Академический Документы

Профессиональный Документы

Культура Документы

National Cranberry PDF

Загружено:

Varun ChandОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

National Cranberry PDF

Загружено:

Varun ChandАвторское право:

Доступные форматы

The National Cranberry Cooperative case illustrates an interesting operational challenge.

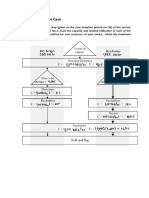

While the information about the cranberry production industry may be dated, we will focus on the process analysis which is real and universal. After reading the case, provide concise answers to the following questions (with supporting computation): 1. What are the problems facing RP1? 2. Draw a process flow diagram for RP1. Compute the capacity of each station in barrels per hour. Whats the Herbie (i.e. bottleneck)? Upon what assumptions do your capacity calculations depend? 3. What happens on a peak day? More specifically: a) How does the backlog of berries grow over time? b) How much overtime labor is used? How much money does that represent? c) At $25 per truck per hour, how much money does all the truck waiting time cost? 4. What recommendations, both short and long term, would you make to Mr. Schaeffer? Specifically, a) Given the peak-day costs developed in Questions 2 and 3, would you follow Wallistons recommendation to buy dryers (at $40,000 each) and to convert the dry holding bins to hold either wet or dry berries (at $7,500 each)? How many, if any, would you pay for? b) Independent of any equipment purchases, what changes to peak-day operations would you recommend to Hugo Schaeffer? To simplify matters and focus attention, use average numbers in all the analysis. Assume that: On a peak day, 18,000 barrels of berries are to be processed. The arrival of berries is evenly distributed over a 12 hour period starting at 7 am (i.e. ignore Exhibit 1 for now!). The delivery load varies from truck to truck; use the average of 75 barrels per truck in your analysis. Each truck takes 5-10 minutes to process at the dumper; use the average of 7.5 minutes. 70% of the berries are wet. Use the shift start times given in Figure E: 7 am for Receiving, 11 am for destine, dechaff, dry, milling, etc. Hint for Question 3c): To find the number of truck-hours spent waiting (in order to compute truck waiting cost), it suffices to find the number of barrel-hours and then divide it by 75 (the average load of each truck). o First find how many barrels are waiting to be unloaded over time. o Then the area underneath the curve represents the total number of barrel hours. The following graph is an example.

barrels of backlog

So the total number of barrel-hours is: =

Area = base * height / 2 = (t3-t2) * (z-y) / 2

(t3-t2) * (z-y) / 2 + [ (t3-t2)+(t4-t1) ] * (y-x) / 2

y Area = (upper width + lower width) * height / 2 = [ (t3-t2)+(t4-t1) ] * (y-x) / 2

t1 t2

time

t3

t4

Вам также может понравиться

- OM - National Cranberry - TemplateДокумент3 страницыOM - National Cranberry - Templatebeta alpha gammaОценок пока нет

- OM WordДокумент3 страницыOM WordpulakitОценок пока нет

- Answers NCCДокумент2 страницыAnswers NCCAmara Khan0% (1)

- National Cranberry Cooperative CASE STUD PDFДокумент10 страницNational Cranberry Cooperative CASE STUD PDFSahil sangwanОценок пока нет

- NCC Awasthi 11BM60071Документ8 страницNCC Awasthi 11BM60071Abhishek AwasthiОценок пока нет

- National Cranberries CaseДокумент7 страницNational Cranberries CaseHyper Green MindОценок пока нет

- Assignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?Документ9 страницAssignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?TerryОценок пока нет

- National Cranberry CaseДокумент10 страницNational Cranberry CaseanshumanОценок пока нет

- IDS 532 - National Cranberry Case Study - AnswersДокумент4 страницыIDS 532 - National Cranberry Case Study - AnswersVikas Mani TripathiОценок пока нет

- NCC - Case StudyДокумент3 страницыNCC - Case StudyDeepika GuptaОценок пока нет

- National Cranberry Case SubmissionДокумент3 страницыNational Cranberry Case SubmissionHardik SemlaniОценок пока нет

- OPIM101 - Spring 2012 - Extra Study Problems With Solutions PDFДокумент17 страницOPIM101 - Spring 2012 - Extra Study Problems With Solutions PDFjoe91bmw100% (1)

- National Cranberry Cooperative - 11BM60070Документ3 страницыNational Cranberry Cooperative - 11BM60070Neelesh KhattarОценок пока нет

- National Cranberry Cooperative (Case Analyse)Документ6 страницNational Cranberry Cooperative (Case Analyse)Teja RaoОценок пока нет

- Guesstimate The Number of COVID Testing Kits Needed by Delhi in OctoberДокумент6 страницGuesstimate The Number of COVID Testing Kits Needed by Delhi in OctobersaiОценок пока нет

- National Cranberry Cooperative 1981Документ10 страницNational Cranberry Cooperative 1981Nicole Dorado0% (1)

- Answers To Old Midterm QsДокумент11 страницAnswers To Old Midterm QsdarshangoshОценок пока нет

- OM Group 5, National Cranberry CooperativeДокумент10 страницOM Group 5, National Cranberry Cooperativesudip2003Оценок пока нет

- Study Group - 2 NCC CaseДокумент7 страницStudy Group - 2 NCC CaseAchin ChatterjeeОценок пока нет

- Donner ReportДокумент27 страницDonner ReportmuruganandammОценок пока нет

- Essay ReviewДокумент11 страницEssay ReviewMilagros AzparrentОценок пока нет

- National Cranberry Cooperative Case Answer 1Документ6 страницNational Cranberry Cooperative Case Answer 1PRITEEОценок пока нет

- The National Cranberry CooperativeДокумент5 страницThe National Cranberry CooperativeHussein BayramОценок пока нет

- Inventory Buit Up With Time Inventory Buildup at TruckДокумент3 страницыInventory Buit Up With Time Inventory Buildup at TruckdfreОценок пока нет

- National Cranberry Case SolutionДокумент7 страницNational Cranberry Case SolutionKarthik TirupatiОценок пока нет

- NCC-Case-Writeup-2021 - Sec D - Group D15Документ9 страницNCC-Case-Writeup-2021 - Sec D - Group D15dfreОценок пока нет

- Operations Management AzharДокумент6 страницOperations Management Azharpuneet_mishra3159Оценок пока нет

- Midterm Exam AnswersДокумент8 страницMidterm Exam AnswersJ100% (1)

- National Cranberry Case Report Operations Management - IДокумент9 страницNational Cranberry Case Report Operations Management - IVikash KumarОценок пока нет

- Operations Research Assignment Sheet 1Документ2 страницыOperations Research Assignment Sheet 1praveen_bpgcОценок пока нет

- What Changes Are Required To Ensure Successful Implementation of Cellular Manufacturing? Is Worker Cross-Training Necessary?Документ4 страницыWhat Changes Are Required To Ensure Successful Implementation of Cellular Manufacturing? Is Worker Cross-Training Necessary?isaavedracastroОценок пока нет

- Group 5 - Section C - NCCДокумент16 страницGroup 5 - Section C - NCCNitish Raj SubarnoОценок пока нет

- Littlefield Technologies ReportДокумент1 страницаLittlefield Technologies ReportHardik RupareliaОценок пока нет

- AIC NetbooksДокумент2 страницыAIC NetbooksSriharsha VavilalaОценок пока нет

- Little FieldДокумент2 страницыLittle FieldFarah SinnoОценок пока нет

- Le Club Francais CaseДокумент8 страницLe Club Francais CaseTushar GoelОценок пока нет

- CranberryДокумент4 страницыCranberryharshkhambraОценок пока нет

- Balancing Process Capacity - .Com - Microsoft.word - Openxmlformats.wordprocessingmlДокумент2 страницыBalancing Process Capacity - .Com - Microsoft.word - Openxmlformats.wordprocessingmlswarnima biswariОценок пока нет

- 2 Manas BuildingДокумент6 страниц2 Manas BuildingSandhali JoshiОценок пока нет

- Little Field Report 1Документ2 страницыLittle Field Report 1Alibaba Lalala100% (1)

- National Cranberry Cooperations 1996Документ15 страницNational Cranberry Cooperations 1996Mithilesh Singh67% (3)

- OM-I Assignment - Group 1 - Section A - National Cranberry CooperativeДокумент8 страницOM-I Assignment - Group 1 - Section A - National Cranberry Cooperativeaglakshmanan50% (2)

- BDO v. Crandell, Crandell Answer and CounterclaimДокумент44 страницыBDO v. Crandell, Crandell Answer and CounterclaimAdrienne GonzalezОценок пока нет

- National Cranberry CooperativeДокумент15 страницNational Cranberry CooperativeSaswata Banerjee100% (4)

- Executive Shirt Company - Group 6Документ8 страницExecutive Shirt Company - Group 6Puneet Agarwal100% (1)

- Manzana Insurance: A Case Analysis OnДокумент8 страницManzana Insurance: A Case Analysis OnsksОценок пока нет

- OM Case Write-UpДокумент2 страницыOM Case Write-UpTushar SinhaОценок пока нет

- AIC Case AssignmentДокумент2 страницыAIC Case AssignmentSinem Düden0% (2)

- USA Today CaseДокумент10 страницUSA Today CaseMasyitha MemesОценок пока нет

- Kim Opim An Enthusiastic Student Is On Her Flight OverДокумент2 страницыKim Opim An Enthusiastic Student Is On Her Flight OverAmit Pandey0% (1)

- Write Up - Case Study - Donner CompanyДокумент6 страницWrite Up - Case Study - Donner CompanyGanesh AroteОценок пока нет

- National Cranberry CaseДокумент20 страницNational Cranberry CaseRicardo David Pareja Baquerizo100% (2)

- NCC QuestionsДокумент1 страницаNCC QuestionsS N Javed ButtОценок пока нет

- NationalCranberryQuestions 12Документ1 страницаNationalCranberryQuestions 12Umi KhanОценок пока нет

- OID611 Cranberry Case AssumptionsДокумент1 страницаOID611 Cranberry Case AssumptionsJLОценок пока нет

- UECM2043, UECM2093 Operations Research Tutorial 1Документ5 страницUECM2043, UECM2093 Operations Research Tutorial 1kamun00% (2)

- National Cranberry - Section 4 Group 16Документ8 страницNational Cranberry - Section 4 Group 16milwandaОценок пока нет

- Ie202 SS1Документ8 страницIe202 SS1HandeeorОценок пока нет

- 225 Final Questions PDFДокумент4 страницы225 Final Questions PDFValerie PriadkinaОценок пока нет

- Prayer For World Teachers Day: Author: Dr. Anthony CuschieriДокумент1 страницаPrayer For World Teachers Day: Author: Dr. Anthony CuschieriJulian ChackoОценок пока нет

- OECD - AI Workgroup (2022)Документ4 страницыOECD - AI Workgroup (2022)Pam BlueОценок пока нет

- Taller InglesДокумент11 страницTaller InglesMartín GonzálezОценок пока нет

- Ulta Beauty Hiring AgeДокумент3 страницыUlta Beauty Hiring AgeShweta RachaelОценок пока нет

- DESIGNATIONДокумент16 страницDESIGNATIONSan Roque ES (R IV-A - Quezon)Оценок пока нет

- Prof. Sujata Patel Department of Sociology, University of Hyderabad Anurekha Chari Wagh Department of Sociology, Savitribaiphule Pune UniversityДокумент19 страницProf. Sujata Patel Department of Sociology, University of Hyderabad Anurekha Chari Wagh Department of Sociology, Savitribaiphule Pune UniversityHarish KumarОценок пока нет

- Military Laws in India - A Critical Analysis of The Enforcement Mechanism - IPleadersДокумент13 страницMilitary Laws in India - A Critical Analysis of The Enforcement Mechanism - IPleadersEswar StarkОценок пока нет

- Curriculam Vitae: Job ObjectiveДокумент3 страницыCurriculam Vitae: Job ObjectiveSarin SayalОценок пока нет

- COVID19 Management PlanДокумент8 страницCOVID19 Management PlanwallyОценок пока нет

- Sally Tour: TOUR ITINRARY With QuoteДокумент2 страницыSally Tour: TOUR ITINRARY With QuoteGuillermo Gundayao Jr.Оценок пока нет

- Merger and Acquisition Review 2012Документ2 страницыMerger and Acquisition Review 2012Putri Rizky DwisumartiОценок пока нет

- Direktori Rekanan Rumah Sakit Internasional 2015Документ1 018 страницDirektori Rekanan Rumah Sakit Internasional 2015Agro Jaya KamparОценок пока нет

- PRIMER - CFC Young Couples ProgramДокумент3 страницыPRIMER - CFC Young Couples Programgeorgeskie8100% (2)

- Infinivan Company Profile 11pageДокумент11 страницInfinivan Company Profile 11pagechristopher sunОценок пока нет

- WHO in The Philippines-Brochure-EngДокумент12 страницWHO in The Philippines-Brochure-EnghОценок пока нет

- Cantorme Vs Ducasin 57 Phil 23Документ3 страницыCantorme Vs Ducasin 57 Phil 23Christine CaddauanОценок пока нет

- Mentor-Mentee 2020-2021Документ17 страницMentor-Mentee 2020-2021sivakulanthayОценок пока нет

- People Vs MaganaДокумент3 страницыPeople Vs MaganacheОценок пока нет

- WN On LTC Rules 2023 SBДокумент4 страницыWN On LTC Rules 2023 SBpankajpandey1Оценок пока нет

- Assignment 1Документ3 страницыAssignment 1Bahle DlaminiОценок пока нет

- International Law Detailed Notes For Css 2018Документ95 страницInternational Law Detailed Notes For Css 2018Tooba Hassan Zaidi100% (1)

- 2 ND Green Investment Brochure New 27-09-2022Документ4 страницы2 ND Green Investment Brochure New 27-09-2022assmexellenceОценок пока нет

- Sikfil ReviewerДокумент6 страницSikfil ReviewerBarrientos Lhea ShaineОценок пока нет

- 504 Loan Refinancing ProgramДокумент5 страниц504 Loan Refinancing ProgramPropertywizzОценок пока нет

- Gogo ProjectДокумент39 страницGogo ProjectLoyd J RexxОценок пока нет

- Adv Tariq Writ of Land Survey Tribunal (Alomgir ALo) Final 05.06.2023Документ18 страницAdv Tariq Writ of Land Survey Tribunal (Alomgir ALo) Final 05.06.2023senorislamОценок пока нет

- Special Penal LawsДокумент14 страницSpecial Penal LawsBrenna ColinaОценок пока нет

- ANA A. CHUA and MARCELINA HSIA, Complainants, vs. ATTY. SIMEON M. MESINA, JR., RespondentДокумент7 страницANA A. CHUA and MARCELINA HSIA, Complainants, vs. ATTY. SIMEON M. MESINA, JR., Respondentroyel arabejoОценок пока нет

- Dewi Handariatul Mahmudah 20231125 122603 0000Документ2 страницыDewi Handariatul Mahmudah 20231125 122603 0000Dewi Handariatul MahmudahОценок пока нет

- Channarapayttana LandДокумент8 страницChannarapayttana Landnagaraja.raj.1189Оценок пока нет