Академический Документы

Профессиональный Документы

Культура Документы

Modelling and Simuation of BLDC Motor in MATLAB GUI

Загружено:

vishiwizardАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Modelling and Simuation of BLDC Motor in MATLAB GUI

Загружено:

vishiwizardАвторское право:

Доступные форматы

Modeling and Simulation of the BLDC Motor in MATLAB GUI

Balogh Tibor, Viliam Fedk, Frantiek urovsk Dept. of Electrical Engineering and Mechatronics, FEI TU of Koice, Slovak Republic tiborb@gmail.com, viliam.fedak@tuke.sk, frantisek.durovsky@tuke.sk results. Several simulation models have been proposed for the analysis of BLDC motor [1], [4], [5]. One of the models has a real back-EMF waveform whose appearance is close to a sinusoidal shape. This paper attempts to compare various types of BLDC motor models - with the trapezoidal and sinusoidal back-EMF waveforms. The simple motor model of a BLDC motor consisting of a 3-phase power stage and a brushless DC motor is shown in Fig. 1. II. CONSTRUCTION AND OPERATING PRINCIPLE

Abstract-The paper proposes a model of brushless DC motor considering behavior of the motor during commutation. The torque characteristic of BLDC motor presents a very important factor in design of the BLDC motor drive system, so it is necessary to predict the precise value of torque, which is determined by the waveforms of back-EMF. After development of simple mathematical model of the BLDC motor with sinusoidal and trapezoidal waveforms of back-EMF the motor is simulated in the MATLAB/Simulink environment. Based on analysis of the time responses a comparison study of results of both BLDC motor types is presented in Graphical User Interface of MATLAB environment.

I.

INTRODUCTION

The Brushless Direct Current (BLDC) motor is rapidly gaining popularity by its utilization in various industries, such as Appliances, Automotive, Aerospace, Consumer, Medical, Industrial Automation Equipment and Instrumentation. As the name implies, the BLDC motors do not use brushes for commutation; instead, they are electronically commutated. The BLDC motors have many advantages over brushed DC motors and induction motors [1]. A few of these are: Better speed versus torque characteristics High dynamic response High efficiency Long operating life Noiseless operation Higher speed ranges In addition, the ratio of torque delivered to the size of the motor is higher, making it useful in applications where space and weight are critical factors [2]. The torque of the BLDC motor is mainly influenced by the waveform of back-EMF (the voltage induced into the stator winding due to rotor movement). Ideally, the BLDC motors have trapezoidal back-EMF waveforms and are fed with rectangular stator currents, which give a theoretically constant torque. However, in practice, torque ripple exists, mainly due to emf waveform imperfections, current ripple and phase current commutation. The current ripple result is from PWM or hysteresis control. The emf waveform imperfections result from variations in the shapes of slot, skew and magnet of BLDC motor, and are subject to design purposes. Hence, an error can occur between actual value and the simulation

The BLDC motor is also referred to as an electronically commuted motor. There are no brushes on the rotor and the commutation is performed electronically at certain rotor positions. The stator magnetic circuit is usually made from magnetic steel sheets. The stator phase windings are inserted in the slots (a distributed winding), or can be wound as one coil on the magnetic pole. The magnetization of the permanent magnets and their displacement on the rotor are chosen in such a way that the back-EMF shape is trapezoidal. This allows the three-phase voltage system, with a rectangular shape, to be used to create a rotational field with low torque ripples. In this respect, the BLDC motor is equivalent to an inverted DC commutator motor, in that the magnet rotates while the conductors remain stationary.

Fig. 1. BLDC motor model of electrical circuits [3]

In the DC commutator motor, the current polarity is reversed by the commutator and the brushes, but in the brushless DC motor, the polarity reversal is performed by semiconductor switches which are to be switched in synchronization with the rotor position. Besides the higher reliability, the missing commutator brings another advantage. The commutator is also a limiting factor in the maximal speed of the DC motor. Therefore the BLDC motor can be employed in applications requiring high speed [1], [3]. Replacement of a DC motor by a BLDC motor place higher demands on control algorithm and control circuit. Firstly, the BLDC motor is usually considered as a threephase system. Thus, it has to be powered by a three-phase power supply. Next, the rotor position must be known at certain angles, in order to align the applied voltage with the back-EMF. The alignment between the back-EMF and commutation events is very important. In this condition the motor behaves as a DC motor and runs at the best working point. But the drawbacks of the BLDC motor caused by necessity of power converter and rotor position measurement are balanced by excellent performance and reliability, and also by the ever-falling prices of power components and control circuits. III. MATHEMATICAL MODEL OF THE BLDC MOTOR

a function of rotor position and the back-EMF of each phase has 120 phase angle difference so equation of each phase should be as follows:

ea = K w f ( e ) eb = K w f ( e 2 3) ec = K w f ( e + 2 3)

where Kw is back EMF constant of one phase [V/rad.s-1], e - electrical rotor angle [ el.], - rotor speed [rad.s-1].

(4) (5) (6)

The electrical rotor angle is equal to the mechanical rotor angle multiplied by the number of pole pairs p:

e =

p m 2

(7)

Where m is mechanical rotor angle [rad]. Total torque output can be represented as summation of that of each phase. Next equation represents the total torque output:

Modeling of a BLDC motor can be developed in the similar manner as a three-phase synchronous machine. Since there is a permanent magnet mounted on the rotor, some dynamic characteristics are different. Flux linkage from the rotor depends upon the magnet material. Therefore, saturation of magnetic flux linkage is typical for this kind of motors. As any typical three-phase motors, one structure of the BLDC motor is fed by a three-phase voltage source. The source is not necessarily to be sinusoidal. Square wave or other wave-shape can be applied as long as the peak voltage does not exceed the maximum voltage limit of the motor. Similarly, the model of the armature winding for the BLDC motor is expressed as follows:

Te =

ea ia + eb ib + ec ic

where Te is total torque output [Nm],

(8)

The equation of mechanical part is represents as follows:

Te Tl = J

d + B dt

(9)

where Tl is load torque [Nm], J - inertia of rotor and coupled shaft [kgm2], B - friction constant [Nms.rad-1]. IV. SIMULINK MODEL OF THE BLDC MOTOR

Va = Ria + L

dia + ea dt di Vb = Rib + L b + eb dt di Vc = Ric + L c + ec dt

(1) (2) (3)

where L is armature self-inductance [H], R - armature resistance [], Va, Vb, Vc - terminal phase voltage [V], ia, ib, ic - motor input current [A], and ea, eb, ec - motor back-EMF [V]. In the 3-phase BLDC motor, the back-EMF is related to

Fig. 2 shows the BLDC motor SIMULINK model. The model was developed in the rotor reference frame of the BLDC motor using equations shown above [5]. Fig. 3 shows the detail of the BLDC motor block. Fig.4 shows SIMULINK diagram of back-EMF. Fig. 4(a) is of trapezoidal back-EMF and Fig. 4(b) is of sinusoidal backEMF. The trapezoidal functions and the position signals are stored in lookup tables that change their output according to the value of the electrical angle [5]. Unlike a brushed DC motor, the commutation of a BLDC motor is controlled electronically. To rotate the BLDC motor, the stator windings should be energized in a sequence. It is important to know the rotor position in order to understand which winding will be energized following the energizing

Fig. 4(a). Trapezoidal model of the back-EMF Fig.2. SIMULINK model of the BLDC motor

sequence. Rotor position is sensed using Hall Effect sensors embedded into the stator. Most BLDC motors have three Hall sensors embedded into the stator on the non-driving end of the motor. Whenever the rotor magnetic poles pass near the Hall sensors, the give a high or low signal, indicating the N or S pole is passing near the sensors. Based on the combination of these three Hall sensor signals, the exact sequence of commutation can be determined. The converter block was developed using equations below:

Fig. 4(b). Sinusoidal model of the back-EMF

V.

SIMULATION RESULTS

Va = ( S1 ) Vd 2 ( S 4 ) Vd 2 Vb = ( S 3 ) Vd 2 ( S 6 ) Vd 2 Vc = ( S 5 ) Vd 2 ( S 2 ) Vd 2

(10) (11) (12)

--> ea, eb, ec [V]

Every 60 electrical degrees of rotation, one of the Hall sensors changes the state. Given this, it takes six steps to complete an electrical cycle. Corresponding to this, with every 60 electrical degrees, the phase current switching should be updated. However, one electrical cycle may not correspond to a complete mechanical revolution of the rotor. The number of electrical cycles to be repeated to complete a mechanical rotation is determined by the rotor pole pairs. For each rotor pole pairs, one electrical degree is completed. The number of electrical cycles/rotations equals the rotor pole pairs [6].

Fig. 5 - 9 shows results of simulation of a BLDC motor with the following parameters: Vd = 30 V, R = 4,98 , L = 5,05 mH, p = 4, J = 15,17.10-6 kgm2, kw = 56,23.10-3 V/rad.s-1, Tl = 0.1 Nm. The load time is 0,15 s. The time courses in Fig. 5(a) belong to the BLDC motor with trapezoidal back-EMF and the responses in Fig. 5(b) are valid for the sinusoidal back-EMF BLDC motor. There is a very good correlation with the responses of the BLDC motor models known in the references [5], [6].

15

10

-5

-10

-15 0 0.05 0.1 0.15 --> t [s] 0.2 0.25

ea eb ec 0.3

Fig. 5(a). Time courses of the trapezoidal back-EMF

Fig. 3. Detailed SIMULINK model of the BLDC motor

15

10

--> ea, eb, ec [V]

-5

-10

-15 0 0.05 0.1 0.15 --> t [s] 0.2 0.25

ea eb ec 0.3

Fig. 6. Time courses of the BLDC motor in MATLAB GUI

Fig. 5(b). Time courses of the sinusoidal back-EMF

VI.

GRAPHICAL USER INTERFACE IN MATLAB

A graphical user interface (GUI) is a pictorial interface to a program. A good GUI can make programs easier to use by providing them with a consistent appearance and with intuitive controls like pushbuttons, list boxes, sliders, menus, and so forth. The GUI should behave in an understandable and predictable manner, so that a user knows what to expect when he or she performs an action. For example, when a mouse click occurs on a pushbutton, the GUI should initiate the action described on the label of the button. If GUIs were not used, people would have to work from the command line interface, which can be extremely difficult and frustrating [7]. A graphical user interface provides the user with a familiar environment in which to work. This environment contains pushbuttons, toggle buttons, lists, menus, text boxes, and so forth, all of which are already familiar to the user, so that he or she can concentrate on using the application rather than on the mechanics involved in doing things. However, GUIs are harder for the programmer because a GUI-based program must be prepared for mouse clicks (or possibly keyboard input) for any GUI element at any time [7]. The three principal elements required to create a MATLAB Graphical User Interface are: Components Figures Callbacks In GUI program, we can simulate the equations that describe not only mechanical but also electrical transients. Fig. 6 is shown GUI for modeling and simulation of the BLDC motor. By blue pushbutton ea, eb, ec we can see time courses of trapezoidal back-EMF in three-phase stator windings of the BLDC motor. Fig. 7 is shown mentioned back-EMF voltages before and after the load mount in time 0.15 s.

In the bottom of GUI simulation model are sliders to change the BLDC motor parameters. After changing the motor parameters we can monitor the behavior of the motor and show time courses of parameters that we want to monitor and analyze. Students by GUI simulation can better understand the theoretical knowledge acquired from lectures into real devices. Via the GUI simulation we can monitor and analyze response time of physical quantities that are available. Fig. 8 is shown a response time of the load variations of 0.1 Nm to 0.2 Nm. After changing we can analyze by the increase in the size of the load that speed of the motor and also back-EMF voltages in each three-phase in the stator winding were decreased. VII. EDUCATIONAL USE OF MODELS

A whole set of electrical machines virtual models developed in GUI MATLAB environment have been successfully integrated in electric machinery courses. They serve for easier understanding operation principles and after performing virtual experiments the students enter the laboratory to work on real devices.

Fig. 7. Experimentation on BLDC motor virtual model - time courses of the speed and back-EMF voltages

The behavior of developed BLDC motor virtual model is shwon in Figs. 7. and 8. The GUI window is completed by basic BLDC motor equations and schemes to be evocated by pushing a button. The motor parameters are set by shifters what enables to observe influence of parameters to the motor operation and modes of the virtual model are set by buttons. Most of the models are integrated to into the web page [9].

ACKNOWLEDGMENT This work was supported by Slovak Cultural and Educational Agency of the Ministry of Education of Slovak Republic under the contract KEGA 103-039 TUKE-4/2010 Students Skills Development for Mechatronic Systems Control. REFERENCES

[1] B.Indu Rani, Ashly Mary Tom, Dynamic Simulation of Brushless DC Drive Considering Phase Commutation and Backemf Waveform for Electromechanical Actuator, IEEE TENCON 2008, Hyderabad. ISBN: 978-1-4244-2408-5. Padmaraja Yedamale, Brushless DC (BLDC) Motor Fundamentals, Microchip Technology Inc., 2003. Pavel Grasblum, Sensorless BLDC motor control using an 8-bit MCU, Freescale. Y.S. Jeon, H.S.Mok, G.H. Choe, D.K. Kim and J.S. Ryu, A New Simulation Model of BLDC Motor with Real Back EMF waveforms, IEEE CNF. On Computers in Power Electronics, 2000. COMPEL 2000. pp. 217 220, July 2000. S. Baldursson, BLDC Motor Modelling and Control A MATLAB/Simulink Implementation, Master Thesis, May, 2005. W. Hong, W. Lee and B. K. Lee, Dynamic Simulation of Brushless DC motor Drives Considering Phase Commutation for Automotive Applications, IEEE International Electric Machines & Drives Conference, 2007. IEMDC 2007, pp.1377-1383, 3-5 May 2007. Abdulla Ismail Abdulla, Introduction to Graphical User Interface (GUI) MATLAB 6.5, IEEE UAE Section Ayetul Gelen, Saffet Asyasun, Realization of Power Electronic Converter Based DC Motor Speed Control Method Using MATLAB/Simulink, International Journal of Engineering Education, Vol.25, pp. 33 41, 2009 Virtual laboratory of Mechatronic Systems Control. Web page of the project 103-039 TUKE-4/2010 - Rozvoj zrunost tudentov pri riaden mechatronickch sstav (Students Skills Development for Mechatronic Systems Control).

[2] [3] [4]

[5] [6] Fig. 8. Experimentation on BLDC motor virtual model - time courses of the speed and back-EMF voltages after increasing the load

[7] [8]

VIII.

CONCLUSION

The modeling procedure presented in this paper helps in simulation of various types of BLDC motors. The performance evaluation results show that, such a modeling is very useful in studying the drive system before taking up the dedicated controller design, accounting the relevant dynamic parameters of the motor.

[9]

Вам также может понравиться

- Circuit Simulation of A BLDC MotorДокумент4 страницыCircuit Simulation of A BLDC MotorjpmacabascoОценок пока нет

- Electrical Machines: Lecture Notes for Electrical Machines CourseОт EverandElectrical Machines: Lecture Notes for Electrical Machines CourseОценок пока нет

- Power Electronics and Electric Drives for Traction ApplicationsОт EverandPower Electronics and Electric Drives for Traction ApplicationsОценок пока нет

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlОт EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlРейтинг: 5 из 5 звезд5/5 (1)

- Power Electronics: Lecture Notes of Power Electronics CourseОт EverandPower Electronics: Lecture Notes of Power Electronics CourseОценок пока нет

- BLDCДокумент4 страницыBLDCmechtex Pvt LtdОценок пока нет

- Universal Motors: Presented by Meraj WarsiДокумент13 страницUniversal Motors: Presented by Meraj WarsiMeraj WarsiОценок пока нет

- Regenerative Braking of BLDC MotorsДокумент21 страницаRegenerative Braking of BLDC Motorsalthaf hussainОценок пока нет

- DC-DC ConverterДокумент24 страницыDC-DC ConverterkandularanjithОценок пока нет

- PX7203-Special Electrical Machines PDFДокумент11 страницPX7203-Special Electrical Machines PDFvaishnavisriОценок пока нет

- Brushless DC Motor ReportДокумент2 страницыBrushless DC Motor ReportAnonymous 7Q1NIAОценок пока нет

- Servo MotorДокумент16 страницServo MotorMinh Tuan Tran100% (1)

- Brushless DC MotorДокумент6 страницBrushless DC Motorpsksiva13Оценок пока нет

- Speed Control of BLDC Motor For Electric Vehicle: Presented byДокумент13 страницSpeed Control of BLDC Motor For Electric Vehicle: Presented byPawan Chauhan100% (1)

- Unit 3Документ5 страницUnit 3Narasimman DonОценок пока нет

- 开关磁阻电机的ANSOFT建模方法Документ28 страниц开关磁阻电机的ANSOFT建模方法Nuwantha FernandoОценок пока нет

- Brushless DC MotorДокумент19 страницBrushless DC MotorSanjeet KumarОценок пока нет

- BLDCДокумент4 страницыBLDCsathishОценок пока нет

- BLDC Brushless DC MotorДокумент22 страницыBLDC Brushless DC MotorNyn SoniОценок пока нет

- Eeeviews: Unit Iv Synchronous Motor DrivesДокумент26 страницEeeviews: Unit Iv Synchronous Motor Driveskrithikgokul selvamОценок пока нет

- Construction and Working of Brushless DC PDFДокумент12 страницConstruction and Working of Brushless DC PDFaswardi8756Оценок пока нет

- Documentation of PMSMДокумент89 страницDocumentation of PMSM07be1a0213Оценок пока нет

- Reluctance MotorДокумент16 страницReluctance Motorapi-382713280% (5)

- Application of Brushless DC Motor in MilitaryДокумент10 страницApplication of Brushless DC Motor in Militarymighty_heart100% (1)

- Chapter 1 - Electric DriveДокумент76 страницChapter 1 - Electric DriveNajihah YusofОценок пока нет

- Permanent Magnet Brushless DC MotorДокумент18 страницPermanent Magnet Brushless DC MotorBala SubramanianОценок пока нет

- Brushless D.C. Motors: Prepared By: Manuj Garg (2k13/EE/070) Mohit Goswami (2k13/EE/073)Документ17 страницBrushless D.C. Motors: Prepared By: Manuj Garg (2k13/EE/070) Mohit Goswami (2k13/EE/073)Manuj GargОценок пока нет

- of BLDCДокумент45 страницof BLDCsmhbОценок пока нет

- Switched Reluctance Motor (SRM)Документ8 страницSwitched Reluctance Motor (SRM)Ömer Faruk AbdullahОценок пока нет

- 2.review of Literature and Statement of ProblemДокумент6 страниц2.review of Literature and Statement of ProblemsheriabhiОценок пока нет

- Universal Motor - WikipediaДокумент27 страницUniversal Motor - WikipediaAlejandro ReyesОценок пока нет

- BLDC Motor Control ANfpgaДокумент8 страницBLDC Motor Control ANfpgasraamu2k55068100% (1)

- Sensorless Speed Control of Brushless DC Motor With Fuzzy Based EstimationДокумент7 страницSensorless Speed Control of Brushless DC Motor With Fuzzy Based EstimationPhạm Văn TưởngОценок пока нет

- Design of Synchronous MachinesДокумент17 страницDesign of Synchronous MachinesNiteshNarukaОценок пока нет

- Ch7 Induction MotorДокумент82 страницыCh7 Induction MotorMuhammad R ShihadehОценок пока нет

- Construction of Three Phase Induction MotorДокумент18 страницConstruction of Three Phase Induction MotorRajeev ValunjkarОценок пока нет

- EE2403 Special Electrical MachinesДокумент19 страницEE2403 Special Electrical MachinesvasanthavananОценок пока нет

- Alireza Tashakori Abkenar Thesis PDFДокумент199 страницAlireza Tashakori Abkenar Thesis PDFYesha ShahОценок пока нет

- BLDC ControlДокумент16 страницBLDC ControlSaurabh DashОценок пока нет

- Medical Application of BLDCДокумент5 страницMedical Application of BLDCAbd Al HAmidОценок пока нет

- Induction Motor BrakingДокумент26 страницInduction Motor BrakingAshwini Singh100% (3)

- Induction MotorsДокумент25 страницInduction Motorsapi-3827132100% (2)

- Industrial DrivesДокумент1 страницаIndustrial DrivesSatish NurukurthiОценок пока нет

- Electric Motor Drives and their Applications with Simulation PracticesОт EverandElectric Motor Drives and their Applications with Simulation PracticesОценок пока нет

- Basic SVPWMДокумент6 страницBasic SVPWMVAMSIKRISHNAEEEОценок пока нет

- Construction of Synrel MotorДокумент18 страницConstruction of Synrel MotorAshok Kumar100% (4)

- 1 Field Oriented Control of Induction Motor 12/6/2015Документ36 страниц1 Field Oriented Control of Induction Motor 12/6/2015Belal Ashraf100% (1)

- Operation of DC/DC Converter For Hybrid Electric Vehicle: Atul Kumar and Prerna GaurДокумент6 страницOperation of DC/DC Converter For Hybrid Electric Vehicle: Atul Kumar and Prerna GaurAhana MalhotraОценок пока нет

- Four - Quadrant Control SystemsДокумент4 страницыFour - Quadrant Control SystemsRICHARDОценок пока нет

- Week 71Документ25 страницWeek 71Raphael SebucОценок пока нет

- Novel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoДокумент6 страницNovel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoNenad Kostadinovic50% (2)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977От EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Оценок пока нет

- Improved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)От EverandImproved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)Оценок пока нет

- LJLVJK LVJJV LKJVДокумент5 страницLJLVJK LVJJV LKJVvishiwizardОценок пока нет

- ACM2 TAU Datasheet enДокумент5 страницACM2 TAU Datasheet envishiwizardОценок пока нет

- 50 SCS Automotive Coatings - Rev0913Документ4 страницы50 SCS Automotive Coatings - Rev0913vishiwizardОценок пока нет

- Hardware Inloop Simulation IEEE LabVIEWДокумент1 страницаHardware Inloop Simulation IEEE LabVIEWvishiwizardОценок пока нет

- Electric Vehicle Motor Design NotesДокумент131 страницаElectric Vehicle Motor Design NotesvishiwizardОценок пока нет

- Part Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisДокумент6 страницPart Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisIjabiОценок пока нет

- Jeas 1012 787Документ5 страницJeas 1012 787vishiwizardОценок пока нет

- 5 SmanualДокумент16 страниц5 SmanualMark ThomasОценок пока нет

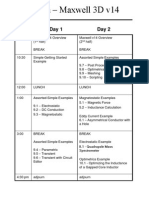

- 852 3D AgendaДокумент1 страница852 3D AgendavishiwizardОценок пока нет

- TRL Definitions PDFДокумент1 страницаTRL Definitions PDFBHARadwajОценок пока нет

- Engineered PlasticsДокумент61 страницаEngineered Plastics고병석Оценок пока нет

- FTF Aut f0234Документ38 страницFTF Aut f0234vishiwizardОценок пока нет

- ReadmeДокумент4 страницыReadmevishiwizardОценок пока нет

- Recent Advances in Materials For Use in Permanent Magnet Machines - A ReviewДокумент7 страницRecent Advances in Materials For Use in Permanent Magnet Machines - A ReviewvishiwizardОценок пока нет

- Insulating Varnish OverviewДокумент2 страницыInsulating Varnish OverviewvishiwizardОценок пока нет

- Op - XT546 246 346 - Op288 V03Документ2 страницыOp - XT546 246 346 - Op288 V03vishiwizardОценок пока нет

- Nit 3600 1Документ5 страницNit 3600 1vishiwizardОценок пока нет

- Presentation 1Документ1 страницаPresentation 1vishiwizardОценок пока нет

- Big Energy Series 11.5.2012 Qing-Chang ZhongДокумент1 страницаBig Energy Series 11.5.2012 Qing-Chang ZhongvishiwizardОценок пока нет

- FAB Resistivity White PaperДокумент8 страницFAB Resistivity White PapervishiwizardОценок пока нет

- Wittich2011 SonkusaleVanderveldeДокумент1 страницаWittich2011 SonkusaleVanderveldevishiwizardОценок пока нет

- Lit Survey RamamurthyДокумент9 страницLit Survey RamamurthyvishiwizardОценок пока нет

- Sensors Used in HEVДокумент4 страницыSensors Used in HEVvishiwizard100% (1)

- Maxwell 2dДокумент7 страницMaxwell 2dvishiwizardОценок пока нет

- BLDC DesignДокумент13 страницBLDC DesignvishiwizardОценок пока нет

- Cam DesignДокумент13 страницCam DesignvishiwizardОценок пока нет

- How To Check A MOSFET Using A Digital Multimeter - Homemade Circuit Designs Just For YouДокумент2 страницыHow To Check A MOSFET Using A Digital Multimeter - Homemade Circuit Designs Just For YouvishiwizardОценок пока нет

- Sona SPEED CatalogueДокумент13 страницSona SPEED CataloguevishiwizardОценок пока нет

- Motor Primer1Документ2 страницыMotor Primer1vishiwizardОценок пока нет

- A Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesДокумент1 страницаA Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesvishiwizardОценок пока нет

- Fiber OpticДокумент9 страницFiber OpticBHUMIОценок пока нет

- Objectives (Antennas and Wave Propagation)Документ13 страницObjectives (Antennas and Wave Propagation)Anonymous sBvtnZQОценок пока нет

- An Endfire Circularly Polarized Complementary Antenna Array For 5G ApplicationsДокумент9 страницAn Endfire Circularly Polarized Complementary Antenna Array For 5G ApplicationsDivanshu JainОценок пока нет

- Laser NumericalsДокумент3 страницыLaser NumericalsMedha Mani0% (2)

- Infrared SpectrosДокумент24 страницыInfrared Spectrosdatha saiОценок пока нет

- 140 TOP TRANSFORMERS Multiple Choice Questions and AnswersДокумент29 страниц140 TOP TRANSFORMERS Multiple Choice Questions and AnswersEarl Jenn AbellaОценок пока нет

- Module-1 - Engineering PhysicsДокумент40 страницModule-1 - Engineering PhysicsT. VARMAОценок пока нет

- Disha Publication Electrical Concept Notes With Exercies Electrical MachinesДокумент64 страницыDisha Publication Electrical Concept Notes With Exercies Electrical MachinesRal Meena100% (1)

- Isc Semester 2 Examination Specimen Question Paper Physics Paper 1 (Theory)Документ5 страницIsc Semester 2 Examination Specimen Question Paper Physics Paper 1 (Theory)marleyОценок пока нет

- Optics - Contact Lens Related - MMSДокумент38 страницOptics - Contact Lens Related - MMSManmohan ShahОценок пока нет

- Physics Value Based Questions Chapter 11 Dual Nature of Radiation and Matter PDFДокумент39 страницPhysics Value Based Questions Chapter 11 Dual Nature of Radiation and Matter PDFMohammad HuzaifaОценок пока нет

- ISO 7027 Turbidity TechniqueДокумент2 страницыISO 7027 Turbidity TechniqueGustavo Sánchez0% (1)

- Color PerceptionДокумент11 страницColor Perceptionrasagna reddyОценок пока нет

- Physics Practice 2Документ8 страницPhysics Practice 2Rinku GhoshОценок пока нет

- RadiationДокумент17 страницRadiationCheppanu BrotherОценок пока нет

- Physics-Project-Class-XII-2021-22-Investigatory-Project (1) OJASVIRAJДокумент16 страницPhysics-Project-Class-XII-2021-22-Investigatory-Project (1) OJASVIRAJaggrima0% (1)

- 120 TOP SINGLE PHASE INDUCTION MOTORS Multiple Choice Questions Electrical Engineering Multiple Choice QuestionsДокумент36 страниц120 TOP SINGLE PHASE INDUCTION MOTORS Multiple Choice Questions Electrical Engineering Multiple Choice QuestionsRaju Ranjan50% (2)

- Noise From Optical Amplifiers: - EDFA Noise - Raman NoiseДокумент23 страницыNoise From Optical Amplifiers: - EDFA Noise - Raman NoiseBui TheQuanОценок пока нет

- Induction Motor EE 307 NewДокумент25 страницInduction Motor EE 307 NewVaradhanОценок пока нет

- Price-List RUB 2023-09-22Документ4 страницыPrice-List RUB 2023-09-22Boby FaesalОценок пока нет

- He Ne LaserДокумент6 страницHe Ne LaserGaurav Kumar TiwariОценок пока нет

- 5 PdaДокумент20 страниц5 PdaKedarnath JakkaОценок пока нет

- Raman DissertationДокумент5 страницRaman DissertationBuyWritingPaperElgin100% (1)

- Experiment 8Документ2 страницыExperiment 8Yash BhimaniОценок пока нет

- Wave OpticsДокумент41 страницаWave OpticsAshishSinghОценок пока нет

- EN SET 081bis 03Документ40 страницEN SET 081bis 03Nazia KhanОценок пока нет

- OPTICAL ANOMALIES IN MINERALS GoodДокумент3 страницыOPTICAL ANOMALIES IN MINERALS GooddeshmukhgeolОценок пока нет

- Electronics - Q3 - Week4-5 - Inductors - Answer SheetДокумент2 страницыElectronics - Q3 - Week4-5 - Inductors - Answer SheetMelissa Gagujas0% (1)

- PMT Tpmz0001eДокумент138 страницPMT Tpmz0001eamit281276Оценок пока нет

- ECE330 Power Circuits and Electromechanics: Dr. Nam Nguyen-Quang Fall 2016Документ9 страницECE330 Power Circuits and Electromechanics: Dr. Nam Nguyen-Quang Fall 2016Tran Nguyen KhangОценок пока нет