Академический Документы

Профессиональный Документы

Культура Документы

APEM4-3 139-150 NoRestriction

Загружено:

Jasdeep SinghОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

APEM4-3 139-150 NoRestriction

Загружено:

Jasdeep SinghАвторское право:

Доступные форматы

Advances in Production Engineering & Management 4 (2009) 3, 139-150 ISSN 1854-6250 Scientific paper

MULTI OBJECTIVE SCHEDULING OF JOBS, AGVs AND AS/RS IN FMS USING ARTIFICIAL IMMUNE SYSTEM

Gnanavelbabu, A.; Jerald, J.; Noorul Haq, A. & Asokan, P.

Department of Production Engineering National Institute of Technology, Tiruchirapalli 620015, INDIA. Email: anhaq@nitt.edu Abstract: The success of any FMS lies in the design of an appropriate scheduling procedure to optimize the required performance measures of the manufacturing systems. This article addresses the problem of simultaneous scheduling of jobs, Automated Storage and Retrieval Systems (AS/RS) and two identical Automated Guided Vehicles (AGVs) in a Flexible Manufacturing System (FMS). It deals scheduling with multiple and competing objectives of FMS and optimized by employing a non-traditional optimization technique called Artificial Immune System (AIS) to generate optimal schedules. The problem considered here is a large variety problem (16 machines and 43 parts) and the multiple objectives considered are minimizing penalty cost, minimizing machine idle time and minimizing the distance travelled by the Storage/ Retrieval (S/R) machine. To prove the performance of proposed algorithm a series of computational experiments are done and a good results are obtained. Keywords: FMS Scheduling, Multi objective function, Artificial Immune System

1. INTRODUCTION

Flexible Manufacturing System (FMS) is a highly sophisticated manufacturing system to meet customers requirements. The FMS fills up the gap between the traditional job shops and highly automated transfer lines. This kind of system is very useful to achieve high productivity and flexibility. The problems in FMS are generally classified into Design, Planning, Scheduling and Control. This work is primarily concerned with the scheduling problems of FMS. In FMS scheduling, the sub-systems like material handling systems, storage and retrieval system, etc. should be considered and also decisions should be taken when the system is in operation. In scheduling problems of FMS, the jobs that are going to various Computer Numerical Control (CNC) machines, Automated Guided Vehicles (AGVs) and Automated Storage and Retrieval System (AS/RS) are scheduled simultaneously. The non-traditional optimization techniques have been also employed for various engineering application problems due to their robustness and convergence to global optima. Sridhar and Rajendran [1] applied GA to part family grouping and parts scheduling within the part families in a flow line based manufacturing cell with the objectives of minimizing the makespan and total flow time had been jointly considered. Gunduz Ulusoy et al [2] implemented GA algorithm for simultaneous scheduling of machines and AGVs in an FMS consisting of several machining centers and one or more identical AGVs. The objective was minimization of makespan. Taghaboni and Tanchoco [3] dealt the routing techniques of AGVs. Jawahar et al [4] linked the operation of the AS/RS with the production schedule and used GA to improve the performance of the AS/RS operation by allocating the materials with minimum movement of the shuttle. Ponnambalam et al [5] proposed a multi-objective evolutionary search algorithm using a travelling salesman algorithm and genetic algorithm for flow-shop scheduling. The proposed algorithm used a weighted sum of multiple objectives that included minimization of makespan, mean flow time and machine idle time. Kim et al [6] proposed an integrated approach of inductive and competitive neutral methods for developing a multi-objective FMS

139

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

schedules. Engin and Alper Doyen [7] introduced a new approach to solve hybrid flow shop scheduling problems by artificial immune system for the future generation computer systems and the AIS algorithm is already used in different applications namely computer and network security [8, 9], fault and anomaly detection [10, 11], optimization [12, 13], data analysis and data mining [14, 15] and flow shop scheduling where AIS produced better results.

2. PROBLEM DESCRIPTION

The problem environment and assumptions [16] of the present work deals with multiple objective functions for Jobs, AGVs and AS/RS are detailed as follows: (i) The FMS considered in this paper has the configuration as shown in Figure 1.

Figure 1: Configuration of the FMS. There are five Flexible Machining Cells (FMCs) each having two to six Computer Numerical Control machines (CNCs) each with an independent and self sufficient tool magazine and one Automatic Tool Changer (ATC) and one Automatic Pallet Changer (APC). Each cell is supported by one to three dedicated robots, for the intra-cell movement of materials between operations. There is a loading station from where the parts are released in batches for manufacturing in the FMS. There is an unloading station from where the finished parts are collected and conveyed to the finished storage. There is one Automatic Storage and Retrieval System (AS/RS) to store the work in progress. The five FMCs are connected by two identical Automated Guided Vehicles (AGV). These AGVs perform the inter cell movements between the FMCs and the movement of loaded pallets from the loading station to any of the FMCs and the movement of finished product from any of the FMCs to the unloading station and the movement of semi finished products between the AS/RS and the FMCs. There is a dedicated robot for loading and unloading AGVs.

140

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

(ii) The assumptions made in this work are: - The FMS operation caters to a pure job shop environment handling 40 to 50 varieties of products with a particular combination of tools in the tool magazines. The machine cells and part families, as shown in the Table I, are optimum with respect to minimum handling and backtracking. FMC No. 5 is a remainder cell catering for all the possible exceptional elements in the machine-part incident matrix. The heuristic developed for the fractional cell formation [17] is employed to obtain this cell-part family configuration. Table I: Part families and machine cells configuration. FMC number 1 2 3 4 5 Machine numbers 7,10 4,15 1,11,12,13 3,14 2,5,6,8,9,16 Part family (Jobs) (1,8,10,12,13,25,26,31,38,39,42) (4,5,14,15,18,19,21,23,29,33,41) (3,9,11,16,20,22,24,27,30,37,43) (2,6,7,17,28,32,34,35,36,40) FMC 5 is a remainder cell

Each type/variety has a particular processing sequence, batch size, due date and penalty cost for not meeting the due date. The processing sequence is based on the optimum route with respect to minimum manufacturing lead-time. Each processing step has a processing time on a specific machine. There is no constraint on the availability of pallets, fixtures, AGVs, robots, AS/RS etc.

A random product-mix generated is shown in the Table II. (iii) In the real time environment it becomes imperative to optimize concurrently several incommensurable and competing objectives. The business environment usually drives operational executives in prioritizing the objectives and the priorities often change. These objectives are set ultimately to improve the overall productivity and the efficiency of the system. However the primary objective remains to maximize the utilization of the capital-intensive system. With the emerging trends towards customer orientation in the world of global market the system cannot afford to ignore objectives that have a direct relation to customer satisfaction. This is also considered as one of the objectives. The minimum movement of Storage/Retrieval (S/R) machine also considered as another objective.

141

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

Table II: Product mix with due date and penalty cost. Job no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 Processing Sequence (Machine No. & processing time in mins.) {6,1},{7,1},{8,1},{10,2} {2,1},{6,1},{8,1},{9,2},{14,4},{16,2) {8,1},{11,3},{13,4} {9,4} {4,5},{5,3},{15,4} {6,5},{14,1} {3,5},{6,3},{16,5} {5,4},{6,5},{8,1} {4,1},{5,5},{8,1},{11,1} {2,2},{9,1},{16,4} {8,4},{12,2} {6,2},{8,4},{10,1} {6,1},{7,5},{10,4} {4,2},{5,3},{6,2},{15,2} {5,4},{8,3} {5,3} {3,1},{6,4},{14,1} {9,2},{16,3} {4,1},{5,5},{6,2},{8,2},{15.5} {8,2},{11,4} {4,5},{5,5},{6,2},{8,2},{15,5} {12,5} {4.2},{5,1},{6,5},{8,4} {8,4},{11,4},{12,5},{13,4} {7,3},{10,2} {10,2} {8,5},{11,5},{12,4} {2,1},{8,1},{9,2} {4,1},{5,5} {11,3},{12,5} {8,2},{10,2} {2,3},{6,4},{9,3} {5,4},{6,5},{15,3} {3,2},{6,2} {3,4},{14,1} {3,2} {1,5},{2,2},{6,3},{8,3},{9,2},{16,4} {2,4},{8,3},{9,2},{16,5} {6,5},{10,5} {2,2},{6,4},{9,4} {5,1},{8,2},{15,1} {2,5},{6,4},{9,3}{16,1} {1,3},{5,2},{6,2},{8,2},{15,3} Due date (days) 17 17 14 26 11 16 26 26 1 20 1 19 25 22 15 27 20 24 5 11 16 24 14 7 24 27 22 3 7 18 2 15 27 12 9 20 22 8 9 7 22 19 15 Batch size (No.) 150 200 800 700 150 700 250 850 100 150 250 1000 700 1000 700 750 650 250 450 50 850 200 50 200 350 450 400 950 700 1000 800 800 500 300 900 700 250 50 500 250 800 400 550 Penalty cost (Rs./units/day) 1.00 1.00 1.00 2.00 1.00 1.00 2.00 2.00 0.00 2.00 1.00 3.00 4.00 4.00 5.00 3.00 4.00 5.00 1.00 5.00 3.00 5.00 4.00 5.00 1.00 0.00 1.00 5.00 1.00 1.00 2.00 1.00 4.00 4.00 2.00 2.00 4.00 1.00 1.00 5.00 4.00 2.00 3.00

142

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

(iv) The structure of the AS/RS considered in this work is shown in Figure 2.

Figure 2: AS/RS structure. The storage structure considered is rectangular with m rows and n columns. Each cell is capable of holding one item of any type. The centre distance between any two adjacent cells in a row is Xr and in a column is Xc. The numbers given inside the cell indicate the address of the storage location. There is one shuttle of the crane type, which is capable of moving vertically and horizontally. The Pickup and Deposit (P&D) station is at the lower left hand corner of the aisle. In this AS/RS, Storage and Retrieval (S/R) machine movement is a major decision parameter for its operation and control. The distance travelled by the S/R machine, when it moves from address a to b to complete one activity, is calculated by the following two steps: Step1: Identification of row and column number: A simple algebraic equation can be used to ascertain the row and column numbers of the attributed address of the storage location. For example A is the address of the storage location and its algebraic equation takes the form: A = quotient * divider + remainder where divider is equal to number of columns n, then: Column number Ac = [reminder if reminder 0 reminder+1, if reminder = 0] Row number Ar = [quotient+1 quotient, if reminder 0 if reminder = 0] (2) (3) (1)

Step2: Distance calculation for the movement from a to b. As per the AS/RS structure shown in Figure 2, the distance between two storage locations a and b can be calculated using general formula: Distance = P + Xr * (mod (ar -br)) + Xc * (mod (ac -bc)) (4) Where P Distance from P&D station to First storage cell.

143

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

Xr & Xc Centre distance between two adjacent cells in a row & column respectively, ar, br - Distance between the locations a and b row wise ac, bc - Distance between the locations a and b column wise 2.1 Combined Objective Function (COF) The objective function can be defined mathematically as follows: (5) Minimize COF = W1 (Xp MPP) + W2 (Xq TE) + W3 (Xt MPD) Where, Xp = Total penalty cost incurred Xp= (CTiDDi) UPCiBSi i i = Job number Xt = Total distance traveled by S/R machine CTi = Completion Time of job i DDi = Due Date for job i UPCi = Unit Penalty Cost for job i BSi = Batch Size of job i MPP = Maximum Permissible Penalty MPD = Maximum Permissible Distance traveled by S/R machine W1 = Weightage factor for Customer satisfaction = 0.4 W2 = Weightage factor for Machine Utilization = 0.3 W3 = Weightage factor for AS/RS Utilization = 0.3 Xq = Total Machine Down Time Xq = MDj j = Machine number: j MDj = TE PTji (6) i TE = Total Elapsed Time PTji = Processing Time of ith job with jth machine: Makespan by considering AGVs time = {(Actual machine time of job + Distance travelled by AGV[i] / Speed AGV[i])} (7) i = 1 and 2 In this work, weightages are given as W1= 0.4, W2= 0.3 and W3 = 0.3. However different ratios can be applied to them according to the demand of business situation. Assumptions: (i) After completion of single job every AGV must come to START position. (ii) Distance between two machine cells is taken as 6 meters. (iii) Speed of each AGV is considered as 100 m/min.

3. ARTIFICIAL IMMUNE SYSTEM (AIS)

The operative mechanisms of immune system are very efficient from a computational standpoint [8]. Table III represents the comparison between the immune system and immune algorithm.

144

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

Table III: Comparison between the immune system and immune algorithm.

Immune System Antigen Antibody Recognition of antigen Production of antibody from memory cells

Immune Algorithm Problem to be solved Best solution vector Identification of the problem Recalling a past successful solution Maintenance of good solutions (memory) Elimination of surplus candidate solutions

Lymphocyte differentiation

T-cell suppression

AIS were built on the two principles of the immune system namely clonal selection principle and Affinity maturation principle. 3.1 Cloning selection principle The clone selection principle, or theory, is the algorithm used by the immune system to describe the basis features of an immune response to an antigenic stimulus, as shown in Figure 3. Each schedule has a makespan value that refers to the affinity value of that antibody. Affinity value of each schedule is calculated from the affinity function. The affinity function is defined as: Affinity (p) = 1/makespan (8) From this relation, lower makespan value gives higher affinity value. Further the cloning of antibodies is done directly proportional to their affinity function values. Therefore, there will be more clones of antibodies that have lower makespan values than those of with higher makespan values in the new generated clone population. Costa et al [18] implemented an immune-based approach to minimize the makespan on parallel processors. An affinity function is defined based on makespan values of the schedules [19].

145

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

Figure 3: Clonal selection principle. 3.2 Affinity maturation principle It consists of two methods namely Mutation and Receptor editing. Mutation: A two phased mutation procedure were used for the generated clones [20]. a) Inverse Mutation b) Pair wise Interchange Mutation Inverse mutation: For a sequence s, let i and j be randomly selected two positions in the sequences. A neighbour of s is obtained by inversing the sequence of jobs between i and j positions. If the makespan value of the mutated sequence is smaller than that of the original sequence then the mutated one is stored in the place of the original one. Otherwise, the sequence will be mutated again with random pair wise interchange mutation. Pair wise interchange mutation: Given a sequence s, let i and j be randomly selected two positions in the sequence s. A neighbour of s is obtained by interchanging the jobs in positions i and j. If the makespan value of the mutated sequence is smaller than that of the original sequence, then store the mutated one in the place of the original one. In the case where the algorithm could not find a better sequence after the two-mutation procedure, then it stores the original sequence. Receptor editing: After cloning and mutation processes, a percentage of the antibodies in the antibody population are eliminated and randomly created antibodies are replaced with them. This mechanism allows finding new schedules that correspond to new search regions in the total search space [21]. Figure 4 presents the flow chart for the proposed Artificial Immune System.

146

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

3.3 Flow Chart for the Proposed AIS Algorithm Generate a set of P antibodies

Calculate Affinity Function Clone the set of sequences

Inverse mutation process

YES

Clone=new sequence

New Seq. COF < Clone COF

NO

Pair wise Interchange Mutation

YES

Clone=new sequence

Mutated New Seq. COF < Clone COF

NO

Clone=Clone, Antibody=Clone

New Sequence after Cloning and Mutation

Receptor Editing Process

New Sequence for next iteration

Figure 4: Flow chart for the proposed Artificial Immune System algorithm.

4. IMPLEMENTATION OF ARTIFICIAL IMMUNE SYSTEM (AIS) ALGORITHM

The artificial immune system algorithm is implemented for optimizing the sequences of parts into the machines, the AGVs sequence and the AS/RS sequence for the problem.

147

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

4.1 Generating Random Sequence First initial populations of ten random sequences are generated and their respective Combined Objective Function (COF) values are calculated. Example for random sequences from initial population # 1 15 28 43 18 41 21 30 20 12 16 17 1 4 42 26 35 8 36 10 7 27 38 31 6 34 32 25 9 5 2 29 3 40 33 23 37 13 19 11 14 24 39 22 COF = 0.22839648 40 42 3 35 7 31 37 21 1 12 13 16 28 33 10 14 19 24 5 26 15 6 43 41 18 32 34 30 11 17 8 36 39 22 4 9 27 20 25 2 23 38 29 COF = 0.2314272 4.2 Cloning the Sequences An average of the COF is taken from the generated population and the affinity values are checked with the average, if the values of the affinities are greater than average values of COF of the population generated, then a clone is generated. A clone is nothing but a copy of the sequence. Here the sequences 1 and 2 were chosen because the COF values are lesser than the average values. 4.3 Mutation A two phased mutation procedure is used for the generated clones. Two mutations namely Inverse Mutation and Pair-wise interchange mutations are carried out and the sequences corresponding to a lower COF than the original is chosen else the original sequence and its COF value is retained. Example for Inverse mutation: Inverse mutation i=4 j=42 Original Sequence 15 28 43 18 41 21 30 20 12 16 17 1 4 42 26 35 8 36 10 7 27 38 31 6 34 32 25 9 5 2 29 3 40 33 23 37 13 19 11 14 24 39 22 COF = 0.22839648 15 28 43 18 24 14 11 19 13 37 23 33 40 3 29 2 5 9 25 32 34 6 31 38 27 7 10 36 8 35 26 42 4 1 17 16 12 20 30 21 41 39 22 COF = 0.2404571 Example for Pair wise mutation: Pair wise mutation i=4 j=26 Original Sequence 15 28 43 18 41 21 30 20 12 16 17 1 4 42 26 35 8 36 10 7 27 38 31 6 34 32 25 9 5 2 29 3 40 33 23 37 13 19 11 14 24 39 22 COF = 0.22839648 15 28 43 32 41 21 30 20 12 16 17 1 4 42 26 35 8 36 10 7 27 38 31 6 34 18 25 9 5 2 29 3 40 33 23 37 13 19 11 14 24 39 22 COF = 0.23442212

5. RESULTS AND DISCUSSION

The proper allocation of the subsystems in the FMS is important to achieve higher efficiency and productivity. Scheduling of FMS is not meant without considering the important subsystems such as AGVs and AS/RS. In this context, jobs, AGVs and AS/RS in the FMS have been scheduled simultaneously. The designed scheduling procedure with Artificial Immune System is developed in the JAVA language to conduct experiments. The results obtained through AIS are tabulated in Table IV. The graphs representing iterations Vs COF values for scheduling of parts, AGVs and AS/RS problem obtained by the implementation of AIS is presented in Figure 5. The graph is drawn choosing the weightage values as W1=0.4, W2 = 0.3 and W3 = 0.3.

148

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

Table IV: Comparison of Results for Scheduling of Parts with AGVs and AS/RS. Method Parts Sequence AGVs Sequence AS/RS Sequence 43 48 31 45 26 14 28 32 2 21 25 29 16 33 1 34 6 42 7 47 23 5 40 13 41 8 0.3063 11 22 36 18 35 10 17 44 49 46 38 15 27 9 39 37 19 COF

26 25 10 18 31 28 23 16 22 1 2 1 2 2 1 2 1 2 2 30 9 34 20 38 13 2 37 40 5 1 2 1 2 2 2 1 2 1 AIS 41 36 24 17 3 19 7 35 11 43 2 1 1 2 2 1 1 1 1 4 27 39 21 42 15 12 14 33 32 1 1 1 2 1 1 1 2 1 8 29 6 2212212

Iteration Vs C.O.F of AIS for values W1=0.4, W2=0.3 & W3=0.3

0.45 0.4 0.35 0.3

C.O.F

0.25 0.2 0.15 0.1 0.05 0 0 200 400 600 800 1000 1200 1400 1600 1800 2000

No. of Iterations

Figure 5: Iterations Vs COF Values Using Artificial Immune System.

6. CONCLUSION

To attain higher flexibility and productivity in the FMS, the subsystems in the FMS such as AGVs and AS/RS should be considered for the scheduling. In this context, this problem considers AGVs scheduling and AS/RS scheduling linked with jobs scheduling. This type of problem has been rarely dealt by researchers and is considered in this work. For the simultaneous scheduling of parts, AGVs and AS/ RS in this FMS, the schedules for jobs, AGVs and AS/RS storage assignments are obtained simultaneously for the minimum COF value by the devised procedure using AIS. Hence this type of approach can be used for various objectives and various FMS configurations also. The AIS parameters can be varied and the weightages given to the objectives can also be varied in future work.

149

Gnanavelbabu, Jerald, Noorul Haq & Asokan: Multi Objective Scheduling of Jobs, AGVs and AS/RS

REFERENCES

[1] Sridhar, J.; Rajendran, C. (1994), A genetic Algorithm for family and job scheduling in a flow line based manufacturing cell, Proceedings of 16th International Conference on Computers & Industrial Engineering, 337-340 Gunduz Ulusoy; Funda Sivrikaya; Umit Bilge. (1997). A genetic algorithm approach to the simultaneous scheduling of machines and automated guided vehicles, Computers and Operations Research, Vol. 24, No.4, 335-351 Taghaboni, F.; Tanchoco, J M A. (1995). Comparison of dynamic routing techniques for automated guided vehicle systems, International Journal of Production Research, Vol. 33, 2653-2669 Jawahar, N. P.; Aravindan, P.; Ponnambalam, S G. (1998). Optimal random storage allocation for an AS/RS in an FMS, International Journal of Advanced Manufacturing Technology, Vol. 14, 116-132 Ponnambalam, S.G.; Jagannathan, H.; Kataria, M.; Gadicherla, A. (2004). A TSP-GA multiobjective algorithm for flow-shop scheduling, International Journal of Advanced Manufacturing Technology, Vol. 23, 909915 Kim, C O.; Min, H S.; Yih, Y. (1998). Integration of inductive learning and neural networks for multi-objective FMS scheduling, International Journal of Production Research, Vol. 36, No 9, 2497-2509 Engin, O.; Alper Doyen.(2004). A new approach to solve hybrid flow shop scheduling problems by artificial immune system, Future Generation Computer Systems, Vol. 20, 10831095 Forrest, S.; Perelson, L.; Allen, R.; Cherukuri. (1994). Self-nonself discrimination in a computer, in: Proceedings of the IEEE Symposium on Research in Security and Privacy, IEEE Computer Society Press, Los Alamitos, CA, 202212 Forrest, S.; Hoffmeyr, S.A. (2000). Engineering an immune system, Graft Vol. 4, No.5, 59 Dasgupta, D.; Forrest, S. (1996). Novelty detection in time series data using ideas from immunology, in: Proceedings of the ISCA96, Reno, Nevada, 1921 Dasgupta, D.; Forrest, S. (1999). Artificial immune systems in industrial applications, Proceedings of the Second International Conference on Intelligent Processing and Manufacturing Materials (IPMM), Honolulu, 1015 De Castro, L.N.; Von Zuben, F.J. (2000). The clonal selection algorithm with engineering applications, Proceedings of the Workshop on GECCO 2000, Las Vegas, 3637 Trojanowski, K.; Wierzchon, S.T. (2002). Searching for memory in artificial immune system, Proceedings of the 11th International Symposium on Intelligent Information Systems, 36 Nasaroui, O.; Dasgupta, D.; Gonzales, F. (2002). The promise and challenges of artificial immune system based web-usage mining, preliminary results, Proceedings of the Workshop on Web Analytics at Second SIAM International Conference on Data Mining (SDM), Arlington, VA, 1113 Timmis, J.; Neal, M.J. (2000). A resource limited artificial immune system for data analysis, in Research and Development in Intelligent Systems XVII, Proceedings of the ES2000, Cambridge, UK, 1932 Jerald, J.; Asokan, P.; Prabhaharan, G.; Saravanan, R. (2005). Scheduling optimization of flexible manufacturing systems using particle swarm optimization algorithm, International Journal of Advanced Manufacturing Technology, Vol. 25, 964-971 Murthy, V.R.; Srinivasan, G. (1995). Fractional cell formation in group technology, International Journal of Production Research, Vol. 33, No.5, 13231337 Costa, A.M.; Vargas, P.A.; Von Zuben, F.J.; Frana, P.M. (2002). Makespan minimization on parallel processors an immune based approach, Proceedings of the Special Sessions on Artificial Immune Systems, IEEE World Congress on Computational Intelligence, Honolulu, Hawaii, 115123 Zheng, H.; Jingxin Zhang; Saeid Nahavandi. (2004). Learning to detect texture objects by artificial immune approaches, Future Generation Computer Systems, Vol. 20, 11971208. May P.; Mander K.; Timmis J. (2003). Mutation Testing, An Artificial Immune System Approach, Computing Laboratory, University of Kent, Canterbury, Kent, CT2 7NF De Castro, L.N.; Von Zuben, F.J. (1999). Artificial immune systems, Part 1, Basic theory and applications, Technical Report, TR-DCA 01/99

[2] [3]

[4] [5]

[6] [7] [8] [9] [10] [11] [12] [13] [14]

[15] [16]

[17] [18]

[19] [20] [21]

150

Вам также может понравиться

- Why File A Ucc1Документ10 страницWhy File A Ucc1kbarn389100% (4)

- Mixing and Agitation 93851 - 10 AДокумент19 страницMixing and Agitation 93851 - 10 Aakarcz6731Оценок пока нет

- Scheduling Job Shop - A CasestudyДокумент8 страницScheduling Job Shop - A Casestudyabbas6063Оценок пока нет

- Tetra IntroductionДокумент65 страницTetra Introductionuniversidaddistrital100% (2)

- Electric Vehicles PresentationДокумент10 страницElectric Vehicles PresentationVIBHU CHANDRANSH BHANOT100% (1)

- Model-Driven Online Capacity Management for Component-Based Software SystemsОт EverandModel-Driven Online Capacity Management for Component-Based Software SystemsОценок пока нет

- Bo 24437446Документ10 страницBo 24437446Kelvin SudaniОценок пока нет

- A Genetic Algorithm For Scheduling FlexibleДокумент20 страницA Genetic Algorithm For Scheduling FlexibleNikkhil RathnakarОценок пока нет

- AGV Schedule Integrated With Production in FlexibleДокумент13 страницAGV Schedule Integrated With Production in FlexibleitzgayaОценок пока нет

- A Review On Parallel Scheduling of Machines and AGV'S in An FMS EnvironmentДокумент8 страницA Review On Parallel Scheduling of Machines and AGV'S in An FMS EnvironmentInternational Journal of computational Engineering research (IJCER)Оценок пока нет

- 16 ConclusionДокумент5 страниц16 ConclusionshrutiОценок пока нет

- A Genetic Algorithm-Based Scheduler For Setup-Constrained FMCДокумент20 страницA Genetic Algorithm-Based Scheduler For Setup-Constrained FMCNikkhil RathnakarОценок пока нет

- (AS/RS) Are Storage Systems Capable of Providing Random Access To All Stored ItemsДокумент8 страниц(AS/RS) Are Storage Systems Capable of Providing Random Access To All Stored ItemsSrinivasan SridharanОценок пока нет

- The Open Automation and Control Systems Journal: Risk-Based Minimum Cost Flow Model For Agvs Path PlanningДокумент7 страницThe Open Automation and Control Systems Journal: Risk-Based Minimum Cost Flow Model For Agvs Path PlanningHo Van RoiОценок пока нет

- Scheduling of Automated Guided Vehicles in Flexible Manufacturing Systems EnvironmentДокумент53 страницыScheduling of Automated Guided Vehicles in Flexible Manufacturing Systems EnvironmentKristin MackОценок пока нет

- P-ACO Approach To Assignment Problem in FMSS: I. Mahdavi, A. Jazayeri, M. Jahromi, R. Jafari, and H. IranmaneshДокумент8 страницP-ACO Approach To Assignment Problem in FMSS: I. Mahdavi, A. Jazayeri, M. Jahromi, R. Jafari, and H. IranmaneshGovardhan KudumulaОценок пока нет

- How Successfully Does JIT Handle Machine Breakdowns in An Automated Manufacturing System?Документ16 страницHow Successfully Does JIT Handle Machine Breakdowns in An Automated Manufacturing System?Nur Izzati KamrulnizamОценок пока нет

- AGVДокумент32 страницыAGVitzgayaОценок пока нет

- Determining Optimum Number of Kanbans For Workstations in A Kanban-Based Manufacturing Line Using Discrete-Event Simulation: A Case StudyДокумент9 страницDetermining Optimum Number of Kanbans For Workstations in A Kanban-Based Manufacturing Line Using Discrete-Event Simulation: A Case StudyKhalid IdrissiОценок пока нет

- AOR 2014 ObeidDauzere PeresYugmaДокумент14 страницAOR 2014 ObeidDauzere PeresYugmaMohamed LaalouОценок пока нет

- Scheduling of Flexible Manufacturing System Using Genetic AlgorithmДокумент4 страницыScheduling of Flexible Manufacturing System Using Genetic AlgorithmerpublicationОценок пока нет

- A Framework For Capacity Planning and Machine Configuration in Flexible Assembly SystemsДокумент30 страницA Framework For Capacity Planning and Machine Configuration in Flexible Assembly SystemsYan1203100% (1)

- Barenji2017 Article ADynamicMulti-agent-basedSchedДокумент15 страницBarenji2017 Article ADynamicMulti-agent-basedSchedRadhikaОценок пока нет

- Bho Sale 2018Документ8 страницBho Sale 2018Rian PrasetyoОценок пока нет

- Optimization of Scheduling of Automated Guided Vehicles in FMSДокумент20 страницOptimization of Scheduling of Automated Guided Vehicles in FMSitzgayaОценок пока нет

- Dynamic Cellular Manufacturing System (DCMS) : Martin Rheault, Jocelyn R. Drolet, Georges AbdulnourДокумент4 страницыDynamic Cellular Manufacturing System (DCMS) : Martin Rheault, Jocelyn R. Drolet, Georges AbdulnourabdstarОценок пока нет

- Fms With ArenaДокумент6 страницFms With ArenaitzgayaОценок пока нет

- Application of Fuzzy Inference Systems and Genetic Algorithms in Integrated Process Planning and SchedulingДокумент17 страницApplication of Fuzzy Inference Systems and Genetic Algorithms in Integrated Process Planning and SchedulingIndah FitrianiОценок пока нет

- Operations Scheduling For An Advanced Flexible Manufacturing System With Multi-Fixturing PalletsДокумент8 страницOperations Scheduling For An Advanced Flexible Manufacturing System With Multi-Fixturing PalletsEduardo Jiménez ChavesОценок пока нет

- Modified Immune Algorithm For Job Selection and Operation Allocation Problem in Exible Manufacturing SystemsДокумент14 страницModified Immune Algorithm For Job Selection and Operation Allocation Problem in Exible Manufacturing Systemsmv_raha001Оценок пока нет

- A N Integrated Analytical/Simulation Approach Economic Design of A N Agv SystemДокумент14 страницA N Integrated Analytical/Simulation Approach Economic Design of A N Agv SystemHarish ShanmuganathanОценок пока нет

- Minimising Makespan in Job-Shops With Deterministic Machine Availability ConstraintsДокумент14 страницMinimising Makespan in Job-Shops With Deterministic Machine Availability Constraintsjuan ardilaОценок пока нет

- 16IJMPERDJUN201916Документ15 страниц16IJMPERDJUN201916TJPRC PublicationsОценок пока нет

- Journal of Advanced Mechanical Design, Systems, and ManufacturingДокумент16 страницJournal of Advanced Mechanical Design, Systems, and ManufacturingAmrik SinghОценок пока нет

- An Uncertain Programming Model For Preventive Maintenance SchedulingДокумент12 страницAn Uncertain Programming Model For Preventive Maintenance Schedulingnovendi eko nugrohoОценок пока нет

- MADO - Software Package For High Order Multidisciplinary Aircraft Design and OptimizationДокумент10 страницMADO - Software Package For High Order Multidisciplinary Aircraft Design and OptimizationmegustalazorraОценок пока нет

- +shafia Automation StrategiesДокумент15 страниц+shafia Automation StrategiesakhlaghyaliОценок пока нет

- Computers and Operations Research: Chunlong Yu, Quirico Semeraro, Andrea MattaДокумент19 страницComputers and Operations Research: Chunlong Yu, Quirico Semeraro, Andrea MattaOlivia brianneОценок пока нет

- A Gravitational Search Based On The Optimization of Job Shop Scheduling ProblemДокумент14 страницA Gravitational Search Based On The Optimization of Job Shop Scheduling ProblemTJPRC PublicationsОценок пока нет

- C0362015022 PDFДокумент8 страницC0362015022 PDFtheijesОценок пока нет

- Tinaporwal,+08 IJETMR19 A01 626Документ11 страницTinaporwal,+08 IJETMR19 A01 626Maimouna CoulibalyОценок пока нет

- Virtual Cellular Manufacturing Configuring Routing FlexibilityДокумент13 страницVirtual Cellular Manufacturing Configuring Routing FlexibilityDrMohamed MansourОценок пока нет

- The Use of Simulation and Genetic Algorithm With Different Genetic Operators To Optimize Manufacturing SystemДокумент12 страницThe Use of Simulation and Genetic Algorithm With Different Genetic Operators To Optimize Manufacturing SystemSam ArОценок пока нет

- EA For Solving Combined Machine Layout and Job Assignment ProblemsДокумент17 страницEA For Solving Combined Machine Layout and Job Assignment ProblemsShivam BhandariОценок пока нет

- Text18 2 - 366 377 PDFДокумент12 страницText18 2 - 366 377 PDFFajril A. M.Оценок пока нет

- Ga Fuzzy AgileДокумент7 страницGa Fuzzy AgileFemi AyoОценок пока нет

- AnalisBasedSimulation PDFДокумент5 страницAnalisBasedSimulation PDFRieska foni YuniarОценок пока нет

- Fei 2022Документ10 страницFei 2022AlexanderОценок пока нет

- An Operating System Architecture For Organic ComputingДокумент15 страницAn Operating System Architecture For Organic ComputingBill PetrieОценок пока нет

- CPIE-2016 Paper 49Документ10 страницCPIE-2016 Paper 49Atul ChauhanОценок пока нет

- Real-Time Near-Optimal Scheduling With Rolling Horizon For Automatic Manufacturing CellДокумент7 страницReal-Time Near-Optimal Scheduling With Rolling Horizon For Automatic Manufacturing Cell許志華Оценок пока нет

- The Effectiveness of A Vehicle Manufacturing Line Using Probabilistic Process TimingДокумент24 страницыThe Effectiveness of A Vehicle Manufacturing Line Using Probabilistic Process TimingIJRASETPublicationsОценок пока нет

- Yulan2008Multi objectiveIntegratedOptim PDFДокумент11 страницYulan2008Multi objectiveIntegratedOptim PDFJai PandeyОценок пока нет

- Determination of Buffer Size in Single and Multi Row Flexible Manufacturing Systems Through SimulationДокумент11 страницDetermination of Buffer Size in Single and Multi Row Flexible Manufacturing Systems Through SimulationAmrik SinghОценок пока нет

- Castellano. 2021. Metaheuristics For The Flowshop Scheduling Problem With Maintenance Activites IntegratedДокумент26 страницCastellano. 2021. Metaheuristics For The Flowshop Scheduling Problem With Maintenance Activites Integratedmilyhya fgОценок пока нет

- Ijecet: International Journal of Electronics and Communication Engineering & Technology (Ijecet)Документ14 страницIjecet: International Journal of Electronics and Communication Engineering & Technology (Ijecet)IAEME PublicationОценок пока нет

- Page 29 Solution PDFДокумент5 страницPage 29 Solution PDFsagsachdevОценок пока нет

- 1 s2.0 S0360835211003196 Main PDFДокумент10 страниц1 s2.0 S0360835211003196 Main PDFitzgayaОценок пока нет

- OptimationДокумент11 страницOptimationrizkiОценок пока нет

- Garcia Sabater2011Документ39 страницGarcia Sabater2011MaisarahОценок пока нет

- Expert Systems With Applications: Said Aqil, Karam AllaliДокумент17 страницExpert Systems With Applications: Said Aqil, Karam AllaliRumah WayangОценок пока нет

- A Method For Cycle Time Estimation of Semiconductor Manufacturing Toolsets With CorrelationsДокумент11 страницA Method For Cycle Time Estimation of Semiconductor Manufacturing Toolsets With CorrelationsDeepak JainОценок пока нет

- 3 Job Shop Scheduling PDFДокумент7 страниц3 Job Shop Scheduling PDF123away123Оценок пока нет

- Ms ProblemДокумент8 страницMs ProblemJasdeep SinghОценок пока нет

- Demand TheoryДокумент15 страницDemand TheoryJasdeep SinghОценок пока нет

- 261 Jasdeep SinghДокумент15 страниц261 Jasdeep SinghJasdeep SinghОценок пока нет

- Management Science-105: PC-7992/NLДокумент4 страницыManagement Science-105: PC-7992/NLJasdeep SinghОценок пока нет

- MBA Regular Part-I (Sem I)Документ17 страницMBA Regular Part-I (Sem I)Jasdeep SinghОценок пока нет

- (ECE 357) Digital Signal Processing Lab: Bachelor of Technology IN Electronics and CommunicationДокумент58 страниц(ECE 357) Digital Signal Processing Lab: Bachelor of Technology IN Electronics and CommunicationJasdeep SinghОценок пока нет

- BST 2Документ2 страницыBST 2Jasdeep SinghОценок пока нет

- Introduction To Digital System Design: RTL Hardware Design by P. Chu 1Документ44 страницыIntroduction To Digital System Design: RTL Hardware Design by P. Chu 1Jasdeep SinghОценок пока нет

- Vice Chancellor's Message: Prof. (DR.) B.S. GHUMANДокумент2 страницыVice Chancellor's Message: Prof. (DR.) B.S. GHUMANJasdeep SinghОценок пока нет

- Alacarte Channels: SR - NO. Channel Name Categories Alacarte RatesДокумент7 страницAlacarte Channels: SR - NO. Channel Name Categories Alacarte RatesJasdeep SinghОценок пока нет

- Balanced Modulator Using DiodesДокумент5 страницBalanced Modulator Using DiodesJasdeep SinghОценок пока нет

- Ray Optics and Optical InstrumentsДокумент6 страницRay Optics and Optical InstrumentsJasdeep SinghОценок пока нет

- Digital System Design: Satish Kashyap. BДокумент47 страницDigital System Design: Satish Kashyap. BJasdeep SinghОценок пока нет

- Ece 102 Basic Electronics L T P Credits 3 1 0 3.5 Section-AДокумент7 страницEce 102 Basic Electronics L T P Credits 3 1 0 3.5 Section-AJasdeep SinghОценок пока нет

- Analog Communication SystemДокумент4 страницыAnalog Communication SystemJasdeep SinghОценок пока нет

- Ragi List - Eng - PDFGДокумент1 страницаRagi List - Eng - PDFGJasdeep SinghОценок пока нет

- How Can Literary Spaces Support Neurodivergent Readers and WritersДокумент2 страницыHow Can Literary Spaces Support Neurodivergent Readers and WritersRenato Jr Bernadas Nasilo-anОценок пока нет

- DIFFERENTIATING PERFORMANCE TASK FOR DIVERSE LEARNERS (Script)Документ2 страницыDIFFERENTIATING PERFORMANCE TASK FOR DIVERSE LEARNERS (Script)Laurice Carmel AgsoyОценок пока нет

- Suspend and Resume Calls: Exit PlugДокумент4 страницыSuspend and Resume Calls: Exit PlugrajuОценок пока нет

- De DusterДокумент6 страницDe DusterArstОценок пока нет

- Dissertation 7 HeraldДокумент3 страницыDissertation 7 HeraldNaison Shingirai PfavayiОценок пока нет

- Ymrtc LogДокумент26 страницYmrtc LogVinicius Silveira0% (1)

- 0 BA Design ENДокумент12 страниц0 BA Design ENFilho AiltonОценок пока нет

- Lista de Precios Agosto 2022Документ9 страницLista de Precios Agosto 2022RuvigleidysDeLosSantosОценок пока нет

- Baxter - Heraeus Megafuge 1,2 - User ManualДокумент13 страницBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliОценок пока нет

- PH of Soils: Standard Test Method ForДокумент3 страницыPH of Soils: Standard Test Method ForYizel CastañedaОценок пока нет

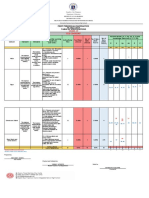

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Документ6 страницRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoОценок пока нет

- Onset Hobo Trade T Cdi 5200 5400 User ManualДокумент3 страницыOnset Hobo Trade T Cdi 5200 5400 User Manualpaull20020% (1)

- Amp DC, OaДокумент4 страницыAmp DC, OaFantastic KiaОценок пока нет

- Contoh Assignment PDFДокумент18 страницContoh Assignment PDFSiti Fatimah A Salam67% (3)

- Automated Dish Washer v1.1Документ21 страницаAutomated Dish Washer v1.1Anonymous XXCCYAEY6M67% (3)

- Standard nfx15-211Документ2 страницыStandard nfx15-211Luis Enrique Cóndor PorrasОценок пока нет

- Geotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonДокумент7 страницGeotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonJuan PerezОценок пока нет

- SEC CS Spice Money LTDДокумент2 страницыSEC CS Spice Money LTDJulian SofiaОценок пока нет

- Agile ModelingДокумент15 страницAgile Modelingprasad19845Оценок пока нет

- Nestlé CASEДокумент3 страницыNestlé CASEAli Iqbal CheemaОценок пока нет

- Properties of LiquidsДокумент26 страницProperties of LiquidsRhodora Carias LabaneroОценок пока нет

- Jurnal Ekologi TerestrialДокумент6 страницJurnal Ekologi TerestrialFARIS VERLIANSYAHОценок пока нет

- Student Exploration: Digestive System: Food Inio Simple Nutrien/oДокумент9 страницStudent Exploration: Digestive System: Food Inio Simple Nutrien/oAshantiОценок пока нет

- Toi Su20 Sat Epep ProposalДокумент7 страницToi Su20 Sat Epep ProposalTalha SiddiquiОценок пока нет

- List of The Legend of Korra Episodes - Wikipedia PDFДокумент27 страницList of The Legend of Korra Episodes - Wikipedia PDFEmmanuel NocheОценок пока нет

- Restaurant Report Card: February 9, 2023Документ4 страницыRestaurant Report Card: February 9, 2023KBTXОценок пока нет