Академический Документы

Профессиональный Документы

Культура Документы

Sludge Thickener

Загружено:

ankur_92009Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sludge Thickener

Загружено:

ankur_92009Авторское право:

Доступные форматы

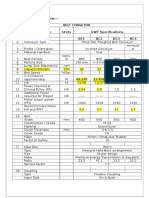

Name of the Plant - 144 MLD Advance WTP Sikandra Agra Name of Structure- Sludge Thickener Main EquipmentsSr.

No. Drive Mechanism Qty one set MakeSr. No. of Equipment Capacity Drive electric Motor MakeSr. No. of Equipment KW/HP RPM Any Other Details Characteristics/Items Sr. No. A Check for Physical verification and orientation Verification Visual, tools A Types of Checks Vertical Cage Assembly Scrapper Arm Assembly Bridge Assembly Qty - one set Qty - one set Qty - one set MakeOverall DimensionsWeight (Approx.)MakeOverall DimensionsWeight (Approx.)MakeOverall DimensionsWeight (Approx.)Instrumentation

1 2 3 4 5 6 7 8 9

Instruments

Class

Quantum Frequency of Reference documents Check and acceptance standard 100% No Physical Damage Orientaion

Format of Records

Remarks

(1) Manufacturees Guarantee (2) Delivery Challan (3) Manufacturers check list for installation and commisioning (4) Site log books (5) Plant and Machinery Record

Foundation elevation levelling and layout verification

Verification

Visual, level, tools, Datum level on Installation

100%

Approved G.A. Drawing Recording the Result/ Status and Piping Layout

Prior check ups before installation - Testing of electric drive for Verification direction of rotation and other standard tests Measurement Assembly, Placement Assembly plumb of foundation and and level, a) orientaion of bridge

Megger, tong tester

100%

As per technical requirement

Report for Review

level tools, Vernier caliper, Scales

100%

Approved G.A. Drawing Recording the Result/ Status and Piping Layout

b) Instalation of Drive casing assembly/vertical cage and its fitting with drive assmbly Assembly and Fitting of Rake Arm Cone Scrapper, Feed Well Rubber Squeezes, Weir Plate

Measurement of gaps for uniformity around center column Balancing, Measurement Assembly Plumb And level,

Level tools, Verniercaliper,Scales

100%

Approved G.A. Drawing Recording the Result/ Status and Piping Layout

Measurement of gaps between floor and scrapper arm for uiformity( at successive 30 degree interval) for complete rotation at various locations at least 1 m distance Approved G.A. Drawing Recording the Result/ Status and Piping Layout As per Standard tolerance permissible Record the results

Assembly of and orientaion Gear Drive Assembly Visual Verification

100%

Alignment of drive and motor/gear box Measurement Operation trial for one rotation Load results Verification of electrical parameters

Feeler gauge/dial gauge

100%

Watch Rotation Time

100%

Approved G.A. Drawing Record the results and analyse and Piping Layout

Вам также может понравиться

- Water Treatment Plant Performance Evaluations and OperationsОт EverandWater Treatment Plant Performance Evaluations and OperationsОценок пока нет

- WSG (KR) - ASME - BPEДокумент35 страницWSG (KR) - ASME - BPEThomas C. Lane100% (1)

- Paddle FlocculatorsДокумент12 страницPaddle FlocculatorsBinyam KebedeОценок пока нет

- Digester Design2Документ16 страницDigester Design2Pragathees WaranОценок пока нет

- SMART Digital - DDA With Profibus DP / Modbus Rtu / Profinet Io / Modbus TCPДокумент2 страницыSMART Digital - DDA With Profibus DP / Modbus Rtu / Profinet Io / Modbus TCPRyan GohОценок пока нет

- Sludge Treatment: Total Solid in Raw Water 600 Kg/dayДокумент12 страницSludge Treatment: Total Solid in Raw Water 600 Kg/dayThava ThavaОценок пока нет

- ProMinent Operating Instructions Meta HM-HKДокумент20 страницProMinent Operating Instructions Meta HM-HKivan_shterevОценок пока нет

- Business Activities ProfileДокумент35 страницBusiness Activities ProfileKapa KamalakarОценок пока нет

- Agitator DesignДокумент3 страницыAgitator DesignSmrutiОценок пока нет

- ASME - Shell Thickenss Calculation MAIN SHELLДокумент4 страницыASME - Shell Thickenss Calculation MAIN SHELLCoralPT WorldwideОценок пока нет

- Dykewall CalculationДокумент4 страницыDykewall CalculationVipul GandhiОценок пока нет

- Filter Press Specifications and Technical DetailsДокумент3 страницыFilter Press Specifications and Technical DetailsAbd Elrahman Hamdy0% (1)

- Presentation of Apex Consultants - NewДокумент20 страницPresentation of Apex Consultants - NewSudhirОценок пока нет

- Recent Advances in Humidification Dehumidification (HDH) Desalination Processes - Improved Designs and ProductivityДокумент16 страницRecent Advances in Humidification Dehumidification (HDH) Desalination Processes - Improved Designs and ProductivityMr NaughtyОценок пока нет

- Partially Full Pipe Flow Calculations - S.I. Units: Workbook ContentsДокумент29 страницPartially Full Pipe Flow Calculations - S.I. Units: Workbook ContentsdiegoОценок пока нет

- Burner specification document summaryДокумент6 страницBurner specification document summaryHafiz Muhammad AbubakarОценок пока нет

- Main CatalogueДокумент10 страницMain CatalogueMohamed SalahОценок пока нет

- Design of paddle type agitator for effluent agitationДокумент4 страницыDesign of paddle type agitator for effluent agitationuttam prabhuОценок пока нет

- What Sets The SaltMaker Apart 1Документ10 страницWhat Sets The SaltMaker Apart 1Furi Sri RahimahОценок пока нет

- AtfdДокумент4 страницыAtfdDarshan PatelОценок пока нет

- Flow Characteristics in Mixers Agitated by Helical Ribbon Blade ImpellerДокумент15 страницFlow Characteristics in Mixers Agitated by Helical Ribbon Blade Impellerkalyan555Оценок пока нет

- Lombardyne Multiple Effect EvaporatorДокумент8 страницLombardyne Multiple Effect EvaporatorKuldeep BhattОценок пока нет

- Air Pollution ControlДокумент35 страницAir Pollution ControlPraveen YadavОценок пока нет

- Types of Agitators, Agitator's Design and Significance - Pharma EngineeringДокумент58 страницTypes of Agitators, Agitator's Design and Significance - Pharma Engineeringmyself_riteshОценок пока нет

- Experiments and Modeling of Bubble Column Dehumidifier PerformanceДокумент11 страницExperiments and Modeling of Bubble Column Dehumidifier PerformanceAl-Kawthari As-SunniОценок пока нет

- 7.5 KLHR MEE Offer (5%)Документ10 страниц7.5 KLHR MEE Offer (5%)kezaihrajОценок пока нет

- Low Temp. EvaporationДокумент40 страницLow Temp. EvaporationManvi Sharma100% (1)

- Pump motor power capacity chart for 120 m3/hr dischargeДокумент2 страницыPump motor power capacity chart for 120 m3/hr dischargeMangesh MandgeОценок пока нет

- Shell and Tube Heat Exchanger CalculationДокумент9 страницShell and Tube Heat Exchanger CalculationKuldeep28883Оценок пока нет

- MicrofilterДокумент17 страницMicrofilterArrianne Jaye MataОценок пока нет

- Design of AgitatorДокумент6 страницDesign of AgitatorVishalОценок пока нет

- Agitator Guide for Mixing and Stirring Tank ProductsДокумент10 страницAgitator Guide for Mixing and Stirring Tank Productsagrocel_bhv5591Оценок пока нет

- C3CBA2 Calculation of Flow Rate V Notch Weir Not 90 DegreesДокумент4 страницыC3CBA2 Calculation of Flow Rate V Notch Weir Not 90 DegreesRanu JanuarОценок пока нет

- Design of AgitatorДокумент3 страницыDesign of AgitatorManish PatelОценок пока нет

- Design of Agitator 8 Batch Volume PDFДокумент3 страницыDesign of Agitator 8 Batch Volume PDFakash kumarОценок пока нет

- Wet Scrubbing Systems ExplainedДокумент4 страницыWet Scrubbing Systems Explainedvarunpassi100% (1)

- Manufacturing & Effluent Treatment ProcessesДокумент28 страницManufacturing & Effluent Treatment ProcessesNeerav Indrajit GadhviОценок пока нет

- Alpema Standerd For Brazed Aluminium Plate-Fin Heat ExchДокумент78 страницAlpema Standerd For Brazed Aluminium Plate-Fin Heat ExchBilal NazirОценок пока нет

- Chemicals Zetag MSDS Powder Zetag 4190 - 0810Документ6 страницChemicals Zetag MSDS Powder Zetag 4190 - 0810PromagEnviro.comОценок пока нет

- Venting CalculationДокумент14 страницVenting CalculationValen MaselaОценок пока нет

- ZENON MBR Tech (Chris Jeffery)Документ70 страницZENON MBR Tech (Chris Jeffery)Srinivas DiviОценок пока нет

- Bubble Column Humidification Dehumidification Desalination SystemДокумент67 страницBubble Column Humidification Dehumidification Desalination SystemAnnjoe MathewsОценок пока нет

- Hadwaco MVR Evaporator Evaluated for Rinse Water RecyclingДокумент43 страницыHadwaco MVR Evaporator Evaluated for Rinse Water RecyclingLuis ValdezОценок пока нет

- Hydrochloric acid Regeneration of Cation Exchange Resin 225 HДокумент8 страницHydrochloric acid Regeneration of Cation Exchange Resin 225 HPravin BoteОценок пока нет

- Valvulas Diafragma Asepticas BPEДокумент104 страницыValvulas Diafragma Asepticas BPEHumberto GonzálezОценок пока нет

- Type k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarДокумент3 страницыType k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarRobinОценок пока нет

- Recovery of Salt by EFCДокумент39 страницRecovery of Salt by EFCApurva PatelОценок пока нет

- Specific Size Agitator Selection Process & Specification PDFДокумент28 страницSpecific Size Agitator Selection Process & Specification PDFParth ThakarОценок пока нет

- Dennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale OperationsДокумент25 страницDennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale Operationssushant_jhawerОценок пока нет

- Technical specifications of belt conveyors and associated equipmentДокумент11 страницTechnical specifications of belt conveyors and associated equipmentbashok20Оценок пока нет

- FWD CALCULATION NOTESДокумент10 страницFWD CALCULATION NOTESMuhammad Ashraful ArifinОценок пока нет

- Aeration System and Oxygen RequirementДокумент7 страницAeration System and Oxygen Requirementdzari6738Оценок пока нет

- Bracket Support or Lug SupportДокумент2 страницыBracket Support or Lug Supportsantoshblonkar100% (1)

- Machine Tool TestingДокумент4 страницыMachine Tool Testingnm2007k100% (1)

- SL # 1-13 ACTIVITY AND CHARACTERISTICSДокумент2 страницыSL # 1-13 ACTIVITY AND CHARACTERISTICSprasanta2011100% (4)

- 1 (1) - PumpДокумент8 страниц1 (1) - PumpJonathan Bacus100% (1)

- RSW WOPQ REV. 2010a Interactive FormДокумент1 страницаRSW WOPQ REV. 2010a Interactive FormcosmicbunnyОценок пока нет

- Quality Assurance Plan For ErectionДокумент8 страницQuality Assurance Plan For Erectionsushant_jhawerОценок пока нет

- Erection ProcedureДокумент4 страницыErection ProcedureRanjit BanerjeeОценок пока нет

- Vibration Analysis and Acceptance StandardДокумент23 страницыVibration Analysis and Acceptance StandardEstebanRivera100% (2)

- Ankur OnePagerДокумент1 страницаAnkur OnePagerankur_92009Оценок пока нет

- Is 800:2007Документ150 страницIs 800:2007crajtry100% (2)

- Welding ProcessesBДокумент440 страницWelding ProcessesBSrimaden SuharningsihОценок пока нет

- Front Page1..Документ2 страницыFront Page1..ankur_92009Оценок пока нет

- New Table of ContentsДокумент8 страницNew Table of Contentsankur_92009Оценок пока нет

- The Temple of ChaosДокумент43 страницыThe Temple of ChaosGauthier GohorryОценок пока нет

- Diia Specification: Dali Part 252 - Energy ReportingДокумент15 страницDiia Specification: Dali Part 252 - Energy Reportingtufta tuftaОценок пока нет

- Oral Nutrition Support NotesДокумент28 страницOral Nutrition Support Notesleemon.mary.alipao8695Оценок пока нет

- Chemistry of FormazanДокумент36 страницChemistry of FormazanEsteban ArayaОценок пока нет

- Ultrasonic Weld Examination ProcedureДокумент16 страницUltrasonic Weld Examination ProcedureramalingamОценок пока нет

- De Thi HSG Tinh Binh PhuocДокумент9 страницDe Thi HSG Tinh Binh PhuocDat Do TienОценок пока нет

- Motor Wiring Diagram: D.C. Motor ConnectionsДокумент1 страницаMotor Wiring Diagram: D.C. Motor Connectionsczds6594Оценок пока нет

- Maintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFДокумент39 страницMaintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFSandeepОценок пока нет

- Aortic Stenosis, Mitral Regurgitation, Pulmonary Stenosis, and Tricuspid Regurgitation: Causes, Symptoms, Signs, and TreatmentДокумент7 страницAortic Stenosis, Mitral Regurgitation, Pulmonary Stenosis, and Tricuspid Regurgitation: Causes, Symptoms, Signs, and TreatmentChuu Suen TayОценок пока нет

- Lyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticДокумент13 страницLyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticJayr Mercado0% (1)

- Baseline Program Rev 3A Presentation 25 July 2020Документ24 страницыBaseline Program Rev 3A Presentation 25 July 2020Shakti Sourava RautrayaОценок пока нет

- 1010 PDS WLBP 170601-EN PDFДокумент4 страницы1010 PDS WLBP 170601-EN PDFIan WoodsОценок пока нет

- B. Pharmacy 2nd Year Subjects Syllabus PDF B Pharm Second Year 3 4 Semester PDF DOWNLOADДокумент25 страницB. Pharmacy 2nd Year Subjects Syllabus PDF B Pharm Second Year 3 4 Semester PDF DOWNLOADarshad alamОценок пока нет

- SRS Design Guidelines PDFДокумент46 страницSRS Design Guidelines PDFLia FernandaОценок пока нет

- 2 - Soil-Only Landfill CoversДокумент13 страниц2 - Soil-Only Landfill Covers齐左Оценок пока нет

- Conjoint Analysis Basic PrincipleДокумент16 страницConjoint Analysis Basic PrinciplePAglu JohnОценок пока нет

- Gotham City: A Study into the Darkness Reveals Dangers WithinДокумент13 страницGotham City: A Study into the Darkness Reveals Dangers WithinajОценок пока нет

- SB Z Audio2Документ2 страницыSB Z Audio2api-151773256Оценок пока нет

- Madeleine Ker - TakeoverДокумент91 страницаMadeleine Ker - Takeover66677785100% (1)

- Air Wellness QRSДокумент2 страницыAir Wellness QRSapi-3743459Оценок пока нет

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualДокумент18 страницKAC-8102D/8152D KAC-9102D/9152D: Service ManualGamerAnddsОценок пока нет

- NDE Procedure - Radiographic TestingДокумент43 страницыNDE Procedure - Radiographic TestingJeganeswaranОценок пока нет

- Swatchh Bharat AbhiyanДокумент13 страницSwatchh Bharat AbhiyanHRISHI SHARMAОценок пока нет

- ASA 2018 Catalog WebДокумент48 страницASA 2018 Catalog WebglmedinaОценок пока нет

- Theoretical and Actual CombustionДокумент14 страницTheoretical and Actual CombustionErma Sulistyo R100% (1)

- LKC CS Assignment2Документ18 страницLKC CS Assignment2Jackie LeongОценок пока нет

- Panasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Документ39 страницPanasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Gordon Elder100% (5)

- Plate-Load TestДокумент20 страницPlate-Load TestSalman LakhoОценок пока нет

- 12 Week Heavy Slow Resistance Progression For Patellar TendinopathyДокумент4 страницы12 Week Heavy Slow Resistance Progression For Patellar TendinopathyHenrique Luís de CarvalhoОценок пока нет

- 2019 Course CatalogДокумент31 страница2019 Course CatalogDeepen SharmaОценок пока нет