Академический Документы

Профессиональный Документы

Культура Документы

Charaterization of A Cold Battery With Double Heat Exchanger in A Dry Mode

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Charaterization of A Cold Battery With Double Heat Exchanger in A Dry Mode

Авторское право:

Доступные форматы

IOSR Journal of Engineering

e-ISSN: 2250-3021, p-ISSN: 2278-8719,

Vol. 2, Issue 12 (Dec. 2012), ||V1|| PP 49-54

www.iosrjen.org 49 | P a g e

Charaterization of a cold battery with double heat

exchanger in a dry mode

B. Dieng

1

, I. Diagne

2

, M. Dieng

2

, A. Kane

2

, and G. Sissoko

2

1

(Physics Section, UFR SATIC, University Bambey, Senegal)

2

(Faculty of Science and Technology, University Cheikh Anta Diop, Dakar, Senegal)

Abstract: The cold battery is a heat exchanger between two fluids, air (secondary fluid) and iced water

(primary fluid). The cold battery is composed of two heat exchangers in series, one of which is made up of

flat-plate in galvanized steel serving as a reservoir for the iced water and the other one a copper shell-

and-tube exchanger with aluminum cooling blades. The two heat exchangers a connected pipe of the same

diameter. These pipes will permit the transit of the iced water coming from the flat-plate exchanger by

gravitation towards the tubes of the second exchanger. These two heat exchangers are incorporated in a

galvanized container coupled with a centrifugal fan for the improvement of the thermal comfort. The

water, after passing through the two heat exchangers is stored in an adiabatic reservoir and will serve as

a water fountain [1,2]. The characterization of that cold battery will be done in a dry regime where there

is only one heat exchanger and the quantity of vapor contained in the air does not varied and also the

surface temperature of the battery is greater than the dew temperature of air [3 ; 4; 5].

Keywords - Battery, Heat exchanger, Temperature, Condensation, Cross flow, Counter flow

NOMENCLATURE

Symbol Description Unit

c

pw

Specific heat of water at constant pressure J.kg

-

1.K

-1

c

pa

Specific heat of air at constant pressure J.kg

-

1.K

-1

C Heat Capacity J/kgC

e

m

Flow rate of water kg/s

a

m

Flow rate of air kg/s

U Coefficient dchange thermique par convection W.m

-2

.K

-1

S Surface m

2

Temperature C

Heat flux W

Indices:

a : air

ai : air flowing into the cold battery

ao :air flowing out of the cold battery

wi : water flowing into the cold battery

wo : water flowing out of the cold battery

ext or e : relative to the air side of the heat exchanger

int or i : relative to the water side of the heat exchanger

r: relative to the dew point of air

t : relative to tube

p : relative to the flat-plate

I. INTRODUCTION

The axial sucksion of air by the fan passes in crossflow the shell-and-tube heat exchanger in which

flows an iced water before being pushed radially by the fan under the flat-plate containing the iced water. The

global heat transfer is the sum of the heat exchanged by the to heat exchangers of the cold battery.

Charaterization of a cold battery with double heat exchanger in a dry mode

www.iosrjen.org 50 | P a g e

The battery is conceived in such a way that the flat-plate heat exchanger operates in in counterflow and the shell

and tube. Heat exchanger in crossflow, these characteristics will be determined by the

lm

and NTU-

techniques [5; 6] and for a given operating point in a dry regime.

Therefore the apparatus we have built is composed of the following elements:

- Two heat exchangers (flat-plate and shell-and tube) in series and connected by pipes.

- A centrifugal fan

- An insulator in Polythene

- A frame in galvanized steel

- A water reservoir in steel

- Two valves

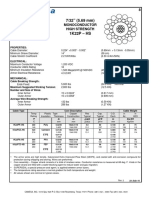

Figure 1: Cold battery with two heat exchangers

E1: Flat-plate heat exchanger

E2: Tube heat exchanger

V1 : Flow rate regulator valve

V2 : Inlet valve to the water fountain

R : Water reservoir

II. HYPOTHESIS

The variables (fluid temperatures) are mainly dependent on their axial position.

The heat capacities of the two fluids are constant during the transformations.

The heat transfer processes are not convective,

The heat exchanger is thermally isolated from the external environment.

There are no heat losses during the transfer of fluid between the two heat exchangers.

We assume that the enthalpy of the saturated air is a linear function of temperature in the intervals considered

III. MODELLING IN DRY REGIME

1. Determination of the heat flux

With the hypotheses of calculation, the overall heat flux will be the sum of flux

1

and

2

because the two heat

exchangers are in series

2 1

| | | + =

5

1

: heat flux due to the shell-and-tube exchanger operating in crossflow

2

: heat flux due to the flat-plate exchanger operating in counterflow

The overall flux which is the sum of the two flux is then given by::

2 1

| | | + =

1

therefore:

( ) ( )

( )

( )

( ) ( )

|

|

.

|

\

|

+

|

|

.

|

\

|

=

02 1

2 01

02 1 2 01

01 2

1 02

01 2 1 02

ln ln

w ai

wi a

w ai wi a

t t

w ai

wi a

w ai wi a

p P

F S U S U

u u

u u

u u 0 u

u u

u u

u u u u

|

2

The correction factor F linking the crossflow and the counterflow is given by charts or correlation equations.

The overall flux can be written as:

Charaterization of a cold battery with double heat exchanger in a dry mode

www.iosrjen.org 51 | P a g e

( ) ( )

( )

( )

|

|

.

|

\

|

=

02 1

1 02

02 1 1 02

ln

.

w ai

wi a

w ai wi a

eq

Y S U

u u

u u

u u u u

|

3

Y is the correction of our double heat exchanger with respect to the counterflow operation. Y is obtained from

equations (2) and (3). We will propose the experimental determination using the input and output conditions of

the fluid and the characteristics of the heat exchanger which is the objective of this paper

III.2. Determination of the efficiency of the battery.

By introducing the number of transfer units NTU

|

|

.

|

\

|

=

min

C

A U

NTU and the ratio of the thermal rates of heat

flow

max

min

C

C

C = , we can write the efficiency of the counterflow heat exchanger as :

( )

( )

1

1

1

1

1

=

C NTU

C NTU

Ce

e

c

8

And that of the crossflow as :

( )_ c

22 , 0

2

exp 1 NTU =

9

where

( )

R

NTU R 1 . exp

78 , 0

= _

10

Knowing the two efficiencies we can find the relationship between the three efficiencies:

1

. 1

1

. 1

1

1

. 1

1

. 1

1

2

2

1

1

2

2

1

1

=

c

c

c

c

c

c

c

c

c

R R

R

R R

11

is the efficiency of the battery with two heat exchangers

Figure 2 : Diagramme of determination of the effective heat transfer coefficient

This diagram enables us to determine the effective heat transfer coefficient of the cold battery by using

the operating point and the measured input and output temperatures of the battery. For that reason we start by

determining the efficiency and resolve it on the grapgh in order to obtain the heat transfer coeficient

Charaterization of a cold battery with double heat exchanger in a dry mode

www.iosrjen.org 52 | P a g e

3. Determination of the heat exchange coefficients and the Y correction factor.

The globall and local heat transfer coefficients of the battery are determined for a given operating point

3.1. Global heat transfer coefficient

For a given operating point and the input and output temperatures of the battery known, the heat transfer

coefficients can be obtained from figure 1.

3.2. Determination of the Y correction factor

Knowing the global heat transfer coefficient we can calculate the Y correction factor given by equation 10.

( )

( ) ( )

( )

( ) ( )

|

|

.

|

\

|

=

|

|

.

|

\

|

=

02 1

02 1

1 02 02 1

1 02

1 02

02 1

1 02 02 1

02 1

ln ln

.

w wi

w ai

wi w w ai

eq

wi w w

wi w

w ai

wi w w ai

eq

a ai a

S U

C

S U

C

Y

u u

u u

u u u u

u u

u u

u u

u u u u

u u

10

3.3. Local heat transfer coefficient on the air side.

To determine the local heat transfer coefficient on the side of air, we consider the fictitious cold battery

having an infinite flow rate of water and giving the same operating conditions to the air. The external heat

transfer coefficient for the cold battery depends only on the operating conditions on the side of air and the

geometry of the battery [7, 8, 9].

Because of the internal resistance nullified by the infinite rate of flow of water, the considered battery gives a

homogeneous and constant temperature. The considered temperature is called mean surface temperature which

is higher than the dew temperature of air.

By letting

w w

c m approach infinity (

w w

c m ) (

w

u A =0) in the expression of the overall efficiency of the

cold battery (11), we obtain the following efficiency for the fictitious battery:

NUT

e

2

1

inf

= c

11

With

min

C

A U

NUT

a a

=

12

This efficiency of the fictitious battery of infinite capacity can be defined as the ratio between the total power

transferred and the maximum transferable power in the ideal case:

( )

( )

ai r

C

ai ao a

C

u u

u u

c

=

min

inf

13

We then deduce the local transfer coefficient on the side of air by a combination of equations 11, 12 and 13 and

the expression of NTU.

( )

inf

1 ln

2

1

c =

pa

c

a

m

a

A

a

U

14

The calculated transfer coefficient on the side of air for the fictitious battery can assimilated to that of the real

battery because this battery has been chosen in such a way that the operating conditions on the side of air are

unchanged. The transfer coefficient depends only on these conditions. In addition the fictitious operating

conditions on the side of air do not arise from an arbitrary choice but from a physical limiting case.

3.4. Local heat transfer coefficient on the water side

This coefficient is deduced from the global heat transfer coefficient from air side and from the

characteristics (, ) of the materials used in design of the battery.

The global heat transfer coefficient is obtained by using the electrical analogy [10, 11].

t

t

p

p

w a eq

e

e

U U U

+ + + =

1 1 1

14

U

a

equivalent external heat transfer coefficient ( air side)

U

w

equivalent internal heat transfer coefficient ( water side)

e

p

and

p

are respectively the thickness and the thermal conductivity of the flat plate heat exchanger.

Charaterization of a cold battery with double heat exchanger in a dry mode

www.iosrjen.org 53 | P a g e

e

p

and

p

are respectively the thickness and the thermal conductivity of the shell and tube heat exchanger.

The exit conditions of the battery could be obtained from the previous equations.

IV. EXPERIMENTAL WORK

This part of the work consists of validating this technique by an experiment for which the battery is

filled with water and thermocouples placed within in order to measure the temperature at different points of the

heat exchanger. The simulation is done by using MATLAB.

- The air temperatures at the entrance and exit of the cross flow heat, the latter gives simultaneous the

air temperatures at the entrance of the flat plat heat exchanger;

- The air temperature at the exit of the flat plat heat exchanger.

- The water temperatures at the entrance and exit of the heat exchanger.

- The rate of flow of water in the heat exchanger (obtained from the operating point).

- Evaluation of the logarithmic mean temperature difference

- Determination of F from tables of values

- Calculation of the effective global heat transfer coefficient

- Determination of the correction factor Y

- Determination of the local heat transfer coefficient on the side of air

- Determination the local heat transfer coefficient on the side of water

These results will be compared with the classical method used to calculate the equivalent heat transfer

coefficient of the battery composed of two heat exchangers (the flat plat and the shell and tube one). This

experiment has been realized in a 9m

2

room with an initial air temperature of 38C and a relative humidity of

45% with a battery filled with 3 liters of tap water at the temperature of 20

o

C with a flow rate of 1g/s and an air

flow rate of 0.13 kg.s

-1

. Since the temperature variations are very small we have taken some values and

calculated the parameters.

The experimental results are presented in this table.

Table 1 : Experimental results

The table gives the local heat transfer coefficients (on the sides of air and water) and the global ones. It

also gives the efficiencies and the Y factors generated by a Matlab programme. The results obtained are

compared to the ones generated by the classical method and we arrive at a conclusion that the proposed method

is satisfactory because the margin of errors does not exceed 5%. The results also show that the best global

coefficients are the ones that correspond to the best efficiencies and are obtained over a period of 30 minutes

time from which the battery will attain its lowest exit air temperature and the highest exit water temperature.

V. CONCLUSION

In this work we are able to present the machine designed for the purpose of cooling a room by using tap

or well. We have also presented a new method of determination of the parameters of the battery. This model is

based on the Log-mean temperature difference applied to a battery operating in a dry mode. This technique is

based on the determination of the operating point of the battery and we have proposed a method of determining

that point. From the experimental results and a MATLAB programme we have determined the local heat

transfer coefficients (for air and water), the global coefficients, the efficiencies and the Y factors. The results

obtained and compared with the classical method are satisfactory given the fact that the margin of error does not

exceed 5%.

Time Measured temperatures

T

(mn)

ai1

a01

Ch

wi

w0

Y Ueq

(exp)

inf

Ua Uw Ueq

(calc

ul)

Erreur

%

5 37 35,5 34 20 23 0,78 0,89 9,19 0,67 5,63 2,93 8,79 4,3

15 36 35 32,5 21 25 0,79 0,90 10,03 0,69 6,33 2,98 9,83 2

30 33,5 31 29 23 27 0,80 0,92 10,86 0,72 6,74 3,07 10,4 4,1

50 30,7 30 28,5 25 29 0,76 0,90 10,45 0,70 6,62 3,07 9,98 4,5

Charaterization of a cold battery with double heat exchanger in a dry mode

www.iosrjen.org 54 | P a g e

BIBLIOGRAPHIE

1). B. DIENG : Thse dEtat Mai 2008 UCAD,

Etude et ralisation dune batterie froide double change couple un ventilateur pour

lamlioration du confort thermique dans lhabitat

2). W. MAAKE, J. ECKERT et J. L. CAUCHEPIN : Le nouveau Polhman Manuel technique du

froid , Pyc dition, 1988.

3). Threlkeld, J. L. Thermal Environmental Engineering, 2

nd

Edition 1970, Englewood Cliffs : Prentice-

Hall, Inc, pp 254-270

4). Kreider,J. F and Rabi A, A. E 310 Fundamentals of Heating Ventilating and air conditioning ASHAE

Systems and Equipement Haadbook.

5). B. DIENG, I. DIAGNE, B. FLEUR, Y. COULIBALY, S. GAYE, G. SISSOKO

Etude et ralisation dune batterie froide double changeur fonctionnant en rgime humide .

Journal des Sciences (2008), Vol.8, N2, pp.70-87. http://www.ucadjds.org

6). L. Banhidi and Z. B. Biro Design and calculation possibilities for the heat exchange conditions of the

human body. Periodeca Polytechnica ser mecheng vol 44 NO 2 PP 185 -193 (2000).

7). CARRIER : Manuel Carrier 1

re

et 2

me

partie, Carrier International LTD, New-York, carrier

corporation 2me Edition, 1960

8). DUMILIL. M : Air humide, Technique de lingnierie 1999 B 2 230-1.

9). ASHRAE Handbook of Fundamentals, SI Edition, American Society of Heating, Refrigerating and Air

Conditioning Engineers, 1994

10). CARRIER, Manuel Carrier 1

re

et 2

me

partie, Carrier International LTD, New-York, carrier

corporation2me Edition, 1960

11). J. R. CAMARGO, C. D EBINUMA AND J. L. SILVEIRA

Experimental performance of a direct evaporative cooler operating during summer in a Brazilian

City. International journal of Refrigeration 20 (2005) 1124 1132.

Вам также может понравиться

- Tietgen Kollegiet, DenmarkДокумент20 страницTietgen Kollegiet, DenmarkBhavika Dabhi100% (1)

- Cooling TowerДокумент40 страницCooling TowerM-poe MampshikaОценок пока нет

- Energy BalanceДокумент16 страницEnergy BalancewizlanОценок пока нет

- Instruction Manual: Kosangas LPG Sdn. BHDДокумент10 страницInstruction Manual: Kosangas LPG Sdn. BHDahmad hafizОценок пока нет

- Pile Foundation Design SpreadsheetДокумент7 страницPile Foundation Design SpreadsheetmuhannedОценок пока нет

- Article B. Dieng Et AlДокумент18 страницArticle B. Dieng Et AlbcenergiesОценок пока нет

- Calculation of Temperature in A Large Turbine Generator With Multilayer Roebel Transposition CoilsДокумент5 страницCalculation of Temperature in A Large Turbine Generator With Multilayer Roebel Transposition CoilsaniekanОценок пока нет

- Heat Exchanger HandoutДокумент11 страницHeat Exchanger Handoutchegg userОценок пока нет

- Chilled Water Plant Optimization Based On Part-Load Cooling Tower PerformanceДокумент22 страницыChilled Water Plant Optimization Based On Part-Load Cooling Tower PerformanceCarlos TorresОценок пока нет

- A Comprehensive Approach To Cooling Tower DesignДокумент17 страницA Comprehensive Approach To Cooling Tower DesignMarcio NunesОценок пока нет

- CMEM01060FUДокумент12 страницCMEM01060FUAbeje AlemnewОценок пока нет

- Thermal Analysis of Water Cooled Charge Air Cooler in Turbo Charged Diesel EngineДокумент5 страницThermal Analysis of Water Cooled Charge Air Cooler in Turbo Charged Diesel EngineesatjournalsОценок пока нет

- Mirjana S. LAKOVI), Slobodan V. LAKOVI), and Miloš J. BANJACДокумент11 страницMirjana S. LAKOVI), Slobodan V. LAKOVI), and Miloš J. BANJACAnonymous YcAZv5qF67Оценок пока нет

- Power Lab #3 (Surface Condenser)Документ4 страницыPower Lab #3 (Surface Condenser)Mahmud L. MusaОценок пока нет

- A.zerrouki Et El The Natural Circulation Solar Water Heater ModelДокумент11 страницA.zerrouki Et El The Natural Circulation Solar Water Heater ModelJuan-Pierre HerbothОценок пока нет

- Cooling Tower CalculationДокумент32 страницыCooling Tower CalculationMohammed Alnefayei100% (10)

- An Electrical Analog of A Flat-Plate Solar Water Heating SystemДокумент4 страницыAn Electrical Analog of A Flat-Plate Solar Water Heating SystemChih-yuan WengОценок пока нет

- Entropy: Performance Optimization of Generalized Irreversible Refrigerator Based On A New Ecological CriterionДокумент15 страницEntropy: Performance Optimization of Generalized Irreversible Refrigerator Based On A New Ecological CriterionKen AdamsОценок пока нет

- Comparative Study Between Three Types of Cooling Towers: Dry, Wet and HybridДокумент10 страницComparative Study Between Three Types of Cooling Towers: Dry, Wet and HybridVivek MОценок пока нет

- HTTPWWW BG Utp Edu Plartjok32007jo20kones20200720no20320vol201420mitianiecДокумент8 страницHTTPWWW BG Utp Edu Plartjok32007jo20kones20200720no20320vol201420mitianiecfrenz2kiranОценок пока нет

- Ocean Thermal Energy ConversionДокумент16 страницOcean Thermal Energy ConversionFIFA Lords & LegendsОценок пока нет

- Calentadores SolaresДокумент12 страницCalentadores SolaresAngel M. AlfaroОценок пока нет

- Thermal Engg Expt 5Документ5 страницThermal Engg Expt 5MithileshОценок пока нет

- Chapter 5 - Heat ExchangerДокумент48 страницChapter 5 - Heat ExchangerHoneydaa FitraОценок пока нет

- A Theoretical Analysis and CFD Simulation On The Ceramic Monolith Heat ExchangerДокумент12 страницA Theoretical Analysis and CFD Simulation On The Ceramic Monolith Heat ExchangerMohamed AshrafОценок пока нет

- The Overall Heat Transfer Characteristics of A Double Pipe Heat Exchanger: Comparison of Experimental Data With Predictions of Standard CorrelationsДокумент12 страницThe Overall Heat Transfer Characteristics of A Double Pipe Heat Exchanger: Comparison of Experimental Data With Predictions of Standard CorrelationsEngr. AbdullahОценок пока нет

- Optimal Cooling of A Tubular Reactor: Created in COMSOL Multiphysics 5.3aДокумент24 страницыOptimal Cooling of A Tubular Reactor: Created in COMSOL Multiphysics 5.3akingsley peprahОценок пока нет

- Lab Manual Convection Radiation (EDocFind - Com)Документ10 страницLab Manual Convection Radiation (EDocFind - Com)Hilmi ÖlmezОценок пока нет

- Practical GuideДокумент10 страницPractical GuideDamaris ThamiОценок пока нет

- Eteiac1411 (Heat Exchanger)Документ6 страницEteiac1411 (Heat Exchanger)Evans IraborОценок пока нет

- Cooling System of Haenam-Jeju HVDC SystemДокумент6 страницCooling System of Haenam-Jeju HVDC SystemMohit Kumar ChowdaryОценок пока нет

- Cooling TowerДокумент32 страницыCooling TowerPrasoon ChaturvediОценок пока нет

- Lab 9Документ5 страницLab 9huzaifa zainОценок пока нет

- Ag04 160913 SyllabusДокумент10 страницAg04 160913 SyllabushortalemosОценок пока нет

- Performance Analysis On A Multi-Type Inverter Air ConditionerДокумент15 страницPerformance Analysis On A Multi-Type Inverter Air ConditionerAdonis A. ClosasОценок пока нет

- 13 - Chapter One - SixДокумент34 страницы13 - Chapter One - SixazlanОценок пока нет

- Free and Forced Convection Heat TransferДокумент10 страницFree and Forced Convection Heat Transferhayder alaliОценок пока нет

- Control 3Документ22 страницыControl 3Ahmed Hassan RashedОценок пока нет

- Effective Thermal Design of Cooling TowersДокумент13 страницEffective Thermal Design of Cooling TowersKarthick VelayuthamОценок пока нет

- Modelling of Tube and Fins Coil Working As Evaporator or CondenserДокумент6 страницModelling of Tube and Fins Coil Working As Evaporator or CondenserAntarip PoddarОценок пока нет

- An Engineering Model of Coils and Heat Exchangers For HVAC System Simulation and OptimizationДокумент6 страницAn Engineering Model of Coils and Heat Exchangers For HVAC System Simulation and Optimizationsilentsoldier781344Оценок пока нет

- Electrical To Thermal 1 ManualДокумент6 страницElectrical To Thermal 1 ManualJake SmithОценок пока нет

- Steady State Model of Cooling Tower Used in Air ConditioningДокумент4 страницыSteady State Model of Cooling Tower Used in Air ConditioningAKBAR KRISNAОценок пока нет

- Effective Thermal Design of Cooling TowersДокумент11 страницEffective Thermal Design of Cooling Towershamid vahedil larijaniОценок пока нет

- Cooling Tower ExperimentsДокумент9 страницCooling Tower ExperimentsOlgalycosОценок пока нет

- Parametric Study Concentric048Документ6 страницParametric Study Concentric048Narayana Swamy GОценок пока нет

- Fluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of AmmoniaДокумент12 страницFluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of AmmoniaZAHID HUSSAINОценок пока нет

- Heat Exchanger Lab Manual ELABДокумент15 страницHeat Exchanger Lab Manual ELAB유지Оценок пока нет

- Coolling System CalculusДокумент33 страницыCoolling System CalculusȘtefan PravățОценок пока нет

- Examen+1+calor+th 16Документ4 страницыExamen+1+calor+th 16Denisse M. ZamoraОценок пока нет

- Objective:-: Double Pipe Concentric Tube Heat ExchangerДокумент5 страницObjective:-: Double Pipe Concentric Tube Heat ExchangerEngr. AbdullahОценок пока нет

- Lab 2Документ17 страницLab 2Callum BiggsОценок пока нет

- Geothermal Energy: Sustainable Heating and Cooling Using the GroundОт EverandGeothermal Energy: Sustainable Heating and Cooling Using the GroundОценок пока нет

- The Experimental Study On The Compatibility Relationship of Polymer and Oil LayerДокумент5 страницThe Experimental Study On The Compatibility Relationship of Polymer and Oil LayerIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Random Fixed Point Theoremsin Metric Space: Balaji R Wadkar, Ramakant Bhardwaj, Basantkumar SinghДокумент9 страницRandom Fixed Point Theoremsin Metric Space: Balaji R Wadkar, Ramakant Bhardwaj, Basantkumar SinghIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Study On Logging Interpretation Model and Its Application For Gaotaizi Reservoir of L OilfieldДокумент6 страницStudy On Logging Interpretation Model and Its Application For Gaotaizi Reservoir of L OilfieldIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- MMSE Adaptive Receiver vs. Rake Receiver Performance Evaluation For UWB Signals Over Multipath Fading ChannelДокумент13 страницMMSE Adaptive Receiver vs. Rake Receiver Performance Evaluation For UWB Signals Over Multipath Fading ChannelIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- G 05913234Документ3 страницыG 05913234IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Application of The Multi-Curve Reconstruction Technology in Seismic InversionДокумент4 страницыApplication of The Multi-Curve Reconstruction Technology in Seismic InversionIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Strength Properties of Commercially Produced Clay Bricks in Six Different Locations/ States in NigeriaДокумент10 страницStrength Properties of Commercially Produced Clay Bricks in Six Different Locations/ States in NigeriaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Introduction To Accounting Professional Judgment ManipulationДокумент3 страницыIntroduction To Accounting Professional Judgment ManipulationIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- The Identification of Lithologic Traps in Nanpu Sag D3 Member of Gaonan RegionДокумент5 страницThe Identification of Lithologic Traps in Nanpu Sag D3 Member of Gaonan RegionIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- A 05910106Документ6 страницA 05910106IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Effectiveness in Addressing The Sustainability and Environmental Issue Involving Use of Coal Ash As Partial Replacement of Cement in ConcreteДокумент6 страницEffectiveness in Addressing The Sustainability and Environmental Issue Involving Use of Coal Ash As Partial Replacement of Cement in ConcreteIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- "Sign Language Translator": Mr. Sangam Mhatre, Mrs. Siuli DasДокумент4 страницы"Sign Language Translator": Mr. Sangam Mhatre, Mrs. Siuli DasIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Validating The Theories of Urban Crime in The City of RaipurДокумент10 страницValidating The Theories of Urban Crime in The City of RaipurIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- I 05815457Документ4 страницыI 05815457IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Construction of Self-Regulated EFL Micro-Course Learning: Zhongwen LiuДокумент4 страницыConstruction of Self-Regulated EFL Micro-Course Learning: Zhongwen LiuIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Modeling and Design of Hybrid Power Plants: Ahmed KH A. E. AlkhezimДокумент5 страницModeling and Design of Hybrid Power Plants: Ahmed KH A. E. AlkhezimIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Constructions Quality Versus Bad Components in Jordanian CementДокумент3 страницыConstructions Quality Versus Bad Components in Jordanian CementIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- G 05813848Документ11 страницG 05813848IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- B 05810814Документ7 страницB 05810814IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- A 05810107Документ7 страницA 05810107IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- I 05745368Документ16 страницI 05745368IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- H 05814953Документ5 страницH 05814953IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- The Research of Source System On Chang 6 Sand Formation in Ansai OilfieldДокумент5 страницThe Research of Source System On Chang 6 Sand Formation in Ansai OilfieldIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Assessment of The Life Quality of Urban Areas Residents (The Case Study of The City of Fahraj)Документ6 страницAssessment of The Life Quality of Urban Areas Residents (The Case Study of The City of Fahraj)IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- G 05743742Документ6 страницG 05743742IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- C 05740912Документ4 страницыC 05740912IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Detecting Spammers in Youtube: A Study To Find Spam Content in A Video PlatformДокумент5 страницDetecting Spammers in Youtube: A Study To Find Spam Content in A Video PlatformIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- D 05741325Документ13 страницD 05741325IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- Zetaframe Datasheet - CleanedДокумент10 страницZetaframe Datasheet - CleanednerittoОценок пока нет

- Roof - Semi-D (Idp)Документ117 страницRoof - Semi-D (Idp)Amalina Idris AlphonsoОценок пока нет

- Sov Model V51Документ5 страницSov Model V51Nani TamizhaОценок пока нет

- Design and Analysis of FRPДокумент4 страницыDesign and Analysis of FRPDanielОценок пока нет

- CONDENSERДокумент24 страницыCONDENSERAmlan ShomeОценок пока нет

- Final Poster - Biodegradeable Metallic StentsДокумент1 страницаFinal Poster - Biodegradeable Metallic StentsMcQuack ÁvilaОценок пока нет

- Astm G15Документ5 страницAstm G15Partth VachhaniОценок пока нет

- Camesa EMC CatalogДокумент40 страницCamesa EMC CatalogRoger DenegriОценок пока нет

- Settlement of A Large Raft FoundationДокумент1 страницаSettlement of A Large Raft Foundationsb1966Оценок пока нет

- Electrical Properties of Lead Solder AlloyДокумент9 страницElectrical Properties of Lead Solder AlloyVedant PrustyОценок пока нет

- 14 Instrument Specifications Erection Annexure-I1Документ20 страниц14 Instrument Specifications Erection Annexure-I1Amarjeet ChauhanОценок пока нет

- Rockwool Vs GlasswoolДокумент8 страницRockwool Vs Glasswooly2karein100% (1)

- Lecture 4 PDFДокумент18 страницLecture 4 PDFdeepakОценок пока нет

- A Review On Modular Construction For High-Rise Buildings: Building Structures-Arc 652Документ6 страницA Review On Modular Construction For High-Rise Buildings: Building Structures-Arc 652SUBHIKSHA D 1861738Оценок пока нет

- 1 Introduction 09 Highway and Airport EngineeringДокумент35 страниц1 Introduction 09 Highway and Airport Engineeringامين الزريقيОценок пока нет

- Ref BooksДокумент6 страницRef BooksUmair AftabОценок пока нет

- Grayloc CatalogДокумент32 страницыGrayloc CatalogRamonОценок пока нет

- 1.bernoullis TheoryДокумент10 страниц1.bernoullis TheorySWETHAОценок пока нет

- Quiz Rce 309Документ4 страницыQuiz Rce 309abhiОценок пока нет

- Technology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishДокумент8 страницTechnology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishUsama AwadОценок пока нет

- Tds Dura-Pure sn95-sb5Документ1 страницаTds Dura-Pure sn95-sb5agus sutiawanОценок пока нет

- QCDD Fire Safety Standards Civil Defense CommentsДокумент7 страницQCDD Fire Safety Standards Civil Defense CommentsjaimonjoyОценок пока нет

- PDF - DownloadДокумент3 страницыPDF - DownloadRohit PanditОценок пока нет

- Chemical Exergy CalculationДокумент7 страницChemical Exergy CalculationmaheshОценок пока нет

- EnhancedДокумент6 страницEnhancedsaurabh Kumar SrivastavОценок пока нет

- DSR 2020 Civil 2Документ150 страницDSR 2020 Civil 2Santosh K SatiОценок пока нет

- Sabic Lldpe 118Wsj: Linear Low Density PolyethyleneДокумент2 страницыSabic Lldpe 118Wsj: Linear Low Density PolyethyleneFahad MohamedОценок пока нет