texture of active alumina powders recovered from aluminum dross tailings chemical waste. Powder Technol. 132, 137144. Garret, L.W., 1982. Process for the Production of Sulfates. US Patent No. 4,337,228. Goodboy, K.P., Downing, J.C., 1990. In: Hart, L.D. (Ed.), Production, Process, Properties and Applications of Activated and Catalytic Aluminas. The American Ceramic Society Inc., Wessterville, Ohio, p. 93.

258

B.R. Das et al. / Minerals Engineering 20 (2007) 252258 Park, H., Lee, H., Kim, J., Yoon, E., 1999. A processing for recycling of the domestic aluminum. Dross, Global Symposium on Recycling, Waste Treatments and Clean Technology, vol. II. REWAS, San Sebastian, Spain, p. 995. Tenorio, J.A.S., Espinosa, D.C.R., 2002. Eect of salt/oxide interaction on the process of aluminum recycling. J. Light Metals 2, 8993. Unger, T.W., Beckmann, M., 1992. Salt slag processing for recycling, light metals. In: Cutshall, E.R., (Ed.), TMS Annual Meeting, San Diego, California, pp. 11591162. Zuck, O.A., 1995. In: Queneau, P.B., Peterson, R. (Eds.), Proceeding of 3rd International Symposium on Recycling of Metals and Engineered Materials. The Minerals, Metals and Materials Society, TMS, pp. 925 930.

Huckabay, J.A., 1984. Method for Treatment of Aluminum Dross Oxides. US Patent No. 4,434,142. Huckabay, D.A., Skiathas, D.A., 1982. Aluminium Sulfate Manufacture from Aluminum Dross Tailings. US Patent No. 4,320,098. Lavoie, S., Lachance, J., 1995. In: Queneau, P.B., Peterson, R. (Eds.), Proceeding of 3rd International Symposium on Recycling of Metals and Engineered Materials. The Minerals, Metals and Materials Society, TMS, p. 791. Lavoie, S., Dube, C., Dube, G., 1991. The Alcan plasma dross treatment process, light metals. In: Elwin Rooy, (Ed.), TMS Annual Meeting, New Orleans, Louisiana, pp. 981985. Osborne, W.B., 1995. In: Queneam, P.B., Peterson, R.D. (Eds.), Proceeding of 3rd International Symposium on Recycling of Metals and Engineered Materials. The Minerals, Metals and Materials Society, TMS, p. 947.

Вам также может понравиться

- APJCE Journal Exergy Calculator ToolДокумент7 страницAPJCE Journal Exergy Calculator ToolböhmitОценок пока нет

- 2.ansys Fluid Dynamics r14Документ8 страниц2.ansys Fluid Dynamics r14Saumya SinhaОценок пока нет

- 1 s2.0 S003259100300216X MainДокумент9 страниц1 s2.0 S003259100300216X MainböhmitОценок пока нет

- Yueguangxi 7Документ6 страницYueguangxi 7böhmitОценок пока нет

- 01 Mascoat Industrial Application InstructionsДокумент7 страниц01 Mascoat Industrial Application Instructionsböhmit100% (1)

- Zinio Opt-Out SuccessfulДокумент1 страницаZinio Opt-Out SuccessfulböhmitОценок пока нет

- Chemical Solution, Inc. Technical Data Sheet: Inspecting Boilers and Related EquipmentДокумент2 страницыChemical Solution, Inc. Technical Data Sheet: Inspecting Boilers and Related Equipmentböhmit0% (1)

- Çan - Turkey CFB Steam Power Plant: High-Sulphur Lignite CombustionДокумент6 страницÇan - Turkey CFB Steam Power Plant: High-Sulphur Lignite CombustionböhmitОценок пока нет

- AlbertEinstein 4454 Chap1Документ18 страницAlbertEinstein 4454 Chap1böhmitОценок пока нет

- Free CADДокумент19 страницFree CADKent PawarОценок пока нет

- WT DiagramДокумент1 страницаWT DiagramböhmitОценок пока нет

- Words For Ideas - John Morley - KapakДокумент1 страницаWords For Ideas - John Morley - Kapakböhmit100% (1)

- Document Title 01Документ1 страницаDocument Title 01böhmitОценок пока нет

- Yunan Myb3 2010 GRДокумент5 страницYunan Myb3 2010 GRböhmitОценок пока нет

- Aluminum Hydroxide WhitenessUS4915930Документ9 страницAluminum Hydroxide WhitenessUS4915930böhmitОценок пока нет

- Aluminum Hydroxide WhitenessUS4786482Документ12 страницAluminum Hydroxide WhitenessUS4786482böhmitОценок пока нет

- Mineral processing techniques for ore comminution and classificationДокумент24 страницыMineral processing techniques for ore comminution and classificationtanmay035Оценок пока нет

- 28 5 373crystalchemistryboehmiteДокумент8 страниц28 5 373crystalchemistryboehmiteböhmitОценок пока нет

- 11 685 447 Direct Sorbent Preparation FeДокумент8 страниц11 685 447 Direct Sorbent Preparation FeböhmitОценок пока нет

- 460 Mwe Super Critical CFB Boiler Design For Lagisza Power PlantДокумент20 страниц460 Mwe Super Critical CFB Boiler Design For Lagisza Power PlantJohn WestОценок пока нет

- Aluminium Anode Energy 1095661Документ10 страницAluminium Anode Energy 1095661böhmitОценок пока нет

- Electrostatic Precipitator 01 ELEXДокумент3 страницыElectrostatic Precipitator 01 ELEXböhmitОценок пока нет

- Hydrothermal Preparation BoehmiteДокумент8 страницHydrothermal Preparation BoehmiteböhmitОценок пока нет

- AluHydroxide Plash Cooling US3486850Документ6 страницAluHydroxide Plash Cooling US3486850böhmitОценок пока нет

- Precipitation of Monohydrate Alumina47697921en6Документ12 страницPrecipitation of Monohydrate Alumina47697921en6böhmitОценок пока нет

- Flow Phenomenon in Steam Turbine Disk-Stator Cavities Channeled by Balance Holes7Документ1 страницаFlow Phenomenon in Steam Turbine Disk-Stator Cavities Channeled by Balance Holes7böhmitОценок пока нет

- Mineral processing techniques for ore comminution and classificationДокумент24 страницыMineral processing techniques for ore comminution and classificationtanmay035Оценок пока нет

- AluminiumHydroxide 15 - AC16Документ12 страницAluminiumHydroxide 15 - AC16böhmitОценок пока нет

- 557262synthesis of Aluminium HydratesДокумент6 страниц557262synthesis of Aluminium HydratesböhmitОценок пока нет

- Flow Phenomenon in Steam Turbine Disk-Stator Cavities Channeled by Balance Holes8Документ1 страницаFlow Phenomenon in Steam Turbine Disk-Stator Cavities Channeled by Balance Holes8böhmitОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Selection of Committee F16 Fastener Specifications: Standard Guide ForДокумент15 страницSelection of Committee F16 Fastener Specifications: Standard Guide ForLeonardo GomideОценок пока нет

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceДокумент12 страниц1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- En 10027 - Designation Systems For SteelsДокумент3 страницыEn 10027 - Designation Systems For Steelskiranrauniyar100% (1)

- SAIC M 2012 (Structural Welding)Документ30 страницSAIC M 2012 (Structural Welding)rubda11100% (1)

- Radiography PresentationДокумент28 страницRadiography PresentationmqasimqasimОценок пока нет

- Valve Types and ApplicationsДокумент82 страницыValve Types and Applicationsrajeshn1Оценок пока нет

- Bridge Types - Historical Overviews - 2006 Pre1930metal PDFДокумент18 страницBridge Types - Historical Overviews - 2006 Pre1930metal PDFrobpallotОценок пока нет

- Magnets for Industry: Powerful Solutions for All ApplicationsДокумент50 страницMagnets for Industry: Powerful Solutions for All Applicationssalty.mothОценок пока нет

- Compression Spring Design InfoДокумент4 страницыCompression Spring Design Infomprabhu4youОценок пока нет

- Report of ElectrogravimetryДокумент12 страницReport of ElectrogravimetryKrisna Raditya PОценок пока нет

- No Good Gremlins Rules PDFДокумент4 страницыNo Good Gremlins Rules PDFPedro HenriqueОценок пока нет

- Komatsu Cat FinalДокумент29 страницKomatsu Cat FinalcperaltaОценок пока нет

- Hughes Brothers PDFДокумент52 страницыHughes Brothers PDFJavier MaldonadoОценок пока нет

- CT Saturation Issues in Power SystemsДокумент2 страницыCT Saturation Issues in Power SystemssenthilanviewОценок пока нет

- Selection of Filler Metal For WeldingДокумент21 страницаSelection of Filler Metal For WeldingRegu vlogsОценок пока нет

- Colour ChartДокумент1 страницаColour ChartgawaОценок пока нет

- Lightweight Metal Foam Heat ExchangersДокумент7 страницLightweight Metal Foam Heat ExchangersPat RОценок пока нет

- Indoor Luminaires: Price List June 2016Документ4 страницыIndoor Luminaires: Price List June 2016khraieric16Оценок пока нет

- Seminar 1 - Stainless Steel and Its ApplicationsДокумент105 страницSeminar 1 - Stainless Steel and Its ApplicationspripramadaОценок пока нет

- INFORME MetalografiaДокумент9 страницINFORME MetalografiaRhaiОценок пока нет

- Grounding & Earthing PDFДокумент108 страницGrounding & Earthing PDFRajeevAgrawal100% (1)

- The Complete Line of Hydraulic Shears Press Brakes Iron WorkersДокумент22 страницыThe Complete Line of Hydraulic Shears Press Brakes Iron WorkersJim ConneryОценок пока нет

- Avail 9 WДокумент1 страницаAvail 9 WnistianaОценок пока нет

- D5-2 Prepainted Galvanized Galvalume Steel Coils With Protective Plastic FilmДокумент2 страницыD5-2 Prepainted Galvanized Galvalume Steel Coils With Protective Plastic FilmFernandoCrespoMonОценок пока нет

- WES Hygienic Design Handbook - Jan 01Документ54 страницыWES Hygienic Design Handbook - Jan 01Alfonso FuentesОценок пока нет

- Magnetic Effects of Stainless SteelДокумент2 страницыMagnetic Effects of Stainless SteelIkhsan LyОценок пока нет

- Storage Tank Design: Email:moemen - Hussein@alexu - Edu.egДокумент58 страницStorage Tank Design: Email:moemen - Hussein@alexu - Edu.egahmadhatakeОценок пока нет

- C BoilermakingДокумент9 страницC BoilermakingAldeline SungahidОценок пока нет

- Creep TestДокумент18 страницCreep Testdeemi75Оценок пока нет

- Mason Job DescriptionДокумент5 страницMason Job Descriptiononeline photoОценок пока нет