Академический Документы

Профессиональный Документы

Культура Документы

RAC Domestic Refrigerator Test Rig

Загружено:

Shashi Bhushan PatelАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RAC Domestic Refrigerator Test Rig

Загружено:

Shashi Bhushan PatelАвторское право:

Доступные форматы

)i4

e-

TH,CH.E,D

Hll'rl

$li'${ tri{::.ii fiiffi,l-{

"*J'q_p$g

fe'/d

Af\4i

d,,ill.,

-Hir{lpj'q{$.ffifu; $"'${-.

$-{$i,fi Jl:4$fi],h:i}f.t \,'$'4-}''fi{ 'ii'J$i:i4,T,' H.t"${;.

i.-'i"lsIq:]riritril: l\'i;,id:ie-:ll*"] }.,-ls.f. {rlj''J',**ltfi{-lir{,ili,o/

hl

nir'nrl'.

'

$-

Fl

C fli-

F,

[tr,

t{* &iil

$* Pi'h

$^I

Fi'i[l

{.]

i}

P''S,F'4 f-i

*f $ [,$, {ii-&^$,{"ffFfr":]\{

xr/h]i,h,Ar5:i-

i-t,,tt.,i,'tu"Fi$3.{\i $ ilX{."llr\$,t, i\itr,4-^fri; '* 1-}'.;+,,'g: A.L'o"l"r\,'Li;\ $;.1. $:$,4".i-\ il A#-{ }}qHi -' s'ft# {}'ffi

i

[i

fi

r #ffi{}-

jl3*

*

r*

$'l

$$

535,

{r:i9+tl?.}';i.?:

F",'r"-i'il

;

n

: qr$4t$- )"j.3?" }i n ll'.3'j;

__..et.$

r] i ,t

$,

*i i;, i,fti

f'tr

u,'

i'j

fi"]]

{} +:, {

*. i titi

flr*r;:

lt'r

trq'triS$i{.;fl}''{*i$i

lti

rs$}..{;.{,r liirr

,lMechanical Engg.- NiT RaiPur

TE,CH-E,D

DOMESTIC REFRIGERATOR TEST RIG

AIM:

and to To conduct performance test on Vapour Compression type Ice plant tutor

find out co-efficient of performance (COP)

SYSTEM

OMP OI\ENTS/SPECIFICATION

1. Refiigeralor: vEDtrOCON, model: vAE,173AN2010, 170 \t

,"-

2. Compressor: -Model: ASB45R,

R-13-41..

,

2.

Ai1 Cooled condenser:

3. Fan motor with blade:

Il35

F{P

./' 4. F.xpansion Device -Capillary

-,'5. Filter Drier -make: INDFOS, Type: DM-50 6. Energy meter -make: BENTEX, Input: 3200impikwh, 5-20

7. Thermostat 8. Pressure/compound gauges: For.HP-LP Measurement.

amps

-/'g.Digital Temperature v'' 10. Thermocouples: ktype (CLlAl)- 5 nos

Indicator: -50 to + 199'9 'C

,*/ 1L Refrigerant:

R-134a

(D om

es

tir

WJrig erot o r

trainer

of Mechanical Engg.- NIT Raipur

TECH-ED

DESCRIPTION:

The apparatus is a laboratory scale working model of a Refrigeration cycle

unit, portable-trolley mounted, housed on a Powder coated MS square tube

frame.

A Domestic /

household refrigerator of VEDIOCON make is fitted on the

frarne containing, compressor with Thermostat, air cooled condenser with fan

motoL, Capillary Expansion and evaporatorl fieezer

The pressure gauges, Energy meter and digital temperature indicator with

selector switch are mounted on the control panel.

THEORY:

Now days, the refrigerator has become an essential parl of a household

rather than a luxury. It is used for preserving food and there by reducing waste. The primary function of a refrigerator or freezer is to provide food storage

space maintained at low temperature for the preservation of food. Its essential

secondary function is the formation of ice cubes for domestic consumption.

They are usually specified by the internal gross volume and the deep fi'eezer's

volume.

A storage temperature of 0' C to Aiic (273 K TO 277 K) is satisfactory for the

preservation of most of the fresh foods. For the shorl term storage of frozen foods (such as in a domestic refrigerator), temperatures much below the

,,

.",---*.,.1

freezingpoint are required. The fi'eezers are generally provided at the top porlion of the refi'igerator space. In some refiigerators, freezers are provided at

bottom. This arrangement seems to be based on the heat transfer considerations but it rnay be noted that the time taken to cool products kept at upper porlion would be more.

Q) o m e s

tic

fufrig erat

trainer

,pt. of Mechanical Engg.-

NIT Raipur

TECH-EI)

I:\ lp(1r'ilt()1' cnilr

I*

t'cr,r.e

i.'lr pi I Ilrr.r

t

ri.,oilll)l.lt'ln1

lit'

iril=

Kitr.hrrn

:50{'

(),, iJl

lrrtilcri,ru"

ct;ilr

( 't ltl'il)l r.':s.t

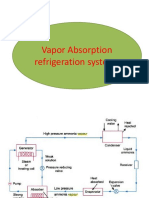

The mechanical vapor compression cycle as well as absorption cycle may be adopted for domestic refi'igerators and freezers, but the mechanical vapor compression system is actually used over absorption system, because

of

its compactness and more efficient use of electrical energy, as shown in figure. The refrigerant used is generallt,*-134A The compressor is mounted at the

bottom of the refrigerator frame. The power of compressor canvary according to size of therefiigerator, (i.e. 75W,92W,125 W, 180 Wetc.). The

condenser is put at the back about 40 to 60 mm away from the cabinet. The condenser may be either chassis type or tube and wire type. In the former, the condenser tube is mounted on a metal sheet which acts as fins. The tube and

wire type condensers are quit simple in which few tubes are held tightly under

wire frame from both sides. These wires act as cylindrical fins increasing the

(D o m e stic

fu{rig erat o r trsiner

4t. of Mechanicai Ettgg.- NIT Raipur

TtrCII.ED

with the evaporator rate of heat transfer. The capillary tube is kept in contact and the evaporator to inlet pipe. A drier is connected between the receiver

eliminate traces of moisture

if any'

in a suitable manner to The evaporator coil is wrapped around the freezer is made from a give efficient heat transfer. Some times, the freezer charnber passage between the sheets pair of sheet joined together in such away that the space is accomplished by fi'ee act as an evaporator coil. The cooling of lower sensing element is convection (due to density gradient). The thermostatic in the freezer up provided to the evaporator coil which can control temperature the type of controlling switch to -15" c in steps or continuously depending upon

employed.

insulation in order to The refrigerator body is provided with good quality mm thick glass looseprevent heat transfer into the system. usually 60 to 100 of these fill fiber or glass rolls or thermo cole is used since the conductivity

insuiating materials are quite low'

Theprincipalpartsareshownonthediagram,andpathofthe

pressure is maintained at refrigerant flow is also shown on the diagram. The valve (high side different levels in fivo parts of the system by the expansion

allow the liquidfloat vaive). The function of the expansion valve is to rate into the low-pressure refrigerant under high pressule to pass at a controlled

through the expanston parl of the system. Some of the liquid evaporates passing pressure (low valve, but greater portion is vaporized in the evaporator ,atlow heat of vaponzation fiom temperature). The liquid refi'igerant absorbs its latent The function of the the air, water or other material, which is being cooled' of the refrigerant above compressor is to iucrease the pressure and temperature

E om e s ti c fufrig erat

r'Ir ain er

pt. of Mechanical Engg.- NIT Raipur

TE,CH.EI)

atmospheric, which

will

be ready to dissipate its latent heat in the condenser' In

heat, which is passing through the condenser, the refrigerant gives up the

work done upon it by absorbed in the evaporator plus the heat equivalent of the which is used as the compressof. This heat is transferred to the air or water,

cooling medium in the condenser'

l l

Li

C,ompressor

-l --

1

L

_ -, EvaPorator

l--

r-

_-----_-l

I |

P"p*t4?evice

l

--

- --,-

BLOCKDIAGRAMoFVAPOURCOMPRESSIONCYCLE,

The standard vapour compression cycle consists of following process:

1. Process,

I-2

replesents reversible adiabatic compression fi'om

2. Proces

saturated vapol to the condensel plessure or superheated Vapor' s 2-3 represents reversible heat rejection at constant pressure,

de preheating and condensation'

3. Process 3-4 represents ireversible constant enthalpy expansion fiom

saturated liquid to the evaporator pressure'

4. Process 4-1 represents reversible heat addition at constant

(Evaporation to saturated vapor)

pressule

'

(D om

es

tit Rcfig

erat o r.{rainer

4t. of Mecl:ranical Engg.- NIT Raipur

The refiigerants such as

TE,CI{.E,I)

as

R-l2, R-22, and R-134a (commercially known

freons) are used as working medium because of their properties, which are required as refrigeration cycles.

Performance of standard vapour compression cycle:

Process 1-2 is the compression process where in Mechanical work is to be supplied to a compressor. This is the quantity to be spent. Process 4 -1 represents the useful refrigeration effect. The index of performance is defined

as coefficient of performance.

1. T1 :Temp.of refiigerant at inlet of compressor'

2. T2:

Temp.of refi'igerant

.,' at outlet of compressor '-'"

at outlet of condenser ".,'/

at outlet of

.,...

3. T3 : Temp.of refrigerant

4. T4: Temp.of refrigerant

5. T5 : Temp.at Evaporator.

expansion

,,

A o me s tic

fufi9

erat

or'Trainer

;pt. of Mechanical Engg.- NIT Raipur'

TE,CH-ED

OPERATII{G PROCEDURE:

1. Put ON mains (DP Switch)

2. Now switch

on the coffIpressor, by using a rotary switch provided achieve this temp., it

3. Allow the fieezer to cool f%gc.Io

approximately

1

wiil

take

t0

1 lz hrs. (Depending on ambient temp. and Power)

4. Fol COP calcuiation,,

A. Put known quantity of water/ brine solution in a bowl I platethen

keep that inside the freezer.

B. Note down the initial temperature of water / brine solution

C. Allow it to cool for some time, simultaneously note down the

respective readings for every

1-0

minutes duration

till it reach 5

**s-9

D. Calculate the COP using given formulae.

5.

T'hen switch off the Compressor using Rotary ON/OF'F switch and

mains

'r

\r

'!i'r"

"il

,.i .t-

\

.,i;

. i I

rtl

i

"

;rl\i

\ rl .l.tr "

.i

,r1 !:'. f.;'

.

:;

r,

i.iji

'

t"

,L.

'

,' .'

\

,'.

'r'i''

i1

. iir

\.

$i''

'ji.)",

rl'lJt_"

",,]}

m e stic

lfrainer fuf-rig er at or

Jept. of lr4echanical Engg.- NIT Raipur

TE,CH.EI)

CALCULATIONS:

F

COPtr,

Theoretical COP

h1 -h4

h2 From t34a charl,

h1

-hI

: :

Enthalpy inkJ/kg coffesponding to pressure P1 & temperature T1

(Vapour Phase)

h3

Enthaipy in kJ/kg corresponding to pressure P2 &. temperature T3

But, h3

h4

h2:Enthalpy in kJ/kg corresponding to pressure P2& temperature T2

coP.ornot

Tl_

T2-T1

Temperature of refrigerarrt" @

T1 T2

: :

inlet of compressor in degree K

outlet of compressor in degree K

A ome

tir fuf rig erato r'lrain er

,J,. of lt""hanical Engg.- NIT Raipur'

TECI{-ED

COP

(actual)

Compressor inPut

a,

where,

mw

: :

Mass ofwater

....... Lg

Co*

,'-

4.18 KJ/kg dg k

-':\\

Tr:

Final chilled water temP' in dg C

.ia-"

ti

....

.-'

;-

initial water temP in dg C

w:

where,

sx3604txEmc

n: no. of impulse of energY meter t:

time taken Emc

energy meter constant

:3200 imp/kWh

Relative COP

COP

(r.erative)

COP COP

tu.tuun

(theor.itical)

(D ome s

tic frefrig

erat

or'lrain er

Jept. of Mechanical Engg.- NIT Raipur

TECHJED

TABIJLAR COLUMI{

SL

P1

P2

T]

NO

Psi

psi

oc

T2

oc

T3

oc

T4

oc

T5 oc

EM

time

Duration

for

1

irnp

'

D ome stir Ref-rig erator

tiaincr

Вам также может понравиться

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963От EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Оценок пока нет

- RAC Experiments FinalДокумент31 страницаRAC Experiments FinalEr Nikhil KakadeОценок пока нет

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideОт EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideОценок пока нет

- RAC Lab ManualДокумент27 страницRAC Lab ManualKewal SinghОценок пока нет

- Refrigeration and Air Conditioning: Lab ManualДокумент48 страницRefrigeration and Air Conditioning: Lab ManualcaxxvadgvadgfsОценок пока нет

- COP Measurements of RefrigeratorДокумент9 страницCOP Measurements of RefrigeratorGanesh JagatapОценок пока нет

- RacДокумент26 страницRacgurunakhale123Оценок пока нет

- 803 Rac (Me-803) Exp. ManualДокумент47 страниц803 Rac (Me-803) Exp. ManualAnonymous z3RsdPToОценок пока нет

- An Introduction To Thermoelectric CoolersДокумент7 страницAn Introduction To Thermoelectric CoolersDiego HinojosaОценок пока нет

- Manufacturers & Suppliers: Izod and Charpy Apparatus Make "Dinesh" Model DS 102Документ3 страницыManufacturers & Suppliers: Izod and Charpy Apparatus Make "Dinesh" Model DS 102Ashish VermaОценок пока нет

- Test On Vapor Compression Refrigeration FINALДокумент8 страницTest On Vapor Compression Refrigeration FINALUdara ManawaduОценок пока нет

- Ball MillДокумент7 страницBall MillAshish VermaОценок пока нет

- Performance Analysis of Refrigerator Using Water Cooled CondenserДокумент21 страницаPerformance Analysis of Refrigerator Using Water Cooled Condenserjaiminspatel127100% (1)

- Smoke Point Apparatus PDFДокумент14 страницSmoke Point Apparatus PDFRavi ParikhОценок пока нет

- Vapour Compression Refrigeration Test RigДокумент1 страницаVapour Compression Refrigeration Test RigPawan NkОценок пока нет

- Cascade Refrigeration Cycle Test RigДокумент16 страницCascade Refrigeration Cycle Test RigRavi Parikh100% (1)

- Lab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Документ47 страницLab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Getachew TikueОценок пока нет

- L-BOX Apparatus PDFДокумент11 страницL-BOX Apparatus PDFRavi ParikhОценок пока нет

- Technological University (Maubin) Department of Mechanical Engineering Mini One Door RefrigeratorДокумент13 страницTechnological University (Maubin) Department of Mechanical Engineering Mini One Door RefrigeratorLin Yi100% (1)

- 16 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairДокумент22 страницы16 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairPRASAD326100% (4)

- Vapor Absorption SystemsДокумент17 страницVapor Absorption SystemsTalibHussainОценок пока нет

- Rac Lab FileДокумент28 страницRac Lab FileGovind AtwalОценок пока нет

- Practica CДокумент2 страницыPractica CAlejandroCalleRuizОценок пока нет

- Cupping Machine Lab ManualДокумент4 страницыCupping Machine Lab ManualAshish VermaОценок пока нет

- Rac Lab ManualДокумент36 страницRac Lab ManualAftab Alam100% (2)

- Design and Fabrication of Thermoelectric Refrigerator: Project Study 1Документ43 страницыDesign and Fabrication of Thermoelectric Refrigerator: Project Study 1Antonette Datoon100% (1)

- Supersonic Flow Over A Double Circular AirfoilДокумент33 страницыSupersonic Flow Over A Double Circular AirfoilDragomirescu Andrei100% (1)

- Projeect PPT-1Документ28 страницProjeect PPT-1Shubham PawarОценок пока нет

- Lab 2Документ14 страницLab 2Dilshad S FaisalОценок пока нет

- Cam AnalysisДокумент7 страницCam AnalysisSandeep Saini100% (1)

- 4.expansion DevicesДокумент18 страниц4.expansion DevicesAbdullahОценок пока нет

- Fluidization Bed Column Lab ManualДокумент10 страницFluidization Bed Column Lab ManualAshish VermaОценок пока нет

- Magnetic Stirrer Lab ManualДокумент3 страницыMagnetic Stirrer Lab ManualAshish VermaОценок пока нет

- Thermal Conductivity of Metal RodДокумент5 страницThermal Conductivity of Metal RodRam NiwasОценок пока нет

- Air-Conditioning Test RigДокумент10 страницAir-Conditioning Test RigPankaj Thombare100% (1)

- Study of Various Electric Control Devices Used in Refrigeration System.Документ3 страницыStudy of Various Electric Control Devices Used in Refrigeration System.MohdQasim100% (1)

- Study of Vapour Absorption RefrigeratorДокумент5 страницStudy of Vapour Absorption RefrigeratorMohdQasimОценок пока нет

- Thermoelectric CoolingДокумент5 страницThermoelectric CoolingDraganОценок пока нет

- Heat Engine-GTU-Sem-1Документ78 страницHeat Engine-GTU-Sem-1Khushank MОценок пока нет

- Reciprocating - Pump - Lab Manual Ms WordДокумент10 страницReciprocating - Pump - Lab Manual Ms WordSandeep SainiОценок пока нет

- Thin Cylinder Lab ManualДокумент5 страницThin Cylinder Lab ManualAshish VermaОценок пока нет

- Introduction of REfrigeratorДокумент45 страницIntroduction of REfrigeratorSantosh Ojha100% (2)

- Refrigeration With Hot and Cooled BoxДокумент69 страницRefrigeration With Hot and Cooled Boxkris_soneОценок пока нет

- Experiment No 7 Pin Fin ApparatusДокумент5 страницExperiment No 7 Pin Fin Apparatusgaur123450% (2)

- Objectives:: Project ReportДокумент4 страницыObjectives:: Project ReportOxmere SalesОценок пока нет

- A262149 P Thermoelectric Cooler Design THESISДокумент79 страницA262149 P Thermoelectric Cooler Design THESISCipta Andri Jhona SinurayaОценок пока нет

- REMF-193 Design and Fabrication of Mini Refrigerator and HeaterДокумент4 страницыREMF-193 Design and Fabrication of Mini Refrigerator and HeaterretechОценок пока нет

- Forced Convection ApparatusДокумент3 страницыForced Convection ApparatusAshish VermaОценок пока нет

- CondenserДокумент12 страницCondenserPrabir Kumar Pati100% (1)

- Effect of Capillary Tube Length On The Vcrs Performance: Experiment No. (1) Mechanical LabДокумент15 страницEffect of Capillary Tube Length On The Vcrs Performance: Experiment No. (1) Mechanical LabDilshad S FaisalОценок пока нет

- MECH3429Air Conditioning and Refrigeration Engineering3Документ84 страницыMECH3429Air Conditioning and Refrigeration Engineering3Umair Khan MarwatОценок пока нет

- Unit 35 Comfort and PsychrometricsДокумент15 страницUnit 35 Comfort and Psychrometricsdavidfr2100% (1)

- Heat Pump and RefrigertorДокумент10 страницHeat Pump and RefrigertordohlalaОценок пока нет

- Internal Heat ExchangerДокумент39 страницInternal Heat ExchangerNeal Christian ParatoОценок пока нет

- ASCДокумент22 страницыASCDeepak MahaleОценок пока нет

- Final Project ReportДокумент20 страницFinal Project ReportNimisha Srivastava0% (1)

- Rac Lab ManualДокумент69 страницRac Lab ManualHrshita SinghОценок пока нет

- 11 AirconditioningДокумент19 страниц11 AirconditioningRohit AgrawalОценок пока нет

- Report Refrigeration SystemsДокумент22 страницыReport Refrigeration SystemsAhmed SalmanОценок пока нет

- Vapor Compression Refrigeration Test Rig Lab Manual LatestДокумент12 страницVapor Compression Refrigeration Test Rig Lab Manual LatestAshish VermaОценок пока нет

- ECS April May 2013Документ2 страницыECS April May 2013Shashi Bhushan PatelОценок пока нет

- Psychrometric Chart From M.l.mathurДокумент1 страницаPsychrometric Chart From M.l.mathurShashi Bhushan PatelОценок пока нет

- Refrigeration and Air Conditioning-IIT Kharagpur NotesДокумент803 страницыRefrigeration and Air Conditioning-IIT Kharagpur Notessangeethsreeni87% (30)

- RAC April-May 2013 PDFДокумент3 страницыRAC April-May 2013 PDFShashi Bhushan PatelОценок пока нет

- PM April-May 2013 PDFДокумент2 страницыPM April-May 2013 PDFShashi Bhushan PatelОценок пока нет

- PM April May 2010 To 2012Документ6 страницPM April May 2010 To 2012Shashi Bhushan PatelОценок пока нет

- RAC Experimental Water Cooler Storage TypeДокумент7 страницRAC Experimental Water Cooler Storage TypeShashi Bhushan PatelОценок пока нет

- CAD Nov-Dec 2012Документ4 страницыCAD Nov-Dec 2012Shashi Bhushan PatelОценок пока нет

- Direct Kinematics of Robotic ManipulatorДокумент6 страницDirect Kinematics of Robotic ManipulatorShashi Bhushan PatelОценок пока нет

- RAC April May 2010 To 2012Документ11 страницRAC April May 2010 To 2012Shashi Bhushan PatelОценок пока нет

- 7TH Semester SyllabusДокумент9 страниц7TH Semester SyllabusShashi Bhushan PatelОценок пока нет

- Heat Transfer by Forced ConvectionДокумент7 страницHeat Transfer by Forced ConvectionShashi Bhushan PatelОценок пока нет

- Mathes 3 NotesДокумент127 страницMathes 3 NotesShashi Bhushan PatelОценок пока нет

- OR 7th Sem NIT Raipur QPaperДокумент37 страницOR 7th Sem NIT Raipur QPaperShashi Bhushan PatelОценок пока нет

- HMT 7th Sem NIT Raipur QPaperДокумент28 страницHMT 7th Sem NIT Raipur QPaperShashi Bhushan PatelОценок пока нет

- FEM 7th Sem NIT Raipur QPaperДокумент22 страницыFEM 7th Sem NIT Raipur QPaperShashi Bhushan PatelОценок пока нет

- Automobile 7th Sem NIT Raipur QPaperДокумент16 страницAutomobile 7th Sem NIT Raipur QPaperShashi Bhushan PatelОценок пока нет

- Project (Exergy Analysis of Steam Power Plant)Документ76 страницProject (Exergy Analysis of Steam Power Plant)Shashi Bhushan Patel88% (8)

- BT2 FserДокумент5 страницBT2 FserShiella Rose VitalisОценок пока нет

- Unit 2 Pressure and Its Measurement 10CV35Документ34 страницыUnit 2 Pressure and Its Measurement 10CV35p6a4nduОценок пока нет

- Thermodynamics 1.EE 2A Stem Midterms. LM 1Документ11 страницThermodynamics 1.EE 2A Stem Midterms. LM 1mery9jean9lasamОценок пока нет

- Chemical Bonding Test ReviewДокумент5 страницChemical Bonding Test ReviewAlakh Jagtap100% (1)

- Sep Lab Exp 1 LatestДокумент20 страницSep Lab Exp 1 LatestChan Chun ChenОценок пока нет

- Calculation Key Gas Use ExcelДокумент5 страницCalculation Key Gas Use Excelfata_ridhwanaОценок пока нет

- U1L1Документ19 страницU1L1tegnap16 tegnap1316Оценок пока нет

- Characterization of A Black ...Документ78 страницCharacterization of A Black ...Watcher InstanceОценок пока нет

- Pressure Changes Gas LawsДокумент6 страницPressure Changes Gas LawstyytrdgОценок пока нет

- Fluid Flow Lab: Experiment 4Документ13 страницFluid Flow Lab: Experiment 4shubhamОценок пока нет

- Steam Design For CoilsДокумент10 страницSteam Design For CoilsstefanosОценок пока нет

- Powder Production Techniques: AtomizationДокумент13 страницPowder Production Techniques: AtomizationVasantha SudasinghaОценок пока нет

- Sihi CehaДокумент20 страницSihi CehaAlexander Rivillas100% (1)

- Choose The Letter of The Correct Answer. Write Your Answer in Your Answer SheetsДокумент2 страницыChoose The Letter of The Correct Answer. Write Your Answer in Your Answer SheetsKIMОценок пока нет

- Wetted Wall Column Experiment and Set UPДокумент4 страницыWetted Wall Column Experiment and Set UPvarun kumarОценок пока нет

- Assignment 3 Inorganic FinalДокумент5 страницAssignment 3 Inorganic FinalTaimoor Hassan KhanОценок пока нет

- PumpsДокумент12 страницPumpsJade Carlo AntonioОценок пока нет

- Compressor - NJ2212GJ (LBP) - DatasheetДокумент5 страницCompressor - NJ2212GJ (LBP) - DatasheetSamuel OsmagОценок пока нет

- Leakage Testing of Sealed Sources PDFДокумент1 страницаLeakage Testing of Sealed Sources PDFZenghu HanОценок пока нет

- Csec Chemistry Notes 1Документ2 страницыCsec Chemistry Notes 1debestie100% (3)

- Gujarat Technological UniversityДокумент2 страницыGujarat Technological UniversityShivam PanchalОценок пока нет

- 3rd - Sem-Ct-23-Chemical EngineeringДокумент3 страницы3rd - Sem-Ct-23-Chemical EngineeringJay RanjanОценок пока нет

- Week 5 - Describing A Process PDFДокумент9 страницWeek 5 - Describing A Process PDFDhea Kirana FaihaОценок пока нет

- Feed Water Tanks PDFДокумент4 страницыFeed Water Tanks PDFAleksei SukhovОценок пока нет

- AMACS Multipocket Vane WebДокумент1 страницаAMACS Multipocket Vane WebadrianioantomaОценок пока нет

- Ideal Gas LawДокумент1 страницаIdeal Gas LawLarry BugaringОценок пока нет

- Science 10 q4 Week 1Документ11 страницScience 10 q4 Week 1Jacqueline FabiaОценок пока нет

- Week 3 Lectures - Differential AnalysisДокумент19 страницWeek 3 Lectures - Differential AnalysisboogolamОценок пока нет

- Models - Heat.potato Drying PDFДокумент26 страницModels - Heat.potato Drying PDFsaleigzer abayОценок пока нет

- ECE224 LEC MODULE Week 1 8 ICEДокумент73 страницыECE224 LEC MODULE Week 1 8 ICEGreen zolarОценок пока нет

- EHB en 7-Sizing PDFДокумент83 страницыEHB en 7-Sizing PDFChristopher Kenneth ChoaОценок пока нет