Академический Документы

Профессиональный Документы

Культура Документы

Birch Bark Canoe Builder

Загружено:

jcoppala4476Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Birch Bark Canoe Builder

Загружено:

jcoppala4476Авторское право:

Доступные форматы

BIRCH-BARK CANOE BUILDER

William Hafeman Perpetuates a Nearly Lost Art

THE ART OF producing birch-bark canoes by use of traditional Indian materials and methods is lost in most areas, but it is kept alive expertly in Minnesota by William ("Bill") Hafeman of Bigfork. The agde, seventythree-year-old outdoorsman has become widely known as "the builder of birch-bark canoes'' because this has been his major occupation in recent years. Thousands of persons have seen his canoe replicas at historic sites and at visitors' centers. Many have viewed him at work via films, television, newspapers, and magazines and in person at the Minnesota State Fair. Through his reconstructions part of the history of North America in general and Minnesota in particular springs alive In fact, it is a fortunate tie-in that he holds forth in this state because Minnesota is a HE SPLITS the cedar log.

THE HAFEMANS trim limbs from the peifect cedar tree they have just cut with a crosscut saw. The wood will be used for the ribs, planking, and gunwales of the canoe.

HE OUTS tlie cedar ribs with a draioknife. 142 Minnesota History

watershed with water\\'a)'s that long furnished routes for the originals of the various canoes Mr. Hafeman makes. In some, Indian people traveled to their destinations, fished, or riccd. In the larger Montreal canoes, voyageurs and other fur traders plied the Great Lakes to Grand Portage in Minnesota's northeastern tip, and in North canoes traders navigated inland lakes and wild rivers to transport tons of barter goods and furs west of Lake Superior. Without these carriers, early exploration of the north country and the existence of the fur trade on a large scale would have been impossible. To take the step-by-step photographs on these pages of Mr. Hafeman constructing a North canoe by Indian methods, Robert C. Wheeler, associate director of the Minnesota Historical Society, made several trips

northward to Bigfork at different times of the year. Mr. Hafeman is one of the few persons anywhere still making birch-bark canoes bv the old methods. H e sa\'s that was not precise])' his goal when he set out more than fift)' -S'ears ago to follow his dreams. In his ^outh Mr. Hafeman had heard tales of the wild north country from a half-Indian janitor where he attended school, and for years he longed to go into the wilderness and live H e and his wife Violet finally m a n a g e d this move in the earl)- 1920s \\-hen the)- left their h o m e in central Wisconsin and went to Bigfork in Itasca County. They returned to Wisconsin brieffy w h e n their son Stewart was born, but \^'hen the bo)' was only a few months old the Hafemans returned to the Bigfork area and have been there ever since.

SPLITTING THE CEDAR into very thin planking iielps achieve the characteristic lightness of the birchbark an important quality on the water and on long portages.

GATHERING THE ROOTS of the spruce tree, or watap, found under the moss in spruce swamps, are John Yiist (left) and Mr. Hafeman. Watap is split and soaked, then used to sew the bark together and to lasii on the gunwales.

STANDING HIGH on the tree, Mr. Hafeman takes a huge sheet of bark from a birch tree. This does not kill the tree since only the outer layer is taken. Huge birch trees free of knots must be used for the bark.

Winter 1972

143

Theirs was an arduous existence for a ^^dlile. The)' lived off the land b)- hunting, trapping, fishing, gardening, and picking and canning wild fruit and berries. Mr. Hafeman also constructed some furniture. Soon he started a boat works that turned out primarib' cedar-strip canoes for resort owners. Mr. Hafeman was ax-^-arc of birch-bark canoes before going to the north countr\, and they had not been forgotten. Once, as a )-outh, he had pulled the bark from some birch trees and built a small, crude replica of a canoe Even then, he thought that someone ought to keep that art alive. Now, with his boat business going well, he decided to try to build a birch-bark canoe His first attempt failed.

Sometime during these xears he met a man who had recently observed and memorized the procedure by which Indians built canoes. He related it to Mr. Hafeman who made another attempt and this time succeeded in building what he called his "banana boat" because of its shape. But he was and is a perfectionist and kept working to recreate as closely as possible the Ojibway (Chippewa) "long-nose" canoe. In 1964 the Smithsonian Institution in Washington, D.C, published a book. The Bark Canoes and Skin Boats of North America, by Edwin Tappan Adney and Howard I. Chappelle. This is the classic work on the various types of canoes and kayaks made bv the different tribes of North America, ft includes mam- photo-

PLANKING IS INSERTED and pounded in under the ribs. The ends of the ribs are caught under the gunivales, thus applying pressure against the planking tvhich in turn exerts pressure against the bark and maintains the form of the canoe.

HE SEWS ivith tlie tvatap. THE BARK on the bow and .stern are also seioecl with loatap.

graphs, diagrams, and explanations of how to construct various birch-bark canoes and gives background information on their origins. With a copy of this book in hand as well as a commission from the Minnesota Historical Societ)-, Mr. Hafeman set about in 1969 to build his first replica of a thirty-six-foot-long Montreal canoe which "extended the Indian birchbark canoe to its ultimate as a cargo vessel," as Eric W. Morse expressed it in his Fur Trade Routes of Canada/Then and Now (Ottawa, 1968). The Montreal or canot du maitre was capable of cari-)'ing three tons of goods plus its cre\\' and its gear. Since then Mr. Hafeman has built for the society a twenty-six-foot North canoe of the type used west of

Lake Superior, two sixteen-foot canoes now on exhibit at Connor's fur post near Pine City, and a third canoe of this size gi\'en to the societv by the Fort Snelling State Park Association. Mr. Hafeman also built a Montreal canoe and a North canoe for exhibition at Grand Portage National Monument, a North canoe on exhibit at the Superior National Forest visitors' center at Ely, and a number of canoes for several well-known persons, including one presented to Mrs. Lyndon B. Johnson and a miniature replica given to H u b e r t H. Humphrey when he was vice-president. In these pictures, Mr. Hafeman builds a North canoe, showing many of the processes starting with selecting a tree and ending with the finished product.

MORE RIBS are pounded

into

place.

PITCHING THE CANOE or putting pitch over the seams is a final Step. Mr. Hafeman substitutes asphalt for spruce pitch or gum the only deviation from tiie original materials, he believes. Spruce pitch tends to crack and cannot withstand the temperatures of a hot day.

THIS COMPLETED NORTH CANOE ivas built for the Natioiml Park Service. Its length over the gunivales is twenty-seven feet, nine inches; its beam or width at the widest point is four feet, eleven inches; its depth, twentysix inches.

ft^i^V-ti

Copyright of Minnesota History is the property of the Minnesota Historical Society and its content may not be copied or emailed to multiple sites or posted to a listserv without the copyright holders express written permission. Users may print, download, or email articles, however, for individual use. To request permission for educational or commercial use, contact us.

www.mnhs.org/mnhistory

Вам также может понравиться

- Dugout Canoe ArticleДокумент10 страницDugout Canoe ArticlekatylobelchoОценок пока нет

- Building Stripper CanoesДокумент7 страницBuilding Stripper Canoesontherig100% (1)

- Home Built 17" Vertical Bandsaw.: PreambleДокумент42 страницыHome Built 17" Vertical Bandsaw.: PreamblekokoОценок пока нет

- Cedar Strip Canoe Part 1Документ9 страницCedar Strip Canoe Part 1galenswrightОценок пока нет

- Canoe Polo HistoryДокумент4 страницыCanoe Polo HistoryFaisalIKОценок пока нет

- An Updraft Long-Stick Wood Gasifier 2005 PDFДокумент15 страницAn Updraft Long-Stick Wood Gasifier 2005 PDFBruno Navarro100% (1)

- Whittle-V8 10cc COMBINEDAdobe9 PDFДокумент39 страницWhittle-V8 10cc COMBINEDAdobe9 PDFartist67_693247670Оценок пока нет

- Design Canoe & KayakДокумент117 страницDesign Canoe & KayakBroto PriyonoОценок пока нет

- FreeCanoePlansB03 10 PDFДокумент32 страницыFreeCanoePlansB03 10 PDFtdfsks100% (1)

- Thoreau Canoeing in The Wilderness 1916Документ226 страницThoreau Canoeing in The Wilderness 1916backwardsmessagesОценок пока нет

- Redwood Canoe PDFДокумент6 страницRedwood Canoe PDFpaulo_enpjОценок пока нет

- Epoxy Works 10Документ24 страницыEpoxy Works 10leather_nunОценок пока нет

- Rolling Home by John WintersДокумент3 страницыRolling Home by John WintersSwift Canoe And Kayak100% (1)

- Fish Mouth Jig For The LatheДокумент5 страницFish Mouth Jig For The Latheradio-chaserОценок пока нет

- Sailingboat PDFДокумент590 страницSailingboat PDFSrini Kalyanaraman50% (2)

- Ol Town Canoe Owners ManualДокумент16 страницOl Town Canoe Owners Manualjekempf3262100% (1)

- How To Build An Easy Home Built Sea Kayak PDFДокумент26 страницHow To Build An Easy Home Built Sea Kayak PDFBritt Fulghum0% (1)

- Shen-Hao 6x17 Roll Film BackДокумент6 страницShen-Hao 6x17 Roll Film BackflyingtrabantОценок пока нет

- Happy Clam SkiffДокумент11 страницHappy Clam SkifffccfОценок пока нет

- Building A Cedar Strip CanoeДокумент8 страницBuilding A Cedar Strip CanoecagedraptorОценок пока нет

- Adirondack Beach Chair W 2 Positions PDFДокумент15 страницAdirondack Beach Chair W 2 Positions PDFNana Obiri Yeboa Darko100% (1)

- How To Make A Babbitting MandrelДокумент1 страницаHow To Make A Babbitting MandrelJason BowmanОценок пока нет

- Bicycle FreewheelДокумент13 страницBicycle Freewheeltransinov100% (1)

- Boat Building 1931Документ218 страницBoat Building 1931orlsalomao77% (13)

- Skiff Building InstructionsДокумент30 страницSkiff Building InstructionsTom Bee0% (2)

- How To Make A Batwing SailДокумент2 страницыHow To Make A Batwing Sailpetey2562Оценок пока нет

- Vstrom 250Документ8 страницVstrom 250Ricardo FernandezОценок пока нет

- Speaking Good Boat Part II: Hullspeed & Beyond - by John WintersДокумент3 страницыSpeaking Good Boat Part II: Hullspeed & Beyond - by John WintersSwift Canoe And KayakОценок пока нет

- Gassers For Newbies-8Документ21 страницаGassers For Newbies-8Gary Hoffman100% (1)

- Trends in Small Craft Design PDFДокумент25 страницTrends in Small Craft Design PDFJOANОценок пока нет

- FAO Building Small Wooden Boats in Myanmar PDFДокумент47 страницFAO Building Small Wooden Boats in Myanmar PDFfridomero100% (5)

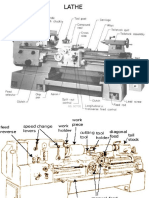

- Lathe: GS, SctceДокумент48 страницLathe: GS, SctceGouthamPrasad100% (2)

- Assembly Instructions of SCULPFUN S6&S9 Series Laser Engraver Multi-Language 8.31Документ60 страницAssembly Instructions of SCULPFUN S6&S9 Series Laser Engraver Multi-Language 8.31Israel TinajeroОценок пока нет

- The Outriggers of Indonesian CanoesДокумент74 страницыThe Outriggers of Indonesian Canoesboon1961100% (2)

- Don't Be A Cart-Aleck: Materials: ToolsДокумент5 страницDon't Be A Cart-Aleck: Materials: ToolsKeith WesleyОценок пока нет

- Tread Hammer RahulДокумент36 страницTread Hammer RahulHemant MaheshwariОценок пока нет

- Tongue Drum: Tones-Of-FunДокумент5 страницTongue Drum: Tones-Of-FungeovarelaОценок пока нет

- KurtДокумент30 страницKurtmachineCanОценок пока нет

- Mason 33 Practical ReviewДокумент5 страницMason 33 Practical ReviewManuelPérez-Sola100% (1)

- Jawa 50 Specification and Operator's ManualДокумент18 страницJawa 50 Specification and Operator's ManualjohnyОценок пока нет

- Mean Wood ExperimentationДокумент30 страницMean Wood Experimentationconfused597Оценок пока нет

- Drilling Boring Reaming and TappingДокумент24 страницыDrilling Boring Reaming and TappingPuneeth KumarОценок пока нет

- Canoe CatalogueДокумент103 страницыCanoe CatalogueTom Ejerie100% (1)

- The Pioneer Woodsman as He Is Related to Lumbering in the NorthwestОт EverandThe Pioneer Woodsman as He Is Related to Lumbering in the NorthwestОценок пока нет

- Making a Chaputs: The Teachings and Responsibilities of a Canoe MakerОт EverandMaking a Chaputs: The Teachings and Responsibilities of a Canoe MakerОценок пока нет

- The West is Calling: Imagining British ColumbiaОт EverandThe West is Calling: Imagining British ColumbiaРейтинг: 4.5 из 5 звезд4.5/5 (1)

- A Waldorf School Doctors PerspectiveДокумент21 страницаA Waldorf School Doctors Perspectivejcoppala4476Оценок пока нет

- The Chemical Factory Within Us: Occurs Naturally in The Human Body!Документ1 страницаThe Chemical Factory Within Us: Occurs Naturally in The Human Body!jcoppala4476Оценок пока нет

- Bone and Joint Disease in Young DogsДокумент7 страницBone and Joint Disease in Young Dogsjcoppala4476Оценок пока нет

- Klenner Protocol For 2013Документ10 страницKlenner Protocol For 2013jcoppala4476Оценок пока нет

- Taste & FlavourДокумент10 страницTaste & Flavourjcoppala4476Оценок пока нет

- Longevity Herbs For DogsДокумент1 страницаLongevity Herbs For Dogsjcoppala4476Оценок пока нет

- The White Flowers of The Curry TreeДокумент2 страницыThe White Flowers of The Curry Treejcoppala4476Оценок пока нет

- Which Path To Persia: Options For A New American Strategy Toward Iran (1999)Документ170 страницWhich Path To Persia: Options For A New American Strategy Toward Iran (1999)Leslie Bishop PaulОценок пока нет

- X-Factor by Chris MasterjohnДокумент26 страницX-Factor by Chris Masterjohnjcoppala4476100% (1)

- Autox India - January 2017Документ172 страницыAutox India - January 2017daawatОценок пока нет

- HW Lesson 3Документ3 страницыHW Lesson 3Ngô Quỳnh Anh K24TCDОценок пока нет

- Listening Test 6Документ6 страницListening Test 6teju patneediОценок пока нет

- Soal Mid Kelas 11Документ5 страницSoal Mid Kelas 11Darul IstiqomahPSPОценок пока нет

- Chess Middle Game GuideДокумент70 страницChess Middle Game GuideRajendra Salokhe100% (2)

- Workshop Manual: ForewordДокумент0 страницWorkshop Manual: Forewordpie031Оценок пока нет

- A Talent Management Case Study: Major League Baseball's Quest For Super KeepersДокумент3 страницыA Talent Management Case Study: Major League Baseball's Quest For Super KeepersKarthick0% (2)

- Heisman D. - Back To Basics TacticsДокумент11 страницHeisman D. - Back To Basics TacticsCassidy VarneyОценок пока нет

- Ap 01Документ24 страницыAp 01Maria Da Conceição PatricioОценок пока нет

- Stadium AtlasДокумент17 страницStadium AtlasNeeraj Desai83% (6)

- Yuri Gagarin - Wikipedia, The Free EncyclopediaДокумент13 страницYuri Gagarin - Wikipedia, The Free Encyclopediad_richard_dОценок пока нет

- Strength Training Guidelines and PrinciplesДокумент4 страницыStrength Training Guidelines and Principlessalva1310Оценок пока нет

- Jane Does 1-21 V MSU - Federal Complaint and Jury Demand Final 9-10-18Документ109 страницJane Does 1-21 V MSU - Federal Complaint and Jury Demand Final 9-10-18Tyler Kingkade100% (1)

- Chicagoblackhawks Hbs PDFДокумент21 страницаChicagoblackhawks Hbs PDFSahil VoraОценок пока нет

- The Illustrated Encyclopedia of Ships, Boats, VesselsДокумент456 страницThe Illustrated Encyclopedia of Ships, Boats, VesselsA Miguel Simão Leal100% (5)

- Captain Matthew WebbДокумент2 страницыCaptain Matthew WebbJ Erik de LeonОценок пока нет

- ListДокумент15 страницListElodie RentonОценок пока нет

- Defensive Transition: Fiba EuropeДокумент3 страницыDefensive Transition: Fiba EuropeeretriaОценок пока нет

- Pages+From+Factbook 2 1-2Документ14 страницPages+From+Factbook 2 1-2Ljupco BozinovskiОценок пока нет

- Acn2013 1winterДокумент12 страницAcn2013 1winterapi-268990286Оценок пока нет

- The Game of Cricket Has A Known History Spanning From The 16th Century To The Present DayДокумент12 страницThe Game of Cricket Has A Known History Spanning From The 16th Century To The Present DayGaurav JaiswalОценок пока нет

- Athlete: Webelos Activity Badge WorkbookДокумент4 страницыAthlete: Webelos Activity Badge Workbooksam91879Оценок пока нет

- Board of Senior Senior Secondary Studies Recognition of Excellence AwardsДокумент18 страницBoard of Senior Senior Secondary Studies Recognition of Excellence AwardsABC News OnlineОценок пока нет

- NCAA Non-Discrimination QuestionnaireДокумент7 страницNCAA Non-Discrimination QuestionnaireDeadspinОценок пока нет

- Indoor Outdoor Recreational ActivitiesДокумент26 страницIndoor Outdoor Recreational ActivitiesJaymie NeriОценок пока нет

- The Force Velocity Mechanical Profile in Sprint Running Perspecives in Hamstring Muscle Injury Follow-Up and PreventionДокумент8 страницThe Force Velocity Mechanical Profile in Sprint Running Perspecives in Hamstring Muscle Injury Follow-Up and PreventionMarthinus SchultzОценок пока нет

- The Best Sports Blogs of 2010 BookДокумент206 страницThe Best Sports Blogs of 2010 BookBall HypedОценок пока нет

- Cleethorpes Town Vs Borrowash VictoriaДокумент18 страницCleethorpes Town Vs Borrowash VictoriaCraig KendallОценок пока нет

- Do You Exercise Every Day?: AudioscriptДокумент3 страницыDo You Exercise Every Day?: AudioscriptANDRES YTОценок пока нет

- Boca Grande Chamber Member DirectoryДокумент41 страницаBoca Grande Chamber Member Directorywebmaster497Оценок пока нет