Академический Документы

Профессиональный Документы

Культура Документы

TOPIC 15 Paper (Note)

Загружено:

Kaynine KikoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TOPIC 15 Paper (Note)

Загружено:

Kaynine KikoАвторское право:

Доступные форматы

SCE3103 Exploring Materials

TOPIC 15

NATURAL MATERIALS- PAPER

Synopsis We use many products made from paper. In this topic you will learn about different types of paper, their properties, the process of making paper and the uses of paper in our daily life. Learning Outcomes

1. 2. 3. 4.

State the types of paper State the properties of paper Explain the process of making paper State the uses of paper in our daily life

OVERVIEW

Figure 15.1 Overview of content CONTENT The word paper derives from the Greek term for the ancient Egyptian writing material called papyrus, which was formed from beaten strips of papyrus plants. Paper is thin material mainly used for writing upon, printing upon or packaging.

15.1

Types of paper

SCE3103 Exploring Materials

Paper is a material that can be obtained in various types that differ in thickness and weight. Some types of paper include: Bank paper Book paper Inkjet paper pH indicator paper Photographic paper Plain paper Recycled paper Rice paper Paper towels Wall paper Wax paper Sand paper Coated paper (glossy and matt surface) Plain paper Newsprint

15.2

Properties of Paper

We use paper everyday. Its usefulness is due to its unique properties such as:

Basis Weight (GSM) Brightness, Whiteness and Colour Dimensional Stability Folding Endurance (Double Folds) Formation Gloss Machine and Cross Direction Moisture Opacity Porosity Sizing / Cobb Smoothness Stiffness Stretch (Elongation) Tearing Resistance Temperature and Humidity: Conditioning of Paper Thickness Wax Pick No. (Surface Strength) Wire side and Felt side

SCE3103 Exploring Materials

Making Notes (2 hours)

To get a better understanding of each of the properties of paper listed above, read the article in the following website: http://www.biltpaper.com/atoz2.asp . Make short notes on each of the properties of paper.

15.3

Process of making paper

Paper is produced by pressing together moist fibers, typically vegetable fibers composed of cellulose, which are held together by hydrogen bonds, and drying them into flexible sheets. While the fibers used are usually natural in origin, a wide variety of synthetic fibers, such as polypropylene and polyethylene, may be incorporated into paper as a way of imparting desirable physical properties. The most common source of these kinds of fibers is wood pulp from pulpwood trees, largely softwoods and hardwoods, such as spruce and aspen respectively. Other vegetable fiber materials including those of cotton, hemp, linen, and rice may be used. The steps in the process of making paper are:

Fiber processing / pulping using chemical pulping or mechanical pulping Adding additives Drying Finishing

Fiber processing/pulping Wood or plant cell walls are composed of fibers bound together. During pulping, these fibers are separated from each other and carbohydrate surfaces, primarily cellulose or hemi-cellulose are exposed. Hydrogen bonding between these carbohydrate surfaces gives paper its strength. Fibers can be separated chemically, mechanically, or via a combination of the two. Chemical pulping The purpose of a chemical pulping process is to break down the chemical structure of lignin and render it soluble in the cooking liquor, so that it may be washed from the cellulose fibers. Because lignin holds the plant cells together, chemical pulping frees the fibers and makes pulp. The pulp must be bleached to produce white paper for printing, painting and writing. Chemical pulps tend to cost more than mechanical pulps, largely due to the low yield, 40-50% of the original wood. Since the process preserves fiber

SCE3103 Exploring Materials

length, however, chemical pulps tend to make stronger paper. Another advantage of chemical pulping is that the majority of the heat and electricity needed to run the process is produced by burning the lignin removed during pulping. Mechanical pulping There are two major mechanical pulps, thermomechanical pulp (TMP) and mechanical pulp. The latter is known in the USA as groundwood pulp. In the TMP process, wood is chipped and then fed into large steam-heated refiners where the chips are squeezed and fiberised between two steel discs. In the groundwood process, debarked logs are fed into grinders where they are pressed against rotating stones and fiberised. Mechanical pulping does not remove the lignin, so the yield is very high, more than 95%, but also causes paper made from this pulp to yellow and become brittle over time. Mechanical pulps have rather short fiber lengths and produce weak paper. Although large amounts of electrical energy are required to produce mechanical pulp, it costs less than chemical pulp. Additives Besides the fibers, pulps may contain fillers such as chalk or china clay, which improve the characteristics of the paper for printing or writing. Additives for sizing purposes may be mixed into the pulp and/or applied to the paper web later in the manufacturing process. The purpose of sizing is to establish the correct level of surface absorbency to suit the ink or paint. Drying After the paper web is produced, the water must be removed from it in order to create a usable product. This is accomplished through pressing and drying. The methods of doing so vary between the different processes used to make paper, but the concepts remain the same. Pressing the sheet removes the water by force. Once the water is forced from the sheet, another absorbent material must be used to collect this water. On a paper machine this is called a felt. When making paper by hand, a blotter sheet is used. Drying involves using air and or heat to remove water from the paper sheet. In the earliest days of papermaking this was done by hanging the paper sheets like laundry. In more modern times, various forms of heated drying mechanisms are used. The most common is the steam-heated can dryer. These dryer cans heat to temperatures above 200F (93C) and are used in long sequences of more than 40 cans. The heat produced by these can easily dry the paper to less than 6% moisture. Finishing The paper may then undergo sizing to alter its physical properties for use in various applications. Paper at this point is uncoated. Coated paper has a thin layer of material such as china clay applied to one or both sides in order to create a surface more suitable for high-resolution half-tone screens. Coated or uncoated papers may have their surfaces polished by calendering. Coated papers are divided into matt, semi-matt or silk, and gloss.

SCE3103 Exploring Materials

The paper is then fed onto reels if it is to be used on web printing presses, or cut into sheets for other printing processes or other purposes. The fibers in the paper basically run in the machine direction. Sheets are usually cut "long-grain", i.e. with the grain parallel to the longer dimension of the sheet. All paper produced by Fourdrinier-type machines is wove paper, i.e. the wire mesh that transports the web leaves a pattern that has the same density along the paper grain and across the grain. Wove paper does not exhibit "laidlines", which are small regular lines left behind on paper when it was handmade in a mould made from rows of metal wires or bamboo. Handmade paper similarly exhibits "deckle edges", or rough and feathery borders. 15.4 Uses of paper

Paper is a versatile material with many uses. Whilst the most common is for writing and printing upon, it is also widely used as a packaging material, in many cleaning products, and in a number of industrial and construction processes, and occasionally as a food ingredient, particularly in Asian cultures. Paper can be produced with a wide variety of properties, depending on its intended use, such as:

To write or print on: the piece of paper becomes a document; this may be for keeping a record (or in the case of printing from a computer or copying from another paper: an additional record) and for communication. To represent a value: paper money, bank note, cheque, voucher, ticket For entertainment: book, magazine, newspaper, art For packaging: corrugated box, paper bag, envelope, wrapping tissue, wallpaper For cleaning : toilet paper, handkerchiefs, paper towels, facial tissue For construction : paper Mache, origami, quiling, paper engineering, clothing Other uses: sandpaper, blotting paper, litmus paper, universal indicator paper, paper chromatography, electrical insulation paper, filter paper

Figure 15.4 Uses of paper (Source: http://images.google.com)

SCE3103 Exploring Materials

Exercise (2 hours)

Access the internet to gather information and to compare and contrast the properties of different types of paper and their uses in daily life.

Thinking (10 hours)

We can reuse paper by recycling it. Make your own recycled paper. Go to the internet for suggestions on how to make recycled paper. This website http://www.recyclenow.com/why_recycling_matters/how_is_it_recycled/pa per/ may be helpful. Create a useful item using the recycled paper you have made. Organise a mini science exhibition to present the process of recycling paper and the products made from the recycled paper. Keep a photograph journal of the exhibition. At the end of the activity, answer the following questions: What have you learnt from this activity? Which part of the primary science curriculum teaches this topic on paper? Discuss how you can use this activity in your teaching and learning. What was the role of the teacher in this activity?

References http://en.wikipedia.org/wiki/Paper (paper) http://www.writersservices.com/wbs/care_history_paper.htm (History of paper making)

SCE3103 Exploring Materials

http://www.writersservices.com/wbs/care_storing_books.htm (how to store books) http://www.biltpaper.com/atoz2.asp (properties of paper) http://www.recyclenow.com/why_recycling_matters/how_is_it_recycled/paper/ (recycling of paper) http://www.paperonweb.com/pmake.htm (processing paper) http://www.geocities.com/kirktayl/ (how to organise a science exhibition) http://www.paperonweb.com/density.htm (properties of paper)

Вам также может понравиться

- Paper Is A Thin Material Produced by Pressing Together MoistДокумент10 страницPaper Is A Thin Material Produced by Pressing Together Moistvijileela8580Оценок пока нет

- Paper and PulpДокумент8 страницPaper and Pulpsamyam shresthaОценок пока нет

- Paper and Pulp Industry Processes and PollutantsДокумент63 страницыPaper and Pulp Industry Processes and PollutantsRamces SolimanОценок пока нет

- Century Pul112Документ48 страницCentury Pul112Shubh Prakash TiwariОценок пока нет

- Paper Making ProcessДокумент13 страницPaper Making ProcessSamin MaharjanОценок пока нет

- Machinery SafetyДокумент12 страницMachinery SafetyAlexius KelupuОценок пока нет

- The Top Ten Factors in Kraft Pulp Yield: What AreДокумент7 страницThe Top Ten Factors in Kraft Pulp Yield: What AreYudhi Dwi KurniawanОценок пока нет

- Fibre FinenessДокумент10 страницFibre Finenessgokul saravananОценок пока нет

- Design of a Manually Operated Paper-Recycling MachineДокумент6 страницDesign of a Manually Operated Paper-Recycling MachineShubhamDabralОценок пока нет

- WPP FabricsdryerДокумент17 страницWPP FabricsdryernotengofffОценок пока нет

- Pulp & PaperNew-1Документ24 страницыPulp & PaperNew-1shamsul amin100% (1)

- Lva1 App6891 PDFДокумент53 страницыLva1 App6891 PDFjjccmmaa100% (1)

- History of CorrugatedДокумент10 страницHistory of CorrugatedVasudeva BhattarОценок пока нет

- Fiber Paper No LowДокумент60 страницFiber Paper No Low120984Оценок пока нет

- Expertip 1 Cleaning and Conditioning of Dryer FabricsДокумент4 страницыExpertip 1 Cleaning and Conditioning of Dryer FabricsnotengofffОценок пока нет

- High Performance Foil Rotor Improves De-Ink Pulp ScreeningДокумент9 страницHigh Performance Foil Rotor Improves De-Ink Pulp ScreeningAliОценок пока нет

- 5 - FlaxДокумент30 страниц5 - FlaxHassaan ShamshadОценок пока нет

- Paper ManufacturingДокумент12 страницPaper ManufacturingPriyanka AryaОценок пока нет

- Cleaning guidelines for forming fabricsДокумент10 страницCleaning guidelines for forming fabricsMr. JahirОценок пока нет

- PULP AND PAPER INDUSTRIESДокумент41 страницаPULP AND PAPER INDUSTRIESCJ SacoboОценок пока нет

- Ring Crush of Paperboard (Rigid Support Method) (Five-Year Review of T 822 Om-02)Документ8 страницRing Crush of Paperboard (Rigid Support Method) (Five-Year Review of T 822 Om-02)ArjuLana Van MaulaОценок пока нет

- Product 1: Flipper-Sweeper Equipments: Technical DetailsДокумент11 страницProduct 1: Flipper-Sweeper Equipments: Technical DetailsstranfirОценок пока нет

- High Strength Sack Kraft Paper for Demanding ApplicationsДокумент1 страницаHigh Strength Sack Kraft Paper for Demanding Applicationssarah ahmedОценок пока нет

- Practical ways to reduce energy usage in tissue manufacturingДокумент7 страницPractical ways to reduce energy usage in tissue manufacturingKoushik MadapatiОценок пока нет

- Technical Specification Horizon Pulp & Paper LTDДокумент1 страницаTechnical Specification Horizon Pulp & Paper LTDvenkОценок пока нет

- The History of Corrugated Fiberboard Shipping Cont PDFДокумент7 страницThe History of Corrugated Fiberboard Shipping Cont PDFPedro Perez La RosaОценок пока нет

- Deculator Article 5 03Документ4 страницыDeculator Article 5 03tsvmpm1765100% (3)

- The Fabric of Paper Machine PerformanceДокумент4 страницыThe Fabric of Paper Machine Performancest7167Оценок пока нет

- A to Z guide to practical paper chemistryДокумент437 страницA to Z guide to practical paper chemistryArnoldo Sánchez D100% (1)

- General Design Principles For Assembly Techniques - Welding, Adhesive Bonding PDFДокумент54 страницыGeneral Design Principles For Assembly Techniques - Welding, Adhesive Bonding PDFkfaravОценок пока нет

- Needle Shower Review Highlights, James E. Stein, JR WeavexxДокумент5 страницNeedle Shower Review Highlights, James E. Stein, JR WeavexxmariabertoloniОценок пока нет

- Sizing Ingredients AssignmentДокумент34 страницыSizing Ingredients AssignmentMuhammad Asif Idrees100% (1)

- Arkhangelsk Pulp and Paper Mill, JSC: Semichemical FlutingДокумент1 страницаArkhangelsk Pulp and Paper Mill, JSC: Semichemical FlutingarceppОценок пока нет

- Paper Fan PumpsДокумент8 страницPaper Fan PumpsnazeerОценок пока нет

- Crowning Benefits - Paper, Film & Foil ConverterДокумент3 страницыCrowning Benefits - Paper, Film & Foil ConverteravgpaulОценок пока нет

- Valmet's Recent Calender Technologies: High Bulk Calendering and OptiCalender CompactДокумент21 страницаValmet's Recent Calender Technologies: High Bulk Calendering and OptiCalender Compactsukallan dharОценок пока нет

- Mini-Encyclopedia of Papermaking Wet-End ChemistryДокумент2 страницыMini-Encyclopedia of Papermaking Wet-End ChemistryTomé SilvaОценок пока нет

- Cleaning Forming FabricsДокумент8 страницCleaning Forming Fabricsismail 811Оценок пока нет

- 2009 Issue 4 IPPTA Article 05Документ4 страницы2009 Issue 4 IPPTA Article 05Lev BОценок пока нет

- ASA Sizing - Control of Particle Size, Stability and HydrolysisДокумент18 страницASA Sizing - Control of Particle Size, Stability and Hydrolysisjohn.sehtОценок пока нет

- Pulp and Paper 1Документ11 страницPulp and Paper 1Caren ReasОценок пока нет

- Hannecard Roll Covers Services Paper Industry en v2Документ16 страницHannecard Roll Covers Services Paper Industry en v2Phu, Le HuuОценок пока нет

- Metering Size PressДокумент22 страницыMetering Size PressDaud ZamanОценок пока нет

- ZZZ 1Документ3 страницыZZZ 1Ressel TatadОценок пока нет

- New Developments in Paper and Board DryingДокумент10 страницNew Developments in Paper and Board DryingSahil DesaiОценок пока нет

- Topic 15 Papermaking Drying LectureДокумент18 страницTopic 15 Papermaking Drying LecturenotengofffОценок пока нет

- 1998 Lumiainen Ch4 PDFДокумент59 страниц1998 Lumiainen Ch4 PDFAnonymous K3FaYFlОценок пока нет

- Introduction:-: Lars Nilsson.Документ18 страницIntroduction:-: Lars Nilsson.Bharat PatilОценок пока нет

- Advanced Training Course On Deinking - Dispersion and KneadingДокумент38 страницAdvanced Training Course On Deinking - Dispersion and KneadingGuido PeraltaОценок пока нет

- Low Consistency RefiningДокумент65 страницLow Consistency RefiningLaboratorio PapelesRegionalesОценок пока нет

- Topic 14 Papermaking Pressing LectureДокумент20 страницTopic 14 Papermaking Pressing LecturenotengofffОценок пока нет

- BASC Pulp and Paper Science Course Revised Syllabus 2012 13Документ71 страницаBASC Pulp and Paper Science Course Revised Syllabus 2012 13Vivek Singh100% (2)

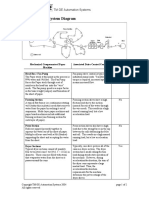

- Paper Machine System Diagram: TM GE Automation SystemsДокумент2 страницыPaper Machine System Diagram: TM GE Automation SystemsWudassie AyeleОценок пока нет

- New Additive With Low Environmental Impact: Improves SoftnessДокумент4 страницыNew Additive With Low Environmental Impact: Improves SoftnessJasmainiОценок пока нет

- Ecoflow FДокумент1 страницаEcoflow FPiotr SokolińskiОценок пока нет

- Oji Fuji PM N 2 (New Machine (Twogether Report) )Документ8 страницOji Fuji PM N 2 (New Machine (Twogether Report) )duducastroОценок пока нет

- Water Removal TIPs ReviewДокумент12 страницWater Removal TIPs Reviewvemanreddy29Оценок пока нет

- 1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivДокумент8 страниц1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivelcarpaneziОценок пока нет

- Topic 16 Papermaking Calendering TextДокумент11 страницTopic 16 Papermaking Calendering TextranjithОценок пока нет

- Setup Streamyx On TPLink TDДокумент3 страницыSetup Streamyx On TPLink TDKaynine KikoОценок пока нет

- BH Didik 23 Aug 2017Документ16 страницBH Didik 23 Aug 2017Kaynine KikoОценок пока нет

- Didik Sains k2 Upsr 2017 PowerpointДокумент45 страницDidik Sains k2 Upsr 2017 PowerpointKaynine KikoОценок пока нет

- BH Didik 4 Sept 2017Документ17 страницBH Didik 4 Sept 2017Umi Sameeha Saleema100% (4)

- Latihan Asas Matematik TambahtolakdarabahagiДокумент58 страницLatihan Asas Matematik TambahtolakdarabahagiKaynine KikoОценок пока нет

- SoilДокумент6 страницSoilKaynine KikoОценок пока нет

- MagnetsДокумент2 страницыMagnetsKaynine KikoОценок пока нет

- Chapter 1Документ53 страницыChapter 1Kaynine Kiko50% (4)

- SoilДокумент1 страницаSoilKaynine KikoОценок пока нет

- TOPIC 14 Natural Polymer - Silk, Cotton & WoolДокумент10 страницTOPIC 14 Natural Polymer - Silk, Cotton & WoolKaynine Kiko100% (1)

- Summary 1Документ5 страницSummary 1Kaynine KikoОценок пока нет

- Health Groups Issue Cervical Cancer Screening GuidelinesДокумент2 страницыHealth Groups Issue Cervical Cancer Screening GuidelinesKaynine KikoОценок пока нет

- Galaxy Is Rich in SmallДокумент2 страницыGalaxy Is Rich in SmallKaynine KikoОценок пока нет

- Global WarmingДокумент7 страницGlobal WarmingKaynine KikoОценок пока нет

- Topic 13 Natural Materials-Rubber: SynopsisДокумент7 страницTopic 13 Natural Materials-Rubber: SynopsisKaynine KikoОценок пока нет

- TOPIC 12 Soaps and DetergentsДокумент14 страницTOPIC 12 Soaps and DetergentsKaynine Kiko50% (2)

- TOPIC 11 Composite Materials (Notes)Документ16 страницTOPIC 11 Composite Materials (Notes)Kaynine KikoОценок пока нет

- Modul Sce 3104Документ86 страницModul Sce 3104Triple R RimaОценок пока нет

- Manufactured Materials - Ammonia, Sulphuric Acid and Nitric Acid ProductionДокумент17 страницManufactured Materials - Ammonia, Sulphuric Acid and Nitric Acid ProductionKaynine KikoОценок пока нет

- CoP Fo Petroleum Road Tanker Vapour Collection Systems and Equipment Used in Unloading OperationsДокумент29 страницCoP Fo Petroleum Road Tanker Vapour Collection Systems and Equipment Used in Unloading OperationsMuhammad Ibad AlamОценок пока нет

- Alcatel U3 - Alcatel U3 User GuideДокумент53 страницыAlcatel U3 - Alcatel U3 User Guideoswaldomarangoni5295100% (11)

- JAYCO CARAVANS - 2016 Silverline and Starcraft PDFДокумент12 страницJAYCO CARAVANS - 2016 Silverline and Starcraft PDFBrisbane CamperlandОценок пока нет

- 2016 Popsicle Stick Bridge RulesДокумент6 страниц2016 Popsicle Stick Bridge RulesMahendra DewasiОценок пока нет

- GSM Channels LogicalДокумент8 страницGSM Channels LogicalbeetelnutsОценок пока нет

- Maximo Sandbox SettingsДокумент6 страницMaximo Sandbox SettingsChandra SekharОценок пока нет

- 2.3 One Way Slab Design-SS, Cant, ContinuousДокумент54 страницы2.3 One Way Slab Design-SS, Cant, ContinuousAhmed SiddiqueОценок пока нет

- 02 - MEE10603 - Fourier Series and Power Computations in Nonsinusoidally Driven CircuitsДокумент33 страницы02 - MEE10603 - Fourier Series and Power Computations in Nonsinusoidally Driven CircuitsMohammad HayazieОценок пока нет

- Wacker Silres Ren - 60 - Silicone Resin Solution For Medium Solids or High Solids Heat ResistancДокумент3 страницыWacker Silres Ren - 60 - Silicone Resin Solution For Medium Solids or High Solids Heat ResistancJameel AhsanОценок пока нет

- Hdpe Alathon H5520 EquistarДокумент2 страницыHdpe Alathon H5520 EquistarEric Mahonri PereidaОценок пока нет

- VELUXДокумент16 страницVELUXEko SalamunОценок пока нет

- 9mm!ূຌዡገ๕ۉ࿋ഗ Rotary Potentiometers With Metal Shaft Series: WH9011A-1-18TДокумент26 страниц9mm!ূຌዡገ๕ۉ࿋ഗ Rotary Potentiometers With Metal Shaft Series: WH9011A-1-18TpeterfunОценок пока нет

- Manual Akaso V50 XДокумент44 страницыManual Akaso V50 XLucas T. CavalcantiОценок пока нет

- 92v Parts List ViperДокумент194 страницы92v Parts List Viperreltih18Оценок пока нет

- Meshing Methods (ANSYS Meshing) - Everyone Is Number OneДокумент14 страницMeshing Methods (ANSYS Meshing) - Everyone Is Number Oneicemage1991Оценок пока нет

- Electrical Power Transmission & DistributionДокумент18 страницElectrical Power Transmission & DistributionMd Saif KhanОценок пока нет

- Smart Card TechnologyДокумент37 страницSmart Card TechnologyShailesh GuptaОценок пока нет

- Sperry Sun - LWD and LWD ServicesДокумент8 страницSperry Sun - LWD and LWD ServicesBAS100% (1)

- WT Lab ManualДокумент44 страницыWT Lab ManualVenkatanagasudheer Thummapudi100% (1)

- Slides - OOP With SmalltalkДокумент51 страницаSlides - OOP With Smalltalkapi-3728136Оценок пока нет

- EC2151 Electric Circuit Important QuestionsДокумент47 страницEC2151 Electric Circuit Important QuestionschitragowsОценок пока нет

- Joker User Guide 3dlabgang Rev2019 12Документ14 страницJoker User Guide 3dlabgang Rev2019 12HD's RC ChannelОценок пока нет

- Undergraduate Architectural Thesis Site and Village Study PDFДокумент4 страницыUndergraduate Architectural Thesis Site and Village Study PDFMalavika LaxmanОценок пока нет

- Transient Analysis of Electrical Circuits Using Runge-Kutta Method and Its ApplicationДокумент5 страницTransient Analysis of Electrical Circuits Using Runge-Kutta Method and Its ApplicationSwati kОценок пока нет

- SHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsДокумент8 страницSHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsMahmoud ElsherifОценок пока нет

- Xtrons - TD609 User ManualДокумент16 страницXtrons - TD609 User ManualadrianОценок пока нет

- Software Development Handbook Transforming For The Digital Age PDFДокумент75 страницSoftware Development Handbook Transforming For The Digital Age PDFdreamer4077Оценок пока нет

- Load Case CombinationsДокумент5 страницLoad Case CombinationsFrancisco UgarteОценок пока нет

- BOnd Strength ASTM-F904-98Документ1 страницаBOnd Strength ASTM-F904-98akash.biradarОценок пока нет

- DB2 WebSphere BestPracticeДокумент53 страницыDB2 WebSphere BestPracticeSpeedyKazamaОценок пока нет