Академический Документы

Профессиональный Документы

Культура Документы

12-3 p36 Conference On Electronics in Mobile Machinery

Загружено:

Vinoth Kumar0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров2 страницыConference on electronics in mobile machinery took place in baden-baden (germany) About 500 participants attended the conferences and visited the joint exhibition. TTTech presented a safety-related controller compliant with ISO 13849 and IEC 61508 respectively IEC 62061. Next year the international VDI "Electronics in vehicles" congress will take place in Baden-Baden in October.

Исходное описание:

Оригинальное название

12-3 p36 Conference on Electronics in Mobile Machinery

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документConference on electronics in mobile machinery took place in baden-baden (germany) About 500 participants attended the conferences and visited the joint exhibition. TTTech presented a safety-related controller compliant with ISO 13849 and IEC 61508 respectively IEC 62061. Next year the international VDI "Electronics in vehicles" congress will take place in Baden-Baden in October.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров2 страницы12-3 p36 Conference On Electronics in Mobile Machinery

Загружено:

Vinoth KumarConference on electronics in mobile machinery took place in baden-baden (germany) About 500 participants attended the conferences and visited the joint exhibition. TTTech presented a safety-related controller compliant with ISO 13849 and IEC 61508 respectively IEC 62061. Next year the international VDI "Electronics in vehicles" congress will take place in Baden-Baden in October.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

T

he first session collect-

ed more attendees than

the room`s capacity of some

160 seats. Peter Hierony-

mus (Claas) and Dirk Jahn

(Putzmeister) introduced

general trends and chal-

lenges for the electronics in

agriculture vehicles respec-

tively in construction ma-

chines. One common top-

ic was the introduction of

functional safety. But both

industries references differ-

ent standards, which leads

to different solutions. By the

way, also in the both oth-

er conferences, function-

al-safety was an important,

not to say the dominating,

topic.

In one of the speech-

es, TTTech presented a

safety-related controller

compliant with ISO 13849

and IEC 61508 respectively

IEC 62061. The carmakers

have an own safety stan-

dard (ISO 26262), which

is supported by some mi-

cro-controllers implement-

ing specific safety circuitry

(see ISO 26262 compli-

ant micro-controllers). The

agriculture machine indus-

try has also its own safety

standard: ISO 25119. Jo-

hannes Lange working with

Conference on electronics

in mobile machinery

Links

www.vdi-wissensforum.de

www.elektronik-auto.de

Baden-Baden Special

This conference

organized by VDI-

Wissensforum, a

daughter of the VDI

association of German

engineers, comprised

three events:

X 5

th

conference on

electronics in road cars

X 3

rd

conference

on electronics in

commercial vehicles

X 1

st

conference on

electronics in mobile

working machines.

The event took place

in Baden-Baden

(Germany) in October

(10

th

and 11

th

).

About 500 participants

attended the conferences

and visited the joint

exhibition. Next year

the international VDI

"Electronics in vehicles"

congress will take place

in Baden-Baden in

October (16

th

and 17

th

).

Claas, explained in his pa-

per requirements and appli-

cations of functional safety

in agriculture engineering.

For implements controlling

the tractor a safe commu-

nication via the Isobus is

required, which meets the

Performance Level c. It is

achieved by transmitting a

running number in the pe-

riodically transmitted CAN

frame. In construction ma-

chines, the CANopen Safe-

ty protocol is a possible

candidate for safe commu-

nication. The Institute for

Occupational Safety and

Health (IFA) has approved

this protocol for application

up to the Safety Integrity

Level 3 comparable with the

Performance Level d or e.

Agriculture as well

as construction machines

make use of CAN-based

networks. While in die-

sel engines commonly the

J1939 protocol is preferred,

the construction machines

often implement CANopen

as higher-layer protocol.

The agriculture machine in-

dustry has developed an

open network approach,

trademarked as Isobus and

internationally standardized

in the ISO 11783 series.

Jan Horstmann (Krone) pre-

sented Isobus implements

(e.g. harvesting machines),

which control the speed of

the truck via the CAN net-

work compliant with ISO

11783. Of course, wireless

truck-to-truck communica-

tion was also an important

topic: Fendt (Agro) report-

ed about a driverless truck,

which follows a manned

truck automatically.

Martin Rajek (Lieb-

herr) explained his under-

standing on long-term and

sustainable concepts for

mobile machinery. It was a

more philosophical paper

with a lot of interesting views

(e.g. that a software update

or review may increase the

value of machine during its

lifetime). One of the chal-

lenges he addressed is the

management (testing and

validation) of control system

variants. This is the same in

agriculture and construction

machinery: The volume is

low and the number of spe-

cific solutions is high. Also

other speakers (e.g. from

Bosch Rexroth, Krone, and

TTTech) spoke about the

need of scalable control de-

vices, and presented their

solutions.

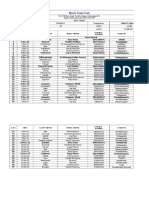

The Tractor Implement Management (TIM) allows for example a baler to communicate

with tractor via the Isobus network allowing the operator to adapt tractor speed automati-

cally to the load on the baler and to prevent overload on the machine

36 CAN Newsletter 4/2012

E

n

g

i

n

e

e

r

i

n

g

ler families for mobile ma-

chines with CAN connec-

tivity. Hydac presented its

CAN connectable hydrau-

lic and sensor devices. At-

mel, Bosch, and Infineon

informed about their CAN

semiconductors portfolios.

Dspace, Etas, and Vector

showed their well-known

development and testing

tools. Holger Zeltwanger

doing. Vector presented its

software tool chain for both

industries supporting the

specific higher-layer proto-

cols (CANopen, Isobus, and

J1939).

The three conferenc-

es were accompanied by

an exhibition, participat-

ed by more than 30 com-

panies. Jetter and TTTech

exhibited their control-

Continuation desired

Just a couple of

months ago, the VDI

decided to organize

the 1

st

conference on

electronics in mobile

machinery. Initiated by

Claas, a manufacturer

of agriculture trucks

and harvesters, and

Putzmeister, producer of

truck-mounted concrete

pumps, as well as some

suppliers (e.g. Hydac),

the event was rather

successful.

Many participants

appreciated the

know-how exchange

and the direct talks to

engineers from other

application fields. Dr.

Wolfgang Runge, one

of the conferences

mentors, thanked

the sponsors and the

speakers to make this

event happen. "It

was just a few month

from the idea to the

event. No doubt, a

follow-up conference

on electronics in mobile

machinery is desired.

Besides Putzmeis-

ter, Liebherr and Wirtgen

reported about their strat-

egies to develop elec-

tronic control systems for

construction machines. In-

teresting is that both mo-

bile machinery industries

develop increasingly the

electronic control systems

by means of the V-model as

the automotive industry is

ISO 26262 compIiant micro-controIIers

Exida (www.exida.com) has certified

Freescale`s Qorivva MPC5643L micro-

controller (MCU) to be compliant with

the ISO 26262 functional safety stan-

dard. The 32-bit MCU with CAN on chip

is designed for use in automotive ap-

plications that require automotive safe-

ty integrity levels (ASIL) up to D. Typi-

cal applications include electric pow-

er steering, active suspension, anti-

lock braking systems and radar-based

advanced driver assistance systems

(ADAS).

The MCU is part of the chipmaker`s

SafeAssure program (www.freescale.

com/SafeAssure). It includes also sen-

sors and analog ICs as well as support

for functional safety application design.

The program is intended to help system

developers achieving more easily com-

pliance with functional safety standards

such as ISO 26262 and IEC 61508.

A similar program has been intro-

duced by Texas Instru-

ments (www.ti.com).

The SafeTI system de-

sign packages for func-

tional safety support

the standards such as

ISO 26262, IEC 60730

(home appliances), and

IEC 61508. TI`s Hercu-

les family of MCUs is

designed for safety ap-

plications, but has not

been yet certified by an

independent authority.

Some of these compo-

nents feature on-chip

CAN modules. There

are chipsets specifically

suitable for motion con-

trol applications requir-

ing compliancy to IEC

61508.

According to the

ISO standard, function-

al safety is the absence

of unreasonable risk

due to hazards caused

by the malfunction of

electrical/electronic

systems. ISO 26262

targets complete

automotive sys-

tems and consists

of 10 parts, including

clauses for hardware,

software, their integra-

tion and the develop-

ment and production pro-

cesses.

Rainer Faller (Exida) said:

"The certificate for Freescale`s MCU is

issued based on a successful assess-

ment of the product design and applied

development and production processes

against all requirements and work prod-

uct definitions of ISO 26262 identified

as applicable to this micro-controller

part. Freescale has done an excellent

job with this product.

37 CAN Newsletter 4/2012

E

n

g

i

n

e

e

r

i

n

g

Вам также может понравиться

- Hans-Leo Ross (Auth.) - Functional Safety For Road Vehicles - New Challenges and Solutions For E-Mobility and Automated Driving-Springer International Publishing (2016)Документ276 страницHans-Leo Ross (Auth.) - Functional Safety For Road Vehicles - New Challenges and Solutions For E-Mobility and Automated Driving-Springer International Publishing (2016)asd asdf100% (1)

- Automotive Electronics Issue-4Документ21 страницаAutomotive Electronics Issue-4Jhenu100% (14)

- 00 - ArtículoДокумент7 страниц00 - Artículoheidy pintoОценок пока нет

- Industrial Ethernet Book Nº97 (11 - 2016)Документ52 страницыIndustrial Ethernet Book Nº97 (11 - 2016)Jorge_Andril_5370100% (1)

- Automotion Spec. Issue Packaging MM-E01409.115Документ69 страницAutomotion Spec. Issue Packaging MM-E01409.115back1949Оценок пока нет

- Beckhoff PC ControlДокумент62 страницыBeckhoff PC ControlGökhan YıldızОценок пока нет

- Embedded System in AutomobilesДокумент42 страницыEmbedded System in AutomobilesManpreet SinghОценок пока нет

- The Controller Area NetworkДокумент70 страницThe Controller Area NetworkRAJI00675% (4)

- Labmewtraces Code in RealtimeДокумент2 страницыLabmewtraces Code in RealtimeLiss D NadieОценок пока нет

- Ima Henning ButzДокумент10 страницIma Henning ButzRichard RaflaiОценок пока нет

- Control Engineering Europe Covering Control, Instrumentation, and Automation Systems WorldwideДокумент1 страницаControl Engineering Europe Covering Control, Instrumentation, and Automation Systems WorldwidesaospieОценок пока нет

- Term Paper OF: Online Automation SystemsДокумент20 страницTerm Paper OF: Online Automation SystemsAditya MalhotraОценок пока нет

- Fieldbus I/O: Tactical BriefДокумент25 страницFieldbus I/O: Tactical BriefAlexander Ariza NadjarОценок пока нет

- Embedded System in AutomobilesДокумент35 страницEmbedded System in AutomobilesKambli MadhusudhanОценок пока нет

- Ziegler Protection1Документ10 страницZiegler Protection1Jose Alberto RodriguezОценок пока нет

- Controller Area Network (CAN) Schedulability Analysis: Refuted, Revisited and RevisedДокумент18 страницController Area Network (CAN) Schedulability Analysis: Refuted, Revisited and RevisedArchana PaiОценок пока нет

- Comunication With DrivesДокумент32 страницыComunication With Drivesvoltus88Оценок пока нет

- The Smarter Way of Firefighting in Rail SystemsДокумент16 страницThe Smarter Way of Firefighting in Rail SystemsmukeshsinghtomarОценок пока нет

- Profisafe: Safety Technology For ProfibusДокумент6 страницProfisafe: Safety Technology For ProfibusRidhoillahiОценок пока нет

- Fieldbuses Release The Hidden Data: Which Protocol?Документ4 страницыFieldbuses Release The Hidden Data: Which Protocol?aliscribd46Оценок пока нет

- Markus Mueck - Networking Vehicles To Everything - Evolving Automotive Solutions-Deg Press (2018)Документ234 страницыMarkus Mueck - Networking Vehicles To Everything - Evolving Automotive Solutions-Deg Press (2018)Javier IzquierdoОценок пока нет

- List of Automation Protocols - Wikipedia, The Free EncyclopediaДокумент5 страницList of Automation Protocols - Wikipedia, The Free EncyclopediaArvind KumawatОценок пока нет

- Black LДокумент4 страницыBlack LOsvaldoОценок пока нет

- All Standards - Safety - of - Mobile - Robot - Systems - in - Industrial - ApplicationsДокумент7 страницAll Standards - Safety - of - Mobile - Robot - Systems - in - Industrial - ApplicationspouriyaОценок пока нет

- Safety-Critical Systems in Rail TransportationДокумент5 страницSafety-Critical Systems in Rail TransportationRăzvan PopaОценок пока нет

- ARM Based Integrated Method For Calculating The Vehicle Parameters by Using CAN ProtocolДокумент8 страницARM Based Integrated Method For Calculating The Vehicle Parameters by Using CAN ProtocolNana LestariОценок пока нет

- Broadcast Authentication in Latency-Critical Applications On The Efficiency of IEEE 1609.2Документ11 страницBroadcast Authentication in Latency-Critical Applications On The Efficiency of IEEE 1609.2Enrico NardiОценок пока нет

- Draft: Project SummaryДокумент8 страницDraft: Project SummaryAndrea NarcisoОценок пока нет

- Using DNP3 & IEC 60870-5 Communication Protocols in The Oil & Gas IndustryДокумент4 страницыUsing DNP3 & IEC 60870-5 Communication Protocols in The Oil & Gas IndustryzdnОценок пока нет

- Pro Safe PLCДокумент44 страницыPro Safe PLClimresОценок пока нет

- Abb Embedded SymДокумент80 страницAbb Embedded SymajithayyappanОценок пока нет

- Automotive Network Architecture For Ecus Communications: April 2009Документ27 страницAutomotive Network Architecture For Ecus Communications: April 2009Wagner PolloОценок пока нет

- Calalog Automatiz 2014Документ282 страницыCalalog Automatiz 2014Paun AlОценок пока нет

- Automotive Application Guide 2014 - BR PDFДокумент60 страницAutomotive Application Guide 2014 - BR PDFbnc1100% (1)

- I/O Technology Reflects Automation Industry TrendsДокумент65 страницI/O Technology Reflects Automation Industry TrendsPandaGendut100% (1)

- AutomtaizacionДокумент302 страницыAutomtaizacionhmc41277Оценок пока нет

- AutomtaizacionДокумент302 страницыAutomtaizacionjoticamario123Оценок пока нет

- Process bus interoperability under IEC 61869-9 + 87L differential protectionДокумент11 страницProcess bus interoperability under IEC 61869-9 + 87L differential protectionkiomitsu mekaruОценок пока нет

- Efficient Integrated Industrial Automation Using FPGA: Group MembersДокумент32 страницыEfficient Integrated Industrial Automation Using FPGA: Group MembersKINGSUK BAGОценок пока нет

- Scada Sub StationДокумент18 страницScada Sub StationLaxman VeerepalliОценок пока нет

- Security Integrated System Based On Wireless Access Protocol For Industrial Applications With SMS Alert System Using GSMДокумент115 страницSecurity Integrated System Based On Wireless Access Protocol For Industrial Applications With SMS Alert System Using GSMDebebe TsedekeОценок пока нет

- The 5 GI/ACM Workshop 2020 Scope and Draft Programme On Standardization of Secure and Safe Smart Manufacturing Systems With Respect To IEC 62443 IACSДокумент5 страницThe 5 GI/ACM Workshop 2020 Scope and Draft Programme On Standardization of Secure and Safe Smart Manufacturing Systems With Respect To IEC 62443 IACSCom DigfulОценок пока нет

- Programmable Logic Controllers, Industrial Field Buses and SCADAДокумент45 страницProgrammable Logic Controllers, Industrial Field Buses and SCADAZeeshan MahmoodОценок пока нет

- Standardizing In-Car Sensors with TinyOSДокумент8 страницStandardizing In-Car Sensors with TinyOSqurat ul ain annieОценок пока нет

- Safety Integrated Ed4 - eДокумент331 страницаSafety Integrated Ed4 - eEmerson KleemОценок пока нет

- TC 65Документ10 страницTC 65darkchess76Оценок пока нет

- Functional Safety and AutomotiveДокумент7 страницFunctional Safety and AutomotiveParasaram SrinivasОценок пока нет

- Vector Press BookДокумент252 страницыVector Press BookEngine Tuning UPОценок пока нет

- CNLM 22-4 p6 History and Trends Non-Automotive Can Applications Olga Fischer CiaДокумент4 страницыCNLM 22-4 p6 History and Trends Non-Automotive Can Applications Olga Fischer CiaBingbing LiОценок пока нет

- Gudlavalleru Engineering CollegeДокумент12 страницGudlavalleru Engineering CollegeManish KumarОценок пока нет

- Advance 2011 3 enДокумент30 страницAdvance 2011 3 enrojas_giancarloОценок пока нет

- SICK MagazineДокумент63 страницыSICK MagazineNicuVisanОценок пока нет

- Networks: Cited by 44 Related Articles All 3 VersionsДокумент1 страницаNetworks: Cited by 44 Related Articles All 3 VersionsAsdfg HjklОценок пока нет

- Embedded Systems ReportДокумент86 страницEmbedded Systems ReportGulati Rohit100% (1)

- CAN Bus Explained: The Controller Area Network ProtocolДокумент25 страницCAN Bus Explained: The Controller Area Network ProtocolBenjamin HouseОценок пока нет

- Industrial Sensors and Controls in Communication Networks: From Wired Technologies to Cloud Computing and the Internet of ThingsОт EverandIndustrial Sensors and Controls in Communication Networks: From Wired Technologies to Cloud Computing and the Internet of ThingsОценок пока нет

- Reliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationОт EverandReliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationОценок пока нет

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsОт EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsОценок пока нет

- Validation and Verification of Automated Systems: Results of the ENABLE-S3 ProjectОт EverandValidation and Verification of Automated Systems: Results of the ENABLE-S3 ProjectОценок пока нет

- RTD Temperature Transmitter DatasheetДокумент1 страницаRTD Temperature Transmitter DatasheetMohan BabuОценок пока нет

- BIOS Configuration Utility User GuideДокумент19 страницBIOS Configuration Utility User GuidecornolioОценок пока нет

- Cad 17 (4) 2020 740-751Документ12 страницCad 17 (4) 2020 740-751GunawanMОценок пока нет

- Dawood University of Engineering and Technology, KarachiДокумент19 страницDawood University of Engineering and Technology, KarachiOSAMAОценок пока нет

- Philips Pm3295 Service ManualДокумент322 страницыPhilips Pm3295 Service Manualglu7833Оценок пока нет

- Acoustic Surveillance Device Comparative Assessment Report: BackgroundДокумент8 страницAcoustic Surveillance Device Comparative Assessment Report: BackgroundmultihumanОценок пока нет

- Paralegal or Legal Assistant or Social Worker or Caseworker or NДокумент2 страницыParalegal or Legal Assistant or Social Worker or Caseworker or Napi-78835395Оценок пока нет

- Onvif: ONVIF Specification Version 18.12 Release NotesДокумент22 страницыOnvif: ONVIF Specification Version 18.12 Release NotesS M HADIUZZAMANОценок пока нет

- Sri Final Job SheetДокумент4 страницыSri Final Job SheetMohan LalОценок пока нет

- Steganography Project ReportДокумент40 страницSteganography Project ReportArunangshu Sen100% (1)

- Igcse Revision Theory pt1 WeeblyДокумент6 страницIgcse Revision Theory pt1 Weeblyapi-454046465Оценок пока нет

- Governance model for Project XXXXДокумент7 страницGovernance model for Project XXXXpiero_zidaneОценок пока нет

- Switch Enterasys Cli - GuideДокумент720 страницSwitch Enterasys Cli - GuideRaul Iglesias Gomez100% (2)

- Sampling PlanДокумент11 страницSampling PlanARIFОценок пока нет

- Инструкция терминала IND310Документ52 страницыИнструкция терминала IND310ДенисОценок пока нет

- CSC 510 Syllabus Spring 2012 Software EngineeringДокумент7 страницCSC 510 Syllabus Spring 2012 Software EngineeringAnubhav JainОценок пока нет

- Dijkstra's, Kruskals and Floyd-Warshall AlgorithmsДокумент38 страницDijkstra's, Kruskals and Floyd-Warshall AlgorithmsRajan JaiprakashОценок пока нет

- IC Risk Register Template For Banks 9419Документ2 страницыIC Risk Register Template For Banks 9419Rahmat ChenaarОценок пока нет

- Intelligent Systems in Big Data, Semantic Web and Machine LearningДокумент6 страницIntelligent Systems in Big Data, Semantic Web and Machine LearningRachid BelfaqihОценок пока нет

- 4TH SEP The College Library Manual PDFДокумент116 страниц4TH SEP The College Library Manual PDFjayesh shuklaОценок пока нет

- Book S Curve For Construction Sample Excel Bing PDFДокумент4 страницыBook S Curve For Construction Sample Excel Bing PDFmy.nafi.pmp5283Оценок пока нет

- Dynamic Routing Security ConsiderationsДокумент19 страницDynamic Routing Security ConsiderationsNickhil RevuОценок пока нет

- United States District Court District of MassachusettsДокумент16 страницUnited States District Court District of Massachusettsbarzilay123Оценок пока нет

- Planos Electricos. Gruas NuevasДокумент122 страницыPlanos Electricos. Gruas NuevasSebastian Segovia100% (1)

- Access Network Optical Network Data Com Core Network Wireless Terminal Storage and Network Security Application & Software Product & Solution Public Icons Cloud IconsДокумент98 страницAccess Network Optical Network Data Com Core Network Wireless Terminal Storage and Network Security Application & Software Product & Solution Public Icons Cloud IconsRaul QuinterosОценок пока нет

- 20ESIT202 - Python ProgrammingДокумент12 страниц20ESIT202 - Python ProgrammingRashim RBОценок пока нет

- IoT Security in Higher EdДокумент16 страницIoT Security in Higher EdBE YOUОценок пока нет

- Drivers For Vostro 1450Документ12 страницDrivers For Vostro 1450cpatra77Оценок пока нет

- User Manual: Flow-States For Growth, Prosperity and Spiritual EvolutionДокумент6 страницUser Manual: Flow-States For Growth, Prosperity and Spiritual EvolutionTezcatzinОценок пока нет

- HAMEG FA Oscilloscopes Why Analog EДокумент2 страницыHAMEG FA Oscilloscopes Why Analog EGeorgeОценок пока нет