Академический Документы

Профессиональный Документы

Культура Документы

Type of Elastomeric Coupling

Загружено:

Amin Buhari Md ZainИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Type of Elastomeric Coupling

Загружено:

Amin Buhari Md ZainАвторское право:

Доступные форматы

Elastomeric Element Couplings

Maska Flexible coupling Selection

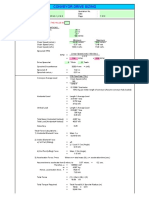

For all Maska Coupling Types

Selection Process: We will present two different ways of selecting the proper coupling -- namely, the torque design and the HP design. 1. Determine the appropriate Coupling Series and Element material Using the General Characteristics chart (pg. 125), determine which coupling series would be more appropriate for your application. From this information, you may have to choose the proper element material according to the related Element Characteristics chart (Starflex pg. 132; 4-Flex pg. 151). 2. Determine the appropriate Service Factor Using the Application Service Factors chart (pgs 129-130) and the Driver Service Factor Adders chart (pg. 128), determine the Service Factor that corresponds the closest to your application. 3. a) Determine the Torque Design Torque Design = (HP x Service Factor x 63025) RPM 3 b) Determine the HP Design per 100 RPM HP per 100 RPM = (HP x Service Factor x 100) RPM

5. Verify the driver/driven shaft sizes Using the proper coupling Dimensions chart, verify that your driver and driven shaft dimensions are smaller or equal to the maximum bore size available on the coupling selected. If the coupling bore size is not large enough for the shaft diameter, select the next largest coupling that will fit the driver/driven shaft diameter. Selection Example: A coupling is needed to join a 5 HP electric high torque motor operating at 1750 RPM to an outdoor agricultural belt conveyor. The shaft size of the motor is 1 1/8" and the conveyor is 1 3/16". 1. Determine the appropriate Coupling Series and Element material According to the General Characteristics chart, the proper series to use would be the MASKA STARFLEX to get the smallest back lash. According to the Element Characteristics chart, Urethane would probably be the best choice for this application.

126

BE SURE TO SPECIFY

COUPLINGS

4 Select the Coupling Size Using the Coupling Ratings & Misalignment charts, locate either the Torque or the HP per 100 RPM columns. As the service factor has already been considered, use the chart with a service factor of 1. Skim this column to the first entry where the torque value or the HP per 100 RPM value is greater or equal to the value calculated in step 3. Once this value is located, refer to the corresponding coupling size in the first column of the chart. Refer to the Maximum RPM and Misalignment values to validate that the application requirements are met. If the requirements are not met at this point, another coupling type may be required for the application. Contact our technical support for assistance, if needed.

Elastomeric Element Couplings

Maska Flexible coupling Selection

continued

2. Determine the appropriate Service Factor To calculate the appropriate service factor to use with your coupling selection, refer to the Application Service Factor chart (pgs 129-130) and the Driver Service Factor Adders chart (pg.128). To obtain the Service Factor, the Driver Service Factor adder has to be added (1) to the Application Service Factor. To calculate the Service Factor for a MASKA STARFLEX used on a belt conveyor driven by a High Torque AC Motor, the application service factor is 1.20 and the driver service factor adder is 0.25. So, the service factor will be 1.20 + 0.25 = 1.45. 3 a) Determine the Torque Design Torque Design = HP x Service Factor x 63025 = . RPM Torque Design = 5 x 1.45 x 63025 = 261.10 in-lbs 1750 OR

3 b) Determine the HP Design per 100 RPM HP per 100 RPM = HP x Service Factor x 100 RPM HP per 100 RPM = 5 x 1.45 x 100 = 0.414 HP per 100 RPM 1750

COUPLINGS

4. Select the Coupling size Using the Coupling Ratings & Misalignment charts for the MASKA STARFLEX Urethane Element, locate either the Torque or the HP per 100 RPM columns with a service factor of 1. Skim down this column to the first item that is greater or equal to the Design Torque: 261.10 in-lbs. or to the HP per 100 RPM: 0.414 HP. For this application, the L095 coupling with a Nominal Torque rating of 291 in-lbs. and a HP per 100 RPM of 0.462 HP is the proper coupling. According to this chart, the maximum RPM of 1750 on the electric motor does not exceed the 9000 RPM maximum allowed for the L095 sized coupling with a Urethane insert. 5. Verify the driver/driven shaft sizes The electric motor has a shaft size of 1 1/8" and the conveyor has a shaft size of 1 3/16". Because the maximum bore of the L095 is less than the conveyor shaft size, the L095 coupling is insufficient for this application. Continuing down the maximum bore column in the chart, the L099 size has a maximum bore size of 1 3/16" which is able to accommodate the driver/driven shaft sizes. Therefore: The required coupling size for this application is a MASKA STARFLEX L099 with a Urethane Element.

127

FOR DEPENDABLE DRIVE COMPONENTS,

Elastomeric Element Couplings

SERVICE FACTOR

SERVICE FACTOR CALCULATION: To calculate the appropriate service factor to use in your coupling selection, both the driver and the driven device have to be known. From this information, determine the Application Service Factor from the chart on the following pages and the Driver Service Factor Adder in the chart below. To obtain the Service Factor, the Driver Service Factor adder has to be added (1) to the Application Service Factor. Ex.: To calculate the Service Factor for a 4FLEX used on a Gyratory Crusher driven by a High Torque AC Motor, the application service factor is 2.00 and the driver service factor adder is 0.50. So, the service factor will be 2.00 + 0.50 = 2.50.

(1) Either add positive values or subtract negative values.

DRIVER SERVICE FACTOR ADDERS

MASKA STARFLEX

Electric Motor w / Standard Torque Electric Motor w / High Torque SF<1.25 Electric Motor w / High Torque SF > 1.25 Steam Turbines SF<1.5 Steam Turbines SF >1.5 1- cyl 2-3 cyl 4-5-cyl SF < 1.25 Recip rocating 4-5-cyl SF > 1.25 6-11 cyl SF < 1.25 Engines*** 6-11 cyl SF > 1.25 12 or more cyl SF < 1.25 12 or more cyl SF > 1.25 0 0.25 0.25 0 0 0.7 0.3 0 0 0 0 0 0

4-FLEX

0 0.25 0.5 -0.25 -0.5 * * 0.25 0.5 0.25 0.5 0.25 0.5

MASKAFLEX

0 0 0 0 0 * * 0.5 0.5 0.5 0.5 0 0

***The service factors shown are for reference only. Reciprocating applications may apply substantial loads on the coupling and/or induce vibration. This could seriously damage the system. Consult MASKA for assistance with these drives. *Contact MASKA for Technical Assistance

128

BE SURE TO SPECIFY

COUPLINGS

Elastomeric Element Couplings

SERVICE FACTOR (continued)

APPLICATION SERVICE FACTORS MASKA STARFLEX

Agitators Blowers Centrifugal Lobe Vane Brewing & distilling Bottling Machinery, Brew Kettles (distilling) Cookers Car Dumpers Car Pullers Compressors ** Centrifugal Screw Lobe Reciprocating 1 cylinder - single acting 1 cylinder - double acting 2 cylinder- single acting 2 cylinder - double acting 3 cl, or more - single acting 3 cl, or more - double acting Conveyors Assembly, Belt, Oven, Screw Cranes & Hoist Main Hoist-Medium Duty Main Hoist-Heavy Duty Crushers Cane Gyratory Dredges Cable reels Cutter Head Drives Maneuvering and Utility Winch, Pumps Dynamometer Fans Centrifugal Cooling Towers Forced Draft Propeller Feeders Belt Screw Reciprocating Filter, Press-oil Generators Not Welding Hoist Welding Kilns Lumber Machinery Band Resaw Barkers, Edger Feeder, LOG HAUL Planer, Slab Conveyor Live Roll - Reciprocating Sawdust Conveyor 1.00 1.00 1.25 1.25 1.25 1.25 2.50 1.50 1.00 1.25 1.25 * * * * * * 1.2 1.50 2.00 3.50 3.00 2.00 2.50 1.50 1.50 1.00 2.00 1.50 1.00 1.00 2.50 1.50 1.00 1.50 2.00 1.50 1.50 2.00 2.00 2.00 1.25

4-FLEX

1.25 1.25 1.50 1.25 1.25 1.25 2.00 2.00 1.25 1.25 1.25 * * * * * * 1.25 1.50 2.00 2.00 2.00 1.50 2.00 1.50 1.25 1.25 2.00 1.50 1.25 1.50 2.00 1.50 1.25 1.50 2.00 2.00 1.50 2.00 1.50 1.25

MASKAFLEX

1.00 1.00 1.50 1.00 1.00 1.00 1.50 1.50 1.00 1.00 2.00 3.50 3.00 3.00 2.50 2.50 2.00 1.00 1.50 2.00 2.00 2.50 1.50 2.50 1.50 1.00 1.00 2.00 1.50 1.00 1.50 2.00 2.00 1.50 2.00 1.50 2.00 1.00

COUPLINGS

129

FOR DEPENDABLE DRIVE COMPONENTS,

Elastomeric Element Couplings

APPLICATION SERVICE FACTORS MASKA STARFLEX

Machine Tools Main Drive Punch Press-gear Driven, Plate Planer Metal Forming Machines Draw Bench, Carriage & Main Drive Extruder Wire Drawing Mills, Rotary Type Ball, Pebble Tube Rod Dryers, Coolers Tumbling, Tumbling Barrel, Rubber Tumbling Mixers Concrete, continuous Muller Oil Industry Chiller (oil) Paper Mills Agitator (mixers), Reel, Winder Barking Drum Beater, Pulper Jordans Calenders Suction Roll (paper) Winder Printing Presses Barge Haul Puller Pulverisers Hammermill-Light Duty Hammermill-Heavy Duty Pug Mill Pumps Centrifugal Gear Reciprocating: 1Cyl, Single Acting 1Cyl, Double Acting 2Cyl, Single Acting 2Cyl, Double Acting 3 or more Cyl Rubber Machinery Banbury Mixers Calender Screens Air washing, Water Coal and Sand Rotary Vibrating Grizzly Textile Machinery Card Machine Mangel Loom, Spinner, Tenter frames Tumbling Barrels Windlass Woodworking Machines 1.50 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 1.50 1.75 1.50 1.50 1.20 2.50 2.00 2.00 1.50 1.50 1.20 1.50 2.00 2.00 2.00 1.75 1.00 1.25 2.00 2.00 2.00 1.75 1.50 2.50 2.00 1.00 1.50 2.50 2.00 1.75 1.20 1.50 1.75 2.00 1.00

4-FLEX

1.50 1.50 2.00 2.00 2.00 2.00 2.00 2.00 1.50 2.00 1.50 1.50 1.50 1.50 2.00 1.50 2.00 2.00 1.50 1.50 1.50 2.00 1.50 2.00 1.50 1.25 1.50 * * * * * 2.00 2.00 1.25 1.50 2.00 2.00 2.00 1.25 1.50 2.00 1.50 1.25

MASKAFLEX

1.50 1.50 2.00 2.00 2.00 2.50 2.50 2.50 1.50 1.50 1.50 1.50 1.00 1.00 2.50 1.50 2.00 2.00 2.00 1.50 1.50 2.50

1.00 1.50 2.50 2.00 2.00 1.50 1.50 2.50 2.00 1.00 1.50 2.50 2.00 1.50 1.00 1.50 2.00 1.50 1.00

*Contact MASKA for technical assistance ** Add 0.5 to factor if without flywheel

130

BE SURE TO SPECIFY

COUPLINGS

1.50 2.00 1.50

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Selecting, Operating, and Maintaining Electric Motors: Instructional Materials Service Texas A&M University 8795Документ153 страницыSelecting, Operating, and Maintaining Electric Motors: Instructional Materials Service Texas A&M University 8795John Reantaso100% (1)

- PC1250Документ16 страницPC1250Gavin Li100% (1)

- Manuale D Officina Z400DДокумент197 страницManuale D Officina Z400DEugy Alex100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Briggs Generic Manual 120000Документ76 страницBriggs Generic Manual 120000Takács István100% (1)

- Caterpillar C15 Engine SpecsДокумент5 страницCaterpillar C15 Engine Specsjinxy5779100% (4)

- HVAC ConstantsДокумент6 страницHVAC ConstantsWilliam Greco100% (8)

- Ea888 Gen3 - Design and Function-Ssp - 820533 - 2 - 0 - Tsi - 4 - 30 - 2014Документ56 страницEa888 Gen3 - Design and Function-Ssp - 820533 - 2 - 0 - Tsi - 4 - 30 - 2014marcddd100% (4)

- Plant Performance - DelhiДокумент83 страницыPlant Performance - DelhiVishal Kumar Laddha100% (3)

- Cyclones Standard For ReferenceДокумент6 страницCyclones Standard For ReferenceAmin Buhari Md ZainОценок пока нет

- Palm Oil Mill - FFB Conveyor Sizing BДокумент4 страницыPalm Oil Mill - FFB Conveyor Sizing BAmin Buhari Md Zain100% (5)

- EH - Topic 1 Reception - Final Draft 300413Документ5 страницEH - Topic 1 Reception - Final Draft 300413Amin Buhari Md Zain100% (1)

- EH - Topic 12 Schedule Maintenance Program - Primary Calendar - 300413Документ7 страницEH - Topic 12 Schedule Maintenance Program - Primary Calendar - 300413Amin Buhari Md ZainОценок пока нет

- PUMP CALCULATION SHEETДокумент4 страницыPUMP CALCULATION SHEETMuhammad BilalОценок пока нет

- Steriliser Type 2Документ17 страницSteriliser Type 2Amin Buhari Md Zain100% (1)

- Palm Oil Mill Design Procedure Ch1Документ2 страницыPalm Oil Mill Design Procedure Ch1Amin Buhari Md Zain100% (3)

- Steriliser Type 1Документ21 страницаSteriliser Type 1Amin Buhari Md Zain100% (1)

- Company Profile and Licensing DocumentsДокумент51 страницаCompany Profile and Licensing DocumentsJOLLY JAYA SENTOSAОценок пока нет

- EMCM5103 Seminar 01Документ63 страницыEMCM5103 Seminar 01Amin Buhari Md ZainОценок пока нет

- Vermeer BC1000XLДокумент2 страницыVermeer BC1000XLPaulОценок пока нет

- Powertech 6125H Diesel EngineДокумент2 страницыPowertech 6125H Diesel EngineErman IndragiriОценок пока нет

- Golf Gti Edition 30 BrochureДокумент6 страницGolf Gti Edition 30 Brochureiolin100% (1)

- Lampiran Perhitungan Efisiensi Kompresor UdaraДокумент3 страницыLampiran Perhitungan Efisiensi Kompresor UdaraAhmad Ghufran Il PrincipinoОценок пока нет

- 0 - Brocure - SY215 ACE English Version PDFДокумент2 страницы0 - Brocure - SY215 ACE English Version PDFLutfi DstrОценок пока нет

- Isuzu REDTech 4J Lit SheetДокумент2 страницыIsuzu REDTech 4J Lit SheetVăn Tuấn NguyễnОценок пока нет

- Helical Worm: Quick Selection GuideДокумент24 страницыHelical Worm: Quick Selection GuideMohammad Ali TaghdiriОценок пока нет

- Variable Speed Drives: in This SectionДокумент68 страницVariable Speed Drives: in This SectionKEVIN PIERO CRUZADO GOICOCHEAОценок пока нет

- Armstrong PRisaireДокумент31 страницаArmstrong PRisaireIVAN ABERLAY SALINAS ESQUINCAОценок пока нет

- KG125W KG125WSДокумент4 страницыKG125W KG125WSSatish SharmaОценок пока нет

- 561 110 Falk True Hold Low Speed Backstops CatalogДокумент23 страницы561 110 Falk True Hold Low Speed Backstops Catalognenny_vhОценок пока нет

- 313D2LДокумент20 страниц313D2LVivek joshiОценок пока нет

- Manual HJ Type 7 Lubricator With Zero Stroke SettingДокумент53 страницыManual HJ Type 7 Lubricator With Zero Stroke SettingGeneratorX707Оценок пока нет

- Logan Clutch Catalog SAE Direct Drive PTOДокумент30 страницLogan Clutch Catalog SAE Direct Drive PTOnksiavashОценок пока нет

- Frame 6 BДокумент15 страницFrame 6 BEliyanto E BudiartoОценок пока нет

- Komatsu DX20 BrochureДокумент6 страницKomatsu DX20 BrochureHoa Thanh PhongОценок пока нет

- H1 Axial Piston Tandem Pumps: Size 045/053Документ56 страницH1 Axial Piston Tandem Pumps: Size 045/053Luis Arturo Arenales MaytaОценок пока нет

- Belaz 7560Документ2 страницыBelaz 7560basОценок пока нет

- Commercial Industrial Exhaust VentilatorДокумент17 страницCommercial Industrial Exhaust VentilatorAnonymous QZwgOjEx3Оценок пока нет

- Surface Vehicle Recommended PracticeДокумент4 страницыSurface Vehicle Recommended PracticeDavid Santaria VargasОценок пока нет