Академический Документы

Профессиональный Документы

Культура Документы

Lubricants: Chapter - 5 Lubricants and Lubrication

Загружено:

Malaika AzeemОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lubricants: Chapter - 5 Lubricants and Lubrication

Загружено:

Malaika AzeemАвторское право:

Доступные форматы

CHAPTER 5 LUBRICANTS AND LUBRICATION

LUBRICANTS In order to reduce metal to metal contact and to reduce the frictional force and heat generation, certain foreign substances are introduced between the rubbing surfaces which keep them apart .These substances are called lubricants. LUBRICATION The process to reduce frictional force between the sliding and rubbing surfaces of metals is called lubrication. FUNCTION OF LUBRICANTS The important functions of lubricants are as follow. It reduces wear and tear of the surfaces by avoiding direct metal to metal contact between the rubbing surfaces, i.e. by introducing lubricants between the two surfaces. It reduces expansion of metal due to frictional heat and destruction of material. It acts as coolant of metal due to heat transfer media. It avoids unsmooth relative motion. It reduces maintenance cost. It also reduces power loss in internal combustion engines. TYPES OF LUBRICATION (1) Fluidfilm lubrication (2) Boundary lubrication (1) FluidFilm Lubrication

This type of lubrication is used when two surfaces of the materials rotate against each other while being completely separated. The liquid lubricants form a very thin film between the moving surfaces and thus avoid the direct metal to metal contact and reduce friction. This condition is known as fluid film lubrication. The resistance to movement of sliding moving parts is only due to the internal resistance between the particles of the lubricants moving over each other. Therefore lubricant chosen should have the minimum viscosity under working conditions and at the same time, it should remain in place and separate the surfaces.

1

Delicate machines and light instruments like watches, clocks, guns, sewing machines, scientific instruments etc. are provided with thick fluid film lubrication. (2) Boundry Lubrication

Boundary lubrication may happen slide or rotate against one another under heavy load, and such conditions there may be contact between the moving surfaces and film breaks down under these conditions, an oil is used which interact with the solid surface of the metal that will between the two sliding surfaces. This can be possible by adsorption of lubricant molecules on the surfaces or by chemical reaction of the lubrication substances with metal surfaces. CLASSIFICATION OF LUBRICANTS (1) Solid lubricants Solid lubricants are used for railway tract joints, chains, air compressors, open gears, heavy machines etc. the examples of solid lubricants are wax, talc, mica, molybdenum disulphide graphite etc. (2) Semi solid lubricants It is used where the machine parts are subjected to slow speed, heavy load & sudden jerks. The examples of semi solid lubricants are grease & Vaseline. (3) Liquid lubricants Liquid lubricants are used in delicate and light machines which work at high speed but under low pressure. Mineral oils, vegetable oils & animal oils are the various types of liquid lubricants. (4) Synthetic lubricants It can be used, where extreme temperature, chemical reactive atmosphere or some very particular operating conditions are involved & where all other lubricants fail to work effectively. e.g. polyglycols, silicones, organic amines, imines & amides. TEST OF LUBRICANTS AND THEIR SIGNIFICANCE

Viscosity

The resistance to flow of liquid is known as viscosity. The unit of viscosity is poise. OR the force in dyne, required to move one square centimetre layer of the liquid with a velocity 1 cm/sec. to another parallel layer of the liquid.

Viscosity Index : The rate of change of viscosity with change in temperature is called viscosity index. A good lubricant is one whose viscosity does not change much with change in temperature. Oilness The power of an oil to maintain a continuous film under pressure while it is used as lubricants. A lubricant which does not squeeze out from the sliding surface & maintain a continuous film is known as lubricant having high degree of oiliness. Volatility Volatility of a lubricant is its tendency to vaporise with the increase of temperature. If the lubricant is highly volatile, it will vaporise readily even at low temperature. A good lubricant should have low volatility. Flash Point The minimum temperature at which a lubricant gives momentary flash of light when a flame is applied to it, but it does not continue to burn. Lubricants with higher flash point are preferred. Fire Point The temperature at which a lubricant catches fire and burns continuously when the flame is applied to it. Fire point of oil is always greater than its flash point. Pour Point It is the lowest temperature at which the oil ceased to flow when cooled under prescribed conditions. If oil is used at a temperature below the pour point, the lubrication action will stop. Cloud Point The cloud point of lubricating oil is the temperature at which cloudiness develops due to separation of wax on cooling. Neutralization Number or Acid Value It is defined as The number of milligrams of KOH required to neutalise one gram of the oil. Saponification Number It is defined as the number of milligram of KOH required to saponify one gram of oil or fats. Emulsification When oil is mixed with water or water is mixed with oil, emulsion is formed. A good lubricant is one which does not form emulsion and even if it forms, the emulsion should break quickly. Copper strip test for Corrosion In this test, a smooth and polished copper strip is immersed in the lubricating oil for a particular length of time at a specific temperature. Copper strip is taken out after specified time. If some pitting or furnished spots are observed, it means the lubricating oil contain some corrosive material. The presence of corrosive material reduces the quality of lubricants.

Carbon Residue Test The deposition of carbon by a lubricating oil, when it is subjected to heat under working conditions is called carbon residue test.Deposition of carbon is harmful. ADDITIVES USED IN LUBRICANTS (1) (2) (3) (4) Anti oxidant --- Aromatic amines,Phenols,Sulphides and phosphates Corrosion Inhibitor --- Amino salts and salts of sulphonic acids Antiwear agents --- Tricresyl phosphate Foam inhibitors --- Glycerols

Selection of lubricants for Gears The gears are generally subjected to high pressures so, it must have following properties. (1) It should possess good oiliness. (2) It should not be removed by centrifugal force from the place of application. (3) It should be highly resistant to oxidation. (4) It should have high load carrying capacity. Selection of lubricants for Cutting Tools Cutting metal tools when used for performing any machining operating such as cutting sawing, turning, boring, drilling etc. required the use of certain oil known as cutting oils must have following properties. (1) The oil must have both lubricating and cooling properties. (2) It should be chemically stable. (3) It should have high conductance to thermal Selection of lubricants for Steam Turbines In steam turbines, lubricating oil is exposed to high temperature and oxidizing conditions hands it should have following properties. (1) It should have emulsification properties. (2) It should have antifoaming properties. (3) It should have corrosion resistance properties. (4) It should have high oxidation properties.

Question asked in T.E.B. exam

Q.1 Q.2 Q.3 Q.4 Q.5 Q.6 Q.7 Q.8 Q.9 Explain boundary lubrication. (with diagram). Classify lubricants with examples. Explain liquid lubricants in detail. Define flash point & fire point, viscosity, saponification number. Define drop point of grease. What type of lubricants you will select for cutting tools ? What is importance of copper strip test of a lubricant ? Write primary aims of lubrication. Which type of lubricants will you select for gears ? Explain fluid film lubrication.

Q.10 Write at least five functions of lubricants. Q.11 What property would you consider while selecting lubricants for the use in steam turbines.

Вам также может понравиться

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityОт EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityРейтинг: 3 из 5 звезд3/5 (4)

- Engineering Chemistry Unit 3 Lubricants Notes PDFДокумент11 страницEngineering Chemistry Unit 3 Lubricants Notes PDFbhanuОценок пока нет

- Engineering Chemistry Unit 3 Lubricants Notes PDFДокумент11 страницEngineering Chemistry Unit 3 Lubricants Notes PDFbhanu100% (1)

- 1.2. BTR - Lubrication NotesДокумент17 страниц1.2. BTR - Lubrication Notesvishnu vishnu G.T.Оценок пока нет

- Engineering Chemistry (Lubricant) FinalДокумент16 страницEngineering Chemistry (Lubricant) FinalJGHH,J,100% (1)

- Lubricants FinalДокумент18 страницLubricants FinalRonak GandhiОценок пока нет

- Engineering Chemistry: LubricantsДокумент7 страницEngineering Chemistry: LubricantsbhanuОценок пока нет

- Engineering Chemistry: LubricantsДокумент7 страницEngineering Chemistry: LubricantsSavita ChemistryОценок пока нет

- Lubricants 7Документ4 страницыLubricants 7chemistrymaster100% (3)

- LubricantsДокумент6 страницLubricantsVrajОценок пока нет

- Lubricants and LubricationДокумент17 страницLubricants and Lubricationry3745654100% (1)

- U - 5Документ10 страницU - 5Shubham KhandelwalОценок пока нет

- Amity - Lubricants - Why So DumbДокумент17 страницAmity - Lubricants - Why So DumbAbhimanyu Singhal100% (2)

- Unit7 Lubricants7Документ5 страницUnit7 Lubricants7engineeringchemistryОценок пока нет

- Lubricants and Lubrication PDFДокумент18 страницLubricants and Lubrication PDFAtul GautamОценок пока нет

- LubricantsДокумент5 страницLubricantsengineeringchemistry100% (2)

- bt-101 PPT Updated (1.0)Документ14 страницbt-101 PPT Updated (1.0)JGHH,J,Оценок пока нет

- M4 LUBRICATION PRINCIPLES and BEARING CONSTRUCTIONSДокумент45 страницM4 LUBRICATION PRINCIPLES and BEARING CONSTRUCTIONSnaresh100% (1)

- Chemistry Notes On LubricantsДокумент4 страницыChemistry Notes On LubricantsSohamDixit67% (3)

- Lubrication Principles: Learning OutcomeДокумент12 страницLubrication Principles: Learning OutcomeMandeep MalikОценок пока нет

- Industrial Lubrication and TribologyДокумент16 страницIndustrial Lubrication and TribologyBonifacio Bagual JrОценок пока нет

- Function of LubricantsДокумент8 страницFunction of LubricantsSheikh ZakirОценок пока нет

- Chapter 5 LubricationДокумент29 страницChapter 5 Lubricationyisakor01Оценок пока нет

- Lubricants NITAДокумент13 страницLubricants NITAnikunj chauhanОценок пока нет

- Substance Frictional: Lubricant: TheДокумент12 страницSubstance Frictional: Lubricant: Therk_gummaluri5334Оценок пока нет

- Industrial ChemistryДокумент15 страницIndustrial Chemistryjhapindra adhikariОценок пока нет

- LubricantsДокумент29 страницLubricantsmuhammadumeryaqoob16Оценок пока нет

- Lubs, Properties & TeatingДокумент33 страницыLubs, Properties & Teatingjamesv52_743942786Оценок пока нет

- Lubrication Systems For Aero Gas Turbines: Ashutosh PandaДокумент10 страницLubrication Systems For Aero Gas Turbines: Ashutosh PandaVishnu RamОценок пока нет

- LubricationsДокумент80 страницLubricationsVANSH BHATI100% (1)

- Lubricants Final 1Документ32 страницыLubricants Final 1onkar nikamОценок пока нет

- UNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015Документ46 страницUNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015anjali sharmaОценок пока нет

- Term Paper of FluidДокумент16 страницTerm Paper of FluidRatnesh Raman PathakОценок пока нет

- LubricantsДокумент21 страницаLubricantsGourav KumarОценок пока нет

- Plain Bearing ReportДокумент15 страницPlain Bearing Reportpresident fishrollОценок пока нет

- TribologyДокумент8 страницTribologyYashwanth H SОценок пока нет

- Lubrication TrainingДокумент49 страницLubrication TrainingzeruОценок пока нет

- LubricantsДокумент17 страницLubricantsChandrasekhar DevarapuОценок пока нет

- Principles of LubricationДокумент109 страницPrinciples of LubricationFaraj Mohamed100% (2)

- Lubrication 160826150651Документ78 страницLubrication 160826150651santoshОценок пока нет

- Lubricants: By: Sahil BidaniДокумент25 страницLubricants: By: Sahil BidaniSiontan GhoshОценок пока нет

- LUBRICANTING OilДокумент18 страницLUBRICANTING OilChetan AgroyaОценок пока нет

- DTS Report Lubrication EditДокумент16 страницDTS Report Lubrication EditPrathamesh RaneОценок пока нет

- LubricantДокумент23 страницыLubricantGADHAОценок пока нет

- 1 LubricantsДокумент21 страница1 LubricantsAmishaОценок пока нет

- Lubricants and LubricationДокумент5 страницLubricants and LubricationsafowanОценок пока нет

- Principles OF LubricationДокумент46 страницPrinciples OF LubricationMurugan GaneshОценок пока нет

- 2.5 Lubrication System - NotesДокумент6 страниц2.5 Lubrication System - NotesAustin ChechecheОценок пока нет

- Report On Engine LubricationДокумент9 страницReport On Engine LubricationJitesh MhatreОценок пока нет

- Lubrication SystemsДокумент26 страницLubrication Systemsshivsena2157Оценок пока нет

- Unit - 2 Notes by Rama PawarДокумент18 страницUnit - 2 Notes by Rama PawarKaran ParajapatiОценок пока нет

- Topic 2 Lubrication PDFДокумент41 страницаTopic 2 Lubrication PDFNazuan NazriОценок пока нет

- Introduction and LubricationДокумент9 страницIntroduction and LubricationslchemОценок пока нет

- Bab2 LubricationДокумент29 страницBab2 LubricationFirdaus ZahariОценок пока нет

- 3 Engine Lubrication System: 3.1 GeneralДокумент2 страницы3 Engine Lubrication System: 3.1 GeneralABDAN MUGHNI SYAFA'ATОценок пока нет

- 5B Ii LubricantsДокумент25 страниц5B Ii Lubricantsmsk3kiidОценок пока нет

- Chapter Four Lubrication and CorrosionДокумент32 страницыChapter Four Lubrication and CorrosionTemesgen GetaОценок пока нет

- Automatic and Manual GreasingДокумент10 страницAutomatic and Manual GreasingAhmed SalahОценок пока нет

- 下载Документ4 страницы下载Mars JackОценок пока нет

- Forging PresentationДокумент17 страницForging PresentationRakesh PuriОценок пока нет

- Boiling and CondensationДокумент13 страницBoiling and CondensationPrithvi de VilliersОценок пока нет

- MG UniversityДокумент2 страницыMG UniversityVaisakVenugopalОценок пока нет

- Manual Msi3 A4 en ScreenДокумент8 страницManual Msi3 A4 en ScreenVladОценок пока нет

- Cummins D1703 Engine Parts Catalog PDFДокумент72 страницыCummins D1703 Engine Parts Catalog PDFxxxxxxxxxxxxxxxxxxx100% (2)

- Shear Strenght ExampleДокумент11 страницShear Strenght ExamplealvinОценок пока нет

- Little Helper. Igantic Effect!: 150 VarioДокумент12 страницLittle Helper. Igantic Effect!: 150 Variokgv_mailsОценок пока нет

- Eccentric ConnecctionsДокумент41 страницаEccentric ConnecctionsShyam Suryawanshi100% (1)

- Fabrication of Turbocharger For Two Wheeler: Ahir Nischal A, Sofia Ali A, Darshan S Shah, Sneh R PrajapatiДокумент8 страницFabrication of Turbocharger For Two Wheeler: Ahir Nischal A, Sofia Ali A, Darshan S Shah, Sneh R PrajapatiDeepak sutarОценок пока нет

- Conex 1 Wedge - 461® - 7.000 - 0.317 - P110-ICYДокумент1 страницаConex 1 Wedge - 461® - 7.000 - 0.317 - P110-ICYAnibal Perdomo SaldañaОценок пока нет

- Aib-Fd160 1998-12-01Документ16 страницAib-Fd160 1998-12-01Filipe GuaranyОценок пока нет

- Interacción Suelo EstructuraДокумент10 страницInteracción Suelo EstructuraDar FallОценок пока нет

- "Don't Be A Normie, I Guess": Invisible MechanicsДокумент30 страниц"Don't Be A Normie, I Guess": Invisible Mechanicssameeryad72Оценок пока нет

- Numerical Cave Propagation SimulationsДокумент14 страницNumerical Cave Propagation SimulationswalterloliОценок пока нет

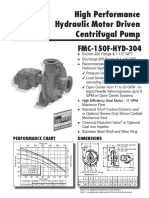

- FMC-150F-HYD-304 - 04-13 Bomba AceДокумент2 страницыFMC-150F-HYD-304 - 04-13 Bomba AceEmerson GomesОценок пока нет

- Za 45-185 PDFДокумент72 страницыZa 45-185 PDFSharad KokateОценок пока нет

- df100 InstructionДокумент20 страницdf100 InstructionFranco SОценок пока нет

- Seleccion de RejillaДокумент4 страницыSeleccion de RejillaCarlos Eduardo Arista FloresОценок пока нет

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalДокумент1 страницаWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavОценок пока нет

- Chapter 2 Stress and Strain: Fig. 2.1 External and Internal Forces in A Structural MemberДокумент14 страницChapter 2 Stress and Strain: Fig. 2.1 External and Internal Forces in A Structural MemberMatthew LinОценок пока нет

- PDDДокумент33 страницыPDDDamotharan Sathesh KumarОценок пока нет

- Centre of Mass - TheoryДокумент46 страницCentre of Mass - TheoryNiteshОценок пока нет

- Advanced Solid Mechanics - Problem 2Документ2 страницыAdvanced Solid Mechanics - Problem 2Sandesh TripathiОценок пока нет

- Swimming EquipmentsДокумент45 страницSwimming EquipmentsHaymanAHMEDОценок пока нет

- Building Utilities Reviewer ComprehensiveДокумент3 страницыBuilding Utilities Reviewer ComprehensiveReynald HarrisОценок пока нет

- PMSM 2012Документ62 страницыPMSM 2012Sreerag Kunnathu Sugathan100% (3)

- Screws Self-DrillingДокумент22 страницыScrews Self-DrillingSamra DukićОценок пока нет

- Augustin - A Contribution To The Design of Ribbed PlatesДокумент10 страницAugustin - A Contribution To The Design of Ribbed Platesm2auОценок пока нет

- Dive Scubapro - Mk2+, Mk2 - Maintenance ProcedureДокумент4 страницыDive Scubapro - Mk2+, Mk2 - Maintenance ProceduremanonpomОценок пока нет