Академический Документы

Профессиональный Документы

Культура Документы

Refrigeracion Excel 93

Загружено:

Daniel GonzálezАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Refrigeracion Excel 93

Загружено:

Daniel GonzálezАвторское право:

Доступные форматы

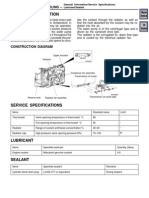

COOLING SYSTEM

Return To Main Table of Contents

GENERAL ............................................................................ 2 COOLING SYSTEM ............................................................ 9 RADIATOR ......................................................................... WATER PUMP ................................................................... 10 13 THERMOSTAT ................................................................... 15 WATER TEMPERATURE GAUGE UNIT, SENSOR .......... 16 WATER HOSE AND PIPE .................................................. 18

25-2

GENERAL

GENERAL

SPECIFICATIONS

Cooling method Cooling system Quantity Radiator cap Main valve opening pressure Vacuum valve opening pressure Water pump Thermostat Valve opening temperature Full-opening temperature Valve lift, fully open Identification mark Water temperature gauge unit Resistance Thermo switch (On radiator) Operating temperature OFF - ON ON - OFF Water temperature sensor Resistance Water-cooled, pressurized, Forced circulation with electrical fan 5.3 lit (5.6 U.S.qts., 5.0 Imp.qts.) 81.4-108 kPa (11.8-15.6 psi, 0.83-1.1 kg/cm2) -6.86 kPa (-1.00 psi, -0.07 kg/cm2) or less Impeller of centrifugal type 88 1.5C (190.4 2.7F) 100C (212F) 8 mm (0.31 in) or more 88 (Stamped on flange) 90.5-117.5 at 70C (158F) 21.3-26.3 at 115C (239F)

85 3C (185 5.4F) 78C (172F) or more 2.21-2.69 K at 20C (68F) 264-382 K at 80C (176F)

SERVICE STANDARD

Standard value Coolant concentration 50%

GENERAL

25-3

TIGHTENING TORQUE

Nm Alternator support nut Alternator adjuster lock bolt Water pump to cylinder block Water pump to cylinder block (alternator brace mounting) Water pump pulley Water temperature gauge unit Water temperature sensor Water outlet fitting bolt 20-25 12-15 12-15 20-27 8-10 10-12 20-40 17-20 kg.cm 200-250 120-150 120-150 200-270 80-100 100-120 200-400 170-200 Ib.ft 14-18 9-11 9-11 14-20 6-7 7-9 15-28 12-14

25-4

GENERAL

TROUBLESHOOTING

Symptom Low coolant level Probable cause Leakage of coolant Heater or radiator hose Faulty radiator cap Thermostat housing Radiator Water pump Foreign material in coolant Faulty thermostat Faulty radiator cap Restricted to flow in cooling system Loosen or missing drive belt Faulty water pump Faulty temperature gauge or wiring Faulty electric fan Faulty thermo-switch in radiator Insufficient coolant Abnormally low coolant temperature Leakage from oil cooling system Faulty thermostat Faulty temperature gauge or wiring Loose connections Cracked or damaged Hoses Pipes Oil cooler Damaged Thermo sensor Electrical motor Radiator fan relay Wiring Remedy

Repair or replace parts Tighten or replace clamps Replace gasket or housing Replace Replace parts Replace coolant Replace parts Clear restriction or replace parts Adjust or replace Replace Repair or replace Repair or replace Replace Refill coolant Replace Repair or replace Tighten Replace

Clogged radiator Abnormally high coolant temperature

Inoperative electrical cooling fan

Repair or replace

GENERAL

25-5

COOLANT LEAK CHECK

1. Wait until the radiator is cool (less than 38C, 100F). Loosen the radiator cap. 2. Confirm that the coolant level is up to the filler neck. 3. Install a radiator cap tester to the radiator filler neck and apply 150 kPa (21 psi, 1.53 kg/cm2) pressure. Hold for two minutes in that condition, while checking for leakage from the radiator, hose, or connection. CAUTION Radiator coolant may be extremely hot. Do not open the system while hot, or scalding water could spray out causing personal injury. Allow the vehicle to cool before servicing this system. Be sure to completely clean away any moisture from the places checked. When the tester is removed, be careful not to spill any coolant from it. Use care, when installing and removing the tester. When testing, do not distort the filler neck of the radiator. 4. If there is leakage, repair or replace the appropriate part.

RADIATOR CAP PRESSURE TEST

1. Use an adapter to attach the cap to the tester. 2. Increase the pressure until the indicator of the gauge stops moving. Main valve opening pressure . . . . . . . . . . . . . . . . 81.4-108 KPa (11.8-15.6 psi, 0.83-1.10 kg/cm2) Limit . . . . . . . . . . . . . . 65 kpa (9.2 psi, 0.66 kg/cm2) 3. Check that the pressure level is maintained at or above the limit. 4. Replace the radiator cap if the reading does not remain at or above the limit. NOTE Be sure the cap is clean before testing. Rust or other foreign material on the cap seal will cause an incorrect indication.

SPECIFIC GRAVITY TEST

1. Measure the specific gravity of the coolant with a hydrometer. 2. Measure the coolant temperature, and calculate the concentration from the relation between the specific gravity and temperature using the following table for reference.

GENERAL

Relation Between Coolant Concentration and Specific Gravity

The following table is applicable only to the specified HIGH QUALITY ETHYLENE GLYCOL (ANTIFREEZE) COOLANT Coolant temperature C (F) and specific gravity 10 (50) 1.054 1.063 1.071 1.079 1.087 1.095 1.103 20 (68) 1.050 1.058 1.067 1.074 1.082 1.090 1.098 30 (86) 1.046 1.054 1.062 1.069 1.076 1.084 1.092 40 (104) 50 (122) 1.042 1.049 1.057 1.064 1.070 1.077 1.084 1.036 1.044 1.052 1.058 1.064 1.070 1.076 Freezing temperature C (F) -16 (3.2) -20 (-4) -25 (-13) -30 (-22) -36 (-32.8) -42 (-44) -50 (-58) Safe operating temperature C (F) -11 (12.2) -15 (5) -20 (-4) -25 (-13) -31 (-23.8) -37 (-35) -45 (-49) Coolant concentration (Specific volume)

30%

35% 40% 45% 50% 55% 60%

Example The safe operating temperature is -15C (5F) when the measured specific gravity is 1.058 at coolant temperature of 20C (68F). CAUTION If the concentration of the coolant is below 30%, the anti-corrosion property will be adversely affected. In addition, if the concentration is above 60%, both the anti-freeze and engine cooling properties will decrease, affecting the engine adversely. For these reasons, be sure to maintain the concentration level within the specified range. Do not mix different brands of coolant.

RECOMMENDED COOLANT

Antifreeze ETHYLENE GLYCOL BASE FOR ALUMINUM Mixture ratio of antifreeze in coolant 50%

GENERAL

DRIVE BELT TENSION DEFLECTION CHECK AND ADJUSTMENT

Drive Belt Measurement And Adjustment

To meet specifications measure belt deflection at point A. If not within specifications loosen the alternator (point B) and adjust in or out to meet specifications in the chart below. Installed new belt Deflection 5.5-7.0 mm (0.22-0.28 in.) 50-70 kg (110-154 lb) Installed used belt 8.0 mm (0.31 in.) 40 kg (88 lb)

Tension (T)

Length Checkup of Drive Belt

After engine is driven, belt length is to be satisfied following value when belt is measured as above method (cold engine temperature of engine cooling water is above 20C (68C). Drive belt check up Deflection Tension (T) 7.0-8.2 mm (0.28-0.32 in.) 35-50 kg (77-110 lb)

25-8

GENERAL

USAGE OF TENSION GAUGE

Using Tension Gauge

BORROUGHS BT-33-73F Type NIPPONDENSO BTG-2 Type

Measuring Method

1. Press down on the tension gauge handle and insert the belt between the spindle and hook of the gauge. 2. Release the handle and read the measurement on the gauge.

NOTE 1. A belt which has been in operation for 5 minutes or more, must be adjusted to the used belt specifications. 2. Check to see that the belt is installed correctly, as shown in the illustration. 3. A loose belt will produce a high-pitched squealing noise. 4. A belt that is too tight will damage the alternator and water pump bearings.

COOLING SYSTEM

25-9

DRIVE BELT AND PULLEY

Removal

Loosen the alternator support nut A and the belt tension adjuster lock bolt B. 2. Rotate the adjuster bolt counterclockwise to relieve belt tension, and remove the belt. 3. Remove the water pump pulley bolts and remove the water pump pulley. Tightening torque A Alternator support nut A . . . . . . . . . . . . . . . 20-25 Nm (200-250 kg.cm, 14-18 Ib.ft) Adjuster lock bolt B . . . . . . . . . . . . . . . . . . 12-15 Nm (120-150 kg.cm, 9-11 Ib.ft) 1.

Inspection

Check the 1. Check 2. Check 3. Check 4. Check following items and replace if defective. the surface for damage, peeling or cracks. the belt surface for oil or grease. the rubber for worn or hardened areas. the surface of the pulley for cracks or damage.

Installation

Install the water pump pulley to the water pump pulley bracket and tighten the bolts firmly. 2. After installing the belt, adjust the belt tension. See DRIVE BELT TENSION DEFLECTION CHECK AND ADJUSTMENT. 1.

RADIATOR

RADIATOR

COMPONENTS

RADIATOR

25-11

REMOVAL

1. Disconnect the fan motor plug. 2. Set the warm water flow control knob of the heater control to the hot position. 3. Loosen the radiator drain plug to drain coolant. 4. Disconnect the upper and lower hose, and the overflow tube. 5. For vehicles with an automatic transaxle, disconnect the oil cooler hoses from the automatic transaxle.

CAUTION

Plug the ends of the oil cooler hoses and the automatic transaxle port to prevent the transaxle fluid from spilling out and foreign material from getting in. 6. Remove the radiator mounting bolts. 7. Remove the radiator together with the fan motor. 8. Remove the fan motor from the radiator.

INSPECTION

Check the radiator for bent, broken or plugged fins. Check the radiator for corrosion, damage, rust or scale. Check the radiator hoses for cracks, damage or deterioration. Check the reservoir tank for damage. Check the radiator cap spring for damage. Pressure test the cap using a cooling system checker. 6. Check the radiator cap seal for cracks or damage. 1. 2. 3. 4. 5.

7. Check for continuity with the thermo sensor in hot water. Continuity at 85 3C (185 5.4F) No continuity at 78C (172F) or more NOTE Immerse the thermo sensor in hot water up to the mounting threads to check for continuity.

Radiator Fan Motor

1. Check to be sure that the radiator fan rotates when battery voltage is applied between the terminals (as shown in the figure). 2. Check to see that abnormal noises are not produced while the motor is turning.

RADIATOR

INSTALLATION

1. Fill the radiator and reservoir tank with a fresh coolant mixture. 2. Run the engine until the coolant has warmed up enough so that the thermostat valve opens, and then stop the engine. 3. Remove the radiator cap, pour in the coolant until it is up to the filler neck of the radiator, and then fill the reservoir tank to the upper level. 4. Check to be sure that there is no leakage from the radiator, hoses or connections.

WATER PUMP

25-13

WATER PUMP

COMPONENTS

TORQUE : Nm (kg.cm, Ib.ft)

REMOVAL

1. 2. 3. 4. 5. Drain the coolant and disconnect the radiator outlet hose from the water pump. Remove the drive belt and water pump pulley. Remove the timing belt covers and the timing belt tensioner. Remove the water pump mounting bolts and remove the alternator brace. Remove the water pump assembly from the cylinder block.

INSPECTION

1. Check for excessive corrosion, cracks, damage, or wear. Replace the water pump assembly if necessary. 2. Check the bearing for damage, abnormal noise, and sluggish rotation. Replace the water pump assembly if necessary. 3. Check for water leakage. If water leaks from hole A, the seal unit is defective. Replace water pump assembly.

25-14

WATER PUMP

INSTALLATION

1. Clean the gasket surfaces of the water pump body and the cylinder block. 2. Install the new O-ring onto the groove on the front end of the water pipe. Wet the O-ring with water. Do not apply oil or grease.

3. Install a new water pump gasket and water pump assembly. Tighten the bolts to the specified torque. Tightening torque Water pump to cylinder block Head mark 4 bolt . . . . . . . . . . . . . . . . . . . . . . 12-15 Nm (120-150 kg.cm, 9-11 lb.ft) Head mark 7 bolt . . . . . . . . . . . . . . . . . . . . . . . 20-27 Nm (200-270 kg.cm, 14-20 lb.ft) 4. Install the timing belt tensioner and the timing belt. Adjust the timing belt tension. Then install the timing belt covers. See Engine, for detailed procedure. 5. Install the water pump pulley and drive belt. Then adjust the belt tension. 6. Refill with fresh coolant mixture. 7. Run the engine and check for leaks.

THERMOSTAT

25-15

THERMOSTAT

COMPONENTS

TORQUE : Nm (kg.cm, lb.ft)

REMOVAL AND INSPECTION

1. 2. 3. 4. 5. 6. Drain the coolant down to the thermostat level or below. Remove the water outlet fitting and gasket. Remove the thermostat. Heat the thermostat as shown in the illustration. Check to see if the valve operates properly. Determine temperature at which the valve begins to open, Valve opening temperature . . . . 88 1.5C (190.4 2.7F) Full opening temperature . . . . . . . . . . . . . 100C (212F) Valve lift (at full open) . . . . . . . . . . 8 mm (0.31 in.) or more

INSTALLATION

1. Make sure that the flange of the thermostat is correctly seated in the socket of the thermostat housing. If the thermostat is installed in the wrong direction, bottom of thermostat will touch the rib inside the intake manifold, making it impossible to seat the flange. 2. Install a new gasket and the water outlet fitting. 3. Refill with fresh coolant mixture.

WATER TEMPERATURE GAUGE UNIT, SENSOR

WATER TEMPERATURE GAUGE UNIT, SENSOR

COMPONENTS

TORQUE : Nm (kg.cm, lb.ft)

REMOVAL

1. Drain the coolant down to the gauge unit level or below. 2. Disconnect the battery ground cable and the engine harness, 3. Remove the water temperature gauge unit, sensor.

INSPECTION

Water Temperature Gauge Unit

1. Heat the water temperature gauge unit by submerging it in hot water. 2. Check that the resistance is within the specified range. Resistance. . . . . . . . . . . . . . . . . 90.5 - 117.5 at 70C (158F) 21.3-26.3 at 115C (239F)

WATER TEMPERATURE GAUGE UNIT, SENSOR Water Temperature Sensor

1. Heat the sensor by submerging it in hot water. 2. Check that the resistance is within the specified range. Resistance . . . . . . . . . . . 2.21-2.69 K at 20C (68F) 264-328 at 80C (176F)

INSTALLATION

1. Apply sealant to the threaded portion of the sensor, gauge unit and tighten to the specified torque. Tightening torque Water temperature gauge unit . . . . . . . . . . . . . . . 10-12 Nm (100-120 kg.cm, 7.2-8.7 lb.ft) Water temperature sensor . . . . . . . . . . . . . . . . . 20-40 Nm (200-400 kg.cm, 14-29 lb.ft)

2. Connect the harness to the water temperature gauge unit, temperature sensor. 3. Connect the battery ground cable. 4. Refill with a fresh coolant mixture.

25-18

WATER HOSE AND PIPE

WATER HOSE AND PIPE

COMPONENTS

[MPI]

[FBC]

TORQUE : Nm (kg.cm, lb.ft)

WATER HOSE AND PIPE

25-19

INSPECTION

Check the water pipe and hose for cracks, damage, or restrictions. Replace if necessary.

INSTALLATION

Fit the O-ring in the groove provided at the water inlet pipe end. Wet the O-ring with water and insert the water inlet pipe. NOTE 1. Do not apply oils or greases to the water pipe O-ring. 2. Keep the water pipe connections free of sand, dust, etc. 3. Insert the water pipe until its bottoms.

Вам также может понравиться

- General Information: Engine CoolingДокумент13 страницGeneral Information: Engine Coolinganonymous2abcОценок пока нет

- Engine Cooling: Section: 1DДокумент19 страницEngine Cooling: Section: 1DDustin WoodsОценок пока нет

- Engine Cooling: Group 14Документ28 страницEngine Cooling: Group 14jagjitemir6014Оценок пока нет

- Air Conditioning SystemДокумент51 страницаAir Conditioning SystemMoaed KanbarОценок пока нет

- 1kr Fe CoolingДокумент128 страниц1kr Fe Coolingfguij100% (1)

- Neonbelt01 PDFДокумент30 страницNeonbelt01 PDFవిష్ణువర్ధన్రెడ్డిОценок пока нет

- Engine Cooling: Section: 1DДокумент19 страницEngine Cooling: Section: 1DAndres GeyerОценок пока нет

- Engine Cooling System: 1988 Toyota CelicaДокумент12 страницEngine Cooling System: 1988 Toyota CelicaToua YajОценок пока нет

- Suzuki SwiftДокумент7 страницSuzuki SwiftAsher GinsbergОценок пока нет

- PL Cooling System 7 - 1Документ0 страницPL Cooling System 7 - 1Luis Alberto OrtegaОценок пока нет

- Chapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesДокумент6 страницChapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesmohhizbarОценок пока нет

- Engine CoolingДокумент29 страницEngine CoolingMarioОценок пока нет

- Sistema de EnfriamientoДокумент12 страницSistema de EnfriamientoFrancisco CortezОценок пока нет

- zxr400 H 03Документ10 страницzxr400 H 03hugo_bikerОценок пока нет

- General Cooling System ServicingДокумент3 страницыGeneral Cooling System ServicingAnimemanuel MuñozОценок пока нет

- Engine Cooling Guide for 6G7 and 4D5 ModelsДокумент18 страницEngine Cooling Guide for 6G7 and 4D5 ModelsGIAN CARLO MAMANI GILES.100% (1)

- 1995 Toyota Camry Cooling System Technical ManualДокумент30 страниц1995 Toyota Camry Cooling System Technical ManualKevin Reilly100% (1)

- Cooling Hyundai ScoupeДокумент19 страницCooling Hyundai ScoupeCanelo BalbinОценок пока нет

- DIGIFANT FUEL INJECTIONДокумент6 страницDIGIFANT FUEL INJECTIONembokoОценок пока нет

- Section 50 - Auxiliary Units - Chapter 1Документ54 страницыSection 50 - Auxiliary Units - Chapter 1Cristian SterieОценок пока нет

- Cooling System Guide for CarsДокумент26 страницCooling System Guide for CarsDalton WiseОценок пока нет

- P250-250S Cap 12 (COOLING SYSTEM)Документ17 страницP250-250S Cap 12 (COOLING SYSTEM)Minh ChuОценок пока нет

- Manual AC CompressorДокумент56 страницManual AC CompressorGerman Diego Salazar RosasОценок пока нет

- Accent Cooling SystemДокумент14 страницAccent Cooling Systemflash_24014910Оценок пока нет

- Maintain Your Vehicle's Cooling SystemДокумент28 страницMaintain Your Vehicle's Cooling SystemLuis Daniel CortesОценок пока нет

- Sabre 25HE CombiДокумент44 страницыSabre 25HE CombiRon Lester0% (1)

- Eg en YlcsДокумент52 страницыEg en YlcsItalo LeivaОценок пока нет

- XJ Cooling System 7 - 1Документ40 страницXJ Cooling System 7 - 1awemetal100% (1)

- CARRIER - Hermetic Centrifugal Chiller 19XLДокумент100 страницCARRIER - Hermetic Centrifugal Chiller 19XLDonny R Wijaya0% (1)

- Isuzu Engine Cooling SystemДокумент21 страницаIsuzu Engine Cooling SystemToan100% (1)

- 3306 Cylinder Head To Block Joint Repair Procedure{1124, 1101, 1201}Документ24 страницы3306 Cylinder Head To Block Joint Repair Procedure{1124, 1101, 1201}Nick Ildefonso Fuenmayor AntunezОценок пока нет

- Engine Cooling: Click On The Applicable Bookmark To Selected The Required Model YearДокумент29 страницEngine Cooling: Click On The Applicable Bookmark To Selected The Required Model YearCao LanОценок пока нет

- SECTION 9002 Air ConditioningДокумент54 страницыSECTION 9002 Air Conditioninglungu mihaiОценок пока нет

- Refrigerator: Service ManualДокумент36 страницRefrigerator: Service Manualjose_suko49Оценок пока нет

- ServiceManuals LG Fridge GR349SQF GR-349SQF Service ManualДокумент41 страницаServiceManuals LG Fridge GR349SQF GR-349SQF Service ManualPaulo Andrade75% (8)

- 07 Cooling SystemДокумент44 страницы07 Cooling SystemHardikPatelОценок пока нет

- Start-Up, Operation, and Maintenance Instructions: 17DA Open-Drive Centrifugal Liquid Chillers 50/60 HZ HFC-134aДокумент32 страницыStart-Up, Operation, and Maintenance Instructions: 17DA Open-Drive Centrifugal Liquid Chillers 50/60 HZ HFC-134aFranz CorasОценок пока нет

- HVAC ChillerДокумент44 страницыHVAC ChilleratereñoneОценок пока нет

- Cooling System (2Az-Fe) : On-Vehicle InspectionДокумент27 страницCooling System (2Az-Fe) : On-Vehicle InspectionTung NguyenОценок пока нет

- Dahatsu Terios COДокумент19 страницDahatsu Terios COJose M Chire0% (2)

- Ethos 24c Maintenance ManualДокумент29 страницEthos 24c Maintenance Manualdanielteo2008Оценок пока нет

- Whirpool - 6LBR5132EQ - Manual Servicio PDFДокумент31 страницаWhirpool - 6LBR5132EQ - Manual Servicio PDFAldo TonatoОценок пока нет

- Start-Up, Operation, and Maintenance Instructions: 17DA Open-Drive Centrifugal Liquid Chillers 50/60 HZ HFC-134aДокумент32 страницыStart-Up, Operation, and Maintenance Instructions: 17DA Open-Drive Centrifugal Liquid Chillers 50/60 HZ HFC-134aVinod NairОценок пока нет

- CatДокумент36 страницCatnagananda_ar100% (1)

- Heater, Air Conditioner and VentilationДокумент36 страницHeater, Air Conditioner and Ventilationmarran almarranyОценок пока нет

- Yorfk ZF 180 To 300Документ7 страницYorfk ZF 180 To 300Martin BourgonОценок пока нет

- Filling and Maintaining BoilersДокумент15 страницFilling and Maintaining BoilersJosé MacedoОценок пока нет

- Pierburg Carburetor 2E3 Settings and TroubleshootingДокумент43 страницыPierburg Carburetor 2E3 Settings and TroubleshootingGjorgi Ljubotenski79% (14)

- Cooling System - Test: SMCS - 1350-040 1350-081Документ14 страницCooling System - Test: SMCS - 1350-040 1350-081anon_909514915Оценок пока нет

- Engine Cooling SystemДокумент68 страницEngine Cooling SystemGreg Hanna0% (1)

- 23xrv 2ssДокумент150 страниц23xrv 2ssLouie DupayaОценок пока нет

- Cooling System: S2.0-3.5FT (S40-70FT, S55FTS) (H187) H2.0-3.5FT (H40-70FT) (P177)Документ30 страницCooling System: S2.0-3.5FT (S40-70FT, S55FTS) (H187) H2.0-3.5FT (H40-70FT) (P177)MONTACARGAS KAPPI S A DE C V LOGISTICAОценок пока нет

- Hyundai Excel X2 1989-1998 Air ConditioningДокумент53 страницыHyundai Excel X2 1989-1998 Air ConditioningaurbinaeОценок пока нет

- En Scroll Replacement Guidelines 0Документ10 страницEn Scroll Replacement Guidelines 0Ferdie FernandezОценок пока нет

- 6ALBR5233JQOДокумент23 страницы6ALBR5233JQOpinticaniulian9042Оценок пока нет

- Cooling System: Safety Precautions Maintenance and RepairДокумент13 страницCooling System: Safety Precautions Maintenance and RepairKiều Văn TrungОценок пока нет

- Service - Service Manual Code 950 - 994 - 653 (1) Kubota V2203Документ30 страницService - Service Manual Code 950 - 994 - 653 (1) Kubota V2203ynadeem100% (4)

- 2AZ FE CoolingДокумент35 страниц2AZ FE CoolingLuks Fernandez50% (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет